Escolar Documentos

Profissional Documentos

Cultura Documentos

PQR Gmaw

Enviado por

Er Sumant Kumar Singh0%(1)0% acharam este documento útil (1 voto)

462 visualizações4 páginasPQR of GMAW

Título original

PQR GMAW

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoPQR of GMAW

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0%(1)0% acharam este documento útil (1 voto)

462 visualizações4 páginasPQR Gmaw

Enviado por

Er Sumant Kumar SinghPQR of GMAW

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 4

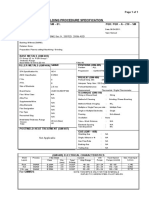

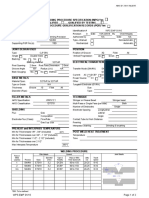

QW-483 FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR)

(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name: Pranjal Projects Pvt. Ltd.

Procedure Qualification Record No.: PPPL/PQR-001 Date: 25-04-2018

Welding Procedure Specification No.: PPPL/PQR-001 Revision:0 Date: 29-09-2018

Welding Process (es): GMAW Type(s): Semi-Automatic

JOINTS (QW-402) (Groove Design of Test Coupon)

Joints Design : SINGAL ‘V’

Root Spacing :2-3 MM

Backing : NA

Backing Material (Type):NA

BASE METALS (QW-403)

Material Specification

Type / Grade, or UNS No.: IS 2062 E 350 GR. B R

P- No. 1 Group No. 1 to P-No. 1 Group No. 1

Thickness of the Test Coupon :20 MM

Diameter of the Test Coupon: NA

Max. Pass thickness : ≤40 mm

Other: NIL

*FILLER METALS (QW-404)

Process GMAW

Spec. No. (SFA) 5.18

AWS No. (Class) ER70S6

Filler Metal F-No. 6

Weld Metal Analysis A-No. 1

Size of Filler Metals Ø 1.2

Filler Metal Product Form NA

Supplemental Filler Metal NA

Electrode-Flux (Class) NA

Flux type NA

Flux Trade Name NA

Weld Metals Thickness 22 MM

Others NIL

Form No. FQ/062 Rev. 3 Page 1 of 4

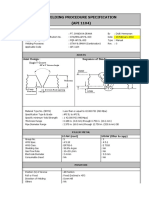

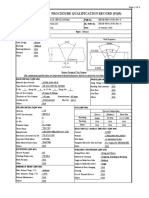

Procedure Qualification Record No.: PPPL/PQR-001 Date: 25-04-2018

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position of Groove : 1G Temperature : NA

Welding Progression : NA Time : NA

Other : NIL Other : NIL

PREHEAT (QW-406) GAS (QW-408) Percent composition

Preheat Temperature, : NA Gas Mixture Flow rate

Inter pass Temperature : NA CO2 NA 22LPM

Others : NIL Shielding: CO2

Trailing : NA

Backing : NA

ELCTRICAL CHARACTERISTICS (QW-409)

Current : DC

Polarity : DCEP

Amps. :140,160,165,150,175

Volts. : 25,26,24,27,26

Tungsten Electrode Size and Type : NA

Mode of Metal Transfer for GMAW :

Heat Input :

Travel Speed : 150 MM/MIN (ROOT), 135MM/MIN FILLING & CAPPING.

Other : NIL

TECHNIQUE (QW-410)

String or Weave Bead : String & Weave Bead (3 X Día of filler).

Orifice, Nozzle, or Gas Cup Size : NA

Initial and Interpass Cleaning (Brushing, Grinding, etc.) : Grinding

Method of Back Gouging / Back Grooving : Grinding

Oscillation : NA

Use of Thermal Processes : NA

Multiple or Single Pass (per side) : Multiple

Multiple or Single Electrodes : Single

Peening : NA

Other : NIL

Form No. FQ/062 Rev. 3 Page 2 of 4

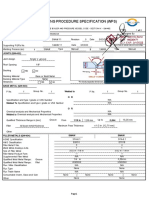

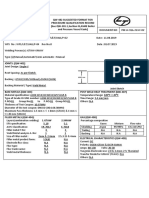

Procedure Qualification Record No.: PPPL/PQR-001 Date: 25-04-2018

Tensile Test (QW-150) Reference No. 00478/NTH(ER)/NDT/12/02/2017

Ultimate Ultimate Type of

Specimen Width Thickness Area

Total Load Unit Stress Failure &

No. (mm) (mm) (mm2)

(Kn) (psi or MPa) Location

01 492.6 MPA *BOW

02 492.6 MPA *BOW

…

* BOW: Broken outside the Weld

Guided Bend Tests (QW-160)

Type and Figure No. Results

SIDE BEND NO CRACKS, SATIFACTORY

SIDE BEND NO CRACKS, SATIFACTORY

SIDE BEND NO CRACKS, SATIFACTORY

SIDE BEND NO CRACKS, SATIFACTORY

Toughness Tests (QW-170):

Test Impact Values

Specimen Notch Specimen Drop weight

Temp. Mils (in)

No. Location Size (mm) Ft-lb or J % Shear Break(Y/N)

(0 C) or mm

Comments: TENSILE AND BEND TEST FOUND SATISFACTORY

Fillet Weld Test (QW-180): NA

Result - Satisfactory: Yes ………. No…………… Penetration into Parent Metal: Yes ……. No……….

Macro - Results ………………………………………………………………………………………………….

OTHER TESTS:

Type of Test:

Deposit Analysis: NA

Other : NIL

Welder's Name: JAKIR HUSSAIN Welder No. PPPL/WQT-001 Stamp No:

Tests conducted by: Pranjal Projects Pvt. Ltd. Laboratory Test No: Reference No.

00478/NTH(ER)/NDT/12/02/2017.

We certify that the statements in this record are correct and that the test welds were prepared, welded and

tested in accordance with the requirements of Section IX of ASME Boiler and Pressure Vessel Code – Edition

2013

Pranjal Projects Pvt. Ltd.

Signature

Name

Date

Form No. FQ/062 Rev. 3 Page 3 of 4

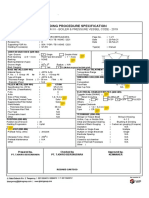

Form No. FQ/062 Rev. 3 Page 4 of 4

Você também pode gostar

- WPS PQR ProcedureDocumento31 páginasWPS PQR Proceduresudeesh kumarAinda não há avaliações

- WPS, PQR, WPQ PoojaDocumento10 páginasWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Documento5 páginasPage No: 01: SA 240 GR 304 SA 240 GR 304jobertAinda não há avaliações

- PQR Is7307Documento1 páginaPQR Is7307Tridib Dey100% (1)

- Fit Up ReportDocumento5 páginasFit Up ReportAkash Singh Tomar100% (1)

- WPQ Sample PrintoutDocumento1 páginaWPQ Sample PrintoutKannan VelAinda não há avaliações

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Documento4 páginasProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabAinda não há avaliações

- Welding Procedure Specification: Page 1 of 1Documento2 páginasWelding Procedure Specification: Page 1 of 1Anderson Perez MartinezAinda não há avaliações

- WPS Format For Asme Ix - Wps - Gtaw SmawDocumento1 páginaWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocumento2 páginasProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXAinda não há avaliações

- WPS, PQR 041Documento21 páginasWPS, PQR 041swamykommula100% (1)

- Welding Procedure For BOXNR Wagon (WPS)Documento8 páginasWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- WPS PQR FormatDocumento1 páginaWPS PQR FormatJatin Kamdar100% (2)

- 1035 03Documento2 páginas1035 03Anuj ShahiAinda não há avaliações

- Draft WPS Welder R0Documento51 páginasDraft WPS Welder R0R Bernanda Argandhi SaputraAinda não há avaliações

- Wps Is 2062 GR B Butt-OkDocumento2 páginasWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Asnt Level Ii - NDT In: Application For The Post Of: QC PIPING INSPECTORDocumento34 páginasAsnt Level Ii - NDT In: Application For The Post Of: QC PIPING INSPECTORJAMHSED KHANAinda não há avaliações

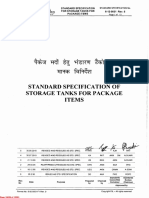

- 6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFDocumento13 páginas6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFpl_arunachalam79Ainda não há avaliações

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Documento1 páginaQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Ainda não há avaliações

- Wps 1010 IfrDocumento28 páginasWps 1010 IfrSyed Mahmud Habibur RahmanAinda não há avaliações

- 19403955-WPS M.S. Is 2062Documento10 páginas19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- WPS ListDocumento2 páginasWPS ListAdeel OmerAinda não há avaliações

- WPS-46 - Gtaw & Smaw Tig + SmawDocumento8 páginasWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaAinda não há avaliações

- ASME P NumbersDocumento3 páginasASME P Numbersrajesh100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocumento6 páginasWPS Resrvoire Sous Pression Smaw SawDanem HalasAinda não há avaliações

- Dokumen - Tips Wqt-FormatDocumento2 páginasDokumen - Tips Wqt-FormatMr Pie100% (1)

- PQRDocumento2 páginasPQRafqzfieAinda não há avaliações

- Pt. Saferad Servis Indonesia: Ultrasonic Inspection ReportDocumento3 páginasPt. Saferad Servis Indonesia: Ultrasonic Inspection Reportkucing_batam0% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Documento2 páginasWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejAinda não há avaliações

- Welder Card - 6G and 3GDocumento1 páginaWelder Card - 6G and 3GRavi singhAinda não há avaliações

- UT Chapter 11Documento70 páginasUT Chapter 11knizam1971100% (1)

- WPS PQR-02Documento8 páginasWPS PQR-02Ranjan Kumar100% (1)

- JIMT Visual Inspection ReportDocumento1.913 páginasJIMT Visual Inspection Reportgomathyselvi100% (1)

- Qualified Welder List Valid Until - 03-12-2019Documento2 páginasQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- GMAW welding parameters for SS400 pipeDocumento2 páginasGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Documento2 páginasWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin RomeroAinda não há avaliações

- Wps p91 - BhelDocumento2 páginasWps p91 - BhelAshish Gupta100% (4)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Documento2 páginasWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajAinda não há avaliações

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocumento10 páginasWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- QC FORMDocumento3 páginasQC FORMRicardo LourençoAinda não há avaliações

- HHHHHHHHJJJJJJ: O O O ODocumento1 páginaHHHHHHHHJJJJJJ: O O O OAli MoosaviAinda não há avaliações

- WPS & PQR (E Co Cr-E)Documento3 páginasWPS & PQR (E Co Cr-E)HossamSAshourAinda não há avaliações

- Fcaw 16 THKDocumento5 páginasFcaw 16 THKparesh2387Ainda não há avaliações

- Sample MTC: Material Test CertificateDocumento2 páginasSample MTC: Material Test CertificateSameer KmAinda não há avaliações

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Documento2 páginasWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemAinda não há avaliações

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocumento3 páginasWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEAinda não há avaliações

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocumento1 páginaPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarAinda não há avaliações

- ASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies PartsDocumento1 páginaASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies Partssathi_mechAinda não há avaliações

- WELDING PROCEDURE SPECIFICATION SHEET 2 OF 2Documento2 páginasWELDING PROCEDURE SPECIFICATION SHEET 2 OF 2surya1960Ainda não há avaliações

- Welding Proposed Pwps For Our Jubail WorkDocumento2 páginasWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPS PQR PDFDocumento23 páginasWPS PQR PDFAhmad Daniel100% (1)

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- Essential welding procedure qualification recordDocumento2 páginasEssential welding procedure qualification recordmainur mechanical engineer0% (1)

- PQR With-PwhtDocumento2 páginasPQR With-PwhtKarthikAinda não há avaliações

- Procedure Qualification RecordDocumento6 páginasProcedure Qualification RecordGaurang PandyaAinda não há avaliações

- PQR ForDocumento3 páginasPQR ForAkash Singh TomarAinda não há avaliações

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDocumento5 páginasLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALAinda não há avaliações

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocumento3 páginasWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanAinda não há avaliações

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocumento3 páginasASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanAinda não há avaliações

- Aic Asf PQR 133Documento3 páginasAic Asf PQR 133AHMED MEDANYAinda não há avaliações

- India Yamaha Motors welding processesDocumento3 páginasIndia Yamaha Motors welding processesshashwat bajpaiAinda não há avaliações

- Raptor Defender® Fixed Plant LWP PDFDocumento20 páginasRaptor Defender® Fixed Plant LWP PDFBorisRakelaGonzalezAinda não há avaliações

- CigweldDocumento128 páginasCigweldkazambo78Ainda não há avaliações

- Summary QPDocumento36 páginasSummary QPviahulAinda não há avaliações

- Distortion Analysis of Welded Stiffeners: O. A. VanliDocumento37 páginasDistortion Analysis of Welded Stiffeners: O. A. VanlialiAinda não há avaliações

- TPS270i User Manual 42 0426 0206 ENDocumento116 páginasTPS270i User Manual 42 0426 0206 ENAkash GhuleAinda não há avaliações

- CSWIP 3.1 Course (2017) - Compressed-471-476Documento6 páginasCSWIP 3.1 Course (2017) - Compressed-471-476Tahar DabbarAinda não há avaliações

- WedingDocumento75 páginasWedingSrinivasan MuthuvelAinda não há avaliações

- SAIC-W-2006 Rev 8Documento4 páginasSAIC-W-2006 Rev 8saravananmenmathiAinda não há avaliações

- Furniture Estimate for ZPHS ROBERTSONPET(TELUGU) SchoolDocumento8 páginasFurniture Estimate for ZPHS ROBERTSONPET(TELUGU) SchoolBharath VAinda não há avaliações

- GMAW Welding GuideDocumento96 páginasGMAW Welding GuideJUAN VASCOAinda não há avaliações

- Catalogo de Partes Miller 2019 PDFDocumento128 páginasCatalogo de Partes Miller 2019 PDFjuventino vazquezAinda não há avaliações

- 00 - AVANTech Capabilities & Experience - NUCLEAR (No Attachments) 11-2018Documento12 páginas00 - AVANTech Capabilities & Experience - NUCLEAR (No Attachments) 11-2018Laura StoutAinda não há avaliações

- Manual Service PEHDocumento70 páginasManual Service PEHStemate ViorelAinda não há avaliações

- CWB Study Guide - Weld Quality and Examination MethodsDocumento56 páginasCWB Study Guide - Weld Quality and Examination MethodsPubcrawlAinda não há avaliações

- Sect 11a P Welding DocumDocumento31 páginasSect 11a P Welding DocumRajeev KumarAinda não há avaliações

- Presentation On: Applications of and Welding in ManufacturingDocumento27 páginasPresentation On: Applications of and Welding in ManufacturingHope ThemAinda não há avaliações

- Preguntas Al Comite API 1104Documento12 páginasPreguntas Al Comite API 1104alefeli26Ainda não há avaliações

- 9686-8470-SP-000-4005 - 01 Welding and NDT SpecDocumento53 páginas9686-8470-SP-000-4005 - 01 Welding and NDT SpecvenkateshAinda não há avaliações

- TESDA training programs and costs circularDocumento22 páginasTESDA training programs and costs circularGazza Bimar DimalantaAinda não há avaliações

- AGA Fume Gases Facts About UKDocumento20 páginasAGA Fume Gases Facts About UKPeter's KitchenAinda não há avaliações

- Accessories & Welding Mig Guns: CatalogDocumento136 páginasAccessories & Welding Mig Guns: CatalogLiceth LunaAinda não há avaliações

- Company Profil CV - Citra Harapan Jaya All CustomerDocumento6 páginasCompany Profil CV - Citra Harapan Jaya All Customersutrisno00Ainda não há avaliações

- Arc Welding Techniques ExplainedDocumento4 páginasArc Welding Techniques ExplainedFaris Kadesh50% (2)

- How To Weld Titanium - Welding HeadquartersDocumento10 páginasHow To Weld Titanium - Welding HeadquartersJesús GarcíaAinda não há avaliações

- A. Introduction To WeldingDocumento29 páginasA. Introduction To WeldingRonel LawasAinda não há avaliações

- Lincoln Welding SP 170t Im794Documento36 páginasLincoln Welding SP 170t Im794Anonymous hR3e8SsAinda não há avaliações

- Aramco Questionnaire Latest One 08062020Documento29 páginasAramco Questionnaire Latest One 08062020brparekh100% (1)

- NDT HandbookDocumento135 páginasNDT Handbooksmeyer-ak93% (28)

- NCWF Syllabus CompleteDocumento96 páginasNCWF Syllabus CompleteNovic JohnsAinda não há avaliações