Escolar Documentos

Profissional Documentos

Cultura Documentos

Khan, Ashfaq Mrawira, Donath - Investigation of The Use of Lightweight A

Enviado por

Mehdi FarrokhiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Khan, Ashfaq Mrawira, Donath - Investigation of The Use of Lightweight A

Enviado por

Mehdi FarrokhiDireitos autorais:

Formatos disponíveis

Investigation of the Use of Lightweight Aggregate Hot-Mixed

Asphalt in Flexible Pavements in Frost Susceptible Areas

Ashfaq Khan, Ph.D.1; and Donath Mrawira, P.E.2

Abstract: Frost related damage in pavements is a major concern for highway engineers in cold regions. The existing methods for

mitigating frost damage in flexible pavements are expensive; they require greater construction control and are not fully effective. This

paper investigates an alternative approach for reducing frost penetration into the pavement layers by engineering a less conductive asphalt

Downloaded from ascelibrary.org by Monash University on 11/09/12. Copyright ASCE. For personal use only; all rights reserved.

surface layer. It proposes a less conductive pavement by replacing conventional aggregate in the asphalt mix with lightweight aggregate

共LWA兲. The paper discusses, in the context of the larger research program, the development of an optimized design of LWA-asphalt mix.

It is has been demonstrated in work published elsewhere that because of its superior insulating behavior, LWA-asphalt mix can reduce

frost penetration into the underlying pavement layers. Thus maintenance cost associated with frost damage can be reduced. This paper

presents the physical properties of LWA, the lessons learned from the mix design process, as well as the preliminary thermal and

mechanical properties of the optimized LWA-asphalt mix.

DOI: 10.1061/共ASCE兲0899-1561共2010兲22:2共171兲

CE Database subject headings: Aggregate; Asphalt; Mixtures; Flexible pavements; Damage; Thermal factors.

Author keywords: Lightweight aggregate; Asphalt mix; Flexible pavements; Frost damage; Thermal properties.

Background The various methods commonly used to mitigate frost action

in flexible pavements focus on remedial actions applied to sub-

Frost action is a phenomenon that occurs in winter and early grade and in some cases fine-grained subbase and base layers.

spring in northern regions. Pavements in these regions are subject The approach proposed in this paper is to evaluate the use of

to freezing in winter and thawing in spring. Frost action can be LWA in asphalt mix and determine optimum conditions for its

quite detrimental to pavements and refers to two separate but application in frost-resistant pavements. In one experimental

related phases: freezing of the soil water and thawing of the soil study conducted by Goodrich and White 共1987兲 on clay and shale

water. Frost action becomes critical in pavements when either the based lightweight aggregate 共LWA兲, the thermal conductivity of

freezing phase is accompanied by noticeable heaving of the road such aggregates was found to be in the range of 0.11 to

surface, or the thawing phase is accompanied by a noticeable 0.17 W m K. The research hypothesis is that because of its lower

softening of the roadbed. thermal conductivity, LWA can produce less conductive asphalt

The direct and indirect economic costs associated with frost pavement layers that will reduce or eliminate frost penetration

damage are enormous. Direct costs are related to need of mainte- into the subgrade.

nance and/or reconstruction to repair frost damaged pavements. LWA is readily available throughout the United States,

Indirect costs include user costs and those related to the decline in Canada, and many other parts of the world. It is produced by

transportation productivity during the period when spring load heating particles of shale, clay or slate in a rotary kiln at a tem-

restrictions are enforced. A variety of approaches has been used to perature of more than 1,000° C. Gases given off during the heat-

prevent or minimize frost damage in flexible pavements. These ing process cause bloating or expansion of the material resulting

include stopping the supply of water into the pavement layers, in reduced bulk density of the particles. The high temperature

removal of frost susceptible subgrade, design of pavement struc- converts the material to ceramic-like particles containing numer-

ture based on reduced subgrade support, and using insulation ous nonconnected voids. After leaving the kiln, the material is

layer between the pavement and subgrade. cooled and processed to precise gradations. LWA is inert, struc-

turally stable and highly insulative 共Gallaway 1997兲. The volume

1 of LWA can be as large as twice the volume of the same weight of

Construction Engineer, Alberta Transportation, Room 223, Provin-

cial Building, 4709-44 Ave., Stony Plain, Alberta, Canada T7Z 1N4. conventional aggregate.

E-mail: ashfaq.khan@gov.ab.ca LWA has been used extensively in concrete bridge decks, high-

2

Associate Professor, Dept. of Civil Engineering, Univ. of New Brun- rise buildings, concrete masonry, and geotechnical applications.

swick, P.O. Box 4400, Fredericton, NB, Canada E3B5A3 共corresponding The use of LWA in pavements has generally been in limited scale

author兲. E-mail: donath@unb.ca with applications such as chip seals and other surface treatments

Note. This manuscript was submitted on February 20, 2008; approved for pothole patching and slurry seals 共Gallaway 1997兲. LWA binds

on October 5, 2009; published online on January 15, 2010. Discussion

period open until July 1, 2010; separate discussions must be submitted for

better to asphalt because of its rough surface texture with a po-

individual papers. This paper is part of the Journal of Materials in Civil tential to extend the pavement service life. Yet, routine use of

Engineering, Vol. 22, No. 2, February 1, 2010. ©ASCE, ISSN 0899- LWA in hot-mixed asphalts for extensive applications in road con-

1561/2010/2-171–178/$25.00. struction has not been investigated.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / FEBRUARY 2010 / 171

J. Mater. Civ. Eng. 2010.22:171-178.

100

90

Blending Sand

80

70

% passing

60

50

40 Pumice

30 Aggregate A

20 Aggregate B

Aggregate C

10

Aggregate D

0

0.075 0.15 0.3 0.6 1.18 2.36 4.75 6.3 9.5 12.5 19.0

Sieve Size (mm) to power 0.45

Fig. 2. Severe stripping of a trial asphalt mix containing pumice

Fig. 1. Gradation curves of aggregates used to achieve an optimized

Downloaded from ascelibrary.org by Monash University on 11/09/12. Copyright ASCE. For personal use only; all rights reserved.

LWA-asphalt mix

according to the ASTM C136 test method. Test results for pumice

were not encouraging. gradation analysis 共Fig. 1兲 for pumice

Objective showed that the material has a high dust content of 22.5%. Mi-

crodeval abrasion test resulted in a 40% loss in mass, which ex-

This paper is part of a larger study that investigates an alternative ceed the maximum allowable limit of 16% according to the

approach for mitigating frost damage by engineering a less con- NBDOT standard specifications. A trial mix containing pumice

ductive pavement structure. The benefits and effectiveness of and 15% asphalt binder exhibited severe stripping problem

using LWA asphalt and LWA aggregates in other pavement layers 共Fig. 2兲. From these results it was decided to stop any further

were demonstrated in the context study and published in recent investigation of pumice as a paving material. Consequently, the

paper by the writers Khan et al. 共2008兲. Also, the larger study remainder of this paper deals with the expanded shale LWA. For

dealt with the determination and measurement of thermal proper- simplicity, only the term LWA will be used in this paper instead of

ties of LWA-asphalt mixes; this work has been published in a expanded shale LWA.

recent article 共Khan and Mrawira 2008兲. This paper focuses on Depending on where it is manufactured, the bulk density of

the mix design for LWA-asphalt mix and initial characterization LWA is roughly about half the bulk density of a conventional

of such a mix for possible use in flexible pavements in frost aggregate ranging from 480 to 1,000 kg/ m3 共Gallaway 1997兲. In

susceptible areas. The scope of this laboratory study is the physi- this study, bulk densities of the LWA and a conventional aggre-

cal characterization of LWA, development of the optimum gate were determined according to ASTM C29 and were found

LWA-asphalt mix design and the mechanical and thermal charac- to be 820 and 1,754 kg/ m3, respectively. It is worth noting that

terization of the resulting LWA-asphalt mix. The structural per- the conventional aggregate used for comparison in this study is

formance of a hypothetical LWA pavement section is evaluated from Springhill Construction Ltd. quarry in Fredericton, New

using the Asphalt Institute mechanistic-empirical relationships. Brunswick.

Specific gravity of an aggregate is useful in making weight-

volume conversions and in calculating voids in mineral aggregate

Material Characterization 共VMA兲 in the compacted asphalt mix. Specific gravity and ab-

sorption of the coarse fraction 共12.5–4.75 mm兲 and fine fraction

Materials used for this study consist of expanded shale LWA ob- 共passing 4.75 mm兲 of LWA were determined according to ASTM

tained from Northeast SOLITE Corporation; blending sand from C127 and ASTM C128, respectively. The two standards specify

Colter pit 共natural deposit兲, New Brunswick; and asphalt binder soaking the aggregates for 24 h. However, given the higher pro-

from Irving Oil Limited. The asphalt binder is a straight-run PG portion of interconnected pores in LWA, these specifications may

58-28 in the Superpave binder grading system. The LWA was not be appropriate for LWA. It was therefore proposed to soak the

crushed to achieve aggregate gradations that satisfy Superpave LWA in water for 72 h so as to ensure saturation of all the open

mix design criteria. Physical properties of pumice 共another type pores. Test results for both coarse and fine aggregate are tabulated

of LWA兲 were also studied. Pumice was supplied by Great Pacific in Table 1. As seen from the table, the specific gravity of the LWA

Pumice Inc. Fig. 1 shows the gradation curves of the four light- fine fraction is 11.7%; more than a percent higher compared to the

weight aggregates, pumice, and the blending sand that were in- LWA coarse fraction. Also, as expected given the higher porosity,

vestigated in this study. the absorption values for LWA are 6 to 10 times higher than those

Before undertaking the mix design, the physical properties of for conventional aggregates.

LWA were evaluated to determine if in fact, LWA can be used in The freeze-thaw durability test was performed according to the

flexible pavements. This phase consisted of testing two types of Ministry of Transportation Ontario 共MTO兲 test procedure MTO

LWA: pumice and expanded shale. Physical properties of the ag- LS-614. The test determines the resistance of coarse aggregate

gregates have significant effects on the performance of pavement. 共retained on the 4.75-mm sieve兲 to disintegration by repeated

The criteria used in this study are the New Brunswick Department freezing and thawing in a sodium chloride solution. The test pro-

of Transportation 共NBDOT兲 standard specifications. The follow- vides a laboratory assessment of the soundness of LWA subject to

ing tests were performed: particle gradation analysis, determina- freezing and thawing action. The durability test results are pre-

tion of bulk density, specific gravity, absorption test, freeze-thaw sented in Table 1. LWA showed only 2% mass loss; this is well

durability test, flat and elongated particles test, and microdeval below the NBDOT maximum allowable limit of 14%. The results

abrasion test. show that LWA is extremely resistant to freezing and thawing

Gradation analysis was performed for each type of aggregate action.

172 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / FEBRUARY 2010

J. Mater. Civ. Eng. 2010.22:171-178.

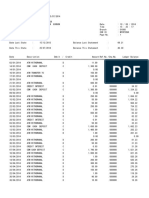

Table 1. Physical Tests Results of LWA phalt plant. Subsequently, we present the three steps of the mix

Conventional NBDOT design process—the aggregate selection, binder selection, and

Physical property LWA aggregate specification identification of the optimum binder content according to

NBDOT specifications.

Gb of coarse fraction 1.45 2.73 —

Fig. 1 shows the gradations of the four lightweight aggregates

Gb of fine fraction 1.66 2.66 —

after size reduction crushing and the blending sand. As seen on

Absorption of coarse fraction 共%兲 10.28 0.66 1.75

the figure, Aggregate A is well graded with a maximum size of 19

Absorption of fine fraction 共%兲 11.68 1.68 —

mm and about 65% retained on the 4.75-mm sieve. Aggregate B

Freeze-thaw durability 2.1 8.6 14

共maximum percent loss兲

is a dense graded 12.5 mm maximum size with about 42% re-

Flat and elongated particles 0.5 10.1 20

tained on the 4.75-mm sieve. Aggregate C is almost a single size

共maximum percent at 4:1兲 with over 94% of the material in the range 12.5–4.75 mm and

Microdeval abrasion 21 16.5 16 79% retained on the 6.3-mm sieve. Aggregate D was obtained by

共maximum percent loss兲 size reduction crushing of Aggregate C and it consists of fine

Downloaded from ascelibrary.org by Monash University on 11/09/12. Copyright ASCE. For personal use only; all rights reserved.

Loose bulk density 共kg/ m3兲 820 1750 — graded 12.5 mm maximum size with only about 34% retained on

Note: Gb = bulk specific gravity; — = not specified. the 4.75-mm sieve.

In order to select the optimum working aggregate skeleton that

can be produced in the asphalt mix plant, the four aggregate gra-

The flat and elongated particles test was performed according dations were combined in the trial and error method 共mathemati-

to MTO LS-608 standard test method. The test determines the

cally兲 to meet Superpave specifications. The common practice in

percentage of flat and elongated particles in coarse aggregate

mix design is to evaluate several aggregate blends of the available

共12.5–4.75 mm兲 by measurement of individual particles. Flat and

aggregates before selecting the best blend for mix design. Typi-

elongated pieces are defined as those whose greatest dimension in

cally the evaluation proceeds by preparing a compacted HMA

the longitudinal axis exceeds the ratio of 4:1 compared to the least

briquette of each aggregate blend at an estimated optimum binder

dimension in a plane perpendicular to the longitudinal axis. Ex-

cessive proportions of flat and elongated particles may cause content and determining the volumetric properties—air voids,

compaction problems and reduce the overall performance of the VMA, and voids filled with asphalt 共VFA兲. The trial blend is also

pavement. As seen in Table 1, LWA tested had only 0.5% of flat evaluated to meet the Superpave compaction requirements. The

and elongated particles by weight. The maximum allowable limit compaction requirements are specified in terms of VMA, VFA,

set by NBDOT is 20%. and maximum theoretical specific gravity at three numbers of

The microdeval abrasion test determines the abrasion loss of gyrations: initial number of gyrations 共Nini兲, design number of

aggregate in the presence of water and an abrasive charge gyrations 共Ndes兲, and maximum number of gyrations 共Nmax兲. For a

共9.5⫾ 0.5 mm steel balls兲. The test was performed according to design traffic load of 3 to 30 million equivalent single axle loads

Test Method LS-618 developed by MTO. The LWA tested 共ESALs兲, NBDOT specifies Nini, Ndes, and Nmax of 8, 100, and

showed a 21% loss 共Table 1兲 in mass; which is slightly higher 160, respectively.

than the allowable limit of 16% specified by NBDOT for the Table 2 summarizes the evaluation of aggregate trial blends

wearing course of flexible pavements. However, as noted before, undertaken in this study. As seen on the table, eight blends were

the LWA showed superior freeze-thaw resistance in addition to its first tried using Aggregates A and B and varying proportions of

better insulative property. It is therefore expected that LWA- blending sand. The goal was to achieve an asphalt mix with

asphalt mix will provide acceptable durability despite the low 12.5 mm nominal maximum size. None of them met the mix

abrasion resistance. Also, given the surface of LWA is vesicular design requirements—especially the air voids requirement. Next,

and more textured than conventional aggregate, higher frictional two blends were tried using only Aggregate B with blending sand.

resistance is expected from LWA asphalt surface mix. The litera- Again, these blends did not meet the requirements. Finally, the

ture shows that in a ranking of polished stone values 共PSVs兲 of trial blends using Aggregates C and D were evaluated. The focus

over 60 different aggregate samples from lowest value to the here was changed to evaluate surface mixes with 9.5 mm nominal

highest, the LWA ranked at top with the PSV of 51 共Gallaway maximum size. As seen on the table, Trial Blends #11 and #12

1997兲. were very close to meeting the volumetric requirements. By

reducing the proportion of blending sand, the Trial Blend #13

was successful in meeting the design requirements. This trial

Design of Lightweight Aggregate-Asphalt Mix blend was selected as the design aggregate skeleton to be evalu-

ated in the final step of mix design—selection of optimum binder

Design Considerations and Aggregate Gradation content. Fig. 3 shows design aggregate gradation that was further

Generally speaking, mix design is a laboratory simulation that investigated for optimized LWA-asphalt mix.

aims to approximate the actual hot-mix asphalt 共HMA兲 plant pro- It is worth noting that the binder used in the evaluation is a

duction, placement, and in-service performance as close as pos- PG58-28, the typical binder specified for medium traffic loading

sible. The laboratory mix design allows an engineer to predict in New Brunswick. The bulk specific gravity of each compacted

the type of mix design that is best for a particular application briquette was determined according to ASTM D2726. Theoretical

and how it will perform. In this paper, the mix design goal was maximum specific gravity of each uncompacted 共loose兲 asphalt

to identify an optimized LWA-asphalt mix that can meet techni- mix was determined according to ASTM D2041. The bulk spe-

cal requirements for paving material with respect to NBDOT or cific gravity value is used not only, as an input in estimating the

Superpave mix design standards. We followed common labora- percentage air voids, but also in calculating specific heat capacity

tory procedures of developing the job mix formula to ensure of the asphalt specimens when thermal diffusivity and thermal

that the optimized mix can be produced in the conventional as- conductivity are known.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / FEBRUARY 2010 / 173

J. Mater. Civ. Eng. 2010.22:171-178.

Table 2. Mix Design Composition and Volumetric Properties of LWA-Asphalt Blends

Aggregate A Aggregate B Aggregate C Aggregate D Sand Asphalt Air voids VMA VFA

Blend # 共%兲 共%兲 共%兲 共%兲 共%兲 共%兲 Gb Gm 共%兲 共%兲 共%兲

1 36.5 52.5 — — 0 11 1.454 1.790 18.80 19.12 1.68

2 36.5 45.3 — — 7.2 11 1.530 1.780 14.00 16.97 17.50

3 19.6 60.5 — — 8.9 11 1.600 1.770 9.60 15.74 38.98

4 23.8 55.4 — — 8.8 12 1.570 1.720 8.70 17.76 51.02

5 23.6 55.1 — — 8.8 12.5 1.623 1.768 8.20 14.24 42.42

6 23.5 54.8 — — 8.7 13 1.640 1.766 7.13 13.79 48.26

7 23.3 54.5 — — 8.7 13.5 1.645 1.765 6.80 14.07 51.69

8 23.2 54.2 — — 8.6 14 1.652 1.762 6.24 14.16 55.90

9 — 80.9 — — 6.1 13 1.636 1.732 5.54 16.28 65.94

10 — 78.3 — — 8.7 13 1.618 1.732 6.58 20.02 67.12

Downloaded from ascelibrary.org by Monash University on 11/09/12. Copyright ASCE. For personal use only; all rights reserved.

11 — — 7.8 70.5 8.7 13 1.675 1.733 3.35 14.28 76.56

12 — — 17.4 63.7 6.1 12.8 1.642 1.699 3.36 13.43 75.00

13 — — 14.8 70.1 2.6 12.5 1.586 1.662 4.57 15.23 69.97

Note: Gb = bulk specific gravity; Gm = maximum theoretical specific gravity; VMA= voids in mineral aggregate; and VFA= voids filled with asphalt.

Design Binder Content fication curve, relating the number of gyrations and the average

maximum theoretical specific gravity 共% Gm兲, was plotted as

In the Superpave mix design method, the optimum binder content

shown in Fig. 5.

共% by weight of total mix兲 is normally selected as that binder

The maximum theoretical specific gravity of the mix at Nini,

content that results in 4% air voids at Ndes. This binder content

Ndes, and Nmax was obtained from the densification curve and was

must also meet other requirements including VMA, VFA, and the

used to calculate the air voids 共%兲 at the three gyration levels.

Superpave compaction requirements. The optimum binder content

According to Roberts et al. 共1996兲, the densification behavior of

is identified by evaluating the effect of varying binder content on

an asphalt mix can be used to predict construction behavior of the

the three volumetric properties—air voids, VMA, and VFA of the

mix. It is desirable for example, for the mix to be easy to compact

design aggregate blend. Three HMA briquettes were prepared at

each binder content, at four levels of increasing binder content 共in

steps of 0.5%兲 from below the estimated optimum. The volumet- 6

ric properties of each asphalt mix were determined at Ndes. Fig. 4

% Air Voids

shows the air voids, VMA, and VFA for the mixes. Starting with 4

air voids graph, the binder content that gives 4% air voids is

selected as the optimum binder content. VMA and VFA at the

2

optimum binder content are found from the corresponding graphs.

As seen in Fig. 4, the optimum binder content, the corresponding

0

VMA and VFA are 12.8, 15.18, and 74%, respectively.

11.5 12 12.5 13 13.5 14

% Asphalt Binder

Densification of LWA-Asphalt Mix

16.0

Two Superpave briquettes of the optimized LWA-asphalt mix

were compacted at Nmax and the corresponding height data of the 15.5

% VMA

briquettes for each number of gyrations was recorded. The densi- 15.0

14.5

100

14.0

90

11.5 12 12.5 13 13.5 14

Maximum Density Line % Asphalt Binder

80

70 90

% Passing

60

Upper Limit 80

50

% VFA

Optimized LWA-HMA

40 70

30

20

60

Low er Limit

10

50

0

0.075 0.15 0.3 0.6 1.18 2.36 4.75 6.3 9.5 12.5 11.5 12 12.5 13 13.5 14

Sieve Size (mm) to power 0.45 % Asphalt Binder

Fig. 3. Design aggregate gradation investigated for an optimized Fig. 4. Asphalt content versus air voids, VMA, and VFA of the

LWA-asphalt mix optimized LWA-asphalt mix

174 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / FEBRUARY 2010

J. Mater. Civ. Eng. 2010.22:171-178.

100

95

% Gm.

90

85

80

1 10 100

Number of Gyrations (log scale) Fig. 6. Test specimens after undergoing indirect split tensile test

Fig. 5. Densification curve of the optimized LWA-asphalt mix

Downloaded from ascelibrary.org by Monash University on 11/09/12. Copyright ASCE. For personal use only; all rights reserved.

mens. One subset was used for freeze-thaw conditioning, one for

moisture conditioning and the last subset was used as the control

and not become gummy during rolling. A Superpave mix should subset.

have air voids of at least 11% at Nini 共i.e., its density must be less The specimens for freeze-thaw subset were first subjected to

than 89% of Gm兲 in order to avoid the characteristics of a tender partial vacuum saturation of 55–80%, then wrapped in plastic

mix. A Superpave mix should also have air voids of at least 2% bags along with 3 mL of water and finally put in a freezer for

共i.e., its density must be less than 98% of Gm兲 at Nmax otherwise 18 h at a temperature of −20° C. The specimens were then placed

the mix would be susceptible to rutting. The optimized LWA- in a hot water bath for 24 h at a temperature of 60° C. Specimens

asphalt mix satisfied all these requirements. Table 3 presents the of the moisture conditioning subset were also subjected to partial

volumetric and mechanical properties of the optimized LWA- vacuum saturation 共55–80%兲 and then kept in a water bath for

asphalt mix. 24 h at a temperature of 60° C. After 24 h, specimens of both the

moisture conditioning subset and freeze-thaw subset were re-

Moisture Sensitivity of the Optimized LWA-Asphalt Mix moved from hot water bath and placed in another water bath at a

temperature of 25° C for 45 min.

As a final step of Superpave mix design method, the moisture The tensile strength of each specimen of all the three subsets

sensitivity of the optimized LWA-asphalt mix was evaluated ac- was determined by conducting indirect tensile strength 共splitting兲

cording to ASTM D4867. A set of nine Marshall Test specimens test at 25° C. Test results are tabulated in Table 4. Moisture sus-

having approximately 102-mm diameter and 64-mm height were ceptibility is reported as the tensile strength ratio 共TSR兲 of the

compacted to an air void content of 6 to 8%. The specimens were moisture conditioned subset or freeze-thaw conditioned subset to

then divided into three subsets, each consisting of three test speci- that of the unconditioned subset 共control兲. Mixtures with a TSR

value of less than 80% are considered moisture susceptible. Av-

erage TSR of the optimized LWA-asphalt mix was found to be

Table 3. Volumetric and Mechanical Properties of the Optimized LWA- 90%. It is therefore concluded that the optimized LWA-asphalt

Asphalt Mix mix is not susceptible to moisture damage. No visual stripping of

Property Result Specification

the test specimens was observed after splitting the specimens

共Fig. 6兲. This indicates that the optimized LWA-asphalt mix has

VMAs 共%兲 15.2 艌15 adequate asphalt film thickness to ensure durability.

VFA 共%兲 74.0 65–77

Air Voids 共%兲 4.0 3–5

Binder Content, Performance, and Cost Comparison

Maximum specific gravity % Gm at Nini 86.1 ⬍89%

of LWA-Asphalt versus Conventional AC

Maximum specific gravity % Gm at Nmax 97.8 ⬍98%

Bulk specific gravity Gb 1.591 — Binder Content and Cost

Maximum specific gravity Gm 1.658 — Binder content in paving contracts is usually specified as a per-

Asphalt absorption 共%兲 6.4 — cent of the total weight of the mix. At 12.8% by weight, the

Film thickness 共m兲 8.9 艌8.5 binder content of the optimized LWA-asphalt mix appears to be

Dynamic modulus 共MPa兲 2650 — high compared to a conventional asphalt concrete 共AC兲. However,

Marshall stability 共N兲 19,733 艌8,000 since the bulk density of LWA mix is only about 67% of the bulk

Marshall flow 共0.25 mm兲 15 12–18 density of conventional asphalt mix, a given tonnage of LWA-

Table 4. Moisture Susceptibility Evaluation of the Optimized LWA-Asphalt Mix

Subset Control Moisture conditioned Freeze-thaw conditioned

Specimen # 1 3 8 2 5 6 4 7 9

Load 共N兲 4,730 4,980 5,105 4,730 4,543 4,543 4,543 4,187 4,246

Average load 共N兲 4,938 4,605 4,325

Average tensile strength 共MPa兲 0.481 0.444 0.419

TSR 共%兲 92.3 87.1

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / FEBRUARY 2010 / 175

J. Mater. Civ. Eng. 2010.22:171-178.

40 kN 40 kN Table 5. Summary of Analysis of Fatigue and Rutting Service Lives

Life

Fatigue ratio

Pavement structure Strain t life 共%兲

p= 0.69MPa p=0.69 MPa

εt 150 mm 750-mm three-layer LWA-asphalt 1.907⫻ 104 2,360,580 100

υ1=0.35 εt E1=2920 MPa 150 mm ACS υ1=0.35 E1=2650 MPa

LWA-asphalt

500-mm three-layer conventional AC 1.856⫻ 104 2,375,624 101

υ2=0.40 E2=228 MPa 350 mm GB υ2=0.40 E2=217 MPa

600 mm

LWA-GB 750-mm three-layer LWA-asphalt 2.009⫻ 104 1,988,593 100

εv εv 750-mm five-layer conventional AC 1.951⫻ 104 2,015,724 101

υ3=0.45 E3=70 MPa υ3=0.45 E3=70 MPa

∞ Subgrade ∞ Subgrade Life

750 mm Conventional pavement 750 mm LWA-pavement Rutting ratio

(a) Three-layer conventional and LWA pavement structures Strain z life 共%兲

750-mm three-layer LWA-asphalt 1.976⫻ 104 52,347,328 100

40 kN 40 kN

500-mm three-layer conventional AC 3.222⫻ 104 5,864,819 11

Downloaded from ascelibrary.org by Monash University on 11/09/12. Copyright ASCE. For personal use only; all rights reserved.

750-mm five-layer LWA-asphalt 3.054⫻ 104 7,453,736 100

750-mm five-layer conventional AC 3.073⫻ 104 7,249,617 97

p= 0.69MPa p=0.69 MPa

50 mm ACS 50 mm

υ1=0.35 E1=2920 MPa υ1=0.35 E1=2650 MPa LWA-asphalt

100 mm

Tensile strain 共t兲 at the bottom of the asphalt layer and com-

υ2=0.35 E2=2920 MPa 100 mm ACB υ2=0.35 E2=2650 MPa

εt εt LWA-asphalt pressive strain 共t兲 at the top of the subgrade soil were calculated

E3=228 MPa υ3=0.40 E3=217 MPa 300 mm

υ3=0.40 200 mm GB

LWA base using ELSYM5. The strains were computed for a single axle load

υ4=0.40 E4=103 MPa υ4=0.40 E4=103 MPa 300 mm GSB

of 80 kN 共18,000 lb兲, i.e., 20 kN 共4,500 lb兲 on each tire with tire

400 mm GSB

pressure of 0.69 MPa 共100 psi兲. The critical strains were used to

εv εv

υ5=0.45 E5=35 MPa

∞ Subgrade

υ5=0.45 E5=35 MPa

∞ Subgrade

calculate service lives of the two pavement alternatives using the

Asphalt Institute fatigue and permanent deformation equations

750 mm Conventional pavement 750 mm LWA pavement

(a) Five-layer conventional and LWA pavement structures N f = 0.0796共t兲−3.291共E1兲−0.854 共2兲

where N f = number of axle load repetitions; t = horizontal tensile

Fig. 7. Cross sections of three-layer and five-layer conventional and strain at bottom of the asphalt layer; and E1 = dynamic modulus of

LWA pavements showing mechanistic properties used in the analysis

asphalt layer 共psi兲.

of fatigue and rutting service lives

Table 5 presents summary of pavement analysis comparing

two pairs of LWA-asphalt and conventional AC structures. As

asphalt mix would pave more area compared to the same tonnage seen from Table 5, LWA-asphalt pavements’ fatigue and rutting

of a conventional asphalt mix. It is obvious that the appropriate performance is comparable to the conventional AC pavements.

comparison of the effect of binder content on paving costs must The pavement analysis results show that both the three-layer and

be through specifying the binder content by volume of the mix, five-layer pavement structures will provide very comparable fa-

rather than by weight. If the LWA-asphalt mixture is compared to tigue service lives. With respect to rut resistance, the three-layer

a typical conventional asphalt mix on the basis of equal volume 500-mm conventional pavement would require increased granular

共or area paved兲, the binder content translates to a ratio of 10:7. base to provide the same rutting service life as a 750-mm LWA

The cost-effectiveness of the asphalt mixture will finally depend pavement. The 750-mm five-layer LWA pavement outperforms an

of the cost ratio of the other materials in the mix, i.e., aggregate as equivalent conventional pavement by 3% longer rutting service

well as the of performance service lives. life.

Pavement Performance LWA-Asphalt versus Conventional AC Cost Comparison

Fig. 7 shows two sets of possible pavement structures, one con- The bulk specific gravities of a typical conventional AC and

sisting of conventional materials and the other consisting of light- LWA-asphalt mixes are 2.375 and 1.591, respectively. Conse-

weight materials. The modulus 共E兲, Poisson ratio 共兲, and quently, the same volume of LWA-asphalt mix is only 67% 共i.e.,

thickness of each layer is shown in the figure. Typical subgrade 1.591/2.375兲 of the weight of a typical conventional asphalt mix.

resilient modulus 共M R兲 values of 70 and 35 MPa were assumed Assuming binder content of 6% for the conventional AC, to pave

for the two sets of pavement structures. The dynamic modulus of the same area with the same layer thickness, the binder content of

the LWA-asphalt mix and the conventional mix were determined the required conventional asphalt mix is 70% of that for LWA-

in the lab according to ASTM D3497 and the recommendations of asphalt mix 关i.e., 共6%/12.8%兲/67%兴. In other words, although the

the National Cooperative Highway Research Program Project binder content of LWA-asphalt mix is more than double that of

9-29 共Bonaquist et al. 2003兲. The California bearing ratio 共CBR兲 conventional mix by weight, the LWA-asphalt mix will consume

of the LWA granular base and the conventional aggregate base only about 43% more binder to pave the same area.

layer was determined according to ASTM D 1883 and was found A similar argument applies to granular base and subbase layers

to be 21 and 22, respectively. The resilient moduli of both types consisting of LWA and conventional aggregates. The ratio of bulk

of the aggregate base layers were obtained by using an empirical specific gravities of conventional to LWA is about 1.75 to 0.82.

relationship developed by Heukelom and Klomp 共1962兲 Therefore, to pave the same area and thickness, one will need

more than twice 共1.75/0.82兲 the weight of the conventional aggre-

M R = 10.3 · CBR 共1兲

gate as for LWA.

where M R = resilient modulus 共MPa兲 of the granular base and As pointed out before, the cost comparison question should

CBR⫽California bearing ratio 共%兲. consider not only the total costs of materials 共aggregates for as-

176 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / FEBRUARY 2010

J. Mater. Civ. Eng. 2010.22:171-178.

100000

phalt mixes, granular base and subbase, and asphalt binder兲 but -15 deg C 5 deg C 10 deg C 23 deg C 33 deg C Master Curve

also service lives of the two pavement systems. The costs of

Dynamic Modulus (MPa)

materials should be worked out bearing in mind the bulk density 10000

differences of the materials as well as hauling cost per volume of

pavement layer constructed. It is therefore recommended that 1000

project procurement documents for the LWA-asphalt mix and

LWA granular layers be changed to include an equivalent volume 100

price rather than by weight price only. This would bring all the

materials on an equal competitive basis by correctly adjusting for 10

-10 -8 -6 -4 -2 0 2 4 6 8 10

the large differences in volume to weight ratio.

Log of Reduced Time (s)

(a)

Mechanical Characterization of LWA-Asphalt Mix 100000

Downloaded from ascelibrary.org by Monash University on 11/09/12. Copyright ASCE. For personal use only; all rights reserved.

-15 deg C 5 deg C 10 deg C 23 deg C 33 deg C Master Curve

In order to evaluate the potential use of LWA in flexible pave-

Dynamic Modulus (MPa)

10000

ments, a comprehensive laboratory testing program was con-

ducted to study the engineering properties of LWA 共Khan 2008兲.

1000

Dynamic modulus, tensile strength, and Marshall stability and

flow of a LWA-asphalt mix were compared to those of a conven-

100

tional mix. The conventional mix showed higher dynamic

modulus values compared to the LWA-asphalt mix. But the LWA-

10

asphalt mix showed superior Marshall stability and flow com- -10 -8 -6 -4 -2 0 2 4 6 8 10

pared to a conventional mix. The indirect tensile strength and Log of Reduced Time (s)

tensile strain at failure of both the mixes were almost the same.

CBR of LWA was also determined to evaluate its potential use in (b)

road base and/or subbase, and was found to be 21 which is ac-

Fig. 8. Master curve of the dynamic moduli of 共a兲 LWA-asphalt mix;

ceptable for subbase and base course construction. On the basis of

共b兲 conventional mix

these test results, it was concluded that LWA in flexible pave-

ments can result in adequate pavement performance.

Marshall test is an empirical test that gives a reasonable pre- sorbs higher asphalt and therefore requires additional asphalt to

diction of pavement performance. Presently, although research achieve adequate film thickness around the aggregate. However,

efforts have been directed toward developing mechanistic- Lee et al. 共1993兲 suggested that the absorption of asphalt into

empirical pavement design methods, many agencies still rely on aggregate pores can also increase the physical interlocking of the

empirical test methods such as the Marshall test to assess stiffness binder and the aggregate, thereby resulting in increased pavement

of an asphalt mix. Marshall test was conducted on three cylindri- strength.

cal test specimens 共having 102-mm diameter and 64-mm height兲

of the optimized LWA-asphalt mix according to ASTM D5581.

Each test established two parameters: stability and flow. Stability Thermal Properties of LWA-Asphalt Mix

is the measure of AC resistance to deformation under traffic loads

whereas flow measures the amount of deformation resulting from Thermal properties 共thermal conductivity and thermal diffusivity

such loads 共Asphalt Institute 1998兲. As seen in Table 3, the opti- heat capacity兲 of the optimized LWA-asphalt mix and a conven-

mized LWA-asphalt mix showed good stability and flow values tional asphalt mix were investigated using the k-alpha tester de-

and satisfied NBDOT specifications. As expected, the vesicular veloped at the University of New Brunswick 共Luca and Mrawira

and more textured surface of the LWA results in increased stabil- 2005兲. The measurement and determination of thermal properties

ity. of the optimized LWA-asphalt mix is detailed in a recent paper by

The new mechanistic-empirical pavement design method 关Na- the writers Khan and Mrawira 共2008兲. The thermal conductivity

tional Cooperative Highway Research Program 共NCHRP兲 2004兴 and thermal diffusivity of the optimized LWA-asphalt mix was

requires dynamic modulus as a strength parameter for pavement found to be 58 and 55% lower than that of the conventional

thickness design and performance analysis of flexible pavements. asphalt mix respectively 共Table 6兲. The specific heat capacity of

Dynamic modulus test was performed at temperatures of ⫺15, 5, the optimized LWA-asphalt mix was found to be 38% higher than

10, 23, 33° C and at the loading frequencies of 25, 10, 5, 1, and that of the conventional asphalt mix. However, because of the

0.1 Hz. Dynamic modulus values measured over a range of tem- lower bulk density of LWA-asphalt mix, its volumetric heat ca-

peratures and loading frequencies were used in the development pacity was found to be 7% lower than that of the conventional

of master curve for characterizing LWA-asphalt mix for pavement

thickness design and performance analysis. Fig. 8 shows the mas-

ter curves of the dynamic moduli for the optimized LWA-asphalt Table 6. Thermal Properties of Conventional AC and LWA-Asphalt

mix and the conventional mix. Test results show acceptable dy- Mixes

namic modulus values for the optimized LWA-asphalt mix. A LWA-asphalt Conventional

typical dynamic modulus of the mix given in Table 3 is based at Property mix asphalt mix

23° C and a frequency of 25 Hz 共0.04 s of loading rate兲, which

Thermal conductivity 共W m K兲 0.79 1.87

represents pavement condition during the summer season under

Thermal diffusivity⫻ 10−7 共m2 / s兲 2.09 4.60

moderate to high traffic speed 共Barksdale et al. 1997兲.

Specific heat capacity 共J kg K兲 2,363 1,710

It is worth noting that because of its porous nature, LWA ab-

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / FEBRUARY 2010 / 177

J. Mater. Civ. Eng. 2010.22:171-178.

mix. The lower thermal conductivity and diffusivity of the LWA- through Discovery Grant No. 217389-04. We would also like to

asphalt mix provide a potential approach for mitigating frost pen- thank New Brunswick DOT, Northeast SOLITE Corporation,

etration and frost damage in flexible pavements. This potential Great Pacific Pumice Inc., and Irving Oil Limited for supporting

has been explored by the authors using a finite element thermal the experimental work and providing materials for this study.

response model HIFIEL 共Khan et al. 2008兲. The model was used

to estimate frost penetration into the subgrade of nine different

pavement structures. It was found that all the LWA pavement

References

structures 共using LWA either in asphalt surface and/or granular

base and subbase兲 can effectively mitigate the frost problem. The Asphalt Institute. 共1998兲. “Construction of hot mix asphalt pavements.”

results of this work were published in a recent article 共Khan et al. Manual series no. 22, Asphalt Institute, Lexington, Ky.

2008兲. Barksdale, R. D., Khosla, A. J., Paul, N., Kim, R. L., Phil, C., and

Rahman, M. S. 共1997兲. “Laboratory determination of resilient modu-

Conclusions lus for flexible pavement design.” NCHRP Report 1–28, National Co-

operative Highway Research Program, Transportation Research

Downloaded from ascelibrary.org by Monash University on 11/09/12. Copyright ASCE. For personal use only; all rights reserved.

Board, National Research Council, Washington, D.C.

The work presented in this paper demonstrates that an asphalt mix

Bonaquist, R. F., Christensen, D. W., and Stump, W., III 共2003兲. “Simple

can be effectively produced from lightweight aggregate. The op-

performance tester for Superpave mix design: First-article develop-

timized LWA-asphalt mix satisfied the volumetric specifications ment and evaluation.” NCHRP Rep. No. 513, Transportation Research

of NBDOT. It was found that the volumetric properties of LWA- Board, Washington, D.C.

asphalt mixes were greatly affected by changing the proportions Gallaway, B. M. 共1997兲. Expanded shale, clay and slate reference

of coarse and fine aggregate in these mixes. Particularly, variation manual for asphalt pavement systems, 2nd Ed., Expanded Shale Clay

in the proportion of blending sand 共from natural deposits兲 signifi- and Slate Institute, Salt Lake City.

cantly changed the VMA of LWA mixes. The study also shows Goodrich, L. E., and White, T. L. 共1987兲 “Thermal conductivities of

that LWA-asphalt mix exhibited good Marshall stability and flow expanded shale and clay lightweight aggregates.” Rep. No. 556, Na-

values and would therefore resist deformation under traffic load- tional Research Council—Institute for Research in Construction, Ot-

ing. Dynamic modulus of the optimized LWA-asphalt mix was tawa, Canada.

also found to be acceptable for the structural design of asphalt Heukelom, W., and Klomp, A. J. G. 共1962兲. “Dynamic testing as a means

pavements. of controlling pavement during and after construction.” Proc., 1st Int.

The TSR of the optimized LWA-asphalt mix was found to be Conf. on Structural Design of Asphalt Pavements, Univ. of Michigan,

90%. It is concluded that the mix is not susceptible to moisture Ann Arbor, Mich., 667–679.

damage by stripping. The main hurdle of using LWA-asphalt mix Khan, A. 共2008兲. “Feasibility of using lightweight aggregate to mitigate

may be related to its high binder content. The binder content of frost damage in flexible pavements.” Ph.D. thesis, Univ. of New Brun-

the optimized LWA-asphalt mix was found to be almost twice that swick, Fredericton, N.B.

Khan, A., and Mrawira, D. 共2008兲. “Influence of selected mix design

of a conventional asphalt mix by weight. However one compares

factors on the thermal behaviour of lightweight aggregate asphalt

this binder content in terms of paving equal volume of pavement,

mixes.” J. Test. Eval., 36共6兲, 492–499.

the binder content of LWA-asphalt mix is only about 43% more Khan, A., Mrawira, D., and Hildebrand, E. E. 共2008兲. “Use of lightweight

compared to a conventional mix. The life-cycle cost implications aggregate to mitigate frost damage in flexible pavements.” Intl. J.

of using LWA-asphalt mixes need to be determined by the user Pavement Eng., 10共5兲, 329–339.

agency by carefully analyzing all pertinent factors such as the Lee, D. Y., Guin, J. A., Kandhal, P. S., and Dunning, R. L. 共1993兲.

costs of aggregates, the cost of hauling materials and the long- “Review on absorption of asphalt into porous aggregates. I: Physico-

term performance of the final pavement structure. The long-term chemical mechanisms and variables affecting absorption.” Fuel Sci.

savings in maintenance costs due to reduced frost damage need to Technol. Int., 11共3 & 4兲, 585–608.

be carefully weighted against the increased cost of binder, for Luca, J. and Mrawira, D. 共2005兲. “New measurement of thermal proper-

example. Such analyses tend to be agency-specific or even ties of Superpave asphalt concrete.” J. Mater. Civ. Eng., 17共1兲, 72–79.

project-specific, and therefore not worth a general investigation in National Cooperative Highway Research Program 共NCHRP兲. 共2004兲.

this paper. “Phase II: Development of the 2002 guide for design of new and

rehabilitated pavement structures.” Project 1-37A, National Coopera-

tive Highway Research Program, Washington, D.C.

Acknowledgments Roberts, F. L., Kandhal, P. S., Brown, E. R., Lee, D. Y., and Kennedy, T.

W. 共1996兲. Hot mix asphalt materials, mixture design and construc-

The writers acknowledge the National Science and Engineering tion, 2nd Ed., National Asphalt Pavement Association 共NAPA兲, Re-

Research Council of Canada for financial support for this research search and Education Foundation, Lanham, Md.

178 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / FEBRUARY 2010

J. Mater. Civ. Eng. 2010.22:171-178.

Você também pode gostar

- Penetration of Bituminous Materials: Standard Test Method ForDocumento4 páginasPenetration of Bituminous Materials: Standard Test Method ForMehdi FarrokhiAinda não há avaliações

- Road Materials and Pavement DesignDocumento13 páginasRoad Materials and Pavement DesignMehdi FarrokhiAinda não há avaliações

- Engler Specific Viscosity of Tar Products: Standard Test Method ForDocumento4 páginasEngler Specific Viscosity of Tar Products: Standard Test Method ForMehdi FarrokhiAinda não há avaliações

- SHRP R-23 Pavement Scoping ToolDocumento1 páginaSHRP R-23 Pavement Scoping ToolMehdi FarrokhiAinda não há avaliações

- Portugal: The Legal 500 Country Comparative GuidesDocumento11 páginasPortugal: The Legal 500 Country Comparative GuidesMehdi FarrokhiAinda não há avaliações

- Bahia Wisconsin UpdateDocumento19 páginasBahia Wisconsin UpdateMehdi FarrokhiAinda não há avaliações

- Dubai Mainland: Coworking Licence PackageDocumento9 páginasDubai Mainland: Coworking Licence PackageMehdi FarrokhiAinda não há avaliações

- What Makes A Special Moment Frame SpecialDocumento3 páginasWhat Makes A Special Moment Frame SpecialMehdi FarrokhiAinda não há avaliações

- 2010 T BC Math ReviewDocumento21 páginas2010 T BC Math ReviewMehdi FarrokhiAinda não há avaliações

- Steel Slag. Conversion of An Industrial Waste Material Into A Value Adding Asphalt IngredientDocumento8 páginasSteel Slag. Conversion of An Industrial Waste Material Into A Value Adding Asphalt IngredientMehdi FarrokhiAinda não há avaliações

- اتصالات از پیش - تائید شده در Aisc - انواع اتصالات قاب خمشی سازه فلزیDocumento39 páginasاتصالات از پیش - تائید شده در Aisc - انواع اتصالات قاب خمشی سازه فلزیMehdi FarrokhiAinda não há avaliações

- APEGBC Guidelines For Satisfactory Experience in EngineeringDocumento2 páginasAPEGBC Guidelines For Satisfactory Experience in EngineeringMehdi FarrokhiAinda não há avaliações

- Quantified Characterization of Phase Structure in SBS Modified Asphalt Based On Microscopic Morphological ParametersDocumento8 páginasQuantified Characterization of Phase Structure in SBS Modified Asphalt Based On Microscopic Morphological ParametersMehdi FarrokhiAinda não há avaliações

- Application TA 012eDocumento2 páginasApplication TA 012eMehdi FarrokhiAinda não há avaliações

- 01b DAnderson 4mm Task Force Decrypted1111111Documento30 páginas01b DAnderson 4mm Task Force Decrypted1111111Mehdi FarrokhiAinda não há avaliações

- VF500 VF600 VR600Documento24 páginasVF500 VF600 VR600Mehdi FarrokhiAinda não há avaliações

- ECV - FIDIC - Comparison - Module - Vienna - June 18 PDFDocumento4 páginasECV - FIDIC - Comparison - Module - Vienna - June 18 PDFMehdi FarrokhiAinda não há avaliações

- New Red Book A Lengthy ReadDocumento8 páginasNew Red Book A Lengthy ReadMehdi FarrokhiAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Descriptive Statistics - SPSS Annotated OutputDocumento13 páginasDescriptive Statistics - SPSS Annotated OutputLAM NGUYEN VO PHIAinda não há avaliações

- CPE Cisco LTE Datasheet - c78-732744Documento17 páginasCPE Cisco LTE Datasheet - c78-732744abds7Ainda não há avaliações

- BreezeAIR 8000 Data SheetDocumento2 páginasBreezeAIR 8000 Data Sheetalfasukarno100% (1)

- Life Cycle Cost Analysis of Hvac System in Office ProjectsDocumento3 páginasLife Cycle Cost Analysis of Hvac System in Office ProjectsVashuka GhritlahreAinda não há avaliações

- Ms Microsoft Office - WordDocumento3 páginasMs Microsoft Office - WordFarisha NasirAinda não há avaliações

- Chat Application (Collg Report)Documento31 páginasChat Application (Collg Report)Kartik WadehraAinda não há avaliações

- Agoura Hills DIVISION - 6. - NOISE - REGULATIONSDocumento4 páginasAgoura Hills DIVISION - 6. - NOISE - REGULATIONSKyle KimAinda não há avaliações

- Dreamweaver Lure v. Heyne - ComplaintDocumento27 páginasDreamweaver Lure v. Heyne - ComplaintSarah BursteinAinda não há avaliações

- V Series: Three Wheel, Counterbalanced Lift TruckDocumento126 páginasV Series: Three Wheel, Counterbalanced Lift TruckВиктор МушкинAinda não há avaliações

- Napoleon RXT425SIBPK Owner's ManualDocumento48 páginasNapoleon RXT425SIBPK Owner's ManualFaraaz DamjiAinda não há avaliações

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDocumento2 páginasBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiAinda não há avaliações

- Exercise 23 - Sulfur OintmentDocumento4 páginasExercise 23 - Sulfur OintmentmaimaiAinda não há avaliações

- Defeating An Old Adversary Cement Kiln BallsDocumento5 páginasDefeating An Old Adversary Cement Kiln BallsManish KumarAinda não há avaliações

- SC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Documento5 páginasSC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Sanjeev kumarAinda não há avaliações

- Introduction Into Post Go-Live SizingsDocumento26 páginasIntroduction Into Post Go-Live SizingsCiao BentosoAinda não há avaliações

- KrauseDocumento3 páginasKrauseVasile CuprianAinda não há avaliações

- Analisa RAB Dan INCOME Videotron TrenggalekDocumento2 páginasAnalisa RAB Dan INCOME Videotron TrenggalekMohammad Bagus SaputroAinda não há avaliações

- Milestone 9 For WebsiteDocumento17 páginasMilestone 9 For Websiteapi-238992918Ainda não há avaliações

- Dynamics of Interest Rate and Equity VolatilityDocumento9 páginasDynamics of Interest Rate and Equity VolatilityZhenhuan SongAinda não há avaliações

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualDocumento12 páginasIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- Capsule Research ProposalDocumento4 páginasCapsule Research ProposalAilyn Ursal80% (5)

- Introduction To AirtelDocumento6 páginasIntroduction To AirtelPriya Gupta100% (1)

- 88 - 02 Exhaust Manifold Gasket Service BulletinDocumento3 páginas88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerAinda não há avaliações

- Case Notes All Cases Family II TermDocumento20 páginasCase Notes All Cases Family II TermRishi Aneja100% (1)

- Bank Statement SampleDocumento6 páginasBank Statement SampleRovern Keith Oro CuencaAinda não há avaliações

- Acevac Catalogue VCD - R3Documento6 páginasAcevac Catalogue VCD - R3Santhosh KumarAinda não há avaliações

- SMK Techno ProjectDocumento36 páginasSMK Techno Projectpraburaj619Ainda não há avaliações

- The Concept of ElasticityDocumento19 páginasThe Concept of ElasticityVienRiveraAinda não há avaliações

- Mercury 150HPDocumento5 páginasMercury 150HP이영석0% (1)

- Test Bank For American Corrections Concepts and Controversies 2nd Edition Barry A Krisberg Susan Marchionna Christopher J HartneyDocumento36 páginasTest Bank For American Corrections Concepts and Controversies 2nd Edition Barry A Krisberg Susan Marchionna Christopher J Hartneyvaultedsacristya7a11100% (30)