Escolar Documentos

Profissional Documentos

Cultura Documentos

PQR

Enviado por

Ravi KumaranDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PQR

Enviado por

Ravi KumaranDireitos autorais:

Formatos disponíveis

Page 1 / 2

Labour and Immigration www.gov.mb.ca/labour/safety/mechanic

Mechanical and Engineering 500 – 401 York Avenue

Winnipeg, MB R3C 0P8

PH: (204) 945-3373

Fax: (204) 948-2309

Procedure Qualification Records (PQR)

(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)

Record Actual Conditions Used to Weld Test Coupon.

Company Name________________________________________________________________________________

Procedure Qualification Record No. ___________________________________ Date: _______________________

WPS No. _____________________________________________________________________________________

Welding Process(es) ____________________________________________________________________________

Types (Manual, Automatic, Semi-Auto.) _____________________________________________________________

Joints (QW-402)

Groove Design of Test Coupon

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal or process used.)

Base Metals (QW-403) Postweld Heat Treatment (QW-407)

Material Spec. _________________________________ Temperature ______________________________

Type or Grade _________________________________ Time _____________________________________

P-No. ________________ to P-No._________________ Other ____________________________________

Thickness of Test Coupon ________________________ _________________________________________

Diameter of Test Coupon _________________________ _________________________________________

Other ________________________________________

_____________________________________________

_____________________________________________ Gas (QW-408)

_____________________________________________ Percent Composition

Gas(es) (Mixture) Flow Rate

Shielding ________ _______ _________

Filler Metals (QW-404) Trailing ________ _______ _________

SFA Specification ______________________________ Backing ________ _______ _________

AWS Classification _____________________________

Filler Metal F- No. ______________________________

Weld Metal Analysis A-No. _______________________ Electrical Characteristics (QW-409)

Size of Filler Metal______________________________ Current__________________________________

Other ________________________________________ Polarity ________________________________

_____________________________________________ Amps. _____________ Volts ________________

Weld Metal Thickness____________________________ Tungsten Electrode Size ____________________

Other ___________________________________

Position (QW-405) Technique (QW – 410)

Position of Groove _____________________________ Travel Speed _____________________________

Weld Progression (Uphill, Downhill) ________________ String or Weave Bead ______________________

Other ________________________________________ Oscillation _______________________________

_____________________________________________ Multipass or Single Pass (per side) ____________

Single or Multiple Electrodes _________________

Other ___________________________________

Preheat (QW-406) ________________________________________

Preheat Temp. __________________________________ ________________________________________

Interpass Temp. _________________________________ ________________________________________

Other _________________________________________ ________________________________________

______________________________________________ ________________________________________

Procedure Qualification Records (PQR) Page 2 / 2

PQR No.________

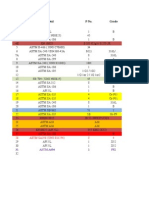

Tensile Test (QW-150)

Type of

Specimen Ultimate Total Ultimate Unit

Width Thickness Area Failure &

No. Load, lb Stress, psi

Location

Guided-Bend Tests (QW-160)

Type and Figure No. Result

Toughness Tests (QW-170)

Impact Drop

Specimen Notch Specimen

Test Temp. Values Weight

No. Location Size

ft-lb % Shear Mils Break (Y/N)

Comments ____________________________________________________________________________________

_____________________________________________________________________________________________

Fillet-Weld Test (QW-180)

Result – Satisfactory: Yes ________ No _________ Penetration into Parent Metal: Yes ________ No __________

Macro – Results ________________________________________________________________________________

Other Tests

Type of Test ___________________________________________________________________________________

Deposit Analysis _______________________________________________________________________________

Other ________________________________________________________________________________________

Welder’s Name ____________________________________ Clock No. ___________ Stamp No. ___________

Tests conducted by :________________________________________ Laboratory Test No. __________________

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in

accordance with the requirements of Section IX of the ASME Code.

Manufacturer: _______________________________

Date __________________________________________ By ________________________________________

(Detail of record of tests are illustrative only and may be modified to conform to the type and number of tests required by the Code.)

Você também pode gostar

- Shipyard Safety PDFDocumento174 páginasShipyard Safety PDFequalizer12345100% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocumento3 páginasN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliAinda não há avaliações

- IRS Specification For Steel Base Plate PDFDocumento4 páginasIRS Specification For Steel Base Plate PDFLakhwant Singh KhalsaAinda não há avaliações

- Application Form For CSWIP 10 Year Assessment (Overseas) No LogbookDocumento10 páginasApplication Form For CSWIP 10 Year Assessment (Overseas) No LogbookKarthikeyanAinda não há avaliações

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Documento30 páginasLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Navneet Singh100% (2)

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDocumento3 páginasInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadAinda não há avaliações

- WPS SMAW - PL en V Con GaugingDocumento1 páginaWPS SMAW - PL en V Con GaugingLuis MirandaAinda não há avaliações

- SSAB Strenx Offshore and Marine Applications LOWDocumento13 páginasSSAB Strenx Offshore and Marine Applications LOWNicolas DE WEVER100% (1)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Documento5 páginasWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- QW-403.2 InterpretationDocumento1 páginaQW-403.2 Interpretationlaz_kAinda não há avaliações

- 2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLDocumento11 páginas2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLnicholas_j_vaughanAinda não há avaliações

- BPVC Ix QW-482Documento2 páginasBPVC Ix QW-482ganesh82Ainda não há avaliações

- WPQR SBM 029Documento3 páginasWPQR SBM 029HoJienHauAinda não há avaliações

- Design & Detail Col Base PlateDocumento19 páginasDesign & Detail Col Base PlateJoel MooreAinda não há avaliações

- TDC QapDocumento69 páginasTDC QapKuppuraj ParamsivamAinda não há avaliações

- PQR Run SheetDocumento1 páginaPQR Run SheetsahadAinda não há avaliações

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocumento3 páginasWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEAinda não há avaliações

- QC - Consumables Colour Coding and IdentificationDocumento3 páginasQC - Consumables Colour Coding and IdentificationfizanlaminAinda não há avaliações

- Wps Sp14 Reva PDFDocumento9 páginasWps Sp14 Reva PDFravi00098Ainda não há avaliações

- Joints (Qw-402) DetailsDocumento3 páginasJoints (Qw-402) DetailsNaqqash SajidAinda não há avaliações

- TopCoreBelco 101 FCDocumento9 páginasTopCoreBelco 101 FCCesar ArellanoAinda não há avaliações

- Procurement Services: Industry & Facilities DivisionDocumento10 páginasProcurement Services: Industry & Facilities Divisionkbpatel123Ainda não há avaliações

- RTCC Manual WPS Approval WE-WPS-001Documento7 páginasRTCC Manual WPS Approval WE-WPS-001Akansha SharmaAinda não há avaliações

- WPS PQR 12 PDFDocumento9 páginasWPS PQR 12 PDFVinay YadavAinda não há avaliações

- 2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDocumento22 páginas2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDadaso Baburao JamdarAinda não há avaliações

- WPS - 003 BDocumento7 páginasWPS - 003 BMAT-LIONAinda não há avaliações

- Coke Drum SpecDocumento33 páginasCoke Drum SpecMahendra Rathore100% (1)

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Documento5 páginasA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableAinda não há avaliações

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsDocumento4 páginasWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanAinda não há avaliações

- Wps Mma PipeDocumento2 páginasWps Mma PipeDimitris NikouAinda não há avaliações

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocumento11 páginasCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONAinda não há avaliações

- Qualified Welder List Valid Until - 03-12-2019Documento2 páginasQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocumento5 páginasQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Ainda não há avaliações

- 2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDocumento22 páginas2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDadaso Baburao JamdarAinda não há avaliações

- List Welder PT - InstrucomDocumento4 páginasList Welder PT - InstrucomHerlan HutabaratAinda não há avaliações

- NoticeDocumento1 páginaNoticeAnirban Sen SharmaAinda não há avaliações

- Proposed WPS For API 5LDocumento1 páginaProposed WPS For API 5LMecon HyderabadAinda não há avaliações

- WPQ WeldCanada PDFDocumento1 páginaWPQ WeldCanada PDFAhmad DanielAinda não há avaliações

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocumento31 páginasALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahAinda não há avaliações

- Welding Procedure Specification (WPS) : Joint Design Welding SequencesDocumento1 páginaWelding Procedure Specification (WPS) : Joint Design Welding SequencesFerhat KahveciAinda não há avaliações

- Din en 12517 - 2006Documento17 páginasDin en 12517 - 2006marcelogf74Ainda não há avaliações

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Documento2 páginasSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzAinda não há avaliações

- Aws N-1 WPS-PQR FormDocumento2 páginasAws N-1 WPS-PQR FormEdwin MariacaAinda não há avaliações

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Documento4 páginasProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabAinda não há avaliações

- Welding PlanDocumento1 páginaWelding Planapi-298346841Ainda não há avaliações

- Safety Comittee Report: Company Logo and Name Time Date VenueDocumento2 páginasSafety Comittee Report: Company Logo and Name Time Date VenueHiren Maheta0% (1)

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocumento1 páginaFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpAinda não há avaliações

- Fb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDocumento13 páginasFb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDan DumbravescuAinda não há avaliações

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDocumento1 página22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforAinda não há avaliações

- List of Inspection Tools (Qaqc)Documento7 páginasList of Inspection Tools (Qaqc)saffririzal4237Ainda não há avaliações

- 03 WPS CS 1Documento3 páginas03 WPS CS 1mohammadAinda não há avaliações

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocumento15 páginasQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarAinda não há avaliações

- CV Painting InsulationDocumento3 páginasCV Painting Insulationhamza brahmiAinda não há avaliações

- QAP For PQR'S - For Impact TestingDocumento3 páginasQAP For PQR'S - For Impact TestingDries VandezandeAinda não há avaliações

- ArcelorMittal Energy Projects - EN10225-2019 Plates - Feb 2020Documento2 páginasArcelorMittal Energy Projects - EN10225-2019 Plates - Feb 2020Vinoth Kumar PothuvudaiAinda não há avaliações

- En 15085-2020-What Has ChangedDocumento2 páginasEn 15085-2020-What Has ChangedBoran YelkenciogluAinda não há avaliações

- P Q R - 005Documento2 páginasP Q R - 005Courtney DukeAinda não há avaliações

- Fm-div01-Qaqc-0361 Company Iso Documents Index DatabaseDocumento26 páginasFm-div01-Qaqc-0361 Company Iso Documents Index DatabaseMayo de la PazAinda não há avaliações

- Wps GT 9b Cvn90 Rev 1 PDFDocumento6 páginasWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniAinda não há avaliações

- FactoryDocumento72 páginasFactorywhitebrosAinda não há avaliações

- DTEC FR04 REV00 Surface Preparation Inspection ReportDocumento18 páginasDTEC FR04 REV00 Surface Preparation Inspection ReportSyaiful Rasyidi TamsirAinda não há avaliações

- Base Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4Documento3 páginasBase Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4MAT-LIONAinda não há avaliações

- S-8018 B2Documento5 páginasS-8018 B2Abhishek AnandAinda não há avaliações

- WeldDocs WPSDocumento2 páginasWeldDocs WPSMDSIKKU_2005Ainda não há avaliações

- Flash Report-2016-2-16Documento3 páginasFlash Report-2016-2-16sujinlongAinda não há avaliações

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Documento4 páginasAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Sample Format: Sensitivity: LNT Construction Internal UseDocumento2 páginasSample Format: Sensitivity: LNT Construction Internal UseKarthikAinda não há avaliações

- Uail - Pin Li-Cqa-213-F-01 WPS FormatDocumento2 páginasUail - Pin Li-Cqa-213-F-01 WPS FormatKarthikAinda não há avaliações

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Documento2 páginasCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemAinda não há avaliações

- Suggested Weldin Lr. VijDocumento4 páginasSuggested Weldin Lr. Vijmallik017100% (2)

- Indaten and Arcorox: Self-Protecting Steels With Raw AestheticDocumento44 páginasIndaten and Arcorox: Self-Protecting Steels With Raw AestheticJOAO ELOIAinda não há avaliações

- Iti Questions.Documento12 páginasIti Questions.SHAFEEK A RAinda não há avaliações

- Variation FormatDocumento9 páginasVariation FormatmohandiazAinda não há avaliações

- CEPL Product CatalogueDocumento51 páginasCEPL Product CataloguevijayAinda não há avaliações

- Book Estrella 18-9-09 BASSADocumento20 páginasBook Estrella 18-9-09 BASSAS.P.Ainda não há avaliações

- Gas WeldingDocumento33 páginasGas Weldingyaswanth1992Ainda não há avaliações

- AMA Pazooki PHDDocumento275 páginasAMA Pazooki PHDLinhNguyenVietAinda não há avaliações

- Corrosion Control by Modern Weld Overlay TechnologyDocumento3 páginasCorrosion Control by Modern Weld Overlay TechnologyAmanda Ariesta ApriliaAinda não há avaliações

- Me6302 - Manufacturing Technology - I: Iii Semester Mechanical EngineeringDocumento69 páginasMe6302 - Manufacturing Technology - I: Iii Semester Mechanical EngineeringamdevaAinda não há avaliações

- Mohamed Mansy-QC EngineerDocumento3 páginasMohamed Mansy-QC EngineerMohamed Anwer Abd ElhamedAinda não há avaliações

- SIRIM-AWS Certified Welder (CW) Brochure 2013Documento2 páginasSIRIM-AWS Certified Welder (CW) Brochure 2013sutimankeminAinda não há avaliações

- Method Statement For Prefabrication and Erection PipingDocumento10 páginasMethod Statement For Prefabrication and Erection Pipingmohd as shahiddin jafriAinda não há avaliações

- PC Spun PilesDocumento2 páginasPC Spun PilesFaridah Zahra100% (1)

- 3-2 Spot WeldingDocumento29 páginas3-2 Spot WeldingNaram AppannaAinda não há avaliações

- Railrod: Data SheetDocumento1 páginaRailrod: Data Sheetmohamed AdelAinda não há avaliações

- Safety Data Sheet: 1. Product and Company IdentificationDocumento5 páginasSafety Data Sheet: 1. Product and Company Identificationmohamed AdelAinda não há avaliações

- Asme IX BQ Art 11Documento5 páginasAsme IX BQ Art 11Maria Alexandra Lange LenzAinda não há avaliações

- Petrosleeve PresentationDocumento26 páginasPetrosleeve PresentationGerman Gonzalo RivasAinda não há avaliações

- IOM Valtek TopEntry ValtekCS DIN&ASME enDocumento20 páginasIOM Valtek TopEntry ValtekCS DIN&ASME enaseem4uAinda não há avaliações

- Curriculum Vitae: Prakriti Kumar GhoshDocumento41 páginasCurriculum Vitae: Prakriti Kumar GhoshaAinda não há avaliações