Escolar Documentos

Profissional Documentos

Cultura Documentos

WQT - WPS 01

Enviado por

Gururaj P KundapurDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

WQT - WPS 01

Enviado por

Gururaj P KundapurDireitos autorais:

Formatos disponíveis

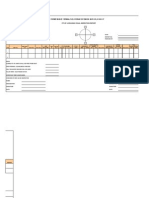

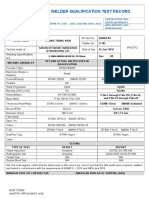

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-01-4

WELDER NAME : MANSA RAM WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 01 TEST COUPON NO.: DAPL-QC-WPS-01/

ADDRESS : DAPL SITE, JAJPUR DAPL-QC-PQR-01

PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/28 LOCATION : DAPL CAMP

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 10.03.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 73 - 107 22 - 34 171.42 - 240.00

HOT PASS BOHLER ( E 8010) 4.0 112 - 146 27 - 35 206.89 - 222.22

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/006 Dtd 11.03.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

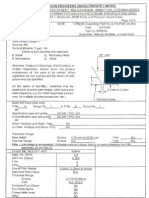

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-08-1

WELDER NAME : S HAIDER RAZA WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W 08 TEST COUPON NO.: DAPL-QC-WPS-01/

ADDRESS : DAPL SITE, JAJPUR DAPL-QC-PQR-01

PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/47 LOCATION : DAPL CAMP

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 10.03.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 73 - 107 22 - 34 171.42 - 240.00

HOT PASS BOHLER ( E 8010) 4.0 112 - 146 27 - 35 206.89 - 222.22

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/006 Dtd 11.03.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

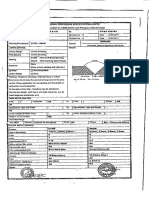

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-05-1

WELDER NAME : PATI RAM MAHTO WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 05 TEST COUPON NO.: DAPL-QC-WPS-01/

ADDRESS : DAPL SITE, JAJPUR DAPL-QC-PQR-01

PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/38 LOCATION : DAPL CAMP

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 10.03.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 190 - 270 20 - 28 150.00 - 240.00

CAPPING BOHLER (E 81T8-FD) 2.0 205 - 275 20 - 28 192.69 - 220.86

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/006 Dtd 11.03.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

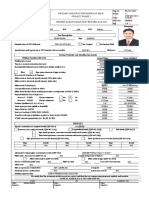

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-09-1

WELDER NAME : VIPIN KUMAR WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 09 TEST COUPON NO.: DAPL-QC-WPS-01/

ADDRESS : DAPL SITE, JAJPUR DAPL-QC-PQR-01

PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/36 LOCATION : DAPL CAMP

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 10.03.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 190 - 270 20 - 28 150.00 - 240.00

CAPPING BOHLER (E 81T8-FD) 2.0 205 - 275 20 - 28 192.69 - 220.86

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/006 Dtd 11.03.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-11-1

WELDER NAME : ADITYA SINGH WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 11

TEST COUPON NO.: KM113/M14

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 02.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 195 - 270 21 - 28 187.50 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 216 - 275 21 - 28 200.00 - 214.28

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/009 Dtd 04.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-14-1

WELDER NAME : KAILASH SENAPATI WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 14

TEST COUPON NO.: KM112/M79

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 06.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 170 - 244 23 - 29 187.50 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 218 - 281 22 - 28 193.54 - 214.28

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/020 Dtd 08.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-15-1

WELDER NAME : SHAKIL AHMED WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W 015

TEST COUPON NO.: KM112/M75

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL CAMP

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 06.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 94 - 117 26 - 34 214.28 - 200.00

HOT PASS BOHLER ( E 8010) 4.0 122 - 153 38 - 47 214.28 - 200.00

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/026 Dtd 13.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-22-1

WELDER NAME : RAJESH KUMAR WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 22

TEST COUPON NO.: KM112/M31

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 14.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 190 - 270 20 - 28 187.50 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 233 - 272 22 - 28 187.50 - 200.00

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/027 Dtd 16.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-23-1

WELDER NAME : HARINDRA PRASAD WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 23

TEST COUPON NO.: KM112/M31

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 14.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 187 - 272 28 - 36 176.47 - 187.5

CAPPING BOHLER (E 81T8-FD) 2.0 218 - 264 26 - 34 181.81 - 193.54

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/027 Dtd 16.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-24-1

WELDER NAME : SANJAY KUMAR WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 24

TEST COUPON NO.: KM112/M29

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 14.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 189 - 268 27 - 36 146.34 - 176.47

CAPPING BOHLER (E 81T8-FD) 2.0 198 - 254 24 - 34 171.42 - 176.47

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/027 Dtd 16.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-25-1

WELDER NAME : SUNIL KUMAR WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 25

TEST COUPON NO.: KM112/M29

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 14.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 194 - 270 20 - 28 142.85 - 157.89

CAPPING BOHLER (E 81T8-FD) 2.0 199 - 258 20 - 27 146.34 - 206.89

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/027 Dtd 16.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-26-1

WELDER NAME : MD MUSTAKEEM ANSARI WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 26

TEST COUPON NO.: KM112/M28

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 14.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 199 - 270 21 - 28 150.00 - 176.47

CAPPING BOHLER (E 81T8-FD) 2.0 192 - 204 21 - 29 166.66 - 200.00

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/027 Dtd 16.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-27-1

WELDER NAME : JAWAHARLAL YADAV WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 27

TEST COUPON NO.: KM112/M28

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 14.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 191 - 265 21 - 27 166.66 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 205 - 270 20 - 26 200.00 - 206.89

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/027 Dtd 16.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-28-1

WELDER NAME : SANJEEV KUMAR WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 28

TEST COUPON NO.: KM112/M07

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL-1 SPREAD

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 17.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

FILLER BOHLER (E 81T8-FD) 2.0 191 - 266 20 - 27 187.5 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 195.3 - 244.2 20 - 26 187.5 - 200.00

ELECTRICAL CHARACTERISTICS : DCEN ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/039 Dtd 18.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-03-4

WELDER NAME : AMERJEET K PRASAD WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 03

TEST COUPON NO.: KM120/M44

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/27 LOCATION : DAPL CAMP

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 23.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 100 - 128 33 - 40 193.54 - 200.00

HOT PASS BOHLER ( E 8010) 4.0 124 - 158 38 - 48 240.00 - 214.28

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/054 Dtd 24.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-04-4

WELDER NAME : GULAB CHAUHAN WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 04

TEST COUPON NO.: KM120/M07

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/30 LOCATION : CH. 120

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 29.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 82 - 103 32 - 40 214.28 - 250.00

HOT PASS BOHLER ( E 8010) 4.0 124 - 158 38 - 48 214.28 - 240.00

FILLER - - - - -

CAPPING - - - - -

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/073 Dtd 30.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

n

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-29-1

WELDER NAME : BIPUL MECH WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 29

TEST COUPON NO.: KM120/M07

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/124 LOCATION : CH. 120

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 29.04.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 91 - 114 32 - 40 300.00 - 333.33

HOT PASS BOHLER ( E 8010) 4.0 131 - 172 37 - 47 333.33 - 400.00

FILLER - - - - -

CAPPING - - - - -

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/073 Dtd 30.04.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-30-1

WELDER NAME : VINOD KUMAR YADAV WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 30

TEST COUPON NO.: KM119/M80

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/127 LOCATION : CH. 119

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 02.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 182 - 262 21 - 27 206.89 - 230.76

CAPPING BOHLER (E 81T8-FD) 2.0 214 - 281 21 - 27 222.22 - 230.76

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/083 Dtd 03.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-31-1

WELDER NAME : LAL BABU RAY WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 31

TEST COUPON NO.: KM119/M80

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/126 LOCATION : CH. 119

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 02.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 192 - 264 20 - 26 200.00 - 214.28

CAPPING BOHLER (E 81T8-FD) 2.0 214 - 281 21 - 27 200.00 - 214.28

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/083 Dtd 03.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-33-1

WELDER NAME : TAROON GOGOI WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 33

TEST COUPON NO.: KM119/M08

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/136 LOCATION : DAPL 2, CH 119

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 09.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 83 - 103 30 - 38 230.76 - 240.00

HOT PASS BOHLER ( E 8010) 4.0 127 - 161 41 - 51 250.00 - 272.72

FILLER - - - - -

CAPPING - - - - -

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/097 Dtd 09.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-34-1

WELDER NAME : BHUPEN CHETIA WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 34

TEST COUPON NO.: KM118/M67

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/142 LOCATION : DAPL 2, CH 118

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 11.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 93 - 118 31 - 43 153.84 - 162.16

HOT PASS BOHLER ( E 8010) 4.0 119 - 156 40 - 51 150.00 - 166.66

FILLER - - - - -

CAPPING - - - - -

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/104 Dtd 14.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-35-1

WELDER NAME : DIGANTO MAJUMDAR WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 35

TEST COUPON NO.: KM118/M79

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/138 LOCATION : DAPL 2, CH 118

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 10.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 80 - 100 31 - 40 153.84 - 166.66

HOT PASS BOHLER ( E 8010) 4.0 117 - 150 37 - 49 157.89 - 162.16

FILLER - - - - -

CAPPING - - - - -

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/103 Dtd 11.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-36-1

WELDER NAME : SADANAND KALITA WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 36

TEST COUPON NO.: KM118/M79

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/139 LOCATION : DAPL 2, CH 118

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 10.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 99 - 124 30 - 37 187.50 - 193.54

HOT PASS BOHLER ( E 8010) 4.0 132 - 164 39 - 51 193.54 - 200.00

FILLER - - - - -

CAPPING - - - - -

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/103 Dtd 11.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-37-1

WELDER NAME : PINKU KUMAR WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 37

TEST COUPON NO.: KM118/M80

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/137 LOCATION : DAPL 2, CH 118

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 10.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 158 - 269 22 - 43 157.89 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 192 - 258 20 - 26 171.42 - 193.54

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/103 Dtd 11.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-38-1

WELDER NAME : ASHIM CHANGMAI WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 38

TEST COUPON NO.: KM118/M80

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/140 LOCATION : DAPL 2, CH 118

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 10.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 142 - 250 21 - 28 166.66 - 187.50

CAPPING BOHLER (E 81T8-FD) 2.0 192 - 264 20 - 27 193.54 - 200.00

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/103 Dtd 11.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-39-1

WELDER NAME : HARI PAL WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 39

TEST COUPON NO.: KM118/M24

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/157 LOCATION : DAPL 2, CH 118

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 16.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 174 - 253 21 - 28 142.85 - 157.89

CAPPING BOHLER (E 81T8-FD) 2.0 197 - 253 21 - 26 153.89 - 157.84

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/129 Dtd 18.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-40-1

WELDER NAME : BALINDRA MAHTO WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 40

TEST COUPON NO.: KM118/M24

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/156 LOCATION : DAPL 2, CH 118

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 16.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 192 - 253 27 - 36 166.66 - 187.66

CAPPING BOHLER (E 81T8-FD) 2.0 202 - 264 27 - 35 176.47 - 200.00

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/129 Dtd 18.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-43-1

WELDER NAME : SANTANU CHETIA WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 43

TEST COUPON NO.: KM114/M40

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : DAPL/INPL003/W/159 LOCATION : DAPL 1, CH 114

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 21.05.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 92 - 118 31 - 41 206.89 - 214.28

HOT PASS BOHLER ( E 8010) 4.0 123 - 160 35 - 46 153.84 - 187.50

FILLER - - - - -

CAPPING - - - - -

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/149 Dtd 25.05.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-32-1

WELDER NAME : LAKHWIR SINGH WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 32

TEST COUPON NO.: KM 84 / M 68

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : H DEEP CONTRACTOR LOCATION : DAPL 1, CH 84

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 20.06.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 209 - 275 20 - 26 171.42 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 195 - 251 20 - 25 200.89 - 200.00

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/293 Dtd 06.07.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-16-2

WELDER NAME : JOGINDER YADAV WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 16

TEST COUPON NO.: KM 84 / M 08

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : H DEEP CONTRACTOR LOCATION : DAPL 1, CH 84

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 20.06.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 203 - 275 20 - 26 181.81 - 206.89

CAPPING BOHLER (E 81T8-FD) 2.0 207 - 265 20 - 26 214.28 - 222.22

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/235 Dtd 22.06.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-10-2

WELDER NAME : LAXMAN SINGH WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 10

TEST COUPON NO.: KM 84 / M 09

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : H DEEP CONTRACTOR LOCATION : DAPL 1, CH 84

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 20.06.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 210 - 221 20 - 21 171.42 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 196 - 204 20 - 21 193.54 - 200.00

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/235 Dtd 22.06.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-17-3

WELDER NAME : BHOLA DAS WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 17

TEST COUPON NO.: KM 84 / M 08

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : INVERTER

PASSPORT / I/C No. : H DEEP CONTRACTOR LOCATION : DAPL 1, CH 84

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 20.06.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 210 - 275 20 - 26 206.89 - 250.00

CAPPING BOHLER (E 81T8-FD) 2.0 196 - 266 21 - 26 206.89 - 222.22

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/235 Dtd 22.06.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-47-1

WELDER NAME : CHARANJIT BAKSHI WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 47

TEST COUPON NO.: KM127/M41

ADDRESS : DAPL SITE, JAJPUR ROAD PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W LOCATION : DAPL 2, CH 127

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW MAINLINE DATE OF TEST : 14.09.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 68 - 90 27 - 35 187.50 - 200.00

HOT PASS BOHLER ( E 8010) 4.0 113 - 143 28 - 35 200.00 - 206.89

FILLER - - - - -

CAPPING - - - - -

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : R & HP - POSITIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Down

Hot Pass : Vertical Down

Subsequent Passes : - N.A-

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/341 Dtd 15.09.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-48-1

WELDER NAME : DHANIK LAL WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 48

TEST COUPON NO.: KM 127 / M 39

ADDRESS : DAPL SITE, JAJPUR ROAD PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W LOCATION : DAPL 2, CH 127

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 15.09.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 189 - 243 20 - 27 187.50 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 194 - 245 19 - 25 187.50 - 200.00

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/342 Page 01 / 02 Dtd 18.09.18 API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-49-1

WELDER NAME : ARVIND KUMAR SINGH WPS NO. : DAPL-QC-WPS-01

WELDER I/D No. : W - 49

TEST COUPON NO.: KM 127 / M 37

ADDRESS : DAPL SITE, JAJPUR ROAD PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W LOCATION : DAPL 2, CH 127

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : FCAW MAINLINE DATE OF TEST : 16.09.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT - - - - -

HOT PASS - - - - -

FILLER BOHLER (E 81T8-FD) 2.0 190 - 246 20 - 26 187.50 - 200.00

CAPPING BOHLER (E 81T8-FD) 2.0 194 - 246 19 - 25 193.54 - 200.00

ELECTRICAL CHARACTERISTICS : DCEP ELECTRODE : (Filler Wire) F & Cap - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: - N.A-

Hot Pass : - N.A-

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Not Applicable

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : ( ü ) Internal ( ) External ( ) Tack Joints

Removal of clamp after : ( ü ) 100% / ( ) 50% of Root Deposition

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/342 Page 01 / 02 Dtd 18.09.18 API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T. IN ACCORDANCE

WITH THE REQUIREMENTS OF THE W.P.S., API 1104, MECON SPECIFICATION.

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

Você também pode gostar

- Wps For Aluminium WeldingDocumento8 páginasWps For Aluminium Weldingvishal bailur50% (2)