Escolar Documentos

Profissional Documentos

Cultura Documentos

Concrete Masony and Sustainable Design PDF

Enviado por

mcx_usaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Concrete Masony and Sustainable Design PDF

Enviado por

mcx_usaDireitos autorais:

Formatos disponíveis

TEK NOTE

September 2010

Concrete Masonry and Sustainable Design are a Natural Fit

The green building movement has gained momentum over Longevity and Durability

the past several years. Rating systems such as LEED and These attributes are among masonry’s greatest assets.

Green Globes have helped to drive this movement. Many masonry buildings have passed their 100-year

Masonry materials can contribute significantly toward rating anniversaries. Structures that last longest, require less

system compliance. (See Figure 1.) Now we must consider maintenance, and can be adapted for reuse cast a

the implications of new green building codes that are being smaller shadow on the environment. Unfortunately,

developed. ASHRAE/USGBC Standard 189.1 has been durability and long service life of buildings have been

published as has the International Green Construction overlooked in most green rating systems. Some

Code (IGCC). At times there have been unintentional designers using LEED have had to use an “Innovation

consequences of using the rating systems. Most notably, in in Design” credit to properly account for durability of

their misapplication in the form of requirements rather than masonry materials in their project. Many designers

providing guidance. Codes and standards on the other consider these masonry qualities to be one of the most

hand are legal documents with mandatory provisions that critical elements of the definition of sustainability.

can be directly adopted by a city or state government.

There is no doubt that longer lasting buildings will help

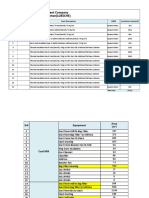

Potential Concrete Masonry Contribution save virgin materials and reduce construction waste.

to LEED Rating Existing green rating systems place more emphasis on

recycled content than durability. In establishing

environmental preferences, it may be more logical to start

with reducing consumption of virgin resources rather that

recycling them. Figure 2 illustrates the relationship

between durability and recyclability of construction

materials. Masonry’s high durability combined with good

recyclable qualities make it an excellent choice for

sustainable designs.

Figure 1.

How does masonry construction fit into the sustainable

design movement? Many aspects of sustainability were

inherent in masonry construction long before “green” and

“sustainable” became buzz words. Let’s look at the Figure 2.

(continued on back)

qualities masonry materials provide.

Resource Efficiency from blasts and bullets. Increased disaster resistance

Concrete masonry block are manufactured using some and improved durability are key components of

of the most abundant materials found on earth. The sustainable buildings.

manner in which materials are collected, transported

short distances, and incorporated into manufactured Aesthetics

products with relatively little energy provide minimal The variety of sizes, shapes, colors, textures and

negative impact on the environment. Concrete masonry patterns available in concrete masonry products

manufacturers use more than 95% of extracted material provide unlimited design flexibility. Aesthetics plays a

in their production and the modular design of the role in sustainable evaluations. It is more likely that

manufactured block helps to reduce construction waste. people will hold onto their attractive, inviting buildings

longer and use them adaptively.

Byproduct Utilization

Concrete masonry products are capable of incorporating Enclosure and Finish

materials that have been recycled from other industries Concrete masonry walls can provide both structural

and consumers. Some recycled materials can be used support and exterior/interior finish. This simplified wall

as aggregate or partial replacement for cement in the system can eliminate the need for additional materials

concrete mix. Block themselves can be easily that require manufacture, installation, maintenance and

transformed into raw materials for new units or repair. This reduces cost and conserves building

aggregates for other purposes. materials.

Energy Efficiency Interior masonry walls do not require paint or other

Because concrete masonry has high thermal mass, it finishes thereby reducing VOCs and improving air

provides very effective thermal storage. Masonry walls quality. The fact that concrete masonry is not a food

remain warm or cool long after the heat or air- source for mold can also improve air quality and lower

conditioning has shut off. This benefit results in lower potential repair costs.

energy consumption in buildings. With proper design,

masonry walls, especially cavity walls, can reduce peak Natural Fit

heating and cooling loads; shift peak loads; moderate As designers move beyond simple consideration of

indoor temperature swings; and reduce the size of environmental impacts to more thorough life-cycle

HVAC systems. Also, passive design strategies can be based design, they realize concrete masonry is an

successfully implemented utilizing masonry materials. affordable, locally available, and environmentally

sensitive building material with an exceptional life-

Safety and Protection cycle. Its intrinsic qualities discussed in this technical

While most environmental rating systems include bulletin make it a natural fit for sustainable design.

occupant health and comfort, they frequently ignore the It is anticipated as green building codes and

safety and protection of those inhabitants. Concrete standards evolve they will justly recognize all these

masonry structures go above and beyond other building important masonry attributes that contribute to practical

systems in providing improved fire safety; shelter from designs, enduring structures and environmental

hurricanes, tornadoes and earthquakes; and protection responsibility.

Durability = Longevity

“It is likely the environmental

impact is much less if we build

Longevity = Sustainability

one 75-year building rather than

three 25-year buildings.”

Sustainability = Masonry

Northwest Concrete Masonry Association

th

19109 36 Avenue West, Suite 211

Lynnwood, WA 98036-5767

425.697.5298

www.nwcma.org

© Copyright 2010 Northwest Concrete Masonry Association. All rights reserved.

No part of this publication may be reproduced in any way without the express consent of the Northwest Concrete Masonry Association.

Every effort has been made to ensure that this document is complete and correct.

However, the Northwest Concrete Masonry Association assumes no responsibility for the accuracy or completeness of this document.

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Water Heater InstallDocumento24 páginasWater Heater Installmcx_usa100% (1)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Chess Teaching ManualDocumento303 páginasChess Teaching Manualmcx_usa100% (1)

- Romanian GrammarDocumento194 páginasRomanian GrammarDianthe91100% (11)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Insulation BOQ Area Wise (Square MTR.)Documento11 páginasInsulation BOQ Area Wise (Square MTR.)Atiq Ur RehmanAinda não há avaliações

- Cohesion Intercept of Soils + Typical Values PDFDocumento5 páginasCohesion Intercept of Soils + Typical Values PDFyajive9970Ainda não há avaliações

- Standard Specs For Racquetball Court Construction Rev 09Documento9 páginasStandard Specs For Racquetball Court Construction Rev 09matador2013Ainda não há avaliações

- Animalfarmpenguin Readers GuideDocumento15 páginasAnimalfarmpenguin Readers Guideapi-194333853Ainda não há avaliações

- Design Calculation For Pile Length Using Meyerhoff FormulaeDocumento1 páginaDesign Calculation For Pile Length Using Meyerhoff Formulaeezarul fitri83% (6)

- Altis Little Havana - UDRB Plan SetDocumento63 páginasAltis Little Havana - UDRB Plan SetNone None None100% (2)

- New Manual of VisTablet PDF Version (Final)Documento0 páginaNew Manual of VisTablet PDF Version (Final)mcx_usaAinda não há avaliações

- New Manual of VisTablet PDF Version (Final)Documento0 páginaNew Manual of VisTablet PDF Version (Final)mcx_usaAinda não há avaliações

- Recycling From E-Waste To ResourcesDocumento120 páginasRecycling From E-Waste To Resourcesrazor75ap100% (1)

- Sustainability and Green Building Rating SystemsDocumento5 páginasSustainability and Green Building Rating Systemstarek.abbas8598Ainda não há avaliações

- The EcoDesign ChecklistDocumento1 páginaThe EcoDesign ChecklistPaolo BartoliAinda não há avaliações

- Smhs E-Blast: Welcome Back Matadors!Documento5 páginasSmhs E-Blast: Welcome Back Matadors!mcx_usaAinda não há avaliações

- Edge Menu September 2019Documento2 páginasEdge Menu September 2019mcx_usaAinda não há avaliações

- Construction Information PDFDocumento4 páginasConstruction Information PDFmcx_usaAinda não há avaliações

- ReporterOnline PDFDocumento60 páginasReporterOnline PDFmcx_usaAinda não há avaliações

- Arizona Driver License Manual: and Customer Service GuideDocumento60 páginasArizona Driver License Manual: and Customer Service GuideAdam NeweyAinda não há avaliações

- 2019 English Calendar PDFDocumento19 páginas2019 English Calendar PDFmcx_usaAinda não há avaliações

- X Force: Owner's ManualDocumento16 páginasX Force: Owner's Manualmcx_usaAinda não há avaliações

- Great Hearts Annual Report 2017 2018 Interactive 10-23-2018Documento30 páginasGreat Hearts Annual Report 2017 2018 Interactive 10-23-2018mcx_usaAinda não há avaliações

- Football Player's Equipment Handout PDFDocumento4 páginasFootball Player's Equipment Handout PDFmcx_usaAinda não há avaliações

- Annual ReportDocumento29 páginasAnnual Reportmcx_usaAinda não há avaliações

- Yamaha YPT 200Documento68 páginasYamaha YPT 200mcx_usaAinda não há avaliações

- What Do The Numbers Mean Colour Sept2012Documento1 páginaWhat Do The Numbers Mean Colour Sept2012mcx_usaAinda não há avaliações

- WorldHappinessReport2013 PDFDocumento156 páginasWorldHappinessReport2013 PDFmcx_usaAinda não há avaliações

- Camry EbrochureDocumento37 páginasCamry Ebrochurefghsda123000Ainda não há avaliações

- Charter Starter 101: How To Start A Charter SchoolDocumento50 páginasCharter Starter 101: How To Start A Charter Schoolmcx_usaAinda não há avaliações

- Passive Lighting TechniquesDocumento30 páginasPassive Lighting Techniquesakhil jainAinda não há avaliações

- Eco-Design in Hospitality ArchitectureDocumento23 páginasEco-Design in Hospitality ArchitectureitsCherylAinda não há avaliações

- Comp Xref 2004Documento8 páginasComp Xref 2004lasAinda não há avaliações

- Madanjeet School Pondicherry UniversityDocumento1 páginaMadanjeet School Pondicherry Universitym a100% (1)

- Soil Components and Soil ProfileDocumento4 páginasSoil Components and Soil ProfilemramagroAinda não há avaliações

- 17 Calefactor Electrico de DuctosDocumento6 páginas17 Calefactor Electrico de DuctosRene Arenas EnecalAinda não há avaliações

- ResumeABDULKALEEM A MDocumento5 páginasResumeABDULKALEEM A MJenniferAinda não há avaliações

- SystemAir Basic KSA PPT (6-3-24)Documento40 páginasSystemAir Basic KSA PPT (6-3-24)baseer abdulAinda não há avaliações

- Modified Proctor Test For SoilDocumento6 páginasModified Proctor Test For SoilSheharyar AhmedAinda não há avaliações

- Spek Teknis HvacDocumento30 páginasSpek Teknis Hvacdhani7Ainda não há avaliações

- How To Work Out The Passive House Form Factor - HEAT, SPACE AND LIGHT LTDDocumento10 páginasHow To Work Out The Passive House Form Factor - HEAT, SPACE AND LIGHT LTDchiomaAinda não há avaliações

- Solar Bidders ListDocumento10 páginasSolar Bidders ListSreekanth SunkeAinda não há avaliações

- ASHP Sizing and Selection Guide (EN)Documento62 páginasASHP Sizing and Selection Guide (EN)zukchuAinda não há avaliações

- Chapter 14 MasonryDocumento5 páginasChapter 14 MasonryPrescila QuietaAinda não há avaliações

- Stabilization of Black Cotton Soil With Lime and Geo-GridDocumento6 páginasStabilization of Black Cotton Soil With Lime and Geo-GridIJIRAEAinda não há avaliações

- TJ Marshall, Mechanical Composition of Soil in Relation To Field Descriptions of TextureDocumento9 páginasTJ Marshall, Mechanical Composition of Soil in Relation To Field Descriptions of TextureScary CreaturesAinda não há avaliações

- All in BrochureDocumento2 páginasAll in Brochureroyalhavilah11Ainda não há avaliações

- Wattle & DaubDocumento9 páginasWattle & DaubRemya R. KumarAinda não há avaliações

- Soil ClassificationDocumento19 páginasSoil Classificationqwerty12348Ainda não há avaliações

- AC MOX330 12HFN8 R MSEPBU 12HRFN8 R - 1661973296 Eb 2925dcd7Documento6 páginasAC MOX330 12HFN8 R MSEPBU 12HRFN8 R - 1661973296 Eb 2925dcd7Szasz ZsomborAinda não há avaliações

- Chatupara HP1N X 1000Documento4 páginasChatupara HP1N X 1000marsplanning108Ainda não há avaliações

- Presented By: Lakshmi Sruthi Leah RoseDocumento16 páginasPresented By: Lakshmi Sruthi Leah RosesharathAinda não há avaliações

- Data Pengamatan Dan Hasil Perhitungan HE Revvvvv-1Documento16 páginasData Pengamatan Dan Hasil Perhitungan HE Revvvvv-1AhmdMaulanaAinda não há avaliações

- Licensed Contractors by Business Name May23Documento214 páginasLicensed Contractors by Business Name May23ALI KHALIDAinda não há avaliações