Escolar Documentos

Profissional Documentos

Cultura Documentos

LM 1500

Enviado por

EDBTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

LM 1500

Enviado por

EDBDireitos autorais:

Formatos disponíveis

Energetech, LLC

Power Generation Equipment

Supplier

7427 S. Main (P.O. Box 400)

Midvale, Utah 84047

(801) 566-5678 Ph. (801) 566-7745 Fx.

LM1500- Gas Turbine

Power Generation Package

STANDARD EQUIPMENT OPTIONS

LM1500A Gas turbine Water wash system

Reduction gearbox (as required) Inlet cooling

Electric generator Anti-icing system

Inlet air filtration system Fuel gas compressor system

Inlet air silencer HRSG

Fuel (liquid or gas) system Oil debris monitor system

Hydraulic start system Individual EGT readout system

GT lube system O&M program

Control system Remote control monitoring

Fire/gas detection system Training course

O&M manuals

RATINGS:

Power Output @ ISO Conditions 10 MW continuous & 11.5 MW peak

Btu/shp-hr 7,800

Btu/kW-hr (LHV) 12,000

Exhaust Gas Temperature 800° F.

Exhaust Gas Flow 160 lb/sec

Power Turbine Speed 5,500 rpm

Shaft Horse Power 15,500

Fuel requirements Distillate and/or Natural Gas

Power Factor 0.8 (Typical)

Gas Generator 17 Stage Compressor – 3 Stage Turbine

Power Turbine Single Stage

MAJOR EQUIPMENT SUPPLIERS:

Gas Turbine Modified G.E. LM1500

Generator Ideal Electric or equivalent

Inlet/Exhaust system Universal Silencer or equivalent

Controls GE Global or equivalent

Reduction gearbox Lufkin Gears or equivalent

Last Update: 11/14/2001

E-mail: energy@energetech.com Page 1 of 14 Web-Site: www.energetech.com

Section 1 – Overview

Energetech LLC is pleased to announce a working relation with a packager that proposes to

supply one (1) turbine-generator package which will consist of the equipment itemized in the

accompanying equipment list (Section 2) and as detailed below. The unit proposed will be

complete, fully tested, ready to run and generate power

It is proposed that the components will be shipped as nearly complete as possible. The turbine

assembly will be shipped as one unit, complete from the bellmouth on the air intake end to the

power turbine on the drive end. The coupling, gear box and generator will be shipped as a skid-

mounted assembly, with the gas turbine mounted on a separate assembly. The control system

cabinet and, lubrication/starter skid will be shipped as loose components to be integrated at site.

A weather resistant sound enclosure will be provided for the complete turbine-generator skid

(the control cabinet will need to be housed in building; other skids are weatherproof). Also

provided will be intake air filter/silencer assembly and exhaust assembly.

The package will include a spare gas generator (gas jet engine) during the warranty period

which can be installed within 4 hours to replace an engine that may have failed during warranty.

The failed engine will be reworked under warranty and provided back to site for reinstallation at

a convenient opportunity.

E-mail: energy@energetech.com Page 2 of 14 Web-Site: www.energetech.com

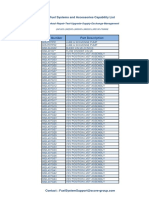

Section 2 – Equipment List

Base Proposal – One Unit

Item Qty. Description

1. 1 LM1500A Gas turbine – complete with the following equipment:

• Bellmouth

• Bullet nose

• Gas turbine complete with fuel nozzles and manifolds for natural gas firing

(#2 Diesel firing available with optional equipment)

• Power turbine

• Lubrication system components

o Lube supply manifold

• Instrumentation:

o (2) Gas turbine speed sensors (magnetic pickup type)

o (2) Power turbine speed sensors (magnetic pickup type)

o (11) Power turbine inlet temperature probes (Chromel/Alumel type)

o (1) Gas generator vibration sensor (accelerometer type)

o (1) Power turbine vibration sensor (accelerometer type)

o (1) Oil supply temperature sensor (RTD single-element type)

o (5) Oil scavenge temperature sensors (RTD single-element type)

o (1) Lube oil supply pressure sensor

o (1) Scavenge oil pressure sensor

o (2) Pressure sensors for compressor discharge pressure

o (1) Power turbine inlet pressure sensor

• Single ignition system (ignitor, high-tension cable, exciter)

• Inlet screen kit

• Air intake assembly with air filter system assembly and silencers; exhaust

stack with silencers

• Weather/sound enclosure (fire and gas detection systems included in gas

turbine enclosure)

• Fire detection/suppression system (for gas turbine enclosure)

• Gas detection system (for gas turbine enclosure)

• Gas turbine skid and separate generator/gearbox skid

2. 1 Gearbox and coupling:

• Lufkin Gears (or equivalent) parallel horizontal offset gear box designed for

input speed of 5500 rpm and output speed of 1800 rpm

• Coupling Corporation of America Flexxor 400C (or equivalent) high speed

diaphragm coupling

3. 1 Generator

• Ideal Electric (or equivalent) “SAB” horizontal brushless air-cooled AC

generator rated for 13.8 KV @ 60 Hz (1800 rpm); with integral lube system

• Voltage regulator cabinet (NEMA 12)

E-mail: energy@energetech.com Page 3 of 14 Web-Site: www.energetech.com

4. 1 Control package

• Turbine monitoring and control package based on MicroNet Series (or

equivalent) control system with non-redundant processor

• NEMA 12 cabinet housing vibration monitor and control system

• Vibration monitor

• Synchronizer

• Gas shutoff, control and vent valves (to be piped at site)

• Diesel shutoff and control valves (optional; to be piped at site)

5. 1 Lube system and starter skid

• Lube oil reservoirs, duplex filters, pumps, local indicators, temperature

regulation, cooler

• Electric/hydraulic starter system

• On-board motor starters

6. LOT Switchgear

Unit will be supplied with 1000A 3φ isolation breaker cubicle complete with

generator protection relays, power monitoring displays. Second cubicle to

contain ground fault protection equipment.

7. 1 Documentation Package

• Installation Design Manual

• Operation and Maintenance Manuals (LM Alternatives will provide O&M

manual for gas turbine; vendor packages will be provided for buy-out

equipment)

8. LOT 480 VAC Power Distribution Center.

Power distribution center to be supplied for isolating disconnects of all auxiliary

skid motors, enclosures, etc.

Section 3 – Clarifications

Technical

1. Reliable operation and low maintenance costs for the gas turbine require that the

installation designs and operating/maintenance practices be in accordance with the

instructions defined in the system drawing packages and the Operation and

Maintenance manual.

2. In order to minimize vibration and misalignment, it is anticipated that suitable concrete

pads will be available for anchoring the components. Main skid is approximately 52’

long by 11’ wide; auxiliary skids are approximately 10’ long by 6’ wide.

3. Components selected by the factory have been designed for precise engineering match

to achieve specific performance criteria. Engineering submittals are mainly for

information only and customer review. Due to time constraints of the project, submittal

will be assumed to be complete and purchasing will commence ten (10) working days

after submittal. Substitution of components at customer request can be accommodated

upon execution of change order and may entail revision of delivery schedule.

E-mail: energy@energetech.com Page 4 of 14 Web-Site: www.energetech.com

4. Final configuration of spare parts package and pricing will be provided after engineering

details are completed and configuration finalized.

5. In order to maintain optimum performance of the gas turbine, fogger skids are

recommended for areas where ambient temperatures during Spring, Summer and Fall

may exceed 80ºF.

6. Final selection of air inlet filter media will be determined after further details from the site

are provided regarding dust loading in the area. Special filters may impact final pricing.

Optional system is proposed with passive filtration

7. Incoming natural gas pressure will be required at constant 275 + 25 psig. Fuel

compressor is available as an option to boost to needed pressure. Fuel quality is

assumed to be at least 19000 Btu/lb (LHV) and PUC grade.

8. It is assumed that control will be done locally through the operator stations supplied in

the shelter. MODBUS interface is available but integration on plant side will be by others

and may cause delay in start-up.

9. Locally required compliance (for example, fire suppression, ammonia leak monitoring) or

other requirements not identified are excluded.

10. Permits (construction, environmental, etc.) excluded.

11. Unit performance is 10,000kW (simple cycle) with peaks to 11,300kW.

12. NOx emissions are approximately 40 ppm firing natural gas and 70 ppm firing #2 Diesel

based on full load firing. CO emissions are approximately 95 ppm. With optional SCR,

emission levels can be reduced to 5 ppm NOx, 10 ppm CO, with 10 ppm NH3 slip.

13. Factory recommends for units with less than 100 starts/year an annual inspection. Oil

filters, depending upon severity of climate, may need to be changed every 6 months.

LM Alternatives proposes to conduct training classes for operations and maintenance

staff. The units are designed for automatic start-up through the digital control system,

requiring minimal input from operators.

14. Routine maintenance costs will include replacing oil filters and lubricating fluids

consumed during operation. Estimated costs for oil filters are $1200 annually;

lubrication fluids should be approximately $100/month. Unless the dust loading is

extremely severe, the air filters should require replacement bi-annually.

Time between major overhauls is typically 40,000 hours firing natural gas and 25,000

hours firing #2 Diesel. Annual inspection of the hot sections of the engine are

recommended for units with less than 100 starts/year. Quarterly inspections of the hot

sections of the engine are recommended for units with starts exceeding 100/year.

15. Noise level shall be maintained at 85dB @ 3 meters in compliance with OSHA standard

regulations.

16. Training of plant personnel will occur informally during start-up and commissioning of

first unit unless separate training is purchased.

E-mail: energy@energetech.com Page 5 of 14 Web-Site: www.energetech.com

17. Final price may be adjusted if, upon finalization of details regarding existing electrical

system and tie-in, additional equipment is found to be necessary.

18. During the course of the warranty period, a service engine will be placed on site in a

shipping container to minimize downtime should there be a component failure on the

engine. The changeout requires approximately 4 hours after engine cool down (about 2

- 4 hours) and can be accomplished with routine hand tools.

19. If protective relay and switchgear is supplied by others, it must meet technical

requirements and approval of LMA.

20. While isolation switchgear, synchronization systems and protective relays and other

necessary components are provided as part of this quotation, final price may be

adjusted if, upon finalization of details regarding existing electrical system and tie-in,

additional equipment is found to be necessary.

E-mail: energy@energetech.com Page 6 of 14 Web-Site: www.energetech.com

Section 4 – Commercial

Terms and Conditions

This proposal is based on the attached terms and conditions.

Validity

Pricing is firm based on proposed configuration.

Delivery

Delivery of unit can be 4 to 5 months depending on options needed and factory production.

Freight

Pricing is FOB factory location for all equipment.

Warranty

Equipment is warranted to satisfy performance criteria for a period of twelve (12) months (or

8000 operating hours) from first firing or eighteen (18) months after shipment, whichever occurs

first. See warranty statement in terms and conditions of sale attached for further details.

Payment Terms

The following payment terms will apply; payable within thirty (30) days of invoice (down payment

must accompany notice to proceed or purchase order before work will proceed; once down

payment received, final delivery date will be confirmed) drawn on irrevocable letter of credit from

a bank acceptable to the Factory:

40% Down payment upon notice to proceed

30% Upon drawing submittals (drawing list attached with proposal)

20% Upon completion of acceptance test

10% Upon shipment to site

Acceptance Test

Reduction gear box and AC generator are tested individually at each factory to verify

performance and tested as an assembly at AC generator factory before final shipment.

Gas turbine is tested at Packager’s test facility to verify proper mechanical operation and

compliance with guarantee performance levels. Testing is in conformance with Packager’s ISO

established test procedures for industrial gas turbines (copy is available upon request). Test

reports will be provided as part of final documentation package.

E-mail: energy@energetech.com Page 7 of 14 Web-Site: www.energetech.com

Service and Training

Field service for installation, start-up and commissioning is available at per diem rates or can be

provided as lump sum extra as part of the contract.

Training can be provided either at site or at Packagers factory. Two types of training are

available: operations; technical. Operations training normally is five days; class size limited to

10 individuals. Technical training is normally ten (10) days; class size is limited to five (5)

individuals. Training can be provided on per diem basis or as lump sum price (please contact

Field Service Department directly for quotation).

Annual Maintenance program provides up to 4 site service calls annually for a total of 64 man-

hours with guaranteed 24 hour response to site for emergencies. As long as the program is in

place, the factory will honor a 15% discount against spare parts prices while the warranty is in

place. It will also honor a reduced daily service rate (normal 8-hour day) from $960/day to

$800/day. Travel and living expenses to be billed at cost plus 5% handling fee.

E-mail: energy@energetech.com Page 8 of 14 Web-Site: www.energetech.com

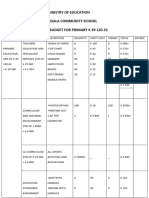

Section 5 – Pricing Summary

BASE PRICE – (for purchase of one 10 MW unit as outlined in the Base Equipment List)

TOTAL FIRM PRICE: Please Call

Optional Equipment

Power/Control Building:

De-Icing System:

Fogging System: 7.5 gallons of demineralized water is required.

Water Wash System:

Dual Fuel:

Extended Warranty:

Annual Maintenance Program:

E-mail: energy@energetech.com Page 9 of 14 Web-Site: www.energetech.com

TERMS AND CONDITIONS OF SALE

GENERAL

This document together with any additional documentation signed by Seller and Buyer represents the Agreement between the

parties. These terms may not be modified except in writing signed by an authorized representative of Seller. Any terms and

conditions submitted in Buyer's inquiry or purchase order shall be null and void unless specifically agreed to by a writing signed by

an authorized representative of Seller. Catalogs, circulars and similar pamphlets of Seller are provided for general information

purposes only and are not a part of the Agreement. Except as expressly contained herein no representation or warranty is made as

to performance, size, durability, or other specifications of Sellers products and any information contained in catalogs, circulars and

similar promotional or advertising material is for general informational purposes only.

TAXES/DUTIES

Any sales, use or other similar type taxes or import or export duties imposed on this transaction are not included in the price. Such

taxes and/or duties shall be billed separately to Buyer. Seller will accept a valid exemption certificate from Buyer if applicable;

however, if such exemption certificate is not recognized by the governmental taxing authority involved and Seller is required to pay

the tax covered by such exemption certificate, Buyer shall promptly reimburse Seller for the taxes paid.

EXCUSABLE DELAYS

Seller shall not be responsible for nonperformance or delays in performance occasioned by any causes beyond Seller's reasonable

control, including, but not limited to labor difficulties, delays of vendors or carriers, Seller's prompt receipt of Buyer's equipment,

Seller's compliance with Buyer's change orders, fires, acts of God, war, non-governmental actions and material shortages. Any

delays occasioned by such circumstances shall affect a corresponding extension of Seller's performance dates.

DELIVERY, TITLE AND RISK OF LOSS

Completion dates are approximate, and are based upon prompt receipt of approvals, receipt of equipment from Buyer or vendors

(as may be appropriate), or otherwise prompt receipt of all necessary information. Unless otherwise specified by Seller, all

shipments are F.O.B., Seller's facility. Full risk of loss (including transportation delays and losses) shall pass to Buyer upon delivery

of products to the F.O.B. point, or if Seller consents to a delay in shipment at the request of Buyer, risk of loss shall pass to Buyer

upon notification by Seller that the products are ready.

WARRANTY

Seller warrants that equipment supplied by it and delivered hereunder will be free from defects in materials and workmanship, and

will meet all specific requirements, if any, of this agreement. Seller warrants its own equipment for a period of twelve (12) months

from installation and all claims for defective parts under this warranty must be made in writing immediately upon discovery, and in

any event, within eighteen (18) months from shipment of the applicable item whichever shall first occur. Upon Buyer's submission of

a claim as provided above and its substantiation, Seller shall at its option either (i) repair Buyer's equipment at the original F.O.B.

point of delivery, (ii) refund an equitable portion of the contract price, (iii) furnish F.O.B., Seller's facility or other point of shipment

any necessary repaired or replacement parts. Small components, such as lights, switches, fuses, that can reasonably be replaced

by Buyer's maintenance staff shall be provided F.O.B. site. Defective items must be held for Seller's inspection and returned to the

original F.O.B. point upon request.

With respect to parts not manufactured by Seller, Seller assigns to Buyer whatever warranty Seller receives from the Supplier of

such parts or services. However, Seller agrees to be Buyer's primary contact on all warranty claims.

The foregoing warranties are exclusive and in lieu of all other warranties, whether written, oral, implied or statutory. NO IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR PURPOSE SHALL APPLY.

Seller makes no performance warranty unless specifically agreed to elsewhere and the effects of corrosion, erosion and normal

wear and tear are specifically excluded from Seller's warranty.

Seller will not be liable to Buyer for any loss or injury to persons or property (including the machinery which is the object of the work)

caused in whole or in part by (1) the acts of Buyer or its agents, (2) failure to observe Seller's instructions, or (3) failure or

malfunctioning of anything not furnished by Seller.

The preceding paragraphs set forth the exclusive remedies for warranty claims, and upon the expiration of the warranty period, all

such liability shall terminate.

PAYMENT TERMS

Payment terms are as indicated in the proposal. Invoiced milestone payments are due within thirty days of invoice date. If the order

is placed from outside the United States, an irrevocable letter of credit will be required, drawn on a bank acceptable to Packager for

the amount of the order. Payment will be drawn against the letter of credit. Payment received thirty days after the invoice date is

subject to interest charges at the maximum allowable rate as provided by applicable law.

E-mail: energy@energetech.com Page 10 of 14 Web-Site: www.energetech.com

LIMITATION OF LIABILITY

Seller shall in no event be liable to Buyer or any successor for any consequential, incidental, or indirect damages arising out of this

Agreement or any breach thereof, including but not limited to damages resulting from: loss of use, profits, revenue, interest or

goodwill; work stoppage, impairment of other goods, shutdown or non-operation, increased expenses of operation; cost of purchase

of replacement power, or claims of Buyer or customers of Buyer for service interruption whether or not such loss or damage is

based on contract, indemnity, tort, product or strict liability or otherwise.

THE REMEDIES OF BUYER SET FORTH HEREIN ARE EXCLUSIVE. THE TOTAL LIABILITY OF SELLER

WITH RESPECT TO THE PERFORMANCE OR BREACH OF THIS AGREEMENT WHETHER BASED ON

CONTRACT, INDEMNITY, TORT, PRODUCT OR STRICT LIABILITY OR OTHERWISE, SHALL NOT

EXCEED THE CONTRACT PRICE OF THE AGREEMENT OR THE PART UPON WHICH SUCH LIABILITY

IS BASED.

ASSIGNMENT

Neither party shall assign or transfer this Agreement without the prior written consent of the other party, which shall not be

unreasonably withheld.

GOVERNING LAW

The rights and obligations of the parties shall be governed by the laws of the State of California, excluding conflict of laws

provisions.

NUCLEAR LIABILITY

If the services are to be performed in a nuclear facility, Buyer shall arrange for insurance and governmental indemnity against

liability. Buyer holds harmless and indemnifies Seller and its suppliers for any damage, including loss of use, in any manner arising

out of a nuclear incident, even if due in whole or in part to the negligence of Seller or its suppliers.

MATERIAL DATA SHEETS

Buyer shall supply to Seller the required Material Data Sheets (MSDS) per Federal Regulation 29CFR1910.1200 Hazardous

Communications for each hazardous material substance with which Seller's employees may have contact in the course of their work

assignment,

E-mail: energy@energetech.com Page 11 of 14 Web-Site: www.energetech.com

E-mail: energy@energetech.com Page 12 of 14 Web-Site: www.energetech.com

WARRANTY PROGRAM

The Factory offers a complete warranty program for the entire package it provides. Term is 12

months (8000 hours) from first firing or 18 months from shipment. This includes the new

equipment provided (i.e., generator, gearbox, control system, etc.), which carries transferable

factory warranties, as well as the refurbished engine and power turbine. Typically small

components (lights, fuses, filters and switches) which can be replaced by plant staff are

supplied shipped loose. Major repairs (control system, gearbox, generator) are performed by

factory service technicians.

The warranty program covering the engine is unique in that during the course of the standard

warranty, the Factory will provide one engine on-site (a service engine) as a replacement

engine should the purchased engine(s) fail. This minimizes downtime for the end user since the

engine can be replaced and the service engine installed in 4 to 6 hours after cool down. The

failed engine is not repaired at site but is immediately returned to the factory. A refurbished

engine in the manufacturing cue will be sent to the site as a replacement for swapping out

during the next normal outage/inspection cycle. The Factory’s customer service concept is to

minimize the end user’s inconvenience and maximize his uptime.

Extended warranty coverage on the engines beyond the initial term is also available. For an

annual fee per engine (slightly higher for engines firing #2 diesel), the Factory will leave a fully

refurbished engine on-site as long as the warranty payments are current. Any time during the

active period an engine fails, a replacement will be provided. The added advantage is that

should the program be in place during the course of the engine’s normal 40,000 hour (for

natural gas firing) maintenance cycle (25,000 hours on engines firing #2 diesel), the initial

engine(s) will be replaced with refurbished engines rather than sending the initial engine(s) out

for service or servicing on-site (labor to remove/install are excluded from price). Thus once

again, the Factory provides a superior service to minimize the end user’s inconvenience and

downtime. After the initial engines are replaced, so long as the warranty is current, a

refurbished engine is kept on site in canister.

E-mail: energy@energetech.com Page 13 of 14 Web-Site: www.energetech.com

E-mail: energy@energetech.com Page 14 of 14 Web-Site: www.energetech.com

Você também pode gostar

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsNo EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsNota: 3.5 de 5 estrelas3.5/5 (6)

- FT 8 PDFDocumento33 páginasFT 8 PDFvcharles100% (1)

- Attachment 3 - G390E7sw00 - (1+1)Documento21 páginasAttachment 3 - G390E7sw00 - (1+1)4nagAinda não há avaliações

- 60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BDocumento5 páginas60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BvcharlesAinda não há avaliações

- GTG 1636FPC PWFT4 50HzDocumento24 páginasGTG 1636FPC PWFT4 50HzEmanuel CondeAinda não há avaliações

- 3412C 725 kVA Prime LowBsfc EU 50HzDocumento6 páginas3412C 725 kVA Prime LowBsfc EU 50Hzrbmr1Ainda não há avaliações

- (Maxplore Energaz Turbine) (Power Generation System Proposal)Documento8 páginas(Maxplore Energaz Turbine) (Power Generation System Proposal)Arthur Savero SaharsonAinda não há avaliações

- GE Frame 9Documento4 páginasGE Frame 9Umar Saeed100% (1)

- 1808720010ff SpecificationDocumento7 páginas1808720010ff SpecificationJezrell JaravataAinda não há avaliações

- .: 139 One GE, Frame 5, MS 5001 N, Zero Hour Overhauled - Gas Turbine Package 24,25 MWDocumento10 páginas.: 139 One GE, Frame 5, MS 5001 N, Zero Hour Overhauled - Gas Turbine Package 24,25 MWAkram GeadAinda não há avaliações

- G3520 Lehe2832 02 PDFDocumento6 páginasG3520 Lehe2832 02 PDFCostas Aggelidis100% (1)

- R2 - Offer - 1 MWDocumento23 páginasR2 - Offer - 1 MWShankar RajaAinda não há avaliações

- 07 Scope 2Documento13 páginas07 Scope 2Octavianus HarahapAinda não há avaliações

- Wartsila 9L20Documento9 páginasWartsila 9L20Vikram BaskarAinda não há avaliações

- Centaur 40 Spec.Documento2 páginasCentaur 40 Spec.Majid Moezi100% (1)

- g3520c Im Natural Gas For 1966Documento6 páginasg3520c Im Natural Gas For 1966Pankaj KambleAinda não há avaliações

- G3516e 2000Documento6 páginasG3516e 2000Zaineb ElhamdiAinda não há avaliações

- Carrier Generator Diagnostic Repair Manual Aspas07-1dmDocumento144 páginasCarrier Generator Diagnostic Repair Manual Aspas07-1dmPeter Dillard100% (1)

- THM Gas TurbinesDocumento4 páginasTHM Gas TurbinesAminovic MostafaAinda não há avaliações

- 0k5093 A sd100 6 7l PDFDocumento6 páginas0k5093 A sd100 6 7l PDFmarpadanAinda não há avaliações

- G3516 (975 Ekw 1218 kVA)Documento7 páginasG3516 (975 Ekw 1218 kVA)Antwon CharlesAinda não há avaliações

- CAT Marina Coast Water 300kw Submittal - CompressedDocumento95 páginasCAT Marina Coast Water 300kw Submittal - CompressedCris DucusinAinda não há avaliações

- g35HH20c 2Documento7 páginasg35HH20c 2koushkiAinda não há avaliações

- MTU10V1600DS550 550kVA Standby FuelOptDocumento4 páginasMTU10V1600DS550 550kVA Standby FuelOptlcsandovalr989Ainda não há avaliações

- Kohler 150kw Prime Gas OilfieldDocumento4 páginasKohler 150kw Prime Gas OilfieldnathandemAinda não há avaliações

- 1000 Kva 400v c32 Low BSFC PrimeDocumento6 páginas1000 Kva 400v c32 Low BSFC PrimeelipholebAinda não há avaliações

- Mpspl1746-125kva Kirloskar Igreen DG Set 3ph-Sree Lakshmi EnggDocumento7 páginasMpspl1746-125kva Kirloskar Igreen DG Set 3ph-Sree Lakshmi EnggBalaji GanesanAinda não há avaliações

- MTU 12V1600 DS660: Diesel Generator SetDocumento5 páginasMTU 12V1600 DS660: Diesel Generator Setabdelmoumene djafer beyAinda não há avaliações

- S 1644DCDocumento5 páginasS 1644DCAnh NguyenAinda não há avaliações

- PG Spec 10V1600DS560 510kVA 3B TAL 50HzDocumento5 páginasPG Spec 10V1600DS560 510kVA 3B TAL 50HzMsahrudi MsahrudiAinda não há avaliações

- Dca 60eseiDocumento10 páginasDca 60eseinelsonyAinda não há avaliações

- Sample Quotation For 30MWDocumento6 páginasSample Quotation For 30MWS V NAGESHAinda não há avaliações

- Catalogo Generador Cat 3512Documento6 páginasCatalogo Generador Cat 3512pamg50% (1)

- Submittal - LS Power Chambersburg - G3096 - 5.15.20Documento419 páginasSubmittal - LS Power Chambersburg - G3096 - 5.15.20kohatian27796105100% (2)

- Jgs616 Ds Preliminary DataDocumento4 páginasJgs616 Ds Preliminary DataEdutamAinda não há avaliações

- Fiche A4 4M11 2020Documento2 páginasFiche A4 4M11 2020DHINAKARAN KumarAinda não há avaliações

- MTU 10V1600 DS560: Diesel Generator SetDocumento5 páginasMTU 10V1600 DS560: Diesel Generator SetAhmed GadAinda não há avaliações

- Specifications: VHP5904LTDocumento2 páginasSpecifications: VHP5904LTmuhammad wafiAinda não há avaliações

- MTU 1085 HPDocumento18 páginasMTU 1085 HPmajdirossross100% (2)

- g3520c Natural Gas For 1950Documento6 páginasg3520c Natural Gas For 1950Shahzad AliAinda não há avaliações

- السعد3 PDFDocumento22 páginasالسعد3 PDFMUBRAKAinda não há avaliações

- 3638-Caterpillar 3516b dp2 SystemDocumento22 páginas3638-Caterpillar 3516b dp2 SystemBembenk Supriyadi100% (1)

- m20 C18 FIRE PUMP 448 BKW 600 BHP 1750 RPMDocumento5 páginasm20 C18 FIRE PUMP 448 BKW 600 BHP 1750 RPMStalinTelmoAinda não há avaliações

- 40 (3ph) KVA-WCDocumento5 páginas40 (3ph) KVA-WCbalu9999Ainda não há avaliações

- CaterpilarDocumento4 páginasCaterpilarpangestu66100Ainda não há avaliações

- Generator BasicsDocumento10 páginasGenerator BasicsSudipta ChatterjeeAinda não há avaliações

- Wartsilla 18V220SGDocumento9 páginasWartsilla 18V220SGZohaib AlamAinda não há avaliações

- MTU12V1600DS550 550kW StandbyDocumento4 páginasMTU12V1600DS550 550kW StandbyLUIS SANCHEZAinda não há avaliações

- GTG 1699iec Solart60 60hzDocumento10 páginasGTG 1699iec Solart60 60hzKhaldoon Alnashi100% (1)

- G 4170Documento4 páginasG 4170Orlando Yerén ValenciaAinda não há avaliações

- TAD941GE: Volvo Penta Industrial DieselDocumento2 páginasTAD941GE: Volvo Penta Industrial DieselroozbehxoxAinda não há avaliações

- Generateur GPR - 330 KvaDocumento4 páginasGenerateur GPR - 330 KvamaryFAinda não há avaliações

- Section 16620 - Natural Gas Engine Generator Set: Division 16 Electrical Project NoDocumento17 páginasSection 16620 - Natural Gas Engine Generator Set: Division 16 Electrical Project NovcharlesAinda não há avaliações

- Gas EngineDocumento6 páginasGas EngineMRizwanSadiq313Ainda não há avaliações

- AC250 Data SheetDocumento5 páginasAC250 Data SheetAshutosh SinghAinda não há avaliações

- PG Spec 12V4000DS2000 2080kVA 3D FC 50HzDocumento5 páginasPG Spec 12V4000DS2000 2080kVA 3D FC 50HzPetrus GunturAinda não há avaliações

- Automotive Air Conditioning and Climate Control SystemsNo EverandAutomotive Air Conditioning and Climate Control SystemsNota: 4 de 5 estrelas4/5 (6)

- TDS 00000542 1 Go en PDFDocumento3 páginasTDS 00000542 1 Go en PDFEDBAinda não há avaliações

- Safety Data Sheet ARDROX 6367: 1 Identification of The Substance/Preparation and The CompanyDocumento8 páginasSafety Data Sheet ARDROX 6367: 1 Identification of The Substance/Preparation and The CompanyEDBAinda não há avaliações

- On Line Off Line: Inc. 18811 N. Roselake Dr. Tomball, Texas 77377 Phone 281-255-6092Documento3 páginasOn Line Off Line: Inc. 18811 N. Roselake Dr. Tomball, Texas 77377 Phone 281-255-6092EDBAinda não há avaliações

- Iplex G: Instructions Industrial EndoscopeDocumento126 páginasIplex G: Instructions Industrial EndoscopeEDBAinda não há avaliações

- Ansaldo List of Cleaning AgentDocumento2 páginasAnsaldo List of Cleaning AgentEDB100% (1)

- 1 Chemtron GMBH - : Info@chemtron - de WWW - Chemtron.deDocumento27 páginas1 Chemtron GMBH - : Info@chemtron - de WWW - Chemtron.deEDBAinda não há avaliações

- Chemetall Ardrox 6366 MSDS - Image.MarkedDocumento8 páginasChemetall Ardrox 6366 MSDS - Image.MarkedEDBAinda não há avaliações

- Corporate Profile: Boustead Singapore LimitedDocumento8 páginasCorporate Profile: Boustead Singapore LimitedEDBAinda não há avaliações

- APP Siemens 2003Documento2 páginasAPP Siemens 2003EDBAinda não há avaliações

- Manual - Hp50a1 and Hp70a1Documento28 páginasManual - Hp50a1 and Hp70a1EDBAinda não há avaliações

- Engine Spec 501KB5SDocumento2 páginasEngine Spec 501KB5SEDBAinda não há avaliações

- Air Cooling of Gas Turbine AccessDocumento15 páginasAir Cooling of Gas Turbine AccessEDBAinda não há avaliações

- Versamax Ip: Programmable Control ProductsDocumento54 páginasVersamax Ip: Programmable Control ProductsEDBAinda não há avaliações

- SGT400 To 2014 SiemensDocumento1 páginaSGT400 To 2014 SiemensEDBAinda não há avaliações

- NaimDocumento29 páginasNaimEDBAinda não há avaliações

- CapabilityList Score Part NumbersDocumento150 páginasCapabilityList Score Part NumbersEDBAinda não há avaliações

- HTGD680559 - 2oo3 Trip Block With Sequencer - TBVS90ADocumento3 páginasHTGD680559 - 2oo3 Trip Block With Sequencer - TBVS90AEDBAinda não há avaliações

- ATT03 HTGD690744V0001-B Sequence ValveDocumento8 páginasATT03 HTGD690744V0001-B Sequence ValveEDBAinda não há avaliações

- Datasheets DS TQ402 TQ412 EA402 IQS450-EnDocumento14 páginasDatasheets DS TQ402 TQ412 EA402 IQS450-EnEDBAinda não há avaliações

- ATT03 HTGD690744V0001-B Sequence ValveDocumento8 páginasATT03 HTGD690744V0001-B Sequence ValveEDBAinda não há avaliações

- lm6000 Business Unit Igt Packaging PDFDocumento10 páginaslm6000 Business Unit Igt Packaging PDFEDBAinda não há avaliações

- Siemens: Notice To Operators Mandatory Safety NoticeDocumento1 páginaSiemens: Notice To Operators Mandatory Safety NoticeEDBAinda não há avaliações

- HMC080 KawasakiDocumento12 páginasHMC080 KawasakiEDB50% (2)

- 2012 WTUI Conference LM2500Documento100 páginas2012 WTUI Conference LM2500EDB100% (1)

- Datasheets DS TQ401 EA401 IQS450-EnDocumento12 páginasDatasheets DS TQ401 EA401 IQS450-EnEDBAinda não há avaliações

- Mesit Company Profile A4 2016-06 ENG-2Documento16 páginasMesit Company Profile A4 2016-06 ENG-2EDBAinda não há avaliações

- LM6000 PD Sprint Spec SheetDocumento1 páginaLM6000 PD Sprint Spec SheetEDBAinda não há avaliações

- Milestone 9 For WebsiteDocumento17 páginasMilestone 9 For Websiteapi-238992918Ainda não há avaliações

- Data Mining - Exercise 2Documento30 páginasData Mining - Exercise 2Kiều Trần Nguyễn DiễmAinda não há avaliações

- Nissan E-NV200 Combi UKDocumento31 páginasNissan E-NV200 Combi UKMioMaulenovoAinda não há avaliações

- MEMORANDUMDocumento8 páginasMEMORANDUMAdee JocsonAinda não há avaliações

- La Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanDocumento4 páginasLa Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanKarlle ObviarAinda não há avaliações

- SQL Datetime Conversion - String Date Convert Formats - SQLUSA PDFDocumento13 páginasSQL Datetime Conversion - String Date Convert Formats - SQLUSA PDFRaul E CardozoAinda não há avaliações

- Load Sharing Strategies in Multiple Compressor Refrigeration SystemsDocumento8 páginasLoad Sharing Strategies in Multiple Compressor Refrigeration SystemsLiu YangtzeAinda não há avaliações

- 6 AsianregionalismDocumento32 páginas6 AsianregionalismChandria Ford100% (1)

- Donation Drive List of Donations and BlocksDocumento3 páginasDonation Drive List of Donations and BlocksElijah PunzalanAinda não há avaliações

- Stock Prediction SynopsisDocumento3 páginasStock Prediction SynopsisPiyushPurohitAinda não há avaliações

- Conflict WaiverDocumento2 páginasConflict WaiverjlurosAinda não há avaliações

- Creative Thinking (2) : Dr. Sarah Elsayed ElshazlyDocumento38 páginasCreative Thinking (2) : Dr. Sarah Elsayed ElshazlyNehal AbdellatifAinda não há avaliações

- Ministry of Education Musala SCHDocumento5 páginasMinistry of Education Musala SCHlaonimosesAinda não há avaliações

- Supreme Court of The United StatesDocumento296 páginasSupreme Court of The United StatesABC News PoliticsAinda não há avaliações

- Liga NG Mga Barangay: Resolution No. 30Documento2 páginasLiga NG Mga Barangay: Resolution No. 30Rey PerezAinda não há avaliações

- Numerical Transformer Differential RelayDocumento2 páginasNumerical Transformer Differential RelayTariq Mohammed OmarAinda não há avaliações

- Quantity DiscountDocumento22 páginasQuantity Discountkevin royAinda não há avaliações

- Dr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Documento2 páginasDr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Najeebuddin AhmedAinda não há avaliações

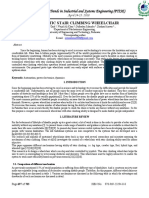

- Automatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Documento7 páginasAutomatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Abdelrahman MahmoudAinda não há avaliações

- Ssasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Documento167 páginasSsasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Sunil Singh100% (1)

- Exercise 23 - Sulfur OintmentDocumento4 páginasExercise 23 - Sulfur OintmentmaimaiAinda não há avaliações

- Steam Source Book PDFDocumento108 páginasSteam Source Book PDFJose Levican A100% (1)

- Bba Colleges in IndiaDocumento7 páginasBba Colleges in IndiaSumit GuptaAinda não há avaliações

- In Partial Fulfillment of The Requirements For The Award of The Degree ofDocumento66 páginasIn Partial Fulfillment of The Requirements For The Award of The Degree ofcicil josyAinda não há avaliações

- Journal of Economic LiteratureDocumento28 páginasJournal of Economic LiteratureEkoKurniadiAinda não há avaliações

- Rehabilitation and Retrofitting of Structurs Question PapersDocumento4 páginasRehabilitation and Retrofitting of Structurs Question PapersYaswanthGorantlaAinda não há avaliações

- RCC Design of Toe-Slab: Input DataDocumento2 páginasRCC Design of Toe-Slab: Input DataAnkitaAinda não há avaliações

- Elliot WaveDocumento11 páginasElliot WavevikramAinda não há avaliações

- Matrix of Consumer Agencies and Areas of Concern: Specific Concern Agency ConcernedDocumento4 páginasMatrix of Consumer Agencies and Areas of Concern: Specific Concern Agency ConcernedAJ SantosAinda não há avaliações

- Notice For AsssingmentDocumento21 páginasNotice For AsssingmentViraj HibareAinda não há avaliações