Escolar Documentos

Profissional Documentos

Cultura Documentos

Automatic Detection and Sorting of Products

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Automatic Detection and Sorting of Products

Direitos autorais:

Formatos disponíveis

Novateur Publication’s

INTERNATIONAL JOURNAL OF INNOVATIONS IN ENGINEERING RESEARCH AND TECHNOLOGY [IJIERT] ISSN: 2394-3696

Conference Proceedings of TECHNO-2K17 (Technical Symposium)

AUTOMATIC DETECTION AND SORTING OF PRODUCTS

AKSHAY VARPE

Department of E & TC Engineering, Marathwada Mitra Mandal's College of Engineering, Pune, India

akshayvarpe82@gmail.com

SNEHAL MARNE

Department of E & TC Engineering, Marathwada Mitra Mandal's College of Engineering, Pune, India

snehalmarne517@gmail.com

MANASI MORYE

Department of E & TC Engineering, Marathwada Mitra Mandal's College of Engineering, Pune, India

mansimorye29@gmail.com

DR. MANISHA JADHAV

Department of E & TC Engineering, Marathwada Mitra Mandal's College of Engineering, Pune, India

manishajadhav@mmcoe.edu.in

ABSTRACT

In manufacturing industries, there is a need of sorting objects. Objects may have different shapes and colors or it may be of same

shape and color. Thus, different objects and different parameters require different type of processing. Aim of this paper is to

classify objects using different image processing algorithms based on the parameters like color and shape. The input for the

system will be an image and then processed for detecting the color or shape and accordingly the products will be further sorted

using embedded algorithms.

KEYWORDS

Digital Image Processing, Embedded System, Conveyor Belt, Embedded Vision, Open Cv, Industrial Automation, Raspberry-pi,

PIC microcontroller, Infrared sensors (IR), color detection, shape detection

INTRODUCTION

In many packaging industries, object counting and sorting is the most important task that needs to be done at final stage. Manual

sorting is the traditional approach which is being performed by human operators in industries that involves visual inspection. This

approach is monotonous, time-consuming, slow and non-consistent. It has become difficult to hire workers who will perform such

tedious task. Therefore, the system is designed and implemented where automatic technique for identifying and sorting the

products using Embedded Vision is done. In recent years, the importance of automation has been increased subsequently with the

growth of industry. For precision and reduced time, output and accuracy of industrial robots is developed. In modern times with

the evolution of robotic industry image processing in many industrial processes has proven its prevalence and dominance [2].

The aim of our proposed system is to test the manufactured component by an automated way instead of testing it manually. It is

aimed to reduce human effort, at the same time increase the productivity and accuracy levels that cannot be achieved with manual

operations. Therefore, products passing over the conveyor will be detected using camera and the processing on that will be done

using Raspberry-Pi, that whether the object is A or B; Raspberry will give signal to the Microcontroller and then the products will

be sorted accordingly. Number of products will be counted after being sorted and the quantity will be displayed. The proposed

system is designed as a low cost solution for Small-Scale Industries.

RELATED WORK

As part of our pre-study, an elaborate literature survey has been conducted. The literature survey presents an overview on the

Automatic Detection and Sorting Mechanism. After analyzing what systems published in the journals, we presented our ideas

which were focused on improving the existing system and replacing the complex programmable logic controllers[PLC] by means

of computer vision technology. In many processes the human eye is a key factor in sorting and inspection of all kind of objects. In

most of these processes vision systems offer possibilities for more efficiency, faster production and better control over product

quality. Furthermore, vision systems enable improvement of processes that have already been automated otherwise.

Embedded/Machine vision is a young discipline in the field of science and technology. It has emerged as a useful industrial tool

for about 25 years and is growing at a higher speed. The applications of embedded vision in industries have been typically seen in

measurements, counting, quality control, object sorting, and robotic guidance. It has become a yielding tool in product inspection

and analysis, because it reduces cost, effort, and time with a significant level of accuracy and reliability. With the recent

advancement in technology, embedded vision can be applied to extract different properties of the objects such as their dimensions,

areas, etc. The application of machine vision has been seen in medical, industrial, and security fields [3].

Open-CV which is a computer vision library used extensively in the industry. We use CPP programming language as it is easy to

use and has sufficient speed for our task[7]. Raspberry Pi 3 is a low cost single board computer which is powerful enough to do

computer vision at real time based on ARM Cortex-A53 1.2GHz/32-bit quad-core[9]. A simple USB camera which is supported

by Raspberry Pi is used to capture the real-time image.With recent advancements in technology highly efficient semiconductor

Organized by Department of Electronics & Telecommunication,

Marathwada Mitra Mandal's College of Engineering , Karvenagar, Pune-52

45 | P a g e

Novateur Publication’s

INTERNATIONAL JOURNAL OF INNOVATIONS IN ENGINEERING RESEARCH AND TECHNOLOGY [IJIERT] ISSN: 2394-3696

Conference Proceedings of TECHNO-2K17 (Technical Symposium)

ICs were developed , based on these advances in IC technology Microchip provides 8-bit,16-bit and 32-bit microcontrollers with

powerful architecture and complete documentation [8].

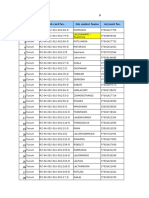

BLOCK DIAGRAM

Figure 1 Block Diagram

The detailed block diagram of proposed system is shown in figure 1.

The Camera is used for image/video acquisition. The video is acquired and then is being processed frame by frame using

various Image processing algorithms.

Image acquired is given to Raspberry-Pi and Open-CV is used as an image processing platform. The Open-CV code written

in CPP is trained to examine the parameters like shape and color for identification of products [7].

The Raspberry-Pi will generate the corresponding signals according to the image data interpreted by Open-CV. These signals

are then given to the controller which further handles the sorting mechanism.

Connected conveyor mechanism is the system used for sorting. These conveyors are driven through DC motors and the

motors are controlled by the PIC controller.

The controller will also perform the operation of counting the number of products and displaying the appropriate count on

LCD [10].

SYSTEM FLOWCHART

Fig 2 System Flowchart

Organized by Department of Electronics & Telecommunication,

Marathwada Mitra Mandal's College of Engineering , Karvenagar, Pune-52

46 | P a g e

Novateur Publication’s

INTERNATIONAL JOURNAL OF INNOVATIONS IN ENGINEERING RESEARCH AND TECHNOLOGY [IJIERT] ISSN: 2394-3696

Conference Proceedings of TECHNO-2K17 (Technical Symposium)

Step 1: Start

Step 2: Turn on the camera and acquire image

Step 3: Image is being processed in Open-CV. Color detection is processed by using color thresholding and shape detection is

done using contour mapping. The objects are differentiated as objects A, B and C

Step 4: Data of each object is sent to microcontroller through UART

Step 5: Motors are controlled using microcontroller and according to the object the conveyors are controlled and the objects are

being sorted and further they are counted at the output.

SPECIFICATION OF THE HARDWARE AND SOFTWARE SYSTEM

A. Camera: -Camera used for the system is a Logitech Webcam B525 with HD video quality of 1280 x 720 pixels consisting of

additional features as Autofocus and Built-in stereo mic.

B. DC Motor:-DC motor is a rotary actuator which has various applications in industry. DC motor is specified by its RPM and

torque (kg/cm). For this system, 300 RPM and 3kg/cm torque motor is used to bear load. DC motor works on direct current.

C. PIC Controller:-PIC microcontroller P18f4520 developed by Microchip is a 8 bit microcontroller. The MP-lab IDE is used for

programming the PIC. It supports various programming techniques like C language and Assembly language programming

[8].

D. Infrared Sensors (IR) :-IR sensor is a combination of IR LED and Photodiode followed by simple comparator circuit using

op-amp 358. It can efficiently detect any object passing the beam of IR-LED; the beam is reflected by the object and strikes

the photodiode further generating a high output signal.

E. Raspberry-Pi:-Raspberry-pi 3 uses a Quad Core 1.2GHz Broadcom BCM2837 64bit CPU with 1GB RAM. It also consists of

Wi-Fi and Bluetooth Low Energy (BLE) on board 40-pin Extended GPIO along with 4x USB 2 ports, 4 Pole stereo output,

composite video port, full size HDMI, Micro SD port for loading the operating system and storing data [9].

F. Motor Driver:-In order to control the DC motor bi-directionally and initiate start and emergency stop for conveyor system

motor drivers are deployed. Motor driver also provide easy control over the RPM of motor making it easy to synchronise the

motors to required speed. Motor driver L298N can provide 1.5Amps continuous current with precise speed and direction

control is preferred for the current system design.

G. Power Supply:-12 V, 5 amps for motors as each motor draw 1 amp of current and 5 Vis needed for the controller and Infrared

sensors (IR).

EXPERMENTAION

Experiments were performed using raspberry-pi in open-cv, for shape detection template matching, edge detection and contour

mapping many such algorithms were performed. Out of these contour mapping is finalized as it gives higher efficiency. Color

detection was performed using template matching, object tracking and color thresholding and finalized color thresholding out of

these algorithms. Raspberry-pi and PIC communication is done using UART. Motor driver was designed using MOSFET,

however heating of MOSFET due to improper switching resulted into failure of the system. Then motor driver design was

finalized using L298N IC.

RESULTS

The final results were satisfactory, color detection using color thresholding and shape detection using contour mapping gives 88%

accuracy. Sorting mechanism is made more efficient by using IR sensors and counting of objects is done using the same.

CONCLUSION

According to the design and algorithms proposed in the experimentation, we come to a conclusion that detection of products using

Digital Image Processing and sorting them which are passing over conveyor using a controller. The products are sorted with high

correctness, good repeatability and high efficiency. Using Digital Image Processing in the system, we can detect the products

based on shape and color. Further the products are sorted according to its type into different conveyors for packaging. The main

advantage of this system is to reduce human efforts and increase productivity by using advanced technologies such as embedded

vision which is a combination of Digital Image Processing and Embedded systems. For future scope in this system the connected

conveyor system can be replaced by a robotic arm. The products can be distinguished with different additional characteristics such

as texture, size, etc.

ACKNOWLEDGMENT

We are having great pleasure presenting our paper „Automatic detection and sorting of products‟. We have tried our best to cover

all the required details related to the topic. Sincere co-operation and constant efforts of all team members have resulted into the

successful completion of this project based publication. We would like to express our gratitude to Dr. Manisha Jadhav, who

guided us throughout the groundwork of this paper. Her inputs and suggestions helped us to improve this paper. We thank her for

providing us valuable suggestions and track of the topic. We would also like to thank our friends for reviewing the paper,

highlighting the mistakes and giving valuable inputs.

Organized by Department of Electronics & Telecommunication,

Marathwada Mitra Mandal's College of Engineering , Karvenagar, Pune-52

47 | P a g e

Novateur Publication’s

INTERNATIONAL JOURNAL OF INNOVATIONS IN ENGINEERING RESEARCH AND TECHNOLOGY [IJIERT] ISSN: 2394-3696

Conference Proceedings of TECHNO-2K17 (Technical Symposium)

REFERENCES

1) Amir Deshmukh, “Design and development of automatic conveyor controlling system for sorting of component on color

basis”, International Journal of Science and Research (IJSR), volume 5, issue 2 February 2016.

2) Nikam Devendra, “Automation of object sorting using an industrial roboarm and MATLAB based image processing”,

International Journal of Emerging Technology and Advanced Engineering,volume 5, issue 2 February 2015.

3) Bikarna Pokharel, “Machine vision and object sorting”, bachelor‟s thesis degree programme in automation engineering

valkeakoski, May 2013,pp:14-17.

4) Avadhoot R.Telepatil, “colour object counting and sorting mechanism using image processing approach”, International

Journal of Modern Trends in Engineering and Research (IJMTER) volume 02, issue 03 March - 2015.

5) Shriya.M.Kumar, “Low cost automation for sorting of objects on conveyor belt” International Journal of Innovative

Research in Science, Engineering and Technology. Vol. 5, Special Issue 10, May 2016.

6) Rahul Kumar, “Object detection and recognition for a pick and place robot”, Conference Paper· November 2014, Research

Gate.

7) www.opencv.org

8) www.microchip.com

9) www.raspberrypi.org

10) Muhammad Ali Mazidi, PIC microcontroller, Pearson, 3rd edition.

Organized by Department of Electronics & Telecommunication,

Marathwada Mitra Mandal's College of Engineering , Karvenagar, Pune-52

48 | P a g e

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Zero Voltage Switching ConvertersDocumento7 páginasZero Voltage Switching ConvertersIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Review of Heat Transfer Parameters of Serrated Plate Fin Heat Exchanger For Different MaterialsDocumento5 páginasReview of Heat Transfer Parameters of Serrated Plate Fin Heat Exchanger For Different MaterialsIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- FEA Based Comparative Analysis of Tube Drawing ProcessDocumento11 páginasFEA Based Comparative Analysis of Tube Drawing ProcessIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Design of Epi-Cyclic Internal Gear Pump For Maximum DischargeDocumento10 páginasDesign of Epi-Cyclic Internal Gear Pump For Maximum DischargeIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- A Review of Restructured Power Development and Reform Programme in IndiaDocumento7 páginasA Review of Restructured Power Development and Reform Programme in IndiaIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Review On Extraction and Isolation of Cashew Nut Shell LiquidDocumento8 páginasReview On Extraction and Isolation of Cashew Nut Shell LiquidIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- 3D Flow Analysis of Heat Transfer in A Scraped Surface Heat Exchanger (Sshe)Documento8 páginas3D Flow Analysis of Heat Transfer in A Scraped Surface Heat Exchanger (Sshe)IJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Review of Heat Transfer Parameters Using Internal Threaded Pipe Fitted With Inserts of Different MaterialsDocumento6 páginasReview of Heat Transfer Parameters Using Internal Threaded Pipe Fitted With Inserts of Different MaterialsIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Identification of Coulomb, Viscous and Particle Damping Parameters From The Response of SDOF Harmonically Forced Linear OscillatorDocumento10 páginasIdentification of Coulomb, Viscous and Particle Damping Parameters From The Response of SDOF Harmonically Forced Linear OscillatorIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- P-Q Theory Based Design of Unified Power Quality Conditioner For Tranquillization of Voltage and Current Unbalance Under Non Linear Load Condition.Documento6 páginasP-Q Theory Based Design of Unified Power Quality Conditioner For Tranquillization of Voltage and Current Unbalance Under Non Linear Load Condition.IJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Zero Voltage Switching ConvertersDocumento8 páginasZero Voltage Switching ConvertersIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Control of Grid Connected Inverter System For Sinusoidal Current Injection With Improved PerformanceDocumento10 páginasControl of Grid Connected Inverter System For Sinusoidal Current Injection With Improved PerformanceIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Failure Analysis of Buttress, Acme and Modified Square Threaded Mild Steel (Is2062) Tie RodsDocumento7 páginasFailure Analysis of Buttress, Acme and Modified Square Threaded Mild Steel (Is2062) Tie RodsIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Review of Plagiarism Detection and Control & Copyrights in IndiaDocumento8 páginasReview of Plagiarism Detection and Control & Copyrights in IndiaIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Health Monitoring KIOSK: An Effective System For Rural Health ManagementDocumento4 páginasHealth Monitoring KIOSK: An Effective System For Rural Health ManagementIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Review of Hooke and Jeeves MethodDocumento14 páginasReview of Hooke and Jeeves MethodaruatscribdAinda não há avaliações

- Effect of CO2 Sequestration On Soil Liquefaction in Geological PitsDocumento9 páginasEffect of CO2 Sequestration On Soil Liquefaction in Geological PitsIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Study On Different Human Emotions Using Back Propagation MethodDocumento6 páginasStudy On Different Human Emotions Using Back Propagation MethodIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Quasi-Z-Source Inverter For Photovoltaic Power Generation SystemsDocumento8 páginasQuasi-Z-Source Inverter For Photovoltaic Power Generation SystemsIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Offline Handwritten Signature Verification Using Neural NetworkDocumento5 páginasOffline Handwritten Signature Verification Using Neural NetworkIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Cloud Computing For Supply Chain ManagementDocumento9 páginasCloud Computing For Supply Chain ManagementIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Overview of Renewable Energy Sources in The Perspective of Carbon Foot Printing ReductionDocumento4 páginasOverview of Renewable Energy Sources in The Perspective of Carbon Foot Printing ReductionIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Review of Scheffler ReflectorDocumento5 páginasReview of Scheffler ReflectorIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Implementation of Intelligent Cap With Drowsy Detection and Vehicle MonitoringDocumento8 páginasImplementation of Intelligent Cap With Drowsy Detection and Vehicle MonitoringIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Applicability of Hooke's and Jeeves Direct Search Solution Method To Metal Cutting (Turning) Operation.Documento9 páginasApplicability of Hooke's and Jeeves Direct Search Solution Method To Metal Cutting (Turning) Operation.IJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Haptic Gloves Controlled Robotic Arm Using MEMS AccelerometerDocumento5 páginasHaptic Gloves Controlled Robotic Arm Using MEMS AccelerometerIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Fuzzy Logic Modeling of Heat Transfer in A Double Pipe Heat Exchanger With Wavy (Corrugated) Twisted Tape InsertsDocumento8 páginasFuzzy Logic Modeling of Heat Transfer in A Double Pipe Heat Exchanger With Wavy (Corrugated) Twisted Tape InsertsIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Intelligent Vehicle Using Embedded SystemDocumento5 páginasIntelligent Vehicle Using Embedded SystemIJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Optimization and Process Parameters of CNC End Milling For Aluminum Alloy 6082Documento6 páginasOptimization and Process Parameters of CNC End Milling For Aluminum Alloy 6082IJIERT-International Journal of Innovations in Engineering Research and TechnologyAinda não há avaliações

- Information Leaflet: 1. Introduction To PieasDocumento4 páginasInformation Leaflet: 1. Introduction To Pieascensored126Ainda não há avaliações

- MGT 162Documento2 páginasMGT 162Myra Choyy100% (1)

- AeroDocumento27 páginasAeroBALAKRISHNANAinda não há avaliações

- Dispersant Manual WebDocumento108 páginasDispersant Manual Webcamilinrodriguezzzz100% (1)

- EMI EMC Project ReportDocumento55 páginasEMI EMC Project ReportAshish Agarwal80% (5)

- Computer Reviewer For Grade 6Documento4 páginasComputer Reviewer For Grade 6Cyril DaguilAinda não há avaliações

- Exercises 1 FinalDocumento2 páginasExercises 1 FinalRemalyn Quinay CasemAinda não há avaliações

- Rahul Soni BiodataDocumento2 páginasRahul Soni BiodataRahul SoniAinda não há avaliações

- Intro To Computing SyllabusDocumento7 páginasIntro To Computing SyllabusAireen Rose Rabino ManguiranAinda não há avaliações

- Heidenhain MotorsDocumento44 páginasHeidenhain MotorsmarhiAinda não há avaliações

- 0003-MI20-00S1-0031 Topside Paint Color Scheme PDFDocumento11 páginas0003-MI20-00S1-0031 Topside Paint Color Scheme PDFSobariandi AndiAinda não há avaliações

- Workbook Answer Key Unit 9 Useful Stuff - 59cc01951723dd7c77f5bac7 PDFDocumento2 páginasWorkbook Answer Key Unit 9 Useful Stuff - 59cc01951723dd7c77f5bac7 PDFarielveron50% (2)

- Nift Panchkula Thesis Gaurav Bajaj 2009 Uar 646Documento10 páginasNift Panchkula Thesis Gaurav Bajaj 2009 Uar 646vedahiAinda não há avaliações

- YALE (C878) GDP135VX LIFT TRUCK Service Repair Manual PDFDocumento20 páginasYALE (C878) GDP135VX LIFT TRUCK Service Repair Manual PDFfjskekdmmemAinda não há avaliações

- Perdele Economic B 2VVDocumento4 páginasPerdele Economic B 2VVakitainupufAinda não há avaliações

- Validation Protocol For Efficacy of Chemical DisinfectantsDocumento8 páginasValidation Protocol For Efficacy of Chemical DisinfectantsMohamed KamalAinda não há avaliações

- The Power of Slope SpectrosDocumento2 páginasThe Power of Slope SpectrosJohn SiricoAinda não há avaliações

- Pulley Groove Dimensions and SelectionDocumento1 páginaPulley Groove Dimensions and Selectionandysupa100% (1)

- GemDocumento23 páginasGemMukesh KumarAinda não há avaliações

- Iris - International Railway Industry StandardDocumento17 páginasIris - International Railway Industry StandardDavid P MAinda não há avaliações

- Kode Simbol Rate TVDocumento10 páginasKode Simbol Rate TVAndri PAinda não há avaliações

- Tuirum Adhaar Update Tur ListDocumento4 páginasTuirum Adhaar Update Tur ListLalthlamuana MuanaAinda não há avaliações

- Pressostato SUCO - 0159Documento3 páginasPressostato SUCO - 0159Hugo Lemos ArthusoAinda não há avaliações

- UNIC Jakarta Internship ApplicationDocumento4 páginasUNIC Jakarta Internship ApplicationMuhammad IkhsanAinda não há avaliações

- Gitlab CICDDocumento15 páginasGitlab CICDdeepak bansal100% (1)

- Ls Pu BackgroundDocumento5 páginasLs Pu BackgroundRolando Cruzada Jr.Ainda não há avaliações

- CP R77.20 EndpointSecurity AdminGuideDocumento168 páginasCP R77.20 EndpointSecurity AdminGuideMSAinda não há avaliações

- Beeman Gs 1000 ManualDocumento4 páginasBeeman Gs 1000 Manualanbsc2100% (1)

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocumento14 páginasWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraAinda não há avaliações

- SMILE System For 2d 3d DSMC ComputationDocumento6 páginasSMILE System For 2d 3d DSMC ComputationchanmyaAinda não há avaliações