Escolar Documentos

Profissional Documentos

Cultura Documentos

Common Rail Crs3 Con 2000 A 2500 Bard y Piezoelectrico

Enviado por

Ber Honza0 notas0% acharam este documento útil (0 voto)

100 visualizações2 páginasBOSCH Common Rail Systems CRS3 with

2,000 to 2,500 bar and piezo injectors

Título original

Common Rail Crs3 Con 2000 a 2500 Bard y Piezoelectrico

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoBOSCH Common Rail Systems CRS3 with

2,000 to 2,500 bar and piezo injectors

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

100 visualizações2 páginasCommon Rail Crs3 Con 2000 A 2500 Bard y Piezoelectrico

Enviado por

Ber HonzaBOSCH Common Rail Systems CRS3 with

2,000 to 2,500 bar and piezo injectors

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

Diesel Systems

Common Rail Systems CRS3 with

2,000 to 2,500 bar and piezo injectors

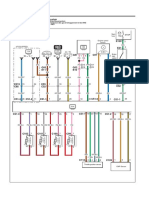

Common Rail System CRS3-20/-25 Fuel consumption is an important economic factor

for the market success of a vehicle; the higher the

mileage, the more so. Emissions, operating noise

Pressure Rail press. and engine power characteristics are also important.

control valve Rail sensor

The modern Common Rail Systems CRS3-20 (with

2,000 bar) and CRS3-25 (with 2,500 bar system

High-

pressure pressure) allow engines to be designed with ideal

pump

properties profiles thanks to their piezo injectors.

Actu- Sensors Piezo

Fuel filter ators injector

Varying fuel qualities are a challenge for every

Electric pre-

EDC

Return line pressure injection system. With the robust piezo actuator the

supply pump El. fuel pump pressure

Pre-filter

T High pressure injectors of the CRS3-20/-25 are perfectly suited.

Return line pressure

Tank Electrical line Compared with a solenoid, the power of the piezo

actuator is about ten times as high. This means it is

less susceptible to small particle contamination in

Customer benefits the fuel.

▶▶High mileage with stable injection quantity

▶▶Very robust system, even for critical fuel CRI3-20 and -25 piezo injectors are benchmarks

qualities regarding minimum pilot-injection quantity, fast

▶▶Efficient and versatile due to modular system succession of injections and volume stability over

design: for engines with 4 to 12 cylinders the lifetime.

▶▶Reduced emissions and combustion noise

due to reduced hydraulic flow rate Since the piezo actuator is integrated into the

▶▶Efficient and fuel-saving in part due to injector body, piezo injectors are slim and need

start/stop compatibility less installation space than solenoid injectors.

▶▶Many years of system experience

▶▶Increased flexibility for basic engine design Possible applications

and application of exhaust-gas treatment CRS3-20 and CRS3-25 are used in the highest-

▶▶CRS3-20: high hydraulic efficiency due to injec- performance passenger cars and light-duty vehicles.

tors without permanent leakage which leads

to lower fuel temperature

Diesel Systems | Common Rail Systems CRS3 with 2,000 to 2,500 bar and piezo injectors

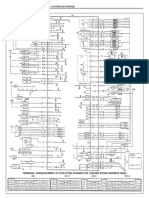

Technical features System design and function

CRS3-20 CRS3-25 The piezo actuator delivers multiple injections

Engine cylinders 4–12 4–12 with minimal intervals. The interaction between

Max. system pressure 2,000 bar 2,500 bar the actuator and the nozzle needle helps to

Max. number of injections 8 8 achieve shortest possible reaction times.

Min. injection separation time 200 µs 150 µS

Operating voltage 12 V/24 V 12 V/24 V Optimized injector characteristics without plateaus

Emission target Euro 5, Euro 6, Euro 5, Euro 6, allow fuel quantity correction over lifetime by means

T2B5, US10, T2B5, US10, of learning functions. These are implemented as

JPNLT JPNLT

software in the electronic control unit.

Service life PC/LD 300,000/ 300,000/

400,000 km 400,000 km

The system consists of a high-pressure pump, the

Applications PC, LD PC, LD

high-pressure rail, an injector for each engine cylinder,

and the electronic control.

System components CRS3-20/-25

Thanks to their high switching speed the CRI3-20/-25

1 2 piezo injectors enable very small pilot-injection

quantities. Because reduced hydraulic power loss

reduces fuel temperature, no additional fuel cooling

is required.

The HFR-20/-25 high-pressure rails feature drilled

throttles, a rail pressure sensor and a pressure-control

valve.

3

The CP4 high-pressure pump’s high hydraulic efficiency

4 leads to a high delivery rate, easily covering all require-

1 CP4 high-pressure pump ments up to light-duty applications.

2 CRI3-20, CRI3-25 piezo injector

3 HFR-20, HFR-25 high-pressure rail

Outlook

4 EDC17 control unit

Bosch engineers are already involved in the further

development of this system, e.g. towards even higher

pressure levels.

Bosch: Automotive competence from a single source

Comprehensive range of services and know-how Robert Bosch GmbH

Diesel Systems

System and network competence

Postfach 30 02 20

Innovator and technology leader 70442 Stuttgart

Germany

Warrantor for quality and dependability Fax: +49 711 811-45090

diesel@bosch.com

Worldwide presence

www.future-with-diesel.com

Universal partner

Printed in Germany

292000P115-C/CCA-201309-En

© Robert Bosch GmbH 2013. All rights reserved, also regarding any disposal, exploitation, reproduction,

editing, distribution, as well as in the event of applications for industrial property rights

Você também pode gostar

- Common Rail Systems CRS2 With 1,600 To 2,000 Bar and Solenoid ...Documento2 páginasCommon Rail Systems CRS2 With 1,600 To 2,000 Bar and Solenoid ...Mihai AncutaAinda não há avaliações

- 8096CRSN3 25 - Factsheet e PDFDocumento2 páginas8096CRSN3 25 - Factsheet e PDFLuis MirandaAinda não há avaliações

- Bosch Crsn3Documento2 páginasBosch Crsn3Johmir TorresAinda não há avaliações

- High-Pressure Pump HDP5Documento2 páginasHigh-Pressure Pump HDP5RICHARDAinda não há avaliações

- Sensor Training PDFDocumento35 páginasSensor Training PDFBudes DanielAinda não há avaliações

- Parts VDO 2008Documento30 páginasParts VDO 2008Edinson Ariel Chavarro QuinteroAinda não há avaliações

- Piezo Injector For Common-Rail Systems: Low Fuel ConsumptionDocumento1 páginaPiezo Injector For Common-Rail Systems: Low Fuel Consumptionalmia tronicsAinda não há avaliações

- Piezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingDocumento10 páginasPiezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingZdravko DudicAinda não há avaliações

- The Common Rail Diesel Injection System Explained: Technical FeaturesDocumento3 páginasThe Common Rail Diesel Injection System Explained: Technical FeaturesDejan MihajlovicAinda não há avaliações

- SRN Brochure UK 03 Aprile18Documento84 páginasSRN Brochure UK 03 Aprile18Marco100% (1)

- Shim Catalogue To PrintDocumento32 páginasShim Catalogue To PrintAkram SiddigAinda não há avaliações

- CRSN4 25Documento2 páginasCRSN4 25Fernando GarcíaAinda não há avaliações

- Advanced Fuel Injection Technology for Future Diesel EnginesDocumento17 páginasAdvanced Fuel Injection Technology for Future Diesel EnginesDan SerbAinda não há avaliações

- Pizzo InjiDocumento3 páginasPizzo InjiprakashAinda não há avaliações

- Protocolo EPS 200: Prueba Inyector Common RailDocumento2 páginasProtocolo EPS 200: Prueba Inyector Common RailMauricio Navarro santanaAinda não há avaliações

- Catalog 2019 Jyhy Diesel PDFDocumento10 páginasCatalog 2019 Jyhy Diesel PDFVerii WongAinda não há avaliações

- CZ 2012 2013 DieselDocumento14 páginasCZ 2012 2013 DieselSoeAyeAinda não há avaliações

- Restore Piezo Stacks with RegenerationDocumento3 páginasRestore Piezo Stacks with RegenerationAbraaj-TTSAinda não há avaliações

- FORD Puma Common Rail SystemDocumento18 páginasFORD Puma Common Rail Systemtomek luciwAinda não há avaliações

- vp44 Pump Detail Schematic PDF FreeDocumento7 páginasvp44 Pump Detail Schematic PDF Freepablo pérezAinda não há avaliações

- Carbonzapp Products (Hires)Documento4 páginasCarbonzapp Products (Hires)MUSTAPHA LAABIDAinda não há avaliações

- Dieselland - Catalog - Eng New 2021 MakoDocumento290 páginasDieselland - Catalog - Eng New 2021 MakoBoban VelinovskiAinda não há avaliações

- Control Common Rail Injectors & Test Electrical PartsDocumento36 páginasControl Common Rail Injectors & Test Electrical PartsJoshua HicksAinda não há avaliações

- CRS3 3Documento18 páginasCRS3 3prueba100% (1)

- 2010-08 CR ContinentalDocumento3 páginas2010-08 CR Continentalrevisione turbine turbo turbocompressoriAinda não há avaliações

- Common Rail Direct InjectionDocumento9 páginasCommon Rail Direct InjectionJoe SparksAinda não há avaliações

- Manual Diesel Test BenchDocumento18 páginasManual Diesel Test BenchMelchor EstradaAinda não há avaliações

- Bomba de Alta Presion Denso HP2 PDFDocumento4 páginasBomba de Alta Presion Denso HP2 PDFDiegoD'AmbrosioAinda não há avaliações

- Covec-F Harness and Connector Installation Standards: 1. Applicable Pump Assembly Part NumbersDocumento13 páginasCovec-F Harness and Connector Installation Standards: 1. Applicable Pump Assembly Part NumbersAlexander NeyraAinda não há avaliações

- R2SDocumento31 páginasR2SdhruvaklAinda não há avaliações

- Vdo Diesel Brochure en 2016 AnsichtDocumento12 páginasVdo Diesel Brochure en 2016 AnsichtSérgio marquesAinda não há avaliações

- 2009-03 CR Injector SparesDocumento10 páginas2009-03 CR Injector SparesAspro Brazil Se IglesiasAinda não há avaliações

- DieselBrochure 10-2012Documento68 páginasDieselBrochure 10-2012enriAinda não há avaliações

- DITEX TECHNOLOGIES injection equipment test reportDocumento1 páginaDITEX TECHNOLOGIES injection equipment test reportIdea electro diesel sasAinda não há avaliações

- Bosch Injector Repair KitsDocumento25 páginasBosch Injector Repair KitsRespaldo GregoryAinda não há avaliações

- Injection Pump Test Bench ManualDocumento15 páginasInjection Pump Test Bench ManualChew LayAinda não há avaliações

- Diesel Specialist Solutions: Crdi - CRP - Eui - Eup - HeuiDocumento8 páginasDiesel Specialist Solutions: Crdi - CRP - Eui - Eup - Heuiayaz100% (1)

- SABRE BASE OPTIONS AND PARTSDocumento10 páginasSABRE BASE OPTIONS AND PARTSHong Seok ChoiAinda não há avaliações

- DENSO Diesel Common Rail Sell Sheet D1070 PDFDocumento2 páginasDENSO Diesel Common Rail Sell Sheet D1070 PDFCesar Bayes RamosAinda não há avaliações

- Service Manual: Common Rail System For NISSAN YD1-K2 Type EngineDocumento40 páginasService Manual: Common Rail System For NISSAN YD1-K2 Type EngineMecanica GeneralAinda não há avaliações

- Bosch ESI (Tronic) 1Q.2015 News PDFDocumento2 páginasBosch ESI (Tronic) 1Q.2015 News PDFAdrián Molina MiguelAinda não há avaliações

- Catalogue 2016 EngDocumento256 páginasCatalogue 2016 Engdiagnopro100% (2)

- Bosch Inline Piezo Injector Delivery PlanDocumento9 páginasBosch Inline Piezo Injector Delivery PlandieseldvAinda não há avaliações

- Toberas Common Rail FBDocumento3 páginasToberas Common Rail FBАмурдеталь БлаговещенскAinda não há avaliações

- Erikc Diesel Injector Parts Catalog - Toni TaoDocumento36 páginasErikc Diesel Injector Parts Catalog - Toni TaoErikc Diesel100% (2)

- Makalah Wirausahawan SuksesDocumento6 páginasMakalah Wirausahawan SuksesSurya IrawanAinda não há avaliações

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDocumento63 páginasERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаAinda não há avaliações

- Bosch ECI Injection - ECIDocumento17 páginasBosch ECI Injection - ECIBeTOAinda não há avaliações

- Ds-Datenbl Crs1 14up enDocumento2 páginasDs-Datenbl Crs1 14up encrastoverkillAinda não há avaliações

- Vehicle Identification: Notes Specified Value Measured ValueDocumento5 páginasVehicle Identification: Notes Specified Value Measured ValueПан ТелемонAinda não há avaliações

- Unidades HeuiDocumento50 páginasUnidades HeuiagnaldoAinda não há avaliações

- DS ProductDataSheet CRS3-27 ENDocumento3 páginasDS ProductDataSheet CRS3-27 ENberbagidatakantor123Ainda não há avaliações

- CRS 2-25 Diesel Common-Rail System With Solenoid Valve Injectors and 2,500 BarDocumento3 páginasCRS 2-25 Diesel Common-Rail System With Solenoid Valve Injectors and 2,500 BarRooffAinda não há avaliações

- MCRS enDocumento2 páginasMCRS enTamer Moustafa100% (1)

- Common Rail Systems With Up To 2,000 Bar For Off-Highway ApplicationsDocumento2 páginasCommon Rail Systems With Up To 2,000 Bar For Off-Highway ApplicationsVladimirAgeevAinda não há avaliações

- Optimized for SEN00303-03 Engine Shop Manual SpecsDocumento25 páginasOptimized for SEN00303-03 Engine Shop Manual SpecsЕгорAinda não há avaliações

- L23 L29 BrochureDocumento8 páginasL23 L29 BrochuremaxAinda não há avaliações

- SC33 50HZ Cummins GeneratorDocumento4 páginasSC33 50HZ Cummins GeneratorChen CarolineAinda não há avaliações

- Denoxtronic2.2 Vehiculos ComercialesDocumento2 páginasDenoxtronic2.2 Vehiculos ComercialesCarlos Guiñez MontecinosAinda não há avaliações

- Suzuki Gran Vitara RH 2001 Gestion MotorDocumento5 páginasSuzuki Gran Vitara RH 2001 Gestion MotorBer HonzaAinda não há avaliações

- ECM Gran Vitara V6 H25Documento2 páginasECM Gran Vitara V6 H25Ber Honza100% (4)

- Códigos de Falla ABS PDFDocumento8 páginasCódigos de Falla ABS PDFBer HonzaAinda não há avaliações

- Pdf - схема Электрооборудования HdDocumento149 páginasPdf - схема Электрооборудования HdGiapy Phuc Tran100% (8)

- Bosch m7.9.7 PDFDocumento25 páginasBosch m7.9.7 PDFRuben Dario Casique83% (24)

- Newholland FeilkoderDocumento19 páginasNewholland Feilkoderaliosha2k89% (9)

- Flash CodesDocumento62 páginasFlash CodesГригорий Григорян100% (4)

- Jeep Compass 2007 2.4 Circuito de ArranqueDocumento1 páginaJeep Compass 2007 2.4 Circuito de ArranqueBer HonzaAinda não há avaliações

- 01j Audi MultitronicDocumento7 páginas01j Audi MultitronicLUIS ALEJANDROAinda não há avaliações

- Diagnosing Audio System Issues in 2004 Toyota CorollaDocumento1 páginaDiagnosing Audio System Issues in 2004 Toyota CorollaBer HonzaAinda não há avaliações

- Volvo 960 Timing Belt Replacement IntervalsDocumento5 páginasVolvo 960 Timing Belt Replacement IntervalsBer HonzaAinda não há avaliações

- Case 621 ServiceDocumento129 páginasCase 621 ServiceBer Honza33% (3)

- Case Ih Fault CodesDocumento44 páginasCase Ih Fault CodesHarlinton descalzi78% (9)

- 2007 ATRA Seminar ManualDocumento272 páginas2007 ATRA Seminar Manualtroublezaur100% (3)

- Weld-On Lip Shrouds For Excavators and LoadersDocumento4 páginasWeld-On Lip Shrouds For Excavators and LoadersBer HonzaAinda não há avaliações

- Mcb-02 en Carros Canbus ConectorDocumento75 páginasMcb-02 en Carros Canbus ConectorGabrielBonatoAinda não há avaliações

- Service Manual: EQ1030T47D-820 Light Commercial TruckDocumento175 páginasService Manual: EQ1030T47D-820 Light Commercial TruckYonny ColqueAinda não há avaliações

- New Holland B110 B115 en Service Manual PDFDocumento993 páginasNew Holland B110 B115 en Service Manual PDFdobas100% (9)

- Service Codes Display Monitor (S.N. 910056-951253)Documento3 páginasService Codes Display Monitor (S.N. 910056-951253)yamilmr60% (5)

- tm1606 TXTX178649Documento10 páginastm1606 TXTX178649Ber HonzaAinda não há avaliações

- Engine Control (5Vz-Fe) : System OutlineDocumento10 páginasEngine Control (5Vz-Fe) : System OutlineBer Honza100% (4)

- Transmission Diagnostic Trouble Codes-Limp Home Mode and Inchless Power ShiftDocumento2 páginasTransmission Diagnostic Trouble Codes-Limp Home Mode and Inchless Power ShiftBer HonzaAinda não há avaliações

- 30 Ecm Chevy c2 Motor Sfi 1.6 L.Documento50 páginas30 Ecm Chevy c2 Motor Sfi 1.6 L.Ber Honza100% (16)

- Transmission Solenoid Circuit TroubleshootingDocumento4 páginasTransmission Solenoid Circuit TroubleshootingBer HonzaAinda não há avaliações

- VOLVO 240 Engines d20 d24 ReconditioningDocumento80 páginasVOLVO 240 Engines d20 d24 ReconditioningMyselvf100% (3)

- HILUX Electrical Wiring Diagram GuideDocumento244 páginasHILUX Electrical Wiring Diagram Guidethailan100% (2)

- Amarok Electrico PDFDocumento387 páginasAmarok Electrico PDFBer HonzaAinda não há avaliações

- Tata Sumo Gold Owner's ManualDocumento114 páginasTata Sumo Gold Owner's ManualBer HonzaAinda não há avaliações

- Nissan Tiida C11 2011 Engine Control System PDFDocumento1.036 páginasNissan Tiida C11 2011 Engine Control System PDFRobertAinda não há avaliações

- S and S International 2016Documento112 páginasS and S International 2016Ber HonzaAinda não há avaliações

- SV650AL7 Cylinder Head PartsDocumento86 páginasSV650AL7 Cylinder Head PartsRicardo MeloAinda não há avaliações

- 1648 Plus Asphalt Paver Parts Manual 918217BDocumento112 páginas1648 Plus Asphalt Paver Parts Manual 918217Btrina0% (1)

- Hercules M. Biacoraelectrical-MachinesDocumento8 páginasHercules M. Biacoraelectrical-MachinesBiacora Manalo HerculesAinda não há avaliações

- Guided By: Submitted byDocumento12 páginasGuided By: Submitted byShubhamAwasthiAinda não há avaliações

- Amp QuestionsDocumento20 páginasAmp QuestionsGaberAinda não há avaliações

- Honda Civic Torque - SpecsDocumento4 páginasHonda Civic Torque - SpecsMimmo Leone100% (1)

- 3176 Turbo Juego PDFDocumento2 páginas3176 Turbo Juego PDFErick AlarconAinda não há avaliações

- Engine Control 1ND-TV, TMMF Made From Nov. 2008 ProductionDocumento17 páginasEngine Control 1ND-TV, TMMF Made From Nov. 2008 Productiondavid aliagaAinda não há avaliações

- Small BlockDocumento42 páginasSmall BlockgrandcaravanAinda não há avaliações

- Unit 4 - Energy Heat and WorkDocumento14 páginasUnit 4 - Energy Heat and WorkraulmipeAinda não há avaliações

- DT4 (88 98)Documento41 páginasDT4 (88 98)cristicozma76Ainda não há avaliações

- Resumen Cummins b3.3Documento6 páginasResumen Cummins b3.3rectificamosAinda não há avaliações

- IO 550 ManualDocumento850 páginasIO 550 ManualJimyToasaAinda não há avaliações

- Ec PDFDocumento26 páginasEc PDFHumberto Cadori FilhoAinda não há avaliações

- Chapter 8B - Gas Power Plant Brayton CycleDocumento17 páginasChapter 8B - Gas Power Plant Brayton CycleBF3nobel100% (1)

- Grupo Electrogeno OlympianDocumento1 páginaGrupo Electrogeno OlympianJuan Josue Cairampoma ReyesAinda não há avaliações

- MotorssDocumento1 páginaMotorssChang ChangAinda não há avaliações

- Installation: 09 - Engine, 2.8L Diesel / Valve Timing / BELT, Timing / InstallationDocumento8 páginasInstallation: 09 - Engine, 2.8L Diesel / Valve Timing / BELT, Timing / InstallationJackson VivasAinda não há avaliações

- KSRTC Report Doc Format NsDocumento32 páginasKSRTC Report Doc Format NsAndrea Perry50% (2)

- February 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsDocumento4 páginasFebruary 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsKarim MuhammedAinda não há avaliações

- Wartsila o e W 26 TRDocumento12 páginasWartsila o e W 26 TRAzis Mufti100% (1)

- Manual de Partes Honda - EP6500Documento83 páginasManual de Partes Honda - EP6500Anonymous fDWyVj0% (1)

- Parts Manual: EX27 EngineDocumento44 páginasParts Manual: EX27 EngineDiego Leandro Garcia HernandezAinda não há avaliações

- Factory carburetor setups for GM big and small blocksDocumento29 páginasFactory carburetor setups for GM big and small blocksFranziska Kujumdshiev100% (1)

- Manual Motor QSB 4.5Documento140 páginasManual Motor QSB 4.5Jeiner Jara100% (1)

- RX8 Short Manual 2007 PDFDocumento7 páginasRX8 Short Manual 2007 PDFgk218Ainda não há avaliações

- Introduction To Automobile SystemsDocumento18 páginasIntroduction To Automobile SystemsSangameshwer EnterprisesAinda não há avaliações

- C9 Cat Operation Testing and Adjusting ManualDocumento82 páginasC9 Cat Operation Testing and Adjusting ManualRami Dal100% (7)

- Wartsila o e W 46fDocumento2 páginasWartsila o e W 46fghostt123Ainda não há avaliações

- Tanaka 3301Documento16 páginasTanaka 3301RepairmanJim100% (1)