Escolar Documentos

Profissional Documentos

Cultura Documentos

32 Jig For Threaded Inserts & Making Raised Panels PDF

Enviado por

Ilberto FortunaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

32 Jig For Threaded Inserts & Making Raised Panels PDF

Enviado por

Ilberto FortunaDireitos autorais:

Formatos disponíveis

ONLINE EXTRAS

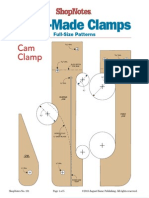

Jig for Threaded Inserts

Most of the devices I’ve threaded inserts, I get out to hold a 6mm-20 hexhead Finally, I added a spring

seen for installing threaded a shop-built, hand-held jig bolt and a nylon bushing. between the bushing and

inserts use a nut and bolt that I use with a ratchet, as The through hole is sized the nut and washer that are

to drive the insert into the in the photo below. This jig to hold the bolt, and the tightened against the insert.

workpiece. The real trick lets me drive the inserts in 12mm-dia. counterbore is The spring provides just

with this procedure is keep- straight every time. drilled 32mm deep to acc- enough downward pres-

ing the insert straight as The tool is just a block of ept the 6mm-i.d. bushing sure to help the threads on

you’re screwing it into the hardwood with an 18mm- that holds the bolt straight the outside of the insert to

{ Threaded inserts wood — it’s not nearly as deep notch cut in one cor- while you tighten it down. cut into the wood. W

(and machine easy as you might think. So ner. A counterbored hole

screws) allow when I need to install some is drilled through the notch NOTE:

you to join two Apply wax

to insert

pieces so they can before

installing

be disassembled

easily later. NOTE: Cut

down a 75mm-long

6mm-20 bolt so only 12mm

hexhead of threads remain

bolt

6mm I.D. x

25mm nylon Drill 12mm

bushing dia. hole

32mm deep

6mm I.D. x

25mm spring 57

Nut and

brass washer 18

{ TThis simple tool makes it easy to install a threaded insert

straight. A nylon bushing and a spring help hold the Threaded

insert

threaded insert upright as it’s driven into the workpiece.

RAISED PANEL

OPTION FOR

FILING CABINET

Making Raised Panels

Front

One of the drawer options To set up the table saw, and make a second “skim” attention.

face for the filing cabinets in first tilt the blade away cut. This also creates the Since the

Woodsmith No. 32 was to from the fence and raise the 3mm-wide shoulder of the blade was

Rebate

on 3 make the false fronts with blade to the correct height, profile. Note: Before moving tilted, the

back

face raised panels instead of flat as in Fig. 1 and left margin. the rip fence for the second shoulder

5° panels, as in photo at right. Once the blade is adjust- pass, cut the bevels on all wi l l b e

I like to cut raised panels ed, I make the cut in two the edges of all the panels. undercut

38

with the table saw, and passes. The first removes With the raised panels slightly.

6 there are a couple of things most of the waste. Then to cut, the last step is to sand To square

I do to end up with smooth, clean up any burn or saw the bevels. But there’s it up, I

6 clean bevels and shoulders. marks, I nudge the fence another area that needs mad e a

sanding

1 2 block that has a bevel

a. a. cut on one edge (Fig. 2).

Bevel edge

Aux.

of sanding block For the file cabinets, you

fence

Set saw to match angle will also need to rebate the

blade to of shoulder

Raised desired panel’s back face, as in the

panel height left margin. And when you

Tall and

angle assemble the frame around

auxiliary

fence the panel, don’t force the

Sand profile

Cut profile to remove saw panel into the grooves. If

on ends marks and the fit is too tight, just sand

first square up shoulder

the bevels. W

Australian Woodsmith No. 32 Online Extras © 2003 August Home Publishing Company

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- MONTANA PatternDocumento23 páginasMONTANA PatternAna Isabel Garcia Perez100% (1)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Woodsmith Magazine 160Documento54 páginasWoodsmith Magazine 160Ilberto FortunaAinda não há avaliações

- 1 CabinetMaker+FDM January 2012 PDFDocumento64 páginas1 CabinetMaker+FDM January 2012 PDFIlberto FortunaAinda não há avaliações

- Woodsmith Magazine 133Documento36 páginasWoodsmith Magazine 133Ilberto FortunaAinda não há avaliações

- Router JigsDocumento2 páginasRouter JigsIlberto Fortuna100% (1)

- Woodsmith Magazine 169Documento52 páginasWoodsmith Magazine 169Ilberto Fortuna100% (1)

- Woodsmith Magazine 140Documento36 páginasWoodsmith Magazine 140Ilberto FortunaAinda não há avaliações

- Woodsmith Magazine 132Documento36 páginasWoodsmith Magazine 132Ilberto Fortuna100% (1)

- Woodsmith Magazine 150Documento36 páginasWoodsmith Magazine 150Ilberto Fortuna100% (1)

- Lowe Sew Is 102015Documento100 páginasLowe Sew Is 102015miulescu_diana5772100% (5)

- Woodsmith Magazine 142Documento36 páginasWoodsmith Magazine 142Ilberto Fortuna100% (1)

- How To Make BokkenDocumento10 páginasHow To Make Bokkenkosen58100% (1)

- Woodsmith Magazine 134Documento36 páginasWoodsmith Magazine 134Ilberto FortunaAinda não há avaliações

- Plant Register TemplateDocumento4 páginasPlant Register TemplateimamtaAinda não há avaliações

- Finger Joints: Fast and EasyDocumento4 páginasFinger Joints: Fast and EasyIlberto FortunaAinda não há avaliações

- Sherwood Creations Winter 2011Documento68 páginasSherwood Creations Winter 2011Ilberto FortunaAinda não há avaliações

- HWHL Router Table PlansDocumento9 páginasHWHL Router Table PlansIlberto FortunaAinda não há avaliações

- Din 571 Vairados PDFDocumento4 páginasDin 571 Vairados PDFmugiwara ruffyAinda não há avaliações

- 63 Portable Mitre Saw Station PDFDocumento1 página63 Portable Mitre Saw Station PDFIlberto FortunaAinda não há avaliações

- Brake Applications CatalogDocumento159 páginasBrake Applications CatalogvidarlovikAinda não há avaliações

- Sherwood Creations Spring 2011Documento68 páginasSherwood Creations Spring 2011Jorge ReyesAinda não há avaliações

- Precision Crosscut Sled - Woodsmith ShopDocumento13 páginasPrecision Crosscut Sled - Woodsmith ShopAnízio Luiz Freitas de Mesquita100% (2)

- Sheetmetal FundamentalsDocumento81 páginasSheetmetal Fundamentalsramkishore_87100% (1)

- Clamp PatternsDocumento5 páginasClamp PatternsGermanHund100% (3)

- Dimensions For Relief GroovesDocumento2 páginasDimensions For Relief Groovesstem86100% (1)

- Shop-Made Cam ClampDocumento68 páginasShop-Made Cam ClampIlberto Fortuna33% (3)

- Amigurumi Fox Crochet PatternDocumento6 páginasAmigurumi Fox Crochet Patternfrancisco100% (1)

- Woodsmith Magazine 130Documento36 páginasWoodsmith Magazine 130Ilberto FortunaAinda não há avaliações

- Din1688 1 PDFDocumento4 páginasDin1688 1 PDFFelipe FernandesAinda não há avaliações

- AW Extra - Double-Duty Shop StoolDocumento15 páginasAW Extra - Double-Duty Shop StoolIlberto FortunaAinda não há avaliações

- Woodsmith Magazine 25Documento28 páginasWoodsmith Magazine 25Ilberto FortunaAinda não há avaliações

- Woodsmith Magazine 24Documento24 páginasWoodsmith Magazine 24Ilberto FortunaAinda não há avaliações

- Woodsmith Magazine 20Documento24 páginasWoodsmith Magazine 20Ilberto FortunaAinda não há avaliações

- Woodsmith Magazine 27Documento24 páginasWoodsmith Magazine 27Ilberto FortunaAinda não há avaliações

- Woodsmith Magazine 99Documento32 páginasWoodsmith Magazine 99Ilberto FortunaAinda não há avaliações

- Woodsmith Magazine 23Documento24 páginasWoodsmith Magazine 23Ilberto FortunaAinda não há avaliações

- 33 Optional BaseDocumento1 página33 Optional Baseapi-3704830Ainda não há avaliações

- Shop-Made Router LiftDocumento6 páginasShop-Made Router LiftIlberto Fortuna100% (2)

- Camera TimelineDocumento1 páginaCamera Timelineapi-278315005Ainda não há avaliações

- Pfaff Hobby 1122/1132 Sewing Machine Instruction ManualDocumento56 páginasPfaff Hobby 1122/1132 Sewing Machine Instruction ManualiliiexpugnansAinda não há avaliações

- Ostara the Spring Fairy BastetartDocumento30 páginasOstara the Spring Fairy BastetartMarisaSonne100% (1)

- Meghalaya Shawl, Chhattisgarh's Dhokra Art, Telangana Bidri ArtDocumento2 páginasMeghalaya Shawl, Chhattisgarh's Dhokra Art, Telangana Bidri ArtPhono CompAinda não há avaliações

- Pilani Campus: Practice, EDD, BITS PilaniDocumento3 páginasPilani Campus: Practice, EDD, BITS PilaniRitik GuptaAinda não há avaliações

- LED Infinity Cube End TableDocumento23 páginasLED Infinity Cube End TableEldglay da Silva DomingosAinda não há avaliações

- Bräcker Fibra Larga Cursores y ArosDocumento25 páginasBräcker Fibra Larga Cursores y ArosAna Belén Herencia UrquizoAinda não há avaliações

- Sharp ChiselDocumento1 páginaSharp ChiselAnonymous xEKsRmtjOAinda não há avaliações

- HDPE Fabrication Guide Rev B 2013.01 2Documento18 páginasHDPE Fabrication Guide Rev B 2013.01 2free4bruceAinda não há avaliações

- Milling & TurningDocumento31 páginasMilling & TurningSils De SabuAinda não há avaliações

- Alternating Cellini Spiral Bead BraceletDocumento18 páginasAlternating Cellini Spiral Bead Braceletcmcelhinney_castro100% (1)

- 1 Workshop For Tech Voc HeadsDocumento154 páginas1 Workshop For Tech Voc HeadsArvie B. MaculAinda não há avaliações

- Wsc2013 Tp07 TW m1 Iso A ActualDocumento1 páginaWsc2013 Tp07 TW m1 Iso A ActualJorge cortesAinda não há avaliações

- Coatings 101 - Understanding wood coating types and usesDocumento26 páginasCoatings 101 - Understanding wood coating types and usesNo NameAinda não há avaliações

- Milling Machine GuideDocumento55 páginasMilling Machine GuideHirwa jean de DieuAinda não há avaliações

- Manual Drilling MachineDocumento60 páginasManual Drilling MachineAbel Aregay100% (1)

- Polymak Abrasives BrochureDocumento16 páginasPolymak Abrasives Brochureravi shankarAinda não há avaliações

- Gadar Bu EtikDocumento48 páginasGadar Bu EtikChristian Benny NathanaelAinda não há avaliações

- Contalning Dlxtures Cotton by A The Subjection: Eethod Uhen Sub-Iected The NeasuredDocumento4 páginasContalning Dlxtures Cotton by A The Subjection: Eethod Uhen Sub-Iected The NeasuredviverefeliceAinda não há avaliações