Escolar Documentos

Profissional Documentos

Cultura Documentos

Jeeves Econo Lift 100 20x20x30 Front Back PDF

Enviado por

Leo RetilusTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jeeves Econo Lift 100 20x20x30 Front Back PDF

Enviado por

Leo RetilusDireitos autorais:

Formatos disponíveis

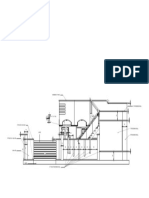

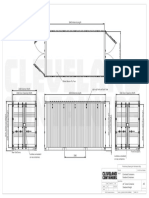

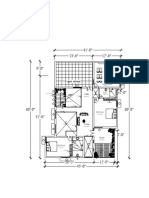

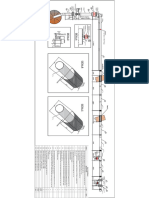

27-½”

Finished Hoistway

1 ½” 21” 5" Sheetrock inside and

Outside Cab

Clearance

Overhead

outside hoistway

6" Min.

20"

Inside Cab

1-½”

2nd Level

32-½”

12"

Door Height

May be at

floor level

Finished Hoistway

Outside Cab

Inside Cab

24”

21”

20”

Center Line

Total Travel

2x12 Planks

27' Max.

between 2x4 studs

12"

1st Level

1-½”

32-½”

2x4 construction

Door Interlock 15-½”

Electrical

Door Height

Disconnect Door may be at floor level 22 ¼”

24" Min.

if machine room or an Rough Opening

Access overhead motor is used.

Door Customer:

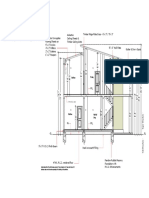

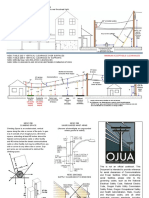

HOISTWAY: The hoistway must be in accordance with “Safety Code for Elevators and

Escalators” (ASME A17.1) and all state and local codes.

PLUMB HOISTWAY: Due to close running clearances owner/agent must ensure that

hoistway is plumb, and square and is in accordance with dimensions on these drawings. Project:

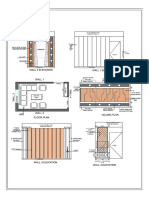

REINFORCED WALL: The rail wall must be reinforced with double 2x12 planks as shown

in the drawings. The machine and rail system requires these 2x12 planks for support.

MACHINE ROOM: Machine room may be located within the hoistway on the bottom floor Location:

or in a closet adjacent to the hoistway (behind the rail wall). The machine room must have

a lockable access door. This door must remained locked at all times.

ECONO-LIFT 100 DUMBWAITER POWER SUPPLY: A lockable fused disconnect must be provided in accordance with local

DOORS – FRONT BACK electrical codes. The supply must be a 115V, 15A dedicated circuit. Date:

20"W x 20"D x 30"H

DOORS: Doors must meet local fire code. Interlock devices are provided and must be

100 lb. Capacity mounted to doors as directed in the installation guide.

Revision 1.1

Você também pode gostar

- Jessie Polka - Nick's Version.v4 (W Harmony)Documento4 páginasJessie Polka - Nick's Version.v4 (W Harmony)12345uAinda não há avaliações

- Electric Machines and Drives - Ned MohanDocumento3 páginasElectric Machines and Drives - Ned MohanNaveed Iqbal0% (4)

- Border 2" ThickDocumento1 páginaBorder 2" ThickMohan KumarAinda não há avaliações

- WatertowerplansDocumento1 páginaWatertowerplansJackSiedschlagAinda não há avaliações

- 1 Structural Floor Framing Plan 1 Structural Framing Base PlanDocumento1 página1 Structural Floor Framing Plan 1 Structural Framing Base PlanNeil ArmstrongAinda não há avaliações

- Office Layout Option 2Documento1 páginaOffice Layout Option 2Rajat CharayaAinda não há avaliações

- Drop ManholeDocumento1 páginaDrop ManholeorganicspolybondAinda não há avaliações

- 20ft High Cube TunnelDocumento1 página20ft High Cube Tunneladnan53Ainda não há avaliações

- Durafold Thresholds Floor Levels DrainageDocumento25 páginasDurafold Thresholds Floor Levels DrainageRoyal JadhavAinda não há avaliações

- Trad Cond Spec 8-99Documento8 páginasTrad Cond Spec 8-99Rey creeperAinda não há avaliações

- Rama Goud Opt-2Documento1 páginaRama Goud Opt-2Y.SRUJANA REDDYAinda não há avaliações

- Floor PlanDocumento1 páginaFloor PlancreamburgindiaAinda não há avaliações

- ST 3Documento1 páginaST 3Kwekwe NekoAinda não há avaliações

- Bedroom Bedroom: First Floor Plan OPT - 01Documento1 páginaBedroom Bedroom: First Floor Plan OPT - 01Shahid MughalAinda não há avaliações

- Sloo Residence Remodel: (N) Deck (N) GarageDocumento1 páginaSloo Residence Remodel: (N) Deck (N) Garageapi-19526984Ainda não há avaliações

- Bedroom Bedroom: Frist Floor Plan OPT - 02Documento1 páginaBedroom Bedroom: Frist Floor Plan OPT - 02Shahid MughalAinda não há avaliações

- Dre Voting Kiosk: Street Name, Suite Number City, State Zip Code 123.456.7890Documento2 páginasDre Voting Kiosk: Street Name, Suite Number City, State Zip Code 123.456.7890Kakoy Lagusan EcobenAinda não há avaliações

- Rama Gound Uncle Plans-Model 55Documento1 páginaRama Gound Uncle Plans-Model 55Y.SRUJANA REDDYAinda não há avaliações

- Preliminary Drawing For Information Only: Revision: Project: Do Not Scale DrawingDocumento1 páginaPreliminary Drawing For Information Only: Revision: Project: Do Not Scale Drawingadnan53Ainda não há avaliações

- UntitledDocumento1 páginaUntitledThushara SilvaAinda não há avaliações

- Subwoofer Box For Skar VD10 - Ported Box - SlotDocumento2 páginasSubwoofer Box For Skar VD10 - Ported Box - SlotMarvin RiveraAinda não há avaliações

- No Pins at Door Opening For Mud Base at Shower: House Foundation PlanDocumento1 páginaNo Pins at Door Opening For Mud Base at Shower: House Foundation PlanFabio DantasAinda não há avaliações

- 1-Ground Plan 10-17Documento1 página1-Ground Plan 10-17api-224876418Ainda não há avaliações

- సేఫ్టిక్ట్ ట్యాంకు డ్రాయింగ్Documento1 páginaసేఫ్టిక్ట్ ట్యాంకు డ్రాయింగ్maheshu78Ainda não há avaliações

- Canteen A2Documento1 páginaCanteen A2architect pavithrasivasankaranAinda não há avaliações

- The High Sierra Main Floor Plan: Head OfficeDocumento2 páginasThe High Sierra Main Floor Plan: Head OfficeHectorGabrielLinerosHenriquezAinda não há avaliações

- 507 CDocumento1 página507 ChuzefaAinda não há avaliações

- Perspective Rendering Five-12 Kitchen Design & Ceiling OptionsDocumento6 páginasPerspective Rendering Five-12 Kitchen Design & Ceiling OptionsCarla GarchiAinda não há avaliações

- TFA Flow ChartDocumento3 páginasTFA Flow Chartkrish69Ainda não há avaliações

- Produced by An Autodesk Student Version: Emergency Exit Emergency ExitDocumento1 páginaProduced by An Autodesk Student Version: Emergency Exit Emergency ExitSakthi MuruganAinda não há avaliações

- Rama Gound Opt-1Documento1 páginaRama Gound Opt-1Y.SRUJANA REDDYAinda não há avaliações

- Wall Elev - DDDocumento1 páginaWall Elev - DDHotel sapphireAinda não há avaliações

- Standards Trifold Revised 8.5x11 5 18 2016Documento2 páginasStandards Trifold Revised 8.5x11 5 18 2016ROBERTO SILVESTREAinda não há avaliações

- Kitchen Measuring GuideDocumento1 páginaKitchen Measuring Guideegmkt.adsAinda não há avaliações

- Boston Maine - Boston AlbanyDocumento1 páginaBoston Maine - Boston AlbanysdAinda não há avaliações

- Working Plan (25-11-17) - Model PDFDocumento1 páginaWorking Plan (25-11-17) - Model PDFVirendra ChavdaAinda não há avaliações

- Working Plan (25-11-17) - Model PDFDocumento1 páginaWorking Plan (25-11-17) - Model PDFVirendra ChavdaAinda não há avaliações

- Publish Drawings - COMPLETEDDocumento4 páginasPublish Drawings - COMPLETEDIngeniería CivilAinda não há avaliações

- Caladium Green Brochure 2Documento11 páginasCaladium Green Brochure 2Lucid BarodaAinda não há avaliações

- Building Section: 26G Galvanize SheetingDocumento1 páginaBuilding Section: 26G Galvanize SheetingDanny ArimaAinda não há avaliações

- Proposed DesignDocumento1 páginaProposed Designb_chethanAinda não há avaliações

- VEERA2Documento1 páginaVEERA2SindhuAinda não há avaliações

- 01 - 19th Penthouse Dubai PDFDocumento8 páginas01 - 19th Penthouse Dubai PDFm.slemanAinda não há avaliações

- LOUNGEDocumento1 páginaLOUNGEjawa42nishantAinda não há avaliações

- Battened and Ledged Door-Model PDFDocumento1 páginaBattened and Ledged Door-Model PDFUtkarsh AnandAinda não há avaliações

- GT Missions 2022Documento3 páginasGT Missions 2022Joseph DemastrieAinda não há avaliações

- Subwoofer Box Skar SDR 8 Doble - Ported Box - SlotDocumento1 páginaSubwoofer Box Skar SDR 8 Doble - Ported Box - SlotMarvin RiveraAinda não há avaliações

- Mechanic PlansDocumento4 páginasMechanic PlansSal ShamAinda não há avaliações

- Internship Exhibit Wall 2Documento1 páginaInternship Exhibit Wall 2api-384971736Ainda não há avaliações

- 29 02 24 SH-12 Preliminary Steel DetailsDocumento1 página29 02 24 SH-12 Preliminary Steel Detailsprasanth parthasarathyAinda não há avaliações

- Taraki Passand Tehreek PDFDocumento5 páginasTaraki Passand Tehreek PDFSyed Tahir Ali Shah75% (4)

- Rama Goud Opt-04Documento1 páginaRama Goud Opt-04Y.SRUJANA REDDYAinda não há avaliações

- LadderDocumento1 páginaLadderCristobal Gutierrez CarrascoAinda não há avaliações

- KJHGunbox 02Documento2 páginasKJHGunbox 02Alberto SolisAinda não há avaliações

- Crokery Storage DetailDocumento1 páginaCrokery Storage DetailSaurabh SinghAinda não há avaliações

- XYL Series e HSC Technical Brochure B 330DDocumento8 páginasXYL Series e HSC Technical Brochure B 330DbocahjeblogAinda não há avaliações

- Property Line: Lower Level - Option 1 1Documento1 páginaProperty Line: Lower Level - Option 1 1api-19526984Ainda não há avaliações

- Nhotchkiss Proj1Documento1 páginaNhotchkiss Proj1api-730308774Ainda não há avaliações

- Concept Plan-1 - 231129 - 105654Documento2 páginasConcept Plan-1 - 231129 - 105654maheedhar231gmailcomAinda não há avaliações

- Total-Ratwai Pipe Line Drawing1Documento1 páginaTotal-Ratwai Pipe Line Drawing1r.karthidbtechAinda não há avaliações

- 5 Day Course Outline of Process Safety Related TopicsDocumento3 páginas5 Day Course Outline of Process Safety Related Topicskanakarao1Ainda não há avaliações

- FTTX Technology ReportDocumento48 páginasFTTX Technology ReportanadiguptaAinda não há avaliações

- Web Designing RaviDocumento18 páginasWeb Designing RaviRavi KumarAinda não há avaliações

- Ubuntu+Server+CLI+pro+tips+ 18X 06.01.20Documento2 páginasUbuntu+Server+CLI+pro+tips+ 18X 06.01.20donna.nix100% (1)

- Blaupunkt True Wireless Earphone BTW-Lite - ManualDocumento17 páginasBlaupunkt True Wireless Earphone BTW-Lite - ManualKiran KissanAinda não há avaliações

- HR Works EssDocumento50 páginasHR Works EssSijesh ThiruthiyilAinda não há avaliações

- Internet & Web Basics Key Concepts Terry Ann Morris, Ed.DDocumento31 páginasInternet & Web Basics Key Concepts Terry Ann Morris, Ed.DDoris EsperanzaAinda não há avaliações

- Analox Sensor Technology LTD PDFDocumento2 páginasAnalox Sensor Technology LTD PDFefren.ramirez.arias9488Ainda não há avaliações

- House Guide TemplateDocumento8 páginasHouse Guide TemplatewandolyAinda não há avaliações

- Aker Wirth - Tunnel Boring Machines, Raise Boring and Full-Face Shaft Boring Machines - Mining Technology PDFDocumento2 páginasAker Wirth - Tunnel Boring Machines, Raise Boring and Full-Face Shaft Boring Machines - Mining Technology PDFFord cellAinda não há avaliações

- Datasheet External Antenna 2000 - Alpha-Con-V7Documento4 páginasDatasheet External Antenna 2000 - Alpha-Con-V7Bravemon23Ainda não há avaliações

- Bootable USBDocumento5 páginasBootable USBZvonimir BatrnekAinda não há avaliações

- 31.33.00010 31-JAN-2023 31-JAN-2023 Closed A318, A319, A320, A321, A330, ... 23-71, 31-33, 31-36, ... External QAR 3TU/2TV Installation/removalDocumento107 páginas31.33.00010 31-JAN-2023 31-JAN-2023 Closed A318, A319, A320, A321, A330, ... 23-71, 31-33, 31-36, ... External QAR 3TU/2TV Installation/removalNaixAinda não há avaliações

- Yale Smart Home Alarm Manual: Conexis L1Documento36 páginasYale Smart Home Alarm Manual: Conexis L1harari itirAinda não há avaliações

- An Efforts Estimate For Agile ProjectsDocumento11 páginasAn Efforts Estimate For Agile ProjectsflytosantyAinda não há avaliações

- EMC Symmetrix Remote Data Facility (SRDF) : Connectivity GuideDocumento150 páginasEMC Symmetrix Remote Data Facility (SRDF) : Connectivity GuidepeymanAinda não há avaliações

- Sumatif Learning Actifivity Part 1 Beserta Kunci JawabanDocumento10 páginasSumatif Learning Actifivity Part 1 Beserta Kunci JawabanFoniamanAinda não há avaliações

- Building Management Systems For Pharma, Healthcare & Life SciencesDocumento12 páginasBuilding Management Systems For Pharma, Healthcare & Life Sciencesdubaisrinivasulu100% (1)

- A5.28 and A5.18 - ER70S-GDocumento10 páginasA5.28 and A5.18 - ER70S-GSurat ButtarasriAinda não há avaliações

- Trade Agreements in Microsoft Dynamics AX 2012Documento24 páginasTrade Agreements in Microsoft Dynamics AX 2012Muawad OrabiAinda não há avaliações

- Plagarisim Report1Documento54 páginasPlagarisim Report1Maulik JainAinda não há avaliações

- Chapter Test Css g12Documento30 páginasChapter Test Css g12flash driveAinda não há avaliações

- A5 EXPERIMENT LVDT and RVDTDocumento14 páginasA5 EXPERIMENT LVDT and RVDTDuminduJayakodyAinda não há avaliações

- Xtrapower Nigeria Inverter and Battery 2021 U.S.E. Price - Feb-1Documento3 páginasXtrapower Nigeria Inverter and Battery 2021 U.S.E. Price - Feb-1Iyaka JamesAinda não há avaliações

- Rotomixx: Cost Effective and Reliable Total Stainless Batch MixersDocumento2 páginasRotomixx: Cost Effective and Reliable Total Stainless Batch MixersYusuf DabhiyaAinda não há avaliações

- ATM200 Actuators PDFDocumento8 páginasATM200 Actuators PDFMiguel ComprésAinda não há avaliações

- ZTE ZXSDR R8882 Product DescriptionDocumento23 páginasZTE ZXSDR R8882 Product Descriptionrdmiguel_198360% (1)

- Lenovo Yoga Book With Windows SWSG en FR Es-Us v1.1 201608Documento48 páginasLenovo Yoga Book With Windows SWSG en FR Es-Us v1.1 201608Jose David Sierra LugoAinda não há avaliações

- Python Class ConceptsDocumento16 páginasPython Class ConceptsPhoenix Liebe JeffAinda não há avaliações