Escolar Documentos

Profissional Documentos

Cultura Documentos

Jsa For Confined Space

Enviado por

jithin shankarTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jsa For Confined Space

Enviado por

jithin shankarDireitos autorais:

Formatos disponíveis

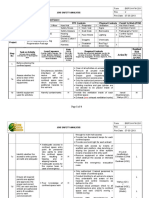

MEGHA ENGINEERING & INFRASTRUCTURES LTD

Job Safety Analysis

JSA Number: NEW REVISED Page No.1 of 5

Job being analysed: FOR CONFINED SPACE

Department/Section doing JSA: JSA

members:

Job Area / Location: Job MEIL, CIVIL

performers:

NORMAL APPROVALS: POSITION Name Designation Signature Date General Job Requirements/Common

PPE

JSA By: EHS

JITHIN a. HSE INDUCTION

SHANKAR b. HELMET

Job Supervisor: c. SAFETY SHOES

d. SAFETY GLASS

e. COVER ALLS

f. HAND GLOVES

Construction Manager

Safety Representative

SE&QFORM070 -- Rev 00 1 of 5 April 02

MEGHA ENGINEERING & INFRASTRUCTURES LTD

Job Safety Analysis

SEQUENCE OF BASIC JOB POTENTIAL HAZARDS ACTIONS (Safe working

STEPS practices/procedures/hazard

(Write risk levels-High/Medium/Low;

control/methods/PPE/action by)

(Number them with description, write frequency)

duration)

(1.0) Identification / classification of Presence of a hazardous atmosphere Establish the Confined space as NON

confined space Presence of an engulfing agent PERMIT REQUIRED CONFINED

Presence of an asphyxiating internal SPACE through physical verification,

configuration hazard analysis and circle of safety If

Presence of any other recognised not,

hazard that may effect a person's (A) The confined space to be

health & safety established as a NON PERMIT

REQUIRED CONFINED SPACE

through hazard elimination

programme and depending upon the

hazard elimination system it may be

further classified as (a) Reclassified

confined space OR (b) Alternate entry

confined space.

(B) The entry cannot be permitted

unless the presence of TRAINED

RESCUER and other protocol.

(2.0) Pre entry preparations Chances of presence of Ensure that the toxic gases are not in

toxic/poisonous /inflammable the inside area. Use a multi gas

gasAsphyxiation detector.

Heat /Temperature difference Natural Ventilations are provided by

opening all the available outlets.

The level of Oxygen will measured

by using a multi gas detector and

monitored at least every 1 hour.

SE&QFORM070 -- Rev 00 2 of 5 April 02

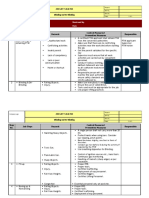

MEGHA ENGINEERING & INFRASTRUCTURES LTD

Job Safety Analysis

Reading will be documented and kept

in handy condition.

All entrants will be evacuated and no

new entry will be allowed in case of

any abnormalities found during

atmospheric monitoring.

Exhaust fan will be kept running as

Darkness long as the activity is in progress.

24 volts hand lamp is to be used for

illumination. Explosive proof lamp

may be provided which will be

Sound abnormalities mounted inside.

Ear plug/Muff will be worn by all the

entrants to minimize the effect of

Communicational irregularities entrapped sound.

/Miscommunication All persons carrying out the activity

must under go the training for

"Entrant”.

The persons deputed to monitor the

activities must undergo the training

for "Attendants".

Method of communication must be

established prior to entry.

One attendant will be deputed, all the

time at the entry point(s).

Entry register must be maintained and

each and every EXIT and ENTRY

will be documented.

(3.0) Pre – Entry Lack of Communication Plan the work involving personnel

responsible for preparation (isolation,

depressurization, draining, venting,

flushing, purging, gas testing etc) of

confined space.

SE&QFORM070 -- Rev 00 3 of 5 April 02

MEGHA ENGINEERING & INFRASTRUCTURES LTD

Job Safety Analysis

Non-compliance of RGT -HSEMS Refer RGT PLANT Regions, HSEMS

Procedures, S Regulations Procedure ‘Entry into Confined Space’

Energized Equipment

Ensure the Confined Space is

positively isolated from all sources of

energy (hydraulic, pneumatic,

electrical etc.)

Use multilock & tag for isolation

Pressurized Fluid carried out.

Pyrophoric Deposition Ensure the confined is depressurized

& content is drained safely.

Flammable & / or Toxic Atmosphere Ensure the pyrophoric deposition

(sludge) is water wetted.

Ensure the confined space is flushed,

Lack of Oxygen purged and thoroughly ventilated as

required.

Ensure the confined space is free

Unauthorized Entry from any flammable / toxic

atmosphere and has sufficient oxygen

No Contact with the Entrant for normal breathing

Obtain the entry permit & other

associated permits for types of work

Fire & Explosion to be carried out

.

Place a Standby Person at manhole to

Welding Fumes / Toxic Hazard maintain contact with the entrant and

record entry / exit.

Ensure the work to be carried out

Entrapment or Collapse of Entrant inside the Confined Space fulfill the

RGT Permit to Work requirement for

the type of work.

Ensure continued gas monitoring.

SE&QFORM070 -- Rev 00 4 of 5 April 02

MEGHA ENGINEERING & INFRASTRUCTURES LTD

Job Safety Analysis

Ensure cross ventilation to dispose

toxic vapor.

Ensure availability of full body

harness & lifeline etc for emergency

retrieval of personnel from Confined

Space.

Re-entry / Completion Left Unattended for Re-Entry Barricade the Confined Space and post

warning notice.

Foreign Materials Left inside Ensure there is no tool, equipment,

rags or other material left inside

Note:

1) If any of the tasks involves biological, physical or chemical hazards, then Industrial Hygienist must also sign this Form, against Any Other

Approving authority above.

2) If steps in a job are more than the space provided above, use a photocopy of this sheet to continue on the next page.

3) Details on safety (PPE, Hazards etc) and environmental requirements can be found in Safety & Environment Procedures available from the

Company Documents & Standards.

SE&QFORM070 -- Rev 00 5 of 5 April 02

Você também pode gostar

- Confined Spaces: Job Safety AnalysisDocumento2 páginasConfined Spaces: Job Safety Analysismalimsaidi_160040895Ainda não há avaliações

- Confined Space JSADocumento1 páginaConfined Space JSADILAL B P100% (16)

- Jsa For Civil Confined Space EntryDocumento11 páginasJsa For Civil Confined Space EntryKhuda BukshAinda não há avaliações

- Jsa Confined SpaceDocumento4 páginasJsa Confined Spacearunmiranda100% (4)

- Bgps H Jsa 008 Jsa Confined SpaceDocumento4 páginasBgps H Jsa 008 Jsa Confined SpaceBuddy EkoAinda não há avaliações

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocumento2 páginasJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Jsa Welding and Sleeve InstallationDocumento5 páginasJsa Welding and Sleeve Installationshinto Lawrence100% (2)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocumento7 páginasJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanAinda não há avaliações

- JSA - Fire Proofing WorksDocumento5 páginasJSA - Fire Proofing WorksAnis Uddin100% (3)

- JSA For Painting Works-Hazards ControlDocumento4 páginasJSA For Painting Works-Hazards Controlkaleem0% (2)

- Form JSA Lifting CraneDocumento6 páginasForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Jsa For Air Flushin & Mech. Cleaning of PipesDocumento17 páginasJsa For Air Flushin & Mech. Cleaning of PipesKhuda Buksh100% (2)

- JHA - Handrails and GratingsDocumento10 páginasJHA - Handrails and GratingsVidyesh Nair67% (3)

- Job Safety Analysis For Pressure TestingDocumento2 páginasJob Safety Analysis For Pressure TestingPerwez2192% (37)

- Job Safety Analysis: Page 1 of 4Documento4 páginasJob Safety Analysis: Page 1 of 4RakeshkasarlaAinda não há avaliações

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocumento12 páginasCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- Jha For HydrotestDocumento14 páginasJha For HydrotestnikAinda não há avaliações

- Mobile - Scaffolds JSADocumento10 páginasMobile - Scaffolds JSABojie Abogadie100% (1)

- JSA For Holiday Testing PDFDocumento4 páginasJSA For Holiday Testing PDFMohammed Minhaj67% (3)

- Jsa Insulation WorkDocumento19 páginasJsa Insulation WorkM M PRADHAN100% (2)

- JSA For Welding of HVACDocumento4 páginasJSA For Welding of HVACMohammed Minhaj100% (1)

- JSA Blinding and de Blinding PDF FreeDocumento3 páginasJSA Blinding and de Blinding PDF Free최승원Ainda não há avaliações

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocumento2 páginasJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- Jsa For Drilling.Documento3 páginasJsa For Drilling.Belsyah Nofriyan75% (4)

- Jsa For Ut TestDocumento2 páginasJsa For Ut Testnasar_mahsood50% (2)

- Jsa For HydrotestDocumento10 páginasJsa For HydrotestAnonymous CcGYhZb080% (5)

- Jsa Working at Height (Maintenance & Cleaning)Documento2 páginasJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- RA Confined Space PDFDocumento10 páginasRA Confined Space PDFrodman823100% (1)

- Job Safety Analysis Sheet: FacilityDocumento1 páginaJob Safety Analysis Sheet: Facilitywahyu nugrohoAinda não há avaliações

- Risk Assessment For InsulationDocumento9 páginasRisk Assessment For InsulationSaleem Akhtar75% (8)

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocumento7 páginasJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- JSa For Operation of Jack HammeringDocumento3 páginasJSa For Operation of Jack Hammeringyc safety0% (1)

- JSA For Fire Water LineDocumento4 páginasJSA For Fire Water Linemyo lwinAinda não há avaliações

- CPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night ShiftDocumento3 páginasCPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night Shiftaioudi100% (1)

- Gas Cutting JsaDocumento4 páginasGas Cutting JsaMohammed Minhaj100% (1)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocumento6 páginasJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- JSA Demolition Wall B#3Documento2 páginasJSA Demolition Wall B#3tit somm100% (3)

- JSA Installation of PumpsDocumento6 páginasJSA Installation of Pumpsyc safety100% (2)

- JHA - To Carry Out Reinstate of Interlock StonesDocumento7 páginasJHA - To Carry Out Reinstate of Interlock Stoneslinga201450% (2)

- Jsa Nitrogen PurgingDocumento2 páginasJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- Jsa Pipe Cutting at Fire PumpDocumento5 páginasJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdAinda não há avaliações

- Jsa For Piping and Erection RevisedDocumento1 páginaJsa For Piping and Erection RevisedAlvin Smith77% (26)

- JSA For Demolation Work at Exiting OfficeDocumento3 páginasJSA For Demolation Work at Exiting OfficeMohammed MinhajAinda não há avaliações

- JSA-055 Hydro-TestDocumento24 páginasJSA-055 Hydro-TestOmar Dhieb100% (7)

- JSA For HILTIDocumento3 páginasJSA For HILTIMohammed Minhaj100% (1)

- Tanks Confined Space JSADocumento5 páginasTanks Confined Space JSAkosoko100% (1)

- Jsa For Cutting, Grinding and Welding For GulfconDocumento3 páginasJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- JSA Welding Confined SpaceDocumento2 páginasJSA Welding Confined Spacegkmlal100% (4)

- JSA For Excavation WorksDocumento4 páginasJSA For Excavation WorksKelly Bates100% (12)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocumento5 páginasJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANAinda não há avaliações

- Risk Assessment For Confined Space Day and Night-1Documento6 páginasRisk Assessment For Confined Space Day and Night-1balasubramaniam100% (1)

- JSA For WrappingDocumento6 páginasJSA For WrappingMohammed Minhaj100% (2)

- Blinding and De-BlindingDocumento3 páginasBlinding and De-Blindingkaremkoko33% (3)

- JSA 04 Confined Sapce EntryDocumento1 páginaJSA 04 Confined Sapce Entrywahyu nugrohoAinda não há avaliações

- Jsa For RadiographyDocumento3 páginasJsa For Radiographyjithin shankarAinda não há avaliações

- LBK JSA-Redrill 04012022 EnglishDocumento6 páginasLBK JSA-Redrill 04012022 EnglishHSE BGP HOAinda não há avaliações

- SWMS2 Confined Space EntryDocumento9 páginasSWMS2 Confined Space EntryIslam Sarhan100% (1)

- Backfilling - CompactionDocumento11 páginasBackfilling - CompactionFarooq MohammadAinda não há avaliações

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Documento2 páginasJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeAinda não há avaliações

- Job Safety AnalysisDocumento2 páginasJob Safety AnalysisAris RNAinda não há avaliações

- JournalDocumento24 páginasJournaljithin shankarAinda não há avaliações

- Defensive Driving TrainingDocumento14 páginasDefensive Driving Trainingjithin shankarAinda não há avaliações

- Price Quotation Without Tax1Documento1 páginaPrice Quotation Without Tax1jithin shankarAinda não há avaliações

- FMEA FMECA The WorkhorseDocumento33 páginasFMEA FMECA The Workhorsejithin shankarAinda não há avaliações

- Stas Ctic IsDocumento1 páginaStas Ctic Isjithin shankarAinda não há avaliações

- IG1 0029 ENG OBE Answer Sheet V1Documento8 páginasIG1 0029 ENG OBE Answer Sheet V1jithin shankar100% (3)

- Alcohol Drug PolicyDocumento2 páginasAlcohol Drug Policyjithin shankarAinda não há avaliações

- Attendeence SheetDocumento2 páginasAttendeence Sheetjithin shankarAinda não há avaliações

- Updated Corporate Training SessionDocumento4 páginasUpdated Corporate Training Sessionjithin shankarAinda não há avaliações

- Legal RegisterDocumento3 páginasLegal Registerjithin shankarAinda não há avaliações

- Accidenn Incident PolicyDocumento2 páginasAccidenn Incident Policyjithin shankarAinda não há avaliações

- Road Safety StandardDocumento2 páginasRoad Safety Standardjithin shankarAinda não há avaliações

- Unit IG2 Tony BabuDocumento14 páginasUnit IG2 Tony Babujithin shankar100% (3)

- Organization ChartDocumento1 páginaOrganization Chartjithin shankarAinda não há avaliações

- Legal Register 01Documento7 páginasLegal Register 01jithin shankarAinda não há avaliações

- RTW Communication PlanDocumento1 páginaRTW Communication Planjithin shankarAinda não há avaliações

- Ehs Hse PlanDocumento50 páginasEhs Hse Planjithin shankarAinda não há avaliações

- Accident ReportDocumento6 páginasAccident Reportjithin shankarAinda não há avaliações

- Organisation Chart Need To UpgradeDocumento1 páginaOrganisation Chart Need To Upgradejithin shankarAinda não há avaliações

- S.No Date Type of Work Depth (MTS) Grade QTY Cum - Qty: Ogt, Ongc, MallavaramDocumento2 páginasS.No Date Type of Work Depth (MTS) Grade QTY Cum - Qty: Ogt, Ongc, Mallavaramjithin shankarAinda não há avaliações

- Legal RegisterDocumento3 páginasLegal Registerjithin shankarAinda não há avaliações

- Hazard Identification Risk AssessmentDocumento5 páginasHazard Identification Risk Assessmentjithin shankarAinda não há avaliações

- TS June MonthDocumento7 páginasTS June Monthjithin shankarAinda não há avaliações

- Activity Potential Hazard Safe Work Practice & Control MeasuresDocumento1 páginaActivity Potential Hazard Safe Work Practice & Control Measuresjithin shankarAinda não há avaliações

- NoDocumento1 páginaNojithin shankarAinda não há avaliações

- RVK CVDocumento7 páginasRVK CVjithin shankarAinda não há avaliações

- Daily Man Power MallavaramDocumento2 páginasDaily Man Power Mallavaramjithin shankarAinda não há avaliações

- Manpower For The Month: SEPT-2020: On Shore Terminal KG DWN 98/2 Development ProjectDocumento2 páginasManpower For The Month: SEPT-2020: On Shore Terminal KG DWN 98/2 Development Projectjithin shankarAinda não há avaliações

- SL No Date Permit No Permit Type Activity Permit Receiver Permit Under ReniwalDocumento2 páginasSL No Date Permit No Permit Type Activity Permit Receiver Permit Under Reniwaljithin shankarAinda não há avaliações

- New Final Requirement-26.05.2017Documento4 páginasNew Final Requirement-26.05.2017jithin shankarAinda não há avaliações

- Us 5596162Documento9 páginasUs 5596162Stanley PinesAinda não há avaliações

- Chemistry Lab ReportDocumento9 páginasChemistry Lab Reportapi-327824087Ainda não há avaliações

- Masterseal 530: Surface Applied Capillary Waterproofing For Concrete and MortarDocumento2 páginasMasterseal 530: Surface Applied Capillary Waterproofing For Concrete and MortarHoang An ViAinda não há avaliações

- Hemodynamic Monitoring in ICUDocumento111 páginasHemodynamic Monitoring in ICUManjunath Gemini100% (2)

- Ap Art and Design Drawing Sustained Investigation Samples 2019 2020 PDFDocumento102 páginasAp Art and Design Drawing Sustained Investigation Samples 2019 2020 PDFDominic SandersAinda não há avaliações

- Global Environment Unit 2Documento13 páginasGlobal Environment Unit 2Se SathyaAinda não há avaliações

- 96-09302-00-01 Reva Technical Manual Inogen One G5Documento18 páginas96-09302-00-01 Reva Technical Manual Inogen One G5Paula Andrea MarulandaAinda não há avaliações

- MHFU Hunter RankDocumento5 páginasMHFU Hunter RankGustin PrayogoAinda não há avaliações

- Kelvin Hughes LTD: Technical Advice SheetDocumento7 páginasKelvin Hughes LTD: Technical Advice SheetVladymirAinda não há avaliações

- HorticultureDocumento12 páginasHorticultureवरुण राठीAinda não há avaliações

- Final Cor 011 Reviewer PDFDocumento104 páginasFinal Cor 011 Reviewer PDFMary JuneAinda não há avaliações

- Final Tana Beles - pdf2222Documento72 páginasFinal Tana Beles - pdf2222Tiruneh Yeneneh100% (1)

- DEVISER S7200 - ManualDocumento326 páginasDEVISER S7200 - ManualNicolas Maldonado BenitezAinda não há avaliações

- CN 235 Aircraft DefinitionDocumento22 páginasCN 235 Aircraft DefinitionMoch Dedy100% (4)

- MOE XT2-XT4 110... 125V Ac/dcDocumento3 páginasMOE XT2-XT4 110... 125V Ac/dcLê Xuân ĐịnhAinda não há avaliações

- Ultrasonic Inspection of Welds in Tubes & Pipes: Educational NoteDocumento13 páginasUltrasonic Inspection of Welds in Tubes & Pipes: Educational NoteleonciomavarezAinda não há avaliações

- Excess Fluid VolumeDocumento27 páginasExcess Fluid VolumeAdrian Ardamil100% (1)

- ELK-3 550 1HC0000742AFEnDocumento20 páginasELK-3 550 1HC0000742AFEnOnur FişekAinda não há avaliações

- PIANC SMART Rivers Proceedings OkDocumento190 páginasPIANC SMART Rivers Proceedings OkMartin PrietoAinda não há avaliações

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDocumento14 páginasDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazAinda não há avaliações

- The Past Is A Foreign Country-1.2Documento25 páginasThe Past Is A Foreign Country-1.2Xinyu DongAinda não há avaliações

- Hira - For Shot Blasting & Upto 2nd Coat of PaintingDocumento15 páginasHira - For Shot Blasting & Upto 2nd Coat of PaintingDhaneswar SwainAinda não há avaliações

- Low - Pass FilterDocumento8 páginasLow - Pass FilterSaurabh BhiseAinda não há avaliações

- J. Agric. Food Chem. 2005, 53, 9010-9016Documento8 páginasJ. Agric. Food Chem. 2005, 53, 9010-9016Jatyr OliveiraAinda não há avaliações

- Today! 2 Activity Book AKDocumento10 páginasToday! 2 Activity Book AKMark Arenz Corixmir80% (5)

- Board ManualDocumento190 páginasBoard ManualkmalAinda não há avaliações

- Hinomoto Tractor Parts Catalogue 2018 C144, C174, E150, E180, E230, E250, E280, E384Documento63 páginasHinomoto Tractor Parts Catalogue 2018 C144, C174, E150, E180, E230, E250, E280, E384Monica Mascarenhas0% (1)

- Accesorios Del Lamborghini VenenoDocumento31 páginasAccesorios Del Lamborghini VenenoVicente Gil PalopAinda não há avaliações

- Parker - Twin FilterDocumento6 páginasParker - Twin FilterNAHASALI11Ainda não há avaliações

- Manual African Airstrip Adventures EnglDocumento46 páginasManual African Airstrip Adventures EnglDele Jnr EriboAinda não há avaliações