Escolar Documentos

Profissional Documentos

Cultura Documentos

Automation For Instrument Cluster Panel

Enviado por

neerajTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Automation For Instrument Cluster Panel

Enviado por

neerajDireitos autorais:

Formatos disponíveis

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

Automation for Instrument Cluster Panel

Testing Using Machine Vision and NI-PXI

Hardware-In-the-Loop

Dr.B.Sharmila1, P.Venkadesan2

Professor, Dept. of EIE, Sri Ramakrishna Engineering College, Coimbatore, Tamilnadu, India1

PG Student, Dept. of CIE, Sri Ramakrishna Engineering College, Coimbatore, Tamilnadu, India2

ABSTRACT: This paper is proposed to develop automated instrument cluster panel testing and validation for shorten

product development life cycle in automotive industry. The NI-PXI hardware-in-the- loop device combining with

vision system is used for implementing closed loop automated Electronic Control Unit [ECU] testing. The LabVIEW

NI-PXI system is simulating the real time hardwired and CAN signal for instrument cluster panel which is distributed

by other ECUs in the vehicle network. The functionality result of concern test signal has been presented in the

instrument cluster panel and the same signal has been captured by vision camera. The captured image is further

processed by image processing algorithm for detecting the features such as detecting gauges, tell tale and text displays.

Further, the closed loop result of each test case presents in the excel report for validation purpose using LabVIEW

software. The test results were compared with ECU requirements specification for the purpose of flawless product

delivery. The proposed system reduce the errors, time consumption and human intervention in ECU testing and

validation.

KEYWORDS: ECU, Instrument cluster panel, Machine Vision, Hardware-in-the-loop.

I.INTRODUCTION

In recent year’s automobile industry is one of fastest developing industries because number of persons using vehicle are

increasing day by day. Automobiles these days are equipped with various electronic control units which provide the

sophisticated vehicle driving information and improving engine efficiency. One of the vehicle driving information

system is instrument cluster panel, in which comprises of various meter like speedometer, fuel gauge, LCD display and

warning light indicators etc. The IC information assists the driver regarding safety related concern for driving the

vehicle. With advancement of technologies, more information is available for the driver to assist him in better driving.

Because of this, instrument cluster panel becomes complex embedded control system. Due to the increasing complexity

of embedded systems and software in vehicles, the automotive industry faces an increasing need for testing and

validation of hardware and software under real time environment for defect less product delivery before apply into real

vehicle. At the same time product development life cycle must be shortened for vehicle manufacturers to be

competitive on the global market, and an increased amount of testing and verification must be performed in less time.

In earlier days, ECUs software and hardware functionalist are tested and validated manually. In the manual testing, it is

difficult to cover all the test cases, time consumption, tedious and product development life cycle increased. The

capturing results are not possible by manual testing because all the results are instantaneous and real time basis.

The manual testing difficulties are overcome by closed loop automated testing and validation scheme using [Hardware-

In-the-Loop] system integrated with vision system. The past few years several HIL techniques have been implemented

to automate instrument cluster panel testing and validation for flawless product delivery in the automotive industry.

Yingping huang et al [1] presents a novel application integrating machine vision and HIL techniques for automated

functional testing of a vehicle instrument cluster and dspace HIL simulator is used for rapid prototyping and model

based testing approach. Amanjot dhaliwal et al [2] proposed HIL system for ECU unit tests and function tests on a

single ECU using open-loop models and interaction between other ECUs can be simulated by generating CAN

messages from the HIL system. T.L Narayana et a [3] implemented LabVIEW based HIL simulator for testing and

Copyright to IJAREEIE 10.15662/ijareeie.2015.0404143 3773

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

validation of instrument cluster panel with integration of vision system for closed loop automation. Much work has

been implemented to solve the problem of manual testing and validation of instrument cluster panel using machine

vision and hardware-in-the-loop [4][5][6][7][8].

This paper presents NI-PXI based HIL techniques with integration of machine vision system for automated functional

testing of a vehicle instrument cluster which is distributed among other ECUs available in the vehicle network.

In the system, NI-PXI HIL set up is used to generate the real time hardwired and CAN simulated signal to the

instrument cluster panel with the help of LabVIEW interactive application software. The machine vision system with

image algorithm to read data present in the instrument cluster panel like speed, fuel level, telltale and text message for

fully automated closed loop test process. Also the LabVIEW application software generates automatic excel test result

report for validation purpose. The closed loop automated system provides low errors, time saving, and repeatable test

and reduce the manpower requirement.

This paper is organized as follows; Section II presents the HIL system architecture which is describing the hardware

block structure of closed loop product testing environment. Section III elaborates implementation of HIL simulator and

Section IV presents the implementation of machine vision system for detecting gauges. Finally, the paper ends with

conclusion in section V.

.

II. HIL SYSTEM ARCHITECTURE

It is vision based hardware in the loop ECU testing. The Fig.1.is Show the system architecture with hardware in loop

test equipment with vision system.

NI-LABVIEW NI-LABVIEW

REAL TIME PC FOR TEST

SEQUENCE EXECUTION

HARDWARE CONFIGURATION,

REAL TIME PXI TEST SEQUENCE & REPORT

CONTROLLER GENERATION

TCP/IP LAN NETWORK

NI-VISION BUILDER & PPS PFG PDMM

IN SIGHT EXPLORER TO & FRO PXI

SYSTEM

USB

3.0

TERMINAL BLOCK & RELAY BOARD

VISION SYSTEM CAMERA

DEVICE UNDER TEST

Fig. 1 Architecture of NI-PXI HIL system

It consists of five vital elements including machine vision system, NI-PXI HIL tester, NI-LabVIEW system, device

under test and communication interfaces.

NI-PXI HIL tester: In the real time PXI system are composed of three basic components- chassis, system controller

and peripheral modules. The chassis provides the rugged and modular packaging for the system. The chassis used here

is 14-slot and 6U sizes. The ADLINK PXIe-3985 PXI express embedded controller, based on the fourth generation

Intel Core i7 processor is specifically designed for hybrid PXI express-based real time testing systems. The PXI-6528

DIO card is used to simulate the ECU DIO functionality such as telltale and warning light indicator. The PXI-8513

CAN card is providing capability of simulating the CAN message signal which is distributed to other ECUs. The PXI-

40-295 programmable resistor module is used to simulate the resistance based input functionality available in the ECU

Copyright to IJAREEIE 10.15662/ijareeie.2015.0404143 3774

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

module. The Agilent-33500 Series is a 30 MHz synthesized waveform generator with built-in arbitrary waveform and

pulse capabilities. It is combination of bench-top and system features makes this waveform generator a versatile

solution for ECU testing requirements. The Sorensen power supply is providing variable power supply to ECU for

simulating with different input voltage. The sleep mode current and operating current of ECU are measured directly

using the agilent digital multi meter. All the PXI system peripheral and HIL equipment are interfaced with the help NI-

LabVIEW software.

Device under Test: DUT or ECU is an instrument cluster panel of AMW tractor consists of following major

components, speed, Fuel, pressure gauge, telltale, warning indicator and LCD display.

NI-LabVIEW System: The LabVIEW system is used to configure HIL test equipment, test case execution for

functionality and report generation for each variant of cluster.

Machine Vision System: The vision system consists of Cognex camera and in-sight-explorer software tool. The in-

sight-explorer has many vision tool libraries like blob and edge tool which is used for image processing algorithm

implementation in closed loop ECU testing.

Communication Interfaces: The TCP/IP protocol is used for communication between NI LabVIEW and vision

system. Also the peripheral instruments are communicated through TCP/IP protocol with LabVIEW system.

III. HIL SIMULATOR IMPLEMENTATION

In the HIL simulator, the peripheral modules and system controller are communicated through PCI/PCI Express bus

which is available in PXI chassis. The HIL equipment such as programmable power supply and function generator is

used for simulate the ECU functionality in Real time. NI-CAN card generates the CAN message for device under test

which has been distributed to other ECUs in the CAN network. The DMM is used for measuring the sleep mode

current passed through ECU. The machine vision system is integrated with NI-PXI system to achieve the closed loop

observation for complete automated ECU testing. The PXI controller and HIL equipment are communicated through

TCP/IP and USB protocol. The ECUs are interfaced through terminal block and relay board. The two types of

NI-LABVIEW application tool has been developed for real time test sequence execution, hardware configuration and

report generation for each variant of device under test. The image processing algorithm has been developed using in-

sight-explorer software tool.

IV. MACHINE VISION SYSTEM IMPLEMENTATION

The machine vision system consists of a camera, lighting, optics and image processing software. A Cognex in-sight

smart camera was selected for image acquisition and stand alone processing which offers a resolution of 800*600 and

64MB programmable flash memory for standalone operation. The acquisition rate of the smart camera is 102 fps. The

image processing software [In-Sight-Explorer] provides a wide library vision tools for feature identification,

verification, measurement and testing application. The primary source of illumination is from LED ring lights with

directional front lighting, which provides high contrast between the object and background. The selection of optical

lens depends on the field of view and working distance. The various functionalities of ECU result has been observed by

vision system such as speed gauge, Fuel level, tell tale checking and text message read from ECU LCD. The closed

loop automated machine vision system is shown in fig.2.

Copyright to IJAREEIE 10.15662/ijareeie.2015.0404143 3775

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

TCP/IP PROTOCOL

NI-LABVIEW

SYSTEM

CAN SIGNAL I/O SIGNAL CAMERA

CAPTURE IMAGE

DEVICE UNDER TEST

Fig. 2 Automated vision system

SPEED GAUGE DETECTION

The observation process for the speed as indicated by the needle of the speedometer is discussed in this section. When

the message for the test is received by the ECU and image of ECU is taken by the USB Camera continuously. In

captured image, two annular of region is drawn with the ends of the region coinciding with the extremes of the

speedometer and then the blobs of the needle is detected using blob detection function which is available in the In-Sight

Explorer as shown in fig.3.

Fig. 3 Vision system implementation tool

Blob is a set of connected pixels with a gray scale value above or below a specified threshold. Once two blobs have

been found in the ROI then draw line between two blobs. Also draw zero reference line between zero point and speed

gauge pivot centre. These two lines are used to find the angle for corresponding speed. This angle helps to determine

the original speed indicating in the meter. The speed gauge detection algorithm flowchart is shown in fig.4.

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

Start

Capture image in continuous mode

Draw annular ROI for finding Blob1

Draw annular ROI for finding Blob 2

Draw line between two founded Blobs

Draw zero reference line using edit line

Find line to line angle between two lines

Calibrate angle to the corresponding speed

Stop

Fig. 4 Algorithm for speed gauge detection

FUEL LEVEL DETECTION

This test determines the fuel level status from the bar graph displayed in the fuel gauge. The “Find multi Line” edge

tools are positioned to detect positions of 0%, 100% and actual fuel level. In machine vision terminology, an edge is

defined as the boundary (a line, arc or circle) between two adjacent pixel groups with contrasting grayscale values.

Start

Capture image in continuous mode

Draw annular ROI using Edge tool

Mention threshold transition for Edge

Count detected Edges

Calibrate edges count into fuel level

Stop

Fig. 5 Algorithm for fuel bar graph detection

The In-Sight Edge Tools are used to detect and process statistics about the found edges. Count the total edges detected

by edge detection algorithm and calibrate the edge count into fuel level. The speed gauge detection algorithm flowchart

is shown in fig.5.

TELL TALE DETECTION

There are various tell-tale indicators on the ECU such as power steering, seatbelt warning, low fuel indicator etc. These

light up or glow depending upon the state of hardware of the vehicle. While the state of on or off can be detected using

Copyright to IJAREEIE 10.15662/ijareeie.2015.0404143 3777

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 4, April 2015

the algorithm to detect the difference between the telltale indicators, pattern matching is required. To run this test, a

template of the indicator is loaded from the memory and learnt by the pattern max tool. The real-time input image of

the cluster is then captured and loaded onto the In-Sight Explorer. The image is then scanned for the learnt pattern and

an ROI is created around the pattern once it is detected. Initially, each standard symbol displayed in the cluster is

trained using PatMaxTM tools and stored as master patterns. The image captured from the unit under test is compared

with the trained patterns. The symbol is recognized based on the pattern matching score returned from the PatMaxTM

tools.

TEXT MESSAGE DETECTION

The warning messages displayed in the message centre is in the need to be checked for their correctness. This test aims

at recognizing and reporting these warning texts in the image processing library, OCR / OCV vision tools are designed

to recognize a text string. However, this tool can only be used for identifying a text string with a known number of

characters. In OCR/OCV, text fonts are trained before recognizing or verify the text. These trained fonts are stored in

database with different instance. The ROI should be defined in the captured image area for recognizing and verification

of text. The OCR/OCV is compared the ROI text with database fonts, once the text is match with database the found

text has been sent to the API based on request.

V.CONCLUSION

Now a days, in automotive vehicle driving information system or instrument cluster panel has more functionality to

assist the driver regarding safety concern. Because of this, instrument cluster panel becomes complex embedded

control system. Testing these functionalities are required more test cases, but it is very tedious work to cover all the test

cases by manually. The implemented NI-PXI system based automated product testing and validation which covered all

the test cases in real time environment, therefore reduces the error and saves the time. The vision system read the

instrument cluster panel result with good accuracy and real time manner. The NI-PXI system with integration of

machine vision was proved efficiency of test and validation of automotive ECUs.

REFERENCES

[1] Yingping Huang and R. Peter Jones, “Design Validation Testing of Vehicle Instrument Cluster Using Machine Vision and Hardware-in-

the-loop”, in Proc.IEEE Conf on Vehicular Electronics and Safety, Sep 22-24, 2008.

[2] Amanjot Dhaliwal, Shreyas C. Nagaraj and Syed Ali “ Hardware-In-The-Loop Simulation For Hybrid Electric Vehicles – An Overview,

Lessons Learnt And Solutions Implemented”, SAE International, 2009.

[3] T. L. Narayana, S.Venkat Rao and K.Gnasen, “Automated Instrument Cluster Testing Using Image Processing” American Journal of

Intelligent Systems, Vol.3 (1) , pp.28-32, 2013.

[4] Thiago Martins and Alexander Wagner, “A Vision System for Electronic Control Unit Testing Using Hardware In the Loop”, 2011.

[5] Sebastian Osswald, Pratik Sheth, Manfred Tscheligi “Hardware-in-the-Loop-Based Evaluation Platform for Automotive Instrument

Cluster Development” EICS’13, June 24–27, 2013.

[6] A. Mouzakitis, D. Copp and R. Parker. “A hardware-in-the-loop system for testing automotive controller diagnostic software”.

Proceedings of the Sixteenth International Conference on Systems Engineering, (ICSE2003), Coventry, UK, vol. 2, pp. 589-594, 2003.

[7] I. R. Kendall and R. P. Jones, “An investigation into the use of hardware-in-the-loop simulation testing for automotive electronic control

systems”, Control Engineering Practice, vol. 7, pp. 1343-1356, 1999.

[8] A. Shafi, “Machine Vision in Automotive Manufacturing”, Sensor Review, vol. 24, no. 4, pp. 337-342, 2004.

[9] Lab VIEW CORE 1 Course Manual- October 2009 Edition- Part Number 325290A-01.

[10] Lab VIEW CORE 2 Course Manual- October 2009 Edition- Part Number 325290A-01.

Copyright to IJAREEIE 10.15662/ijareeie.2015.0404143 3778

Você também pode gostar

- UniFlo Smart Gas Meters UNDocumento4 páginasUniFlo Smart Gas Meters UNprasanthvvAinda não há avaliações

- Auto Parts PDFDocumento36 páginasAuto Parts PDFNitin ShenoyAinda não há avaliações

- RGBSI ShortProfile-2015Documento34 páginasRGBSI ShortProfile-2015Alok PurohitAinda não há avaliações

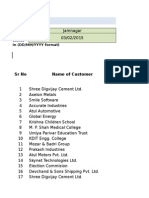

- Top 100 Indian engineering companies listDocumento13 páginasTop 100 Indian engineering companies listhem1980Ainda não há avaliações

- Wireless Charging of Evs: Mohammed Nivas.S S5 Eee RNO:38 REG NO:19030635Documento14 páginasWireless Charging of Evs: Mohammed Nivas.S S5 Eee RNO:38 REG NO:19030635Salim UmerAinda não há avaliações

- TVS Group company details and industry analysisDocumento49 páginasTVS Group company details and industry analysisEr KarthikAinda não há avaliações

- Synopsis of ProjectDocumento67 páginasSynopsis of ProjectInSoMniA9991% (11)

- RFQ-CP - November 2017Documento12 páginasRFQ-CP - November 2017KshirabdhiTanayaSwainAinda não há avaliações

- Suspension System For An Electric All-Terrain Vehicle (ATV) PDFDocumento11 páginasSuspension System For An Electric All-Terrain Vehicle (ATV) PDFMuhd MuzafarAinda não há avaliações

- TelephoneBook NewDocumento58 páginasTelephoneBook Newsuperbs1001Ainda não há avaliações

- Sales Funnel JMN NewDocumento1.561 páginasSales Funnel JMN NewJignesh KareliyaAinda não há avaliações

- Cad Cam PuneDocumento20 páginasCad Cam PuneMrunal DoiphodeAinda não há avaliações

- Ashok LeylandDocumento59 páginasAshok LeylandManjeet SinghAinda não há avaliações

- Exh List AutoExpoDocumento58 páginasExh List AutoExpoPrafful PawarAinda não há avaliações

- Mutual Industries LTD - CorporateDocumento40 páginasMutual Industries LTD - CorporateKool LeisureAinda não há avaliações

- Company DetailsDocumento36 páginasCompany DetailsAnonymous 8pCXXsAinda não há avaliações

- Automotive Radar - From Its Origins To Future DirectionsDocumento8 páginasAutomotive Radar - From Its Origins To Future Directionsmadhu_g100% (1)

- Company Details and Stall Numbers by IndustryDocumento6 páginasCompany Details and Stall Numbers by IndustryIshu AroraAinda não há avaliações

- Parker Electronics Update 160316 PDFDocumento71 páginasParker Electronics Update 160316 PDFMaria Lavinia IordacheAinda não há avaliações

- Ochure PDFDocumento8 páginasOchure PDFSachin DarneAinda não há avaliações

- 2020-11-09 Q4 FY20 Investor PresentationDocumento76 páginas2020-11-09 Q4 FY20 Investor PresentationPOPAinda não há avaliações

- Report2017 e PDFDocumento110 páginasReport2017 e PDFstarchitectAinda não há avaliações

- Department Transfer SummaryDocumento13 páginasDepartment Transfer SummaryPradeep AdsareAinda não há avaliações

- SSD1325 2.1 PDFDocumento61 páginasSSD1325 2.1 PDFKrishna SgAinda não há avaliações

- LG Produkt Catalog 2019Documento15 páginasLG Produkt Catalog 2019timo eichmannAinda não há avaliações

- Cipet Bhubaneswar Skill Development CoursesDocumento1 páginaCipet Bhubaneswar Skill Development CoursesDivakar PanigrahiAinda não há avaliações

- Suzuki All New XL7 Quotation CASH 1010Documento1 páginaSuzuki All New XL7 Quotation CASH 1010Jorj YasayAinda não há avaliações

- ANSYS - OPTICAL SOLUTIONS Brochure (V4)Documento2 páginasANSYS - OPTICAL SOLUTIONS Brochure (V4)ssvivekanandhAinda não há avaliações

- ConsultantsDocumento69 páginasConsultantsasuras1234Ainda não há avaliações

- Seminar Report JanDocumento8 páginasSeminar Report Janjanaki ram0% (2)

- Depp Profile Data AprilDocumento93 páginasDepp Profile Data AprilAkshat EnterpriseAinda não há avaliações

- Indian Automotive Industry: / LgcinDocumento6 páginasIndian Automotive Industry: / LgcinPrasoon SharmaAinda não há avaliações

- Rail Interiors Magazine-2011Documento84 páginasRail Interiors Magazine-2011Jaijith ...100% (2)

- Top 50 Rank List for M.E Applied ElectronicsDocumento133 páginasTop 50 Rank List for M.E Applied ElectronicsGangatharan NarayananAinda não há avaliações

- Electronic - Components-EDM Diciembre PDFDocumento526 páginasElectronic - Components-EDM Diciembre PDFalvaro marrugoAinda não há avaliações

- Gear Technology India 2013 # 4 PDFDocumento68 páginasGear Technology India 2013 # 4 PDFUday Sankar Sarma YerramilliAinda não há avaliações

- Design of Instrument ClusterDocumento114 páginasDesign of Instrument ClusterWan ShahmisufiAinda não há avaliações

- VVDNDocumento2 páginasVVDNPriya KabirAinda não há avaliações

- Enviro Serve Private Limited: Excellence in Automation SolutionsDocumento26 páginasEnviro Serve Private Limited: Excellence in Automation SolutionsSneha R ScindiaAinda não há avaliações

- Safety Equipment: Product Seller Contact No. SR. NODocumento7 páginasSafety Equipment: Product Seller Contact No. SR. NOPurvesh M PatelAinda não há avaliações

- Continental Sibiu Presentation Overview (38Documento22 páginasContinental Sibiu Presentation Overview (38Nicolae StefanoaeaAinda não há avaliações

- CCNA Network Engineer ResumeDocumento2 páginasCCNA Network Engineer Resumeyadav123456Ainda não há avaliações

- PWC Karnataka Aerospace Hub of India Report 091211Documento32 páginasPWC Karnataka Aerospace Hub of India Report 091211sreeramk13Ainda não há avaliações

- Fastenet JUN-JUL 2022Documento140 páginasFastenet JUN-JUL 2022Joao Pedro Rendeiro Correia de SousaAinda não há avaliações

- Company Lists 2018Documento8 páginasCompany Lists 2018Scrappy Trading CompanyAinda não há avaliações

- BAWAL LIST COMPANIESDocumento5 páginasBAWAL LIST COMPANIESromeoyadav100% (1)

- Name 1Documento69 páginasName 1bishtamitdip100% (1)

- Top 40 Agricultural Machinery and Farm Equipment Companies in IndiaDocumento18 páginasTop 40 Agricultural Machinery and Farm Equipment Companies in IndiabiplavAinda não há avaliações

- Retroreflective PPT V1Documento21 páginasRetroreflective PPT V1prasannapatnaikrcert1538Ainda não há avaliações

- Mobile India Expo BrochureDocumento2 páginasMobile India Expo BrochureĀr Fåîzâl RähmåñAinda não há avaliações

- IT Service Providers Contact ListDocumento3 páginasIT Service Providers Contact ListsujitaAinda não há avaliações

- Electronica and ProductronicaDocumento7 páginasElectronica and ProductronicaMujib AlamAinda não há avaliações

- Ather 450 Quick Start GuideDocumento66 páginasAther 450 Quick Start GuidevadiAinda não há avaliações

- Group Company ListDocumento12 páginasGroup Company ListsigmasundarAinda não há avaliações

- Integrated Testing of Launch Vehicle Telemetry Avionics Using PXI and NI LabviewDocumento6 páginasIntegrated Testing of Launch Vehicle Telemetry Avionics Using PXI and NI LabviewAleem AzharAinda não há avaliações

- Benchmarking Single-Point Performance On National Instruments Real-Time HardwareDocumento8 páginasBenchmarking Single-Point Performance On National Instruments Real-Time HardwaremafmonteAinda não há avaliações

- Fault Diagnostician of Induction Machine Using LabviewDocumento5 páginasFault Diagnostician of Induction Machine Using LabviewJimmy Arias (JimmyStron)Ainda não há avaliações

- Experimental Study363 Article Text 1601 2-10-20191031Documento6 páginasExperimental Study363 Article Text 1601 2-10-20191031xx okeeAinda não há avaliações

- A Virtual Laboratory For Distance Education: Virtual Control Lab ArchitectureDocumento4 páginasA Virtual Laboratory For Distance Education: Virtual Control Lab ArchitectureMusawwir UsmanAinda não há avaliações

- Interfacing PIC Microcontrollers: Embedded Design by Interactive SimulationNo EverandInterfacing PIC Microcontrollers: Embedded Design by Interactive SimulationAinda não há avaliações

- Monopoles and Electricity: Lawrence J. Wippler Little Falls, MN United StatesDocumento9 páginasMonopoles and Electricity: Lawrence J. Wippler Little Falls, MN United Stateswaqar mohsinAinda não há avaliações

- Nais Control 1131 FP0FP1FPM Instruction SetDocumento613 páginasNais Control 1131 FP0FP1FPM Instruction SettlilinouraAinda não há avaliações

- Engineering Data Ip5-3600Documento2 páginasEngineering Data Ip5-3600CESAR SEGURAAinda não há avaliações

- HypergraphDB: A Graph-Oriented DatabaseDocumento20 páginasHypergraphDB: A Graph-Oriented DatabaseandresAinda não há avaliações

- Load Cell (UTM)Documento1 páginaLoad Cell (UTM)José Rubén Ramos GarzaAinda não há avaliações

- Assignment No1 Current and ElectricityDocumento1 páginaAssignment No1 Current and ElectricityshreyaAinda não há avaliações

- NFC 17102 - Lightning Protection - Protection of Structures and Open Areas Against Lightning Using Early Streamer Emission Air TerminalsDocumento58 páginasNFC 17102 - Lightning Protection - Protection of Structures and Open Areas Against Lightning Using Early Streamer Emission Air TerminalsLEONARDOAinda não há avaliações

- DRC800 Remote Control UserGuideDocumento2 páginasDRC800 Remote Control UserGuideLuis MurilloAinda não há avaliações

- Contact Inform 2002 PDFDocumento24 páginasContact Inform 2002 PDFFrank AlmeidaAinda não há avaliações

- Ernest H Hill Ltd Equipment Catalogue SummaryDocumento17 páginasErnest H Hill Ltd Equipment Catalogue SummaryhillpumpsAinda não há avaliações

- AF09-30-01-13 100-250V50/60HZ-DC Contactor: Product-DetailsDocumento5 páginasAF09-30-01-13 100-250V50/60HZ-DC Contactor: Product-DetailsTheo Pozo JAinda não há avaliações

- ABC Vs Acb Phase Seq t60 Get-8431bDocumento3 páginasABC Vs Acb Phase Seq t60 Get-8431bkcirrenwodAinda não há avaliações

- Line Follower NXTDocumento21 páginasLine Follower NXTKen LeAinda não há avaliações

- Details of Measurement: Total Qnty Nos. Length Breadth Height SN Description of Item Unit MEASUREMENT (In MTRS)Documento6 páginasDetails of Measurement: Total Qnty Nos. Length Breadth Height SN Description of Item Unit MEASUREMENT (In MTRS)Biswajit SahooAinda não há avaliações

- Type 3025 Sizes P462, P460-200 and P900 Diaphragm Actuator: Bulletin 61.1:3025Documento8 páginasType 3025 Sizes P462, P460-200 and P900 Diaphragm Actuator: Bulletin 61.1:3025Datt NguyenAinda não há avaliações

- Gauss Lab 01Documento4 páginasGauss Lab 01Diego Giraldo BoteroAinda não há avaliações

- User Manual Kxtda 30 600Documento252 páginasUser Manual Kxtda 30 600kabeh1Ainda não há avaliações

- Banner Printing Set UpDocumento21 páginasBanner Printing Set UpAsanka ChandimaAinda não há avaliações

- Daftar Alat TSMDocumento2 páginasDaftar Alat TSMagus ImawanAinda não há avaliações

- Ship Stability 5Documento31 páginasShip Stability 5jeaneva guiaoAinda não há avaliações

- FintechDocumento8 páginasFintechArnab Das50% (4)

- CD 74 HCT 164 MDocumento16 páginasCD 74 HCT 164 MfabriziocasAinda não há avaliações

- Super PaveDocumento20 páginasSuper PaveHashem EL-MaRimeyAinda não há avaliações

- PHD Thesis BentzDocumento320 páginasPHD Thesis Bentzcrusanu50% (2)

- Statement of PurposeDocumento2 páginasStatement of PurposeAan DaisyAinda não há avaliações

- Refresher Day 3Documento4 páginasRefresher Day 3Jevan A. CalaqueAinda não há avaliações

- DE Ee1Documento4 páginasDE Ee1Jj JumawanAinda não há avaliações

- Mobile Robots & Kinematics: Session 2: Nicol As Ilich Samus February 27, 2014Documento5 páginasMobile Robots & Kinematics: Session 2: Nicol As Ilich Samus February 27, 2014Nicolás Ilich SamusAinda não há avaliações

- Lizmontagens Group ProfileDocumento5 páginasLizmontagens Group ProfileRui Carlos Delgado Lopes AlvesAinda não há avaliações

- Canon Ir3245 Series-PcDocumento154 páginasCanon Ir3245 Series-PcPetrescu CezarAinda não há avaliações