Escolar Documentos

Profissional Documentos

Cultura Documentos

Pumps Vibrations Limits As Per International Standards - EnggCyclopedia PDF

Enviado por

Mohamed Adel0 notas0% acharam este documento útil (0 voto)

55 visualizações5 páginasTítulo original

Pumps vibrations limits as per international standards - EnggCyclopedia.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

55 visualizações5 páginasPumps Vibrations Limits As Per International Standards - EnggCyclopedia PDF

Enviado por

Mohamed AdelDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 5

EnggCyclopedia

CODES AND STANDARDS • OPERATION & MAINTENANCE

• PROCESS EQUIPMENTS

Pumps vibrations

limits as per

international

standards

3 Min Read

All rotating machines, pumps included, vibrate to

some extent due to various reasons, the most

common of which are typically the following:

Improper installation at site

Improper balancing of pump rotor

Excessively turbulent 㷢uid 㷢ow

Pressure 㷢uctuations

Cavitation or internal recirculation in pumps

Normal pump wear after prolonged operation.

Therefore, process and design engineers should

not be so much interested as to whether or not a

pump vibrates but concerned and instead ask

themselves the following questions:

Is the amplitude and frequency of the pump

vibration suᓢ亂cient to cause damage to any of

the pump components.

Is the pump vibration a symptom of some

other more worrying phenomena occurring

within the pump, like for example - pump

cavitation?

Pump vibration monitoring

instruments

Gas Blowdown Multi Phase Flow Meter...

Large sized centrifugal pumps are generally

recommended to be equipped with typically two

(2) vibration measurement instruments per

bearing, one at the x-axis and the second at the y-

axis. These instruments are typically programmed

with two threshold values: an alarm point and a

trip point. When the alarm point is reached,

operator is noti혒㨪ed at the control room in order

to take measures to verify and limit the vibration

level. In case the trip point is reached, the pump is

tripped in order to avoid any further sustained

damage which could be catastrophic to the pump

and operating personnel.

Vibration monitoring instruments for pumps are

generally characterised as velocimetric type.

Velocimetric type instruments have a measuring

range typically in inches/sec or mm/sec.

Accelerometric (in inches/sec2 or mm/sec2) or

distance-type (typically in microns) vibration

readings are usually taken at bearings and shafts

of more high-tech equipments like turbines.

Damage due to excessive

pump vibration

There are basically three (3) international

standards setting limits on pump vibrations. Goal

of these standards is to help pump users avoid

excessive levels of vibration and catastrophic

failures caused by pump vibrations, which could

include severe damages to pump bearings, shaft

distortion etc.

In general, bearing lifetime (L10) decreases

rapidly with even small increments of vibration

value. Taking an example mentioned in ANSI/HI

9.6.4 standard, assuming that a vibration intensity

of 0.1 inches/sec corresponds to 100% of nominal

bearing lifetime, simply increasing the vibration

level to 0.2 inches/ sec could reduce bearing

lifetime to 60-70% of nominal bearing lifetime.

Standards for pump vibration

limits

- Hydraulic Institute (HI), namely with ANSI/HI

9.6.4 standard

- American Petroleum Institute (API), namely with

API 610 standard

- International Standards Organisation (ISO),

namely with ISO 10816 standard

Figure - 1 Typical pumps vibration levels in

accordance with ANSI/HI and API standards

Figure - 2 Typical pumps vibration levels in

accordance with ISO 10816 standards (Category A

is typically required for newly-manufactured

pumps

Vote and Share!

23 5 3

Awesome Inspiring Love

25

You may also like

October 19, 2016

October 16, 2016

October 6, 2012

Login

Username or Email:

Password:

signup now | forgot password?

Remember Me

LOG ME IN

Sign up for free if you are not a member already.

Advertise with us

Advertise directly with us. Get links to your website.

Reach out to our reader base of engineering

professionals. Email - admin@enggcyclopedia.com

Você também pode gostar

- ANSI B16.5 Pressure & TemperatureDocumento1 páginaANSI B16.5 Pressure & TemperatureMuhamad ZahdiAinda não há avaliações

- Valve Pit 5th DecDocumento3 páginasValve Pit 5th DecMohamed AdelAinda não há avaliações

- Lavith CV 1-5Documento4 páginasLavith CV 1-5Mohamed AdelAinda não há avaliações

- Equipment Used During VentingDocumento9 páginasEquipment Used During VentingRahulChoudharyAinda não há avaliações

- Instr Loop Check PDFDocumento3 páginasInstr Loop Check PDFMohamed AdelAinda não há avaliações

- World Class ManufacturingPlant Start Up and Commissioning ProcedureDocumento17 páginasWorld Class ManufacturingPlant Start Up and Commissioning ProcedureMohamed AdelAinda não há avaliações

- Refractory Dry Out ProceduresDocumento18 páginasRefractory Dry Out ProceduresTamer Abd Elrasoul0% (2)

- CBR Test Procedure Determination of California Bearing Ratio For Road Design PDFDocumento5 páginasCBR Test Procedure Determination of California Bearing Ratio For Road Design PDFMohamed AdelAinda não há avaliações

- Hydrocracking Technology: Prepared By: GuideDocumento12 páginasHydrocracking Technology: Prepared By: GuideMohamed AdelAinda não há avaliações

- Mansil-125 P-GDocumento1 páginaMansil-125 P-Gkanu PatelAinda não há avaliações

- CBM Motor Test ReportDocumento4 páginasCBM Motor Test ReportRaj Kiran76% (21)

- Cooling Tower Project ReportDocumento51 páginasCooling Tower Project ReportOsama Hasan97% (31)

- Method Statement For Instrument Calibration PDFDocumento14 páginasMethod Statement For Instrument Calibration PDFMohamed AdelAinda não há avaliações

- Zeolite 4A White Powder For Detergent Det Build 150Documento2 páginasZeolite 4A White Powder For Detergent Det Build 150kanu Patel100% (1)

- API Refractory Lining and Burner Brick RequirementDocumento29 páginasAPI Refractory Lining and Burner Brick RequirementsprathAinda não há avaliações

- Supported Metal Catalysts PreparationDocumento9 páginasSupported Metal Catalysts Preparationandyblabla100% (1)

- Molecular Sieve Type 5ADocumento2 páginasMolecular Sieve Type 5Akanu PatelAinda não há avaliações

- Vacuum Drying TheoryDocumento5 páginasVacuum Drying TheoryShishir Koyare100% (1)

- Pressure Rating PDFDocumento4 páginasPressure Rating PDFMohamed AdelAinda não há avaliações

- Erection and Commissioning ProcedureDocumento94 páginasErection and Commissioning Procedurekdsrathod5100% (6)

- Supported Metal Catalysts PreparationDocumento9 páginasSupported Metal Catalysts Preparationandyblabla100% (1)

- Check List For Instrumentation Design PDFDocumento22 páginasCheck List For Instrumentation Design PDFMohamed AdelAinda não há avaliações

- Hydrocarbon Vapor Recovery Systems PDFDocumento26 páginasHydrocarbon Vapor Recovery Systems PDFMohamed AdelAinda não há avaliações

- RBS 6000 Commissioning Procedure - PA1Documento17 páginasRBS 6000 Commissioning Procedure - PA1He Ro90% (10)

- Flare Gas Recovery Data Sheet PDFDocumento1 páginaFlare Gas Recovery Data Sheet PDFMohamed AdelAinda não há avaliações

- Oil Flushing PDFDocumento51 páginasOil Flushing PDFMohamed AdelAinda não há avaliações

- Catalyst ProcedureDocumento99 páginasCatalyst Procedurejtirenti50% (2)

- 2-MS. Cleaning and Flushing of PipeworkDocumento7 páginas2-MS. Cleaning and Flushing of PipeworkBaha'a F. AbdulhadiAinda não há avaliações

- GGS Operating Manual Vol 1Documento271 páginasGGS Operating Manual Vol 1SDP02100% (1)

- Boiler Chemical Cleaning Procedure PDFDocumento11 páginasBoiler Chemical Cleaning Procedure PDFheppy prastyo nugroho100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Airfoil Lift Procedures PDFDocumento12 páginasAirfoil Lift Procedures PDFmatthias.s.sommer3656Ainda não há avaliações

- DNA and RNA: The Molecules of HeredityDocumento42 páginasDNA and RNA: The Molecules of HeredityLyssaMarieKathryneEgeAinda não há avaliações

- Processing of The Pyrite Concentrates To Generate Sulfurous Anhydride For Sulfuric Acid ProductionDocumento6 páginasProcessing of The Pyrite Concentrates To Generate Sulfurous Anhydride For Sulfuric Acid ProductionLuis La TorreAinda não há avaliações

- A Finite Element Method Based Analysis of Casting Solidification Onpermanent Metallic ModelsDocumento10 páginasA Finite Element Method Based Analysis of Casting Solidification Onpermanent Metallic ModelsseenisitAinda não há avaliações

- Air Freshener Safety Data Sheet RevisionDocumento8 páginasAir Freshener Safety Data Sheet RevisionCitra Rizky FernandaAinda não há avaliações

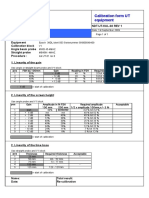

- Calibration Sheet Ultrasonic Test EquipmentDocumento1 páginaCalibration Sheet Ultrasonic Test EquipmentjohnAinda não há avaliações

- 2DoorCatalogue 2012-0Documento15 páginas2DoorCatalogue 2012-0Akanksha GuptaAinda não há avaliações

- Derivation of Fluid Flow Equations Review of Basic StepsDocumento9 páginasDerivation of Fluid Flow Equations Review of Basic StepsAaron LisandrioAinda não há avaliações

- Bracing Requirements For Elastic Steel BeamsDocumento87 páginasBracing Requirements For Elastic Steel BeamsbiomechanicsAinda não há avaliações

- Uncertainty IR PDFDocumento8 páginasUncertainty IR PDFluisAinda não há avaliações

- Diffusion and Osmosis LabDocumento2 páginasDiffusion and Osmosis LabJustin NgAinda não há avaliações

- Determining Cation Exchange Capacity: A New Procedure For Calcareous and Gypsiferous SoilsDocumento5 páginasDetermining Cation Exchange Capacity: A New Procedure For Calcareous and Gypsiferous SoilsM. Yusuf HermawanAinda não há avaliações

- Analysis of Hull ResistanceDocumento6 páginasAnalysis of Hull ResistanceSahil JawaAinda não há avaliações

- Form I-1 Centrifugal Pump Data SheetDocumento4 páginasForm I-1 Centrifugal Pump Data SheetJohnAinda não há avaliações

- Understanding The Results of An Intelligent Pig InspectionDocumento18 páginasUnderstanding The Results of An Intelligent Pig InspectionLeonardo VazAinda não há avaliações

- SPE 37084 Horizontal Well Length: Drill Short or Long Wells?Documento9 páginasSPE 37084 Horizontal Well Length: Drill Short or Long Wells?Waleed Barakat MariaAinda não há avaliações

- Concrete Pavers Roof Decks - Tech Spec 14 PDFDocumento12 páginasConcrete Pavers Roof Decks - Tech Spec 14 PDFbatteekhAinda não há avaliações

- Ruhrpumpen PDFDocumento41 páginasRuhrpumpen PDFMariano NogarAinda não há avaliações

- 08-Field Density TestDocumento15 páginas08-Field Density Testmustafurade1Ainda não há avaliações

- Hydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesDocumento26 páginasHydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesRahul AroraAinda não há avaliações

- Role of Nitrite Addition in Chloride Stress Corrosion Cracking of A Super Duplex Stainless SteelDocumento5 páginasRole of Nitrite Addition in Chloride Stress Corrosion Cracking of A Super Duplex Stainless Steelherschel5Ainda não há avaliações

- Motion Canada - Bearing CatalogDocumento212 páginasMotion Canada - Bearing CatalogEric Lafrance100% (1)

- C55Documento4 páginasC55Rufo CascoAinda não há avaliações

- Activity No. 2 The Microscope: Term FunctionDocumento5 páginasActivity No. 2 The Microscope: Term FunctionUNSA MANEAinda não há avaliações

- Caustic Potash SpecificationDocumento1 páginaCaustic Potash SpecificationJayakumar AAinda não há avaliações

- NPTELDocumento2 páginasNPTELMayur ArodaAinda não há avaliações

- How to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreDocumento2 páginasHow to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreNo PersonAinda não há avaliações

- Vibration Isolation PDFDocumento9 páginasVibration Isolation PDFl8o8r8d8s8i8v8Ainda não há avaliações

- Heater Catalog 0618Documento576 páginasHeater Catalog 0618abasakAinda não há avaliações

- Russell J. Donnelly - Fifty-Five Years of Taylor - Couette FlowDocumento35 páginasRussell J. Donnelly - Fifty-Five Years of Taylor - Couette FlowQMDhidnwAinda não há avaliações