Escolar Documentos

Profissional Documentos

Cultura Documentos

Spin5 PDF

Enviado por

Lalit KashyapDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Spin5 PDF

Enviado por

Lalit KashyapDireitos autorais:

Formatos disponíveis

CONTENTS

Sr No Contents Page No.

1. Basic Textile Terms of Spinning 1

2. Sequence of spinning process 2

3. Material Flow in Spinning 3

4. Functions of Ring Frame Machine 5

5. Details of Ring Frame Machine 6

6. Operating Ring Frame Machine 9

7. Instructions for Shift Change 13

8. Importance of Health & Safety 14

1. Basic Textile Terms of Spinning:

Fiber: The fundamental component used in making textile yarns and fabrics. Fibers

are fine substances with a high ratio of length to thickness. They can be either

natural (e.g. cotton, wool, silk etc.) or synthetic (e.g. polyester, nylon, acrylic etc.).

Blow room Lap: finished product of blow room in the form of a sheet of fibers.

Chute feed system: It is a system of feeding small tufts of fibers directly from blow

room to a series of cards, arranged in a circuit through pneumatic pipe.

Sliver: The strand of loose, roughly parallel, untwisted fibers produced in Carding,

Draw frame.

Roving: A product of speed frame in the form of a soft strand of fiber that has been

twisted, attenuated, and free from foreign matter preparatory to spinning.

Yarn: A continuous strand of textile fibers that may be composed of endless

filaments or shorter fibers twisted or otherwise held together .

Spinning: The process of making yarns from the textile fiber is called spinning.

Spinning is the twisting together of drawn out strands of fibers to form yarn.

Yarn Count/Sliver Hank

Yarn count is the numerical expression of yarn, which defines its fineness or

coarseness. (Linear density)

Yarn count system:

Indirect system: English count (Ne), Worsted Count etc.

i.e. Higher the yarn number, Finer the yarn.

Direct System: Tex, Denier.

i.e. Higher the yarn number , Coarser the yarn.

Similarly numerical expression of fineness or coarseness of sliver & roving are called

Hank.

Note: English (Ne) count system is commonly followed in India.

English Count: No. of Hanks of length 840 yds weighing in 1 pound

1yds: 0.9144 mtrs.

1lbs: 0.453 Kgs.

e.g. 40s Ne = 40 hanks of 840 yds weighs 1 lbs.

20s Ne = 20 hanks of 840 yds weighs 1 lbs.

Page No 1 RSA DOCUMENT

Version No.01

2. Sequence of Spinning Process:

Bale Opening

Mixing

Blow Room

Carding

Pre comber

drawing

Lap Former

Combing

Breaker Drawing

Post Comber Drawing

Finisher Drawing OE Frame

Speed Frame

Ring Frame

Cone Winding

Checking & Packing

Page No 2 RSA DOCUMENT

Version No.01

3. Material Flow in Spinning:

Carded Yarn Manufacturing:

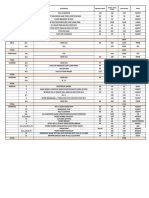

TABLE-1

STAGE MACHINE INPUT OUT PUT PACKAGE

MATERIAL MATERIAL FORM

Opening & Blow Room machines Raw cotton Lap or chute -

cleaning feed

Carding Card Lap or chute Card sliver Slivers in Can

feed

1st drawing Breaker Draw frame Card sliver Drawn sliver Sliver can

2nd drawing Finisher Draw frame Drawn sliver Drawn sliver Sliver can for

Roving

Roving Speed Frame Drawn sliver Roving Roving bobbin

Spinning Ring spinning frame Roving Ring-spun Spinning

yarn Cops

Post- Winding Yarn in Yarn package Cone, Cheese

Spinning spinning cops & Hank as

processes required

Combed Yarn Manufacturing

TABLE-2

STAGE MACHINE INPUT OUT PUT PACKAGE

MATERIAL MATERIAL FORM

Opening & Blow Room Raw cotton Lap or chute -

cleaning machines feed

Carding Carding machine Lap or chute Card sliver Carded Slivers in

feed Cans

Pre comber Breaker Draw Carded Sliver Drawn Sliver Drawn slivers in

Drawing Frame cans

Lap Super Lap or Lap Drawn Slivers Lap Laps in spools

Formation Former

Combing Comber Lap Combed Sliver Combed sliver in

Cans

Post Finisher Draw Combed Drawn sliver Post comber

comber Frame sliver Draw frame

Drawing slivers in cans

Roving Speed Frame Post comber Roving Roving bobbin

Draw frame

sliver

Spinning Ring spinning Roving Ring-spun Spinning Cops

frame yarn

Post- Winding Yarn in Yarn Cone, Cheese &

Spinning spinning cops Hank as required

processes

Page No 3 RSA DOCUMENT

Version No.01

Various Package Form:

Page No 4 RSA DOCUMENT

Version No.01

4. Functions of Ring Frame Machine:

To produce required count of yarn from the supplied roving by drafting.

To insert sufficient amount of twist to the yarn to impart strength.

To wind the yarn onto the bobbin.

To build the yarn package properly.

Page No 5 RSA DOCUMENT

Version No.01

5. Details of Ring Frame Machine:

Page No 6 RSA DOCUMENT

Version No.01

Different Zones in Ring Frame Machine:

Creeling:

Roving is fed to the Ring frame from

roving bobbin held by creels. For all

the spindles roving bobbin are

creeled on the machine. The roving

is guided and passed through

trumpet. The roving then passes

through the drafting rollers.

Drafting:

To draft the roving to reduce weight

per unit length.The Drafting zone in

Ring Frame attenuates the roving to

desired fineness by imparting

required draft to the roving by top

arm pressure and the speed

variations in the Bottom rollers of

drafting zone.

Twisting: The drafted strand of the

material is finer than rove and twist

is inserted to strengthen the material

i.e. yarn.

Winding: Winding of the yarn on to

the bobbin is done by raising and

lowering the ring rail. The traverse

movement of the ring rail is less than

that of the bobbin height. The ring

rail must therefore be raised by

small amount after each layer of

coils.

Building: To make conical or tapper

shape of the ring bobbin.

Page No 7 RSA DOCUMENT

Version No.01

Pneum.afil : When an end breaks

the fibre strand coming out from

front roller are collected through

suction system fixed just below the

front roller with suitable holes for

effecting suction

Ring& Traveller:

The ring guides the circular run off

the traveller. The drafted strands of

fibres as they are delivered by the

front rollers are given twist to

produce a yarn. The Ring and

travellers enable to Wind the yarn

onto the bobbin & maintain winding

tension of the yarn. It acts as a

second guide for the yarn on the

way to be wound on the bobbin.

Doffing: To replace with empty

bobbins when the Ring Bobbins

become full.

Page No 8 RSA DOCUMENT

Version No.01

Signal Lamps:

Signal lamps are provided on the

machine to indicate the reason for

stoppage of machine

Understand each signal lamp and

their purpose in the machine.

Display Panel:

It displays various operating

machine parameters like speed,

production, Count of yarn etc.

Understand the details in the display

panel and work accordingly

6. Operating Ring Frame Machine:

Creel the required number of roving bobbins and draw the roving forward.

Take the roving over the creel rod and then through trumpet and feed to drafting

zone.

Operate the control switches for starting and stopping of ring frame.

Follow the different signal lamps & stop motions used in machines.

Piece the roving during breakages.

Piece the yarn during yarn breakage while winding on the cops.

Ensure passage of material after piecing.

Support the doffing team while doffing the ring bobbins .

View the display panel and identify the reasons for machine stoppages if any.

Inform the supervisor and maintenance in charge in case of any break-downs.

Support for carrying out maintenance activities.

Carryout cleaning activities in creeling, drafting, and in spindle assembly.

Remove the waste while attending breakage/creeling , roller lapping etc and put

them in appropriate waste collection bins.

Remove the pneumafil waste and yarn waste and deposit in the respective waste

collection bags.

Page No 9 RSA DOCUMENT

Version No.01

Always keep Ring frame area clean.

Importance of Colour coding:

The details related to colour coding like Roving bobbins colour, Ring Cops colour

and other relevant information like Hank of roving, Count of yarn produced etc, are

normally displayed in respective machine’s display board. It is the responsibility of

the machine operator to understand them & work accordingly.

Identifying Defects:

Defects in roving like irregular roving, slubby roving, excessive roving breaks etc,

are to be identified and informed to supervisor for necessary action.

Defects in roving bobbins like soft bobbins , stained bobbins, unequal tapering,

uneven and fluff accumulated bobbins etc are to be identified and informed to

supervisor for necessary action.

Defects in spinning cops like, uneven cops, stained b unch of yarn wound etc., are

to be identified and informed to supervisor for necessary action.

Creeling

Bring the correct colour coded bobbins (like colour of Bobbin, tinted colour of

roving etc.) from roving bobbin storage using bobbin trolley.

Identify exhausted roving bobbins in the creel and replace exhausted roving

bobbin with correct colour coded bobbins on the creel from the reserve holder /

trolley.

Page No 10 RSA DOCUMENT

Version No.01

Attending the roving break at the Creel:

Check the creels and identify which roving is broken, identify the reasons for roving

breakage i.e. whether roving is broken at creel or roving is exhausted in the Roving

bobbin.

Take proper passage of roving from creel to drafting zone through creel rod and

trumpet.

Take minimum time for piecing the roving.

Keep the roving waste in the waste collection hip bag/ apron pocket and then put the

waste in waste collection box.

Page No 11 RSA DOCUMENT

Version No.01

Attending yarn breakage

Patrol around the machine to ensure proper production of Ring spun yarn.

If there is any yarn breakage, apply the knee break to stop the spindle.

Take yarn from cop to feed through Ring traveller & lappet hook.

Cut the yarn (10mm) and start piecing,while piecing avoid staining the yarn.

Piecing should be fast and qualitative to ensure the thickness of pieced portion is not

thick or thin.

Take minimum time for piecing the yarn.

Ensure proper seating of cops in the spindle after yarn piecing and release the knee

break.

Check proper traveller running.

Ensure proper material handling of ring cops.

Ensure proper tension of the pieced yarn.

Verify proper material passage from drafting zone till the yarn wound in cop .

Remove the pneumafil waste and yarn waste and deposit in the respective waste

collection bags.

Ensure safety while carrying out piecing activities.

Attend the end breakage as and when they occur

Page No 12 RSA DOCUMENT

Version No.01

Cleaning of Ring frame & Waste disposal:

Carry out cleaning of machine at periodic intervals as instructed.

Clean the creeling area at periodical intervals & keep the creeling zone free from fluff

& dust accumulation.

Use the cleaning equipment given to clean the drafting Zone. Periodically arrange to

clean the top roll clearer roller (Scavenger Roller).E nsure that the clearer roller is

always kept clean

If there is any over lapping noticed, remove the roller lapping manually or with tools

provided, without damaging the cots. Clean pneumafil pipes and ensure that the

suction orifices are free from fluff accumulation.

Collect the roving wastes and yarn waste in the hip bag provided and deposit them

category wise in the designated bags at specified places.

Clean around the Ring frame machine using proper cleaning equipments .

Keep the Ring frame department clean.

7. Instructions for Shift Change:

Take Charge of the Shift

Come at least 10 - 15 minutes earlier to the work spot.

Meet the previous shift operator and discuss regarding the issues faced by them with

respect to the quality or production or spare or safety or any other specific instruction

etc.

Page No 13 RSA DOCUMENT

Version No.01

Understand the count produced, colour coding followed in the ring frame for his

allocated number of Spindles/ machines.

Check and understand the technical details mentioned in the display board.

Check for the availability of the roving bobbins

Check the condition of all the Spindles, ensure proper functioning of Ring frame

machine parts.

Check the cleanliness of the machines & other work areas.

Check whether the waste collection boxes are empty while taking charge of shift.

Handing over the Shift:

Properly hand over the shift to the incoming shift operator.

Provide the details regarding count produced, colour coding for roving bobbins and

empty ring bobbins for allocated spindles/machines.

Provide all relevant information regarding the, idle spindles, damaged machine parts

etc.,

Collect the wastes from waste collection bags weigh them and transport to storage

place.

Check the cleanliness of the work place.

Get clearance from the incoming counterpart before leaving the work spot, in case if

the next shift operators do not come, report it to shift supervisor.

Report to the shift supervisor about the quality / production / safety issues/ any other

issue faced in the shift and leave the department only after getting concurrence for

the same from supervisors.

8. Importance of Health & Safety

Follow the work & safety instructions and adopt safe working practices like not

opening the doors of the machine, not cleaning the interior parts & not taking any

choked material when the machine is in running condition.

Always use head cap, face mask and ear plug in the work spot.

Do not carry any metallic parts during machine running as there are chances of fire

and damage to machine parts.

Page No 14 RSA DOCUMENT

Version No.01

Take action based on instructions in the event of fire, emergencies or accidents,

participate in mock drills/ evacuation procedures organized at the workplace as per

organization procedures.

Page No 15 RSA DOCUMENT

Version No.01

Você também pode gostar

- Blow Room Carding Draw Frame TX Comm. 35 Pges PDFDocumento35 páginasBlow Room Carding Draw Frame TX Comm. 35 Pges PDFKannan Krishnamurthy100% (1)

- Technology of Yarn Manufacture - Unit II Carding and Draw Frame Question BankDocumento2 páginasTechnology of Yarn Manufacture - Unit II Carding and Draw Frame Question BankSivakumar K100% (1)

- Carding enDocumento15 páginasCarding envenkatAinda não há avaliações

- CMT of Faults PDFDocumento1 páginaCMT of Faults PDFJigneshSaradavaAinda não há avaliações

- Carding CalculationsDocumento11 páginasCarding CalculationsSuraj VishwakarmaAinda não há avaliações

- Blow RoomDocumento44 páginasBlow RoomSiva smglAinda não há avaliações

- Textile Dyeing AuxiliariesDocumento95 páginasTextile Dyeing AuxiliariesKamal PathakAinda não há avaliações

- Data ColorDocumento95 páginasData ColorArifZamanAinda não há avaliações

- JUTE Fibre To Yarn PDFDocumento217 páginasJUTE Fibre To Yarn PDFMoshiur RahmanAinda não há avaliações

- Yarn Manufacture - Set of 2 VolsDocumento2 páginasYarn Manufacture - Set of 2 VolsAnonymous Pt7NHkat9Ainda não há avaliações

- Pressing Defects: BY A.Ilakkiya Priya (14texa06) II-M.sc TADDocumento7 páginasPressing Defects: BY A.Ilakkiya Priya (14texa06) II-M.sc TADsimplyDIYs TamilAinda não há avaliações

- Blowroom 2Documento27 páginasBlowroom 2Abhi ParamAinda não há avaliações

- CARDING (Textile) Process ParametersDocumento4 páginasCARDING (Textile) Process ParametersKavudham ASAinda não há avaliações

- Anant Spinning MillDocumento18 páginasAnant Spinning MillgaganAinda não há avaliações

- DesizingDocumento4 páginasDesizingsyed asim najam100% (2)

- Draw FrameDocumento50 páginasDraw FrameDev Narayan KushwahaAinda não há avaliações

- Bi ComponentDocumento13 páginasBi ComponentA.K.M. Rashedul IslamAinda não há avaliações

- Dyeing Basics Dyeing Process and MachineDocumento5 páginasDyeing Basics Dyeing Process and MachineNakib Ibna BasharAinda não há avaliações

- Singeing Process: Presented By: Bhawana Mohta Manuj Shukla Nuti Mehta Dhruva Vaghela Presented To: Prof Pranav VoraDocumento19 páginasSingeing Process: Presented By: Bhawana Mohta Manuj Shukla Nuti Mehta Dhruva Vaghela Presented To: Prof Pranav VoraManuj ShuklaAinda não há avaliações

- 2.pirn Winding Machine (Main Parts & Yarn Path Diagram)Documento10 páginas2.pirn Winding Machine (Main Parts & Yarn Path Diagram)Ferdaus Hasan BappiAinda não há avaliações

- Rapier MotionDocumento9 páginasRapier MotionuxmaAinda não há avaliações

- Spinning MilesDocumento7 páginasSpinning MilesKirubas KaranAinda não há avaliações

- Conventional and Modern ProcessDocumento16 páginasConventional and Modern ProcessAshiqueAinda não há avaliações

- Dyeing FaultsDocumento10 páginasDyeing FaultsMehedi Hassan EvanAinda não há avaliações

- Sulur Ranga TextilesDocumento38 páginasSulur Ranga TextilesraviAinda não há avaliações

- Lecture Flax FiberDocumento29 páginasLecture Flax FiberFahad jutt100% (1)

- Yarn Manufacturing 3Documento12 páginasYarn Manufacturing 3Md. Humayun KabirAinda não há avaliações

- Mechanical FinishingDocumento43 páginasMechanical FinishingUjwala Jain100% (1)

- Product Specification of Terry TowelsDocumento2 páginasProduct Specification of Terry TowelsAbhishek SrivastavaAinda não há avaliações

- Carding MachineDocumento17 páginasCarding MachineMairaj Ud Din100% (1)

- Thermosol Dyeing Method of Polyster FabricDocumento1 páginaThermosol Dyeing Method of Polyster FabricMohammed Atiqul Hoque ChowdhuryAinda não há avaliações

- JBF Industries Ltd. Dalal Mott Mac DonaldDocumento76 páginasJBF Industries Ltd. Dalal Mott Mac DonaldJimish PanchalAinda não há avaliações

- Elements of Circular KnittingDocumento5 páginasElements of Circular KnittingSanika JoshiAinda não há avaliações

- Global Service Network: Total Customer Support Based On Total Customer ServiceDocumento6 páginasGlobal Service Network: Total Customer Support Based On Total Customer ServiceHardik VavdiyaAinda não há avaliações

- The Card: "The Heart of Spinning"Documento101 páginasThe Card: "The Heart of Spinning"Umår F ÃfriDiAinda não há avaliações

- To Study Effect of Comber Noil Percentage On Yarn Quality: ArticleDocumento12 páginasTo Study Effect of Comber Noil Percentage On Yarn Quality: Articlelalit kashyapAinda não há avaliações

- BASE Textiles LimitedDocumento76 páginasBASE Textiles LimitedPushpa BaruaAinda não há avaliações

- Carding TheoriesDocumento2 páginasCarding TheoriesVaibhav K Dhange50% (2)

- Lect5 - Carding Machine 2Documento13 páginasLect5 - Carding Machine 2Mina Samy abd el zaherAinda não há avaliações

- Overview of Jute SpinningDocumento10 páginasOverview of Jute SpinningTuan Nguyen MinhAinda não há avaliações

- SpinningDocumento62 páginasSpinningPalash100% (2)

- RapierDocumento14 páginasRapierSri Meeina100% (1)

- Blow RoomDocumento104 páginasBlow RoomPrakash Chavali100% (1)

- LMW Card Lc636Documento9 páginasLMW Card Lc636MY Lê Thị TràAinda não há avaliações

- Akshara Spinning MillsDocumento42 páginasAkshara Spinning MillsbalaAinda não há avaliações

- MercerizationDocumento3 páginasMercerizationsyed asim najamAinda não há avaliações

- Research Report On Spinning Sector of Bangladesh-InitiationDocumento24 páginasResearch Report On Spinning Sector of Bangladesh-InitiationjohnsumonAinda não há avaliações

- Textile Printing KushalDocumento88 páginasTextile Printing KushalKushal Chowdhary C.S100% (1)

- MercerizationDocumento141 páginasMercerizationkreeshnuAinda não há avaliações

- Indigo Dyeing Machinery The Concept Dyes Chemicals Express TextileDocumento6 páginasIndigo Dyeing Machinery The Concept Dyes Chemicals Express TextilechtamoorAinda não há avaliações

- Rice Byproducts As Sustainable Adsorbents For Textile Waste Water After-Treatment: A Comprehensive ReviewDocumento4 páginasRice Byproducts As Sustainable Adsorbents For Textile Waste Water After-Treatment: A Comprehensive ReviewInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- By: Hemant Ghanghor & Patanjal KumarDocumento15 páginasBy: Hemant Ghanghor & Patanjal KumarpatanjaliictAinda não há avaliações

- Textile Dyeing - Introduction-LibreDocumento10 páginasTextile Dyeing - Introduction-LibreGanga DharanAinda não há avaliações

- H1 Faults PDFDocumento5 páginasH1 Faults PDFvsmirthuAinda não há avaliações

- SingeingDocumento15 páginasSingeingAli RazaAinda não há avaliações

- Computer Application in Modern Spinning SectionDocumento17 páginasComputer Application in Modern Spinning SectionShekh belalAinda não há avaliações

- Spin8 PDFDocumento15 páginasSpin8 PDFMadhavkumarAinda não há avaliações

- Spin7 PDFDocumento14 páginasSpin7 PDFKandha SamyAinda não há avaliações

- Spin2 PDFDocumento35 páginasSpin2 PDFBalasaheb A ZipareAinda não há avaliações

- Unit-1 March 2021Documento130 páginasUnit-1 March 2021Lalit KashyapAinda não há avaliações

- Hindi AlphabetsDocumento3 páginasHindi AlphabetsLalit KashyapAinda não há avaliações

- Ring Frame: Linc ConerDocumento16 páginasRing Frame: Linc ConerLalit KashyapAinda não há avaliações

- Count Wise Ipi Hike LC Vs Ut5 (March)Documento12 páginasCount Wise Ipi Hike LC Vs Ut5 (March)Lalit KashyapAinda não há avaliações

- Curriculum Vitae: Permanent AddressDocumento3 páginasCurriculum Vitae: Permanent AddressLalit KashyapAinda não há avaliações

- L40 TFO TwistingDocumento10 páginasL40 TFO TwistingLalit KashyapAinda não há avaliações

- Faqmod6 PDFDocumento2 páginasFaqmod6 PDFLalit KashyapAinda não há avaliações

- Nnex 1 List of EquipmentsDocumento10 páginasNnex 1 List of EquipmentsLalit KashyapAinda não há avaliações

- Shivpoojane 3Documento3 páginasShivpoojane 3Lalit KashyapAinda não há avaliações

- January February March April: S M T W T F S S M T W T F S S M T W T F S S M T W T F SDocumento2 páginasJanuary February March April: S M T W T F S S M T W T F S S M T W T F S S M T W T F SLalit KashyapAinda não há avaliações

- Vaibhav Laxmi Spintex LLP Phase - Ii: Shift: 1 CardingDocumento95 páginasVaibhav Laxmi Spintex LLP Phase - Ii: Shift: 1 CardingLalit KashyapAinda não há avaliações

- Ticket AMD-KNU-AMD IF1910242330787Documento2 páginasTicket AMD-KNU-AMD IF1910242330787Lalit KashyapAinda não há avaliações

- Measurement Conversion Table PDFDocumento1 páginaMeasurement Conversion Table PDFLalit KashyapAinda não há avaliações

- M/C No Stoppages Per M/C Mins Loss in Kgs Fault Taken Total MinsDocumento2 páginasM/C No Stoppages Per M/C Mins Loss in Kgs Fault Taken Total MinsLalit KashyapAinda não há avaliações

- Indian Railways PassDocumento11 páginasIndian Railways PassLalit KashyapAinda não há avaliações

- Curriculum Vita: Ø To Acquire Advanced Knowledge in My Concern. Seeking A Challenging CareerDocumento2 páginasCurriculum Vita: Ø To Acquire Advanced Knowledge in My Concern. Seeking A Challenging CareerLalit KashyapAinda não há avaliações

- New York LifeDocumento38 páginasNew York LifeDaniel SineusAinda não há avaliações

- Chapter 3Documento26 páginasChapter 3Francis Anthony CataniagAinda não há avaliações

- Fundamentals of Logistics XI - 2023Documento45 páginasFundamentals of Logistics XI - 2023saiyaAinda não há avaliações

- Note 15-Feb-2023Documento4 páginasNote 15-Feb-2023Oliver ScissorsAinda não há avaliações

- Annex A2 - CS Form 100 - Revised 2023 - CSESP - A1 - Edited - A1Documento2 páginasAnnex A2 - CS Form 100 - Revised 2023 - CSESP - A1 - Edited - A1obs.obando2022Ainda não há avaliações

- Pre-Qin Philosophers and ThinkersDocumento22 páginasPre-Qin Philosophers and ThinkersHelder JorgeAinda não há avaliações

- Preparatory Newsletter No 3 2013Documento22 páginasPreparatory Newsletter No 3 2013SJC AdminAinda não há avaliações

- Clay & Shale Industries in OntarioDocumento193 páginasClay & Shale Industries in OntarioJohn JohnsonAinda não há avaliações

- Edagogy of Anguages: VerviewDocumento54 páginasEdagogy of Anguages: VerviewMukesh MalviyaAinda não há avaliações

- FORM 2 Enrolment Form CTU SF 2 v.4 1Documento1 páginaFORM 2 Enrolment Form CTU SF 2 v.4 1Ivy Mie HerdaAinda não há avaliações

- UBO - Lecture 07 - Implementing and Managing Organisational ChangeDocumento0 páginaUBO - Lecture 07 - Implementing and Managing Organisational ChangeShahNooraniITAinda não há avaliações

- GEODynamics CONNEX Brochure 2008.10 - Rev2 Final PDFDocumento12 páginasGEODynamics CONNEX Brochure 2008.10 - Rev2 Final PDFSusin LimAinda não há avaliações

- T.Y.B.B.A. (CA) Sem VI Practical Slips 2019 PatternDocumento30 páginasT.Y.B.B.A. (CA) Sem VI Practical Slips 2019 PatternJai Ramteke100% (2)

- Cics 400 Administration and Operations GuideDocumento343 páginasCics 400 Administration and Operations GuidedafraumAinda não há avaliações

- Tok EssayDocumento2 páginasTok EssayNeto UkpongAinda não há avaliações

- SB Roadmap B1 1Documento161 páginasSB Roadmap B1 1Carmen Flores AloyAinda não há avaliações

- Ga-Ta10 (LHH)Documento181 páginasGa-Ta10 (LHH)Linh T.Thảo NguyễnAinda não há avaliações

- Shaheed Suhrawardy Medical College HospitalDocumento3 páginasShaheed Suhrawardy Medical College HospitalDr. Mohammad Nazrul IslamAinda não há avaliações

- Some Sunsickday - Kitchenro11Documento356 páginasSome Sunsickday - Kitchenro11Spencer HAinda não há avaliações

- Culture Performance and Economic Return of Brown ShrimpDocumento8 páginasCulture Performance and Economic Return of Brown ShrimpLuã OliveiraAinda não há avaliações

- Paper 3 FrinqDocumento4 páginasPaper 3 Frinqapi-301975170Ainda não há avaliações

- Test Bank For Macroeconomics 8th Canadian Edition Andrew AbelDocumento16 páginasTest Bank For Macroeconomics 8th Canadian Edition Andrew AbelstebinrothAinda não há avaliações

- Dawn of The DhammaDocumento65 páginasDawn of The Dhammaarkaprava paulAinda não há avaliações

- Active and Inactive Volcano LPDocumento2 páginasActive and Inactive Volcano LPhorace hernandez100% (5)

- 100 IELTS Essay Topics For IELTS Writing - My IELTS Classroom BlogDocumento16 páginas100 IELTS Essay Topics For IELTS Writing - My IELTS Classroom BlogtestAinda não há avaliações

- Causal Relationships WorksheetDocumento2 páginasCausal Relationships Worksheetledmabaya23Ainda não há avaliações

- Steve Talbott Getting Over The Code DelusionDocumento57 páginasSteve Talbott Getting Over The Code DelusionAlexandra DaleAinda não há avaliações

- FinancialAccountingTally PDFDocumento1 páginaFinancialAccountingTally PDFGurjot Singh RihalAinda não há avaliações

- Resume Pet A Sol LanderDocumento3 páginasResume Pet A Sol LanderdreyesfinuliarAinda não há avaliações

- English Idioms and PhrasesDocumento384 páginasEnglish Idioms and Phrasesthwe thweAinda não há avaliações