Escolar Documentos

Profissional Documentos

Cultura Documentos

Geometrical Approach PDF

Enviado por

VienNgocQuangTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Geometrical Approach PDF

Enviado por

VienNgocQuangDireitos autorais:

Formatos disponíveis

LATEST TRENDS on SYSTEMS (Volume II)

Geometric approach to inverse kinematics for arm manipulator

KRZYSZTOF TOKARZ, SLAWOSZ KIELTYKA

Institute of Informatics

Silesian University of Technology

ul. Akademicka 16, 44-100 Gliwice

POLAND

Krzysztof.Tokarz@polsl.pl http://zmitac.aei.polsl.pl/KT

Abstract: - In this paper the construction of the arm of the robot has been presented. The possibilities of different

methods of calculations of reverse kinematics has been discussed. The geometric approach intended to work with the

controller based on low-resource microcomputer has been presented. Details about mechanical and electronic

construction of the arm of the robot has been described.

Key-Words: - robot, inverse kinematics, forward kinematics

1 Introduction The action of joint can be described with the variable

Since many years people try to replace human work with that represents the angle for revolute joints and the

machines. Machines called robots are faster and more displacement in the case of prismatic joints. Set of joint

effective than people. Many elements of robots are built variables determines the current position of the effector

with inspiration from the nature. Construction of the in the space. Controlling the arm placement can be done

manipulator as the arm of the robot is based on human using one of two possible algorithms: forward and

arm. The scope of this paper is to present the geometrical inverse kinematics. In forward kinematics all joint

approach to calculations needed to control the arm variables are known and are used to calculate

manipulator constructed in Institute of Informatics at coordinates of current position of the effector [5]. The

Silesian University of Technology. Second part of the question of inverse kinematics is to calculate set or sets

paper presents also some details about hardware of joint variables that allows effector to reach the chosen

implementation of the arm and software implementation point in the space. Inverse kinematics calculations are

of calculations. much more complicated than forward kinematics.

Forward kinematics always has the solution and it is

always only one solution. Inverse kinematics can have

the solution or not. It can give also infinite number of

2 Background solutions. In some situations even if the solution exists it

Arm consists of segments named links that represent

can be unreachable because of construction of the robot.

bones, and joints. Palm is represented with the effector

Set of reachable points forms the working space. The

placed at the end of the arm. Arms of robots are built

subset of this is the full operation space [2] in which

usually with servos connected together with the links.

points can be reachable with specific approach of the

Servos can be prismatic or revolute. Prismatic servos

effector. To reach any point in the working space with

move linearly with the effect of link extension. Revolute

any angle of the effector the arm should have six degrees

servos turn changing the angle between concurrent links

of freedom. Any arm that has more than six degrees of

(Fig.1.).

freedom is called redundant– the human arm has seven

degrees of freedom. Generally redundant robot possesses

more degrees of freedom than is needed to execute a

given task [11]. Controlling the redundant manipulator is

difficult because there are more than one way to reach

the position, and calculations often give infinite number

of results. The algorithm commonly used in inverse

kinematics calculations is Denavit-Hartenberg. It is

based on transformations of matrix, and has big

computational complexity [3]. Other algorithms are

geometrical and use trigonometric calculations [4].

Fig.1 Types of joints Trigonometric approach is simpler for manipulators with

smaller number of degrees of freedom. For manipulators

ISSN: 1792-4235 682 ISBN: 978-960-474-214-1

LATEST TRENDS on SYSTEMS (Volume II)

with larger number of degrees of freedom one possible is named inverse position kinematics, second is named

solution is to split the problem into smaller parts and inverse orientation kinematics. It is possible to make

make calculations with geometrical approach [6][7]. It is calculations for both parts with planar geometric

usually done while the controller has too small approach. Calculations need the wrist to be spherical

computational power to make calculations with matrices. with all axes intersecting at one point. It means that

position of the center of the wrist is the function of

variables calculated for the inverse position kinematics.

3 Construction of the arm This approach with sample calculations is in details

The construction of presented arm of the robot is described in [1]. Calculations of inverse position

inspired by human arm [8][10]. Original arm has seven kinematics presented here are based on this approach.

degrees of freedom and the same the constructed arm

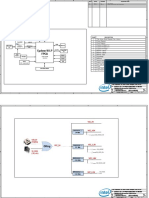

has. The detailed configuration is presented in the Fig.2.

The mechanical arm uses 8 servos controlled by 8-bit

microcomputer.

Fig.3 Configuration for position of the center of the wrist

Fig.2 Configuration of the arm of the robot

Human arm does not allow prismatic move so all servos

used to build the arm are revolute. The servo number 8 is

for moving the effector, so it is out of the scope of this

paper.

4 Geometric approach Fig.4 Configuration of spherical wrist

The arm is controlled with simple, 8-bit microcontroller.

The point for decoupling is located at the end of the link

Computational power of this microcontroller does not

d3 where the joint number q4 is placed. Because

allow to perform advanced algorithms on it. Because the

described arm has seven degrees of freedom split is not

seven degrees of freedom manipulator needs

enough, the first part of the arm is still too sophisticated

sophisticated calculations there is a need to find simpler

for geometrical calculations, so additional simplification

methods of calculations, especially for the inverse

has to be made. Calculations assume that the joint

kinematics. Decoupling inverse kinematic problem into

number q2’ is immobile in such position that links d1,

simpler problems seems to be interesting solution. One

d2’, d2”, and d3 are coplanar reducing to 6 number of

approach is to split the arm into two parts – the arm and

degrees of freedom for the arm. In such situation length

the spherical wrist. First part as the arm with elbow

d2 is the sum of d2’ and d2”. Because the arm can be

presented in the fig.3, is responsible for locating the

used also in forward kinematics mode this joint can be

center of wrist. Second, as presented in fig.4, determines

still used in this mode of operation.

the orientation of the wrist. Fist part calculation problem

ISSN: 1792-4235 683 ISBN: 978-960-474-214-1

LATEST TRENDS on SYSTEMS (Volume II)

Point of the split, marked as P2 in fig.5 is the center If point P2 is placed on the Z0 axis equation (4) gives

point of spherical wrist, and also the central point of the infinite number of results. In such situation the angle q1

frame X1, Y1, Z1. Calculations begin with determining can be left unchanged.

joint variables for servos 1, 2 and 3 representing angles Next is to calculate the distance d from the joint 2 to

q1, q2 and q3. These variables determine the position of point P2.

the wrist. Second is to calculate variables specifying the d 2 = p 2 x 2 + p 2 y 2 + ( p 2 z − d1 ) 2 (5)

orientation of the wrist.

d = d 2 + d 3 − 2 * d 2 d 3 * cos(π + q3 )

2 2 2

(6)

From equations (5) and (6) it is possible to calculate

angle q3.

2 2

p x 2 + p 2 y 2 + ( p 2 z − d1 ) 2 − d 2 − d 3

cos(q3 ) = 2 (7)

2 * d 2d3

1− D2

q3 = arctan( ) (8)

D

for the joint 3 as shown in fig. 5 or

− 1 − D2

q3 = arctan( ) (9)

D

for the joint 3 in the position below line d.

Now it is possible to calculate q2 as the sum of angles

λ and µ.

p 2 z − d1

λ = arctan( ) (10)

p2 x 2 + p2 y 2

d 3 * sin( q3 )

µ = arctan( ) (11)

d 2 + d 3 * cos(q3 )

Of course while the joint 3 is below line d angle q2 will

be the difference

q2 = λ − µ (12)

Fig.5 Geometric schema of the manipulator

Next step is to calculate joint variables of spherical

The input parameters for the calculations are coordinates wrist. The geometric schema of the wrist is shown in the

of the point PP and angles α, β, and γ. Having fig. 6. Angles q1, q2 and q3 determine position of frame

coordinates px, py and pz first task is to calculate X1, Y1, Z1. Geometrical approach to calculations can be

coordinates of point P2 as the center of the spherical used also for inverse orientation kinematics i.e. for

wrist: p2x, p2y and p2z. setting joint variables for the spherical wrist.

p2 x = px − l * cos(α ) (1) First it is to calculate two angles α1 and β1 as

p2 y = py − l * sin(α ) transformations of angles α and β into frame X1, Y1, Z1.

(2)

α1 = α − q1 (13)

p2 z = pz − d 4 * sin( β ) (3)

where: l = d 4 * cos( β )

β1 = β − (q2 + q3 ) (14)

Calculation of the q1 angle is trivial. The assumption has been made that the X1 axis is

px coaxial to d3. The angle between planes X1Y1 and

tan(q1 ) = 2 X0Y0 is q2+q3. The angle between planes X1Z1 and

p2 y

(4) X0Z0 is q1.

px

q1 = arctan( 2 )

p2 y

ISSN: 1792-4235 684 ISBN: 978-960-474-214-1

LATEST TRENDS on SYSTEMS (Volume II)

5.1 Mechanical part

Mechanical implementation of the arm of the robot is

based on servos. There are two groups of servos

available, digital and analog. Digital servos have better

stability and accuracy, but are much more expensive.

Because the arm of the robot is first project of this type

the less expensive analog servos have been used. Both

types of servos are controlled using pulse width

modulation signal. Frequency of this signal must be

50Hz that gives 20ms of the period. In typical servo

during the 20 ms period the pulse of length from 0.5 ms

to 2.5 ms should appear. Pulse of 1.5 ms sets the servo to

neutral position equal to 90°, 0.5 ms pulse sets servo to

0° while 2.5 ms pulse sets servo to 180°.

Fig.6 Geometric schema of the spherical wrist Servos are connected with links of lengths as shown in

fig 7. Servos are loaded with the charge taken by the

Now it is to calculate d4ry as the projection of d4 onto effector and by other servos. This load depends on the

the X1Z1 plane and d4rz as the projection of d4 onto the weight of servos and the length of links. The most

X1Y1 plane. loaded servo is the servo 2 which in the most stressed

d 4ry = d 4 cos( β1 ) sin(α1 ) (15) position must handle the load exceeding 4 kg. In table 1

the loads between servos are presented. Servo 1 is for

d 4rz = d 4 sin( β1 ) (16) rotating the whole arm so it is not taken in the table.

Joint 3 is on the axis of 2’ so their loads are equal, the

Having these values it is to calculate joint variables for same for joints 4 and 5.

spherical wrist.

d 4ry

q 4 = arctan (17)

d 4rz

d 4ry 2 + d 4rz 2

q5 = arctan (18)

cos( β1 ) cos(α1 )

Last angle q6 can be calculated with known value of q4.

π π

γ − q 4 ⇒ β ∈ − 2 ; 2

q6 =

π − (γ − q 4) ⇒ β ∈ − π ;− π ∨ β ∈ π ; π

2 2

If both angles α1 and β1 are 0 then the q4 is unspecified

and can be chosen arbitrary.

Fig.7 Lengths of arm links (in mm)

Table 1. Loads for servos [kg/cm]

5 Implementation No. of

Implementation consists of two main parts, 2 2’ and 3 4 and 5

servo

mechanical and electronic. Mechanical part has 2’ 0,330 - -

been developed with servos connected with links. 3 0,715 - -

Electronic part is made using 8-bit microcontroller 4 1,045 0,330 -

with few additional elements. 5 1,375 0,660 -

6 0,308 0,165 0,033

7 0,352 0,209 0,077

sum 4,125 1,364 0,110

ISSN: 1792-4235 685 ISBN: 978-960-474-214-1

LATEST TRENDS on SYSTEMS (Volume II)

Servos used in the project have parameters that allow

effector to carry the load not exceeding 0,4 kg.

Parameters of servos are presented in table 2.

Table 2. Parameters of servos used

Servo 6,7 1,2’,3,4,5 2

Dimensions h 23 40.7 66

[mm] l 12.2 19.7 30.2

w 29 42.9 64.4

[kg/cm] 1.8 13 20

Speed [s/60˚] 0.13 0.20 0.20

Power supply [V] 4.8-6 4.8-7.2 4.8-7.2

Fig.9 Sequence of pulses

Weight [g] 13 55 160

The keyboard is read during interrupt generated by timer

5.2 Electronic part number 1. LCD display is controlled by main function.

Electronic part of the project is based on 8-bit Calculations are also done in main function, results are

microcontroller Atmega 644. This integrated circuit is available for next cycle.

equipped with 64 kB memory for the program, 4 kB

memory for data and 32 input/output ports. The block

schema of the controller is presented in the fig. 8. Arm

of the robot can be controlled directly with keyboard. 6 Summary

Every servo has two keys, one for right and one for left In this article the construction of the arm of the robot has

direction of the rotation. Arm can be also controlled been presented. To make the arm moving two algorithms

from PC computer using serial port. Current state of the have been implemented. One of them, forward

controller is shown in the alphanumerical LCD display kinematics algorithm does not need high computational

that has 2 lines of 16 characters. Servos are connected to power. Second, inverse kinematics algorithm in matrix

microcontroller with 74HTC238 multiplexer working version is too sophisticated for the microcontroller used

with rotating logic one on the outputs. This multiplexer in the project. To allow 8-bit one chip microcomputer to

can reduce usage of microcontroller outputs from 8 to 4. control the arm the simplified method of calculations has

been used. Geometrical approach with split the

calculations into two parts is the good choice for small

8-bit microcomputers. The arm built is intended to be the

base for next research on control algorithms with usage

of different methods and more powerful processors.

References:

[1] M. W. Spong, M. Vidyasagar “Robot Dynamics and

control,” Wiley, New York, 1989.

[2] O. Khatib, “A Unified Approach to Motion and

Force Control of Robot Manipulators: The

Operational Space Formulation,” IEEE J. Robotics &

Fig.8 Block schema of the controller Automation, vol. 3, no. 1, pp. 43-53, 1987.

[3] K. W. Lilly and D. E. Orin, “Alternate Formulations

Software for microcontroller has been written in C using for the Manipulator Inertia Matrix,” International

WinAVR programming environment. The main function Journal of Robotics Research, vol. 10, pp. 64-74,

of the software is sending periodically pulses to all February 1991.

servos. The frequency of pulses must be stable so [4] G. Rodriguez, A. Jain and K. Kreutz-Delgado, “A

procedures are triggered by interrupts generated by two Spatial Operator Algebra for Manipulator Modelling

hardware timers. Timer number 1 is used to generate 2,5 and Control,” Int. J. Robotics Research, vol. 10, no.

ms periods, timer number 2 generates pulses of variable 4, pp. 371-381, 1991.

length for controlling all servos. Whole cycle consists of [5] M. Brady, J. M. Hollerbach, T. L. Johnson, T.

eight 2,5 ms periods one for each servo. During each Lozano-Perez, and M. T. Mason, Robot Motion:

period one servo gets 0,5 – 2,5 ms pulse. Sample cycle is Planning and Control. Cambridge, MA: The MIT

presented in fig 9. Press, 1982.

ISSN: 1792-4235 686 ISBN: 978-960-474-214-1

LATEST TRENDS on SYSTEMS (Volume II)

[6] X. Wang and J.-P. Verriest, A geometric algorithm

to predict the arm reach posture of computer-aided

ergonomic evaluation, J. Visualization Comput.

Animat. 9, pp 33–47. 1998.

[7] M. Raghavan and B. Roth, Kinematic analysis of the

6R manipulator of general geometry, in Proceeding

of the 5th International Symposium on Robotics

Research, 1990.

[8] K. Asano, Human arm kinematics, in Proceedings of

the 5th International Symposium on Robotics

Research, 1990.

[9] J. M. Hollerbach and G. Sahar, Wrist-partitioned

inverse kinematic accelerations and manipulator

dynamics, Internat. J. Robot. Res. 2, pp 61–76, 1983.

[10] K. Kondo, Inverse kinematics of a human arm, J.

Robot. Systems 8(2), 1991, 115–175.

[11] D. DeMers and K. Kreutz-Delgado, “Solving

Inverse Kinematics for Redundant Manipulators,” in

Neural Systems for Robotics, O. Omidvar and P. v.

d. Smagt ed., Academic Press, 1997.

ISSN: 1792-4235 687 ISBN: 978-960-474-214-1

Você também pode gostar

- Sc11 Cuda C BasicsDocumento68 páginasSc11 Cuda C BasicsPoncho CoetoAinda não há avaliações

- c10lp Eval A1 SCHDocumento17 páginasc10lp Eval A1 SCHVienNgocQuangAinda não há avaliações

- To Opencv: Marvin SmithDocumento29 páginasTo Opencv: Marvin SmithVienNgocQuang100% (1)

- c10lp Eval A1 SCHDocumento17 páginasc10lp Eval A1 SCHVienNgocQuangAinda não há avaliações

- Workshop Manual (Eng-Rus)Documento40 páginasWorkshop Manual (Eng-Rus)VienNgocQuangAinda não há avaliações

- c10lp Eval A1 SCHDocumento56 páginasc10lp Eval A1 SCHVienNgocQuangAinda não há avaliações

- GTC Express Itseez Opencv Webinar PDFDocumento35 páginasGTC Express Itseez Opencv Webinar PDFazazel17Ainda não há avaliações

- Role Profile Teaching Assistant HCMCDocumento4 páginasRole Profile Teaching Assistant HCMCVienNgocQuangAinda não há avaliações

- ch2 PDFDocumento6 páginasch2 PDFVienNgocQuangAinda não há avaliações

- Lee-Enfield Rifle RF Short MksI and II (II)Documento4 páginasLee-Enfield Rifle RF Short MksI and II (II)VienNgocQuangAinda não há avaliações

- E911 Provisioning System Software Test Plan (STP)Documento11 páginasE911 Provisioning System Software Test Plan (STP)VienNgocQuangAinda não há avaliações

- The Silenced de Lisle Commando CarbineDocumento6 páginasThe Silenced de Lisle Commando CarbineVienNgocQuang100% (1)

- C For MathematiciansDocumento41 páginasC For MathematicianschinssuAinda não há avaliações

- T-34 in Angola 1970s 1980s - WwiiafterwwiiDocumento24 páginasT-34 in Angola 1970s 1980s - WwiiafterwwiiVienNgocQuang100% (1)

- DllmeDocumento1 páginaDllmeVienNgocQuangAinda não há avaliações

- Lee-Enfield Rifle 22RF Pattern 14Documento5 páginasLee-Enfield Rifle 22RF Pattern 14VienNgocQuangAinda não há avaliações

- Angle Iload Uload IsDocumento10 páginasAngle Iload Uload IsVienNgocQuangAinda não há avaliações

- MP 1Documento4 páginasMP 1VienNgocQuangAinda não há avaliações

- People Republic of KampucheaDocumento129 páginasPeople Republic of KampucheaVienNgocQuangAinda não há avaliações

- Industrial Sensors (Electromagnetic Flowmeter, Density (Consistency) Meter, Pressure Transmitter and Water Treatment Analyzer)Documento1 páginaIndustrial Sensors (Electromagnetic Flowmeter, Density (Consistency) Meter, Pressure Transmitter and Water Treatment Analyzer)VienNgocQuangAinda não há avaliações

- MP 2Documento3 páginasMP 2VienNgocQuangAinda não há avaliações

- JM 154Documento226 páginasJM 154VienNgocQuangAinda não há avaliações

- MP 3Documento3 páginasMP 3VienNgocQuangAinda não há avaliações

- Khmer Rouge Division 703Documento216 páginasKhmer Rouge Division 703VienNgocQuang100% (1)

- TOSHIBA Global Internship 2018 - Application Guidelines & Position ListDocumento17 páginasTOSHIBA Global Internship 2018 - Application Guidelines & Position ListVienNgocQuangAinda não há avaliações

- SummaryDocumento1 páginaSummaryVienNgocQuangAinda não há avaliações

- Cam Total WarDocumento142 páginasCam Total WarVienNgocQuangAinda não há avaliações

- Nikolaidis Pitas - Facial Feature Extraction and Pose DeterminationDocumento20 páginasNikolaidis Pitas - Facial Feature Extraction and Pose DeterminationVienNgocQuangAinda não há avaliações

- Summary and Future WorkDocumento2 páginasSummary and Future WorkVienNgocQuangAinda não há avaliações

- FN 98 Mauser Model 98 Rifle Operators ManualDocumento28 páginasFN 98 Mauser Model 98 Rifle Operators ManualAdam Ward100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Sukrosa PDFDocumento5 páginasSukrosa PDFSilvi TatianAinda não há avaliações

- DC Rectifier - OrionDocumento12 páginasDC Rectifier - OrionLimbagaAinda não há avaliações

- 320d WiringDocumento2 páginas320d WiringMohamed Harb100% (5)

- Chapter 4. FRC Manufacturing - Fundamental ConceptsDocumento5 páginasChapter 4. FRC Manufacturing - Fundamental ConceptsNarendra GadkariAinda não há avaliações

- Grade 11 Electricity W.sheetDocumento6 páginasGrade 11 Electricity W.sheetUsman AmeenAinda não há avaliações

- Thermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsDocumento39 páginasThermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsGregory MacLeodAinda não há avaliações

- (52621001078) DM - DM Half Inch Flex Jumper Spec SheetDocumento2 páginas(52621001078) DM - DM Half Inch Flex Jumper Spec SheetmicroqualAinda não há avaliações

- Table StructureDocumento180 páginasTable StructureVictor PathakAinda não há avaliações

- Deep Drive - Customer Interface in AR - Oracle Apps EpicenterDocumento38 páginasDeep Drive - Customer Interface in AR - Oracle Apps Epicenterjeetu_87Ainda não há avaliações

- Important RCC Questions-Short and LongDocumento15 páginasImportant RCC Questions-Short and LongmailjoelsamuelAinda não há avaliações

- Structural MembersDocumento37 páginasStructural Membersmario gadianoAinda não há avaliações

- Understand and Troubleshoot Virtualized Domain Controller in Windows Server 8 BetaDocumento168 páginasUnderstand and Troubleshoot Virtualized Domain Controller in Windows Server 8 BetaChiTownITAinda não há avaliações

- Typical Signage Drawings: Information Sign ManualDocumento49 páginasTypical Signage Drawings: Information Sign ManualMaynard BaricaAinda não há avaliações

- C Ds Unit - II NotesDocumento50 páginasC Ds Unit - II NotesAshish ThirunagariAinda não há avaliações

- Engineering Journal::Review On Cold Rolling Mill Roll DeformationDocumento8 páginasEngineering Journal::Review On Cold Rolling Mill Roll DeformationEngineering JournalAinda não há avaliações

- 2014 - Solved Problems in Facility PlanningDocumento135 páginas2014 - Solved Problems in Facility Planninghshshdhd86% (7)

- H Beam Load Bearing CalculationDocumento31 páginasH Beam Load Bearing CalculationMuhammad Attiq Ur RahmanAinda não há avaliações

- Powershell Import Update Users Groups From CSV FileDocumento2 páginasPowershell Import Update Users Groups From CSV FilecrakchakibAinda não há avaliações

- Method of Statement For Electrical Works-UPDATEDocumento35 páginasMethod of Statement For Electrical Works-UPDATEWaleed AbdulsattarAinda não há avaliações

- Analysis+of+Non Symmetrical+Flapping+AirfoilsDocumento18 páginasAnalysis+of+Non Symmetrical+Flapping+AirfoilsAsif HameedAinda não há avaliações

- Microstrip Patch Antenna DesignDocumento19 páginasMicrostrip Patch Antenna DesignNgoc Lan Nguyen50% (2)

- HSE FRM 32 Final Incident ReportDocumento6 páginasHSE FRM 32 Final Incident ReportDilshad aliAinda não há avaliações

- SamplesDocumento14 páginasSamplesSanjayAinda não há avaliações

- AC DC AcDocumento3 páginasAC DC AcPhani KumarAinda não há avaliações

- Reinforced Concrete Design BS 8110Documento15 páginasReinforced Concrete Design BS 8110Kutty Mansoor75% (4)

- Work, Kinetic Energy and Potential EnergyDocumento28 páginasWork, Kinetic Energy and Potential EnergyMaey AkimAinda não há avaliações

- 10 - Design of Doubly Reinforced BeamsDocumento13 páginas10 - Design of Doubly Reinforced BeamsammarnakhiAinda não há avaliações

- Company ProfileDocumento6 páginasCompany ProfileFaidzil ChabibAinda não há avaliações

- Foxpro Treeview ControlDocumento5 páginasFoxpro Treeview ControlJulio RojasAinda não há avaliações