Escolar Documentos

Profissional Documentos

Cultura Documentos

AMERLOCK

Enviado por

AbdulDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AMERLOCK

Enviado por

AbdulDireitos autorais:

Formatos disponíveis

PRODUCT DATA SHEET April 13, 2018 (Revision of October 2, 2017)

AMERLOCK® 880 HS

DESCRIPTION

Two-component, glass flake high-build polyamine adduct cured epoxy coating

PRINCIPAL CHARACTERISTICS

• For use in both offshore and onshore business

• Designed for use in heavy-duty and corrosive environments

• Glass-flake reinforced for improved impact and abrasion resistance

• Excellent seawater, cracking and corrosion resistance

• Long-term protection in a single-coat application

• Resistant to well designed cathodic protection

• Strong adhesion properties, suitable for wet blast cleaned substrates (damp or dry)

• Continues to cure when immersed in water

COLOR AND GLOSS LEVEL

• Light gray (other colors available on request)

• Gloss

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density 1.6 kg/l (12.9 lb/US gal)

Volume solids 90 ± 3%

VOC (Supplied) Directive 1999/13/EC, SED: max. 97.0 g/kg

UK PG 6/23(92) Appendix 3: max. 150.0 g/l (approx. 1.3 lb/US gal)

Recommended dry film thickness 250 - 1000 µm (10.0 - 40.0 mils)

Theoretical spreading rate 3.0 m²/l for 300 µm (120 ft²/US gal for 12.0 mils)

Dry to touch 4 hours

Overcoating Interval See overcoating tables

Shelf life Base: at least 24 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA – Spreading rate and film thickness

- See ADDITIONAL DATA – Overcoating intervals

- See ADDITIONAL DATA – Curing time

Ref. P565 Page 1/5

PRODUCT DATA SHEET April 13, 2018 (Revision of October 2, 2017)

AMERLOCK® 880 HS

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Substrate conditions

• Coating performance will depend upon the surface preparation degree

• Steel; blast cleaned to ISO-Sa2 or ISO-Sa2½

• Blasting profile of 40 – 80 µm (1.6 – 3.1 mils) is recommended

• Hydrojetted to VIS WJ2/3 L

• Compatible previous coat must be dry and free from any contamination

Substrate temperature

• Substrate temperature during application and curing should be above 5°C (41°F)

• Substrate temperature during application should be at least 3°C (5°F) above dew point

INSTRUCTIONS FOR USE

Mixing ratio by volume: base to hardener 80:20 (4:1)

• Do not thin more than is required by appropriate application property

• Adding too much thinner results in reduced sag resistance and slower cure

• If required, thinner should be added after mixing the components

Induction time

None

Pot life

1.5 hours at 20°C (68°F)

Note: See ADDITIONAL DATA – Pot life

Air spray

Recommended thinner

THINNER 91-92

Volume of thinner

4 - 8%, depending on required thickness and application conditions

Nozzle orifice

1.5 – 3.0 mm (approx. 0.060 – 0.110 in)

Nozzle pressure

0.2 - 0.4 MPa (approx. 2 - 4 bar; 29 - 58 p.s.i.)

Ref. P565 Page 2/5

PRODUCT DATA SHEET April 13, 2018 (Revision of October 2, 2017)

AMERLOCK® 880 HS

Airless spray

Recommended thinner

THINNER 91-92

Volume of thinner

0 - 5%, depending on required thickness and application conditions

Nozzle orifice

Approx. 0.53 – 0.69 mm (0.021 – 0.027 in)

Nozzle pressure

15.0 MPa (approx. 150 bar; 2176 p.s.i.)

Brush/roller

• Only for touch-up and repair

Recommended thinner

THINNER 91-92

Volume of thinner

0 – 5%

Cleaning solvent

THINNER 90-53

ADDITIONAL DATA

Spreading rate and film thickness

DFT Theoretical spreading rate

300 µm (12.0 mils) 3.0 m²/l (120 ft²/US gal)

500 µm (20.0 mils) 1.8 m²/l (72 ft²/US gal)

1000 µm (40.0 mils) 0.9 m²/l (36 ft²/US gal)

Ref. P565 Page 3/5

PRODUCT DATA SHEET April 13, 2018 (Revision of October 2, 2017)

AMERLOCK® 880 HS

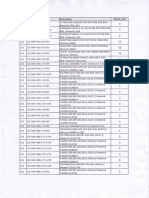

Overcoating interval for DFT up to 500 µm (20.0 mils)

Overcoating with... Interval 5°C (41°F) 10°C (50°F) 20°C (68°F) 30°C (86°F) 40°C (104°F)

itself Minimum 16 hours 8 hours 4 hours 2 hours 1.5 hours

Maximum 1 month 1 month 28 days 21 days 14 days

epoxy coatings Minimum 16 hours 8 hours 4 hours 2 hours 1.5 hours

Maximum 20 days 14 days 10 days 7 days 4 days

polyurethanes Minimum 28 hours 20 hours 14 hours 10 hours 6 hours

Maximum 20 days 14 days 10 days 7 days 4 days

Note: Surface should be dry and free from any contamination

Curing time for DFT up to 500 µm (20 mils)

Substrate temperature Dry to touch Dry to handle Full cure

5°C (41°F) 12 hours 30 hours 18 days

10°C (50°F) 6 hours 18 hours 14 days

20°C (68°F) 4 hours 10 hours 7 days

30°C (86°F) 3 hours 6 hours 5 days

40°C (104°F) 2 hours 3 hours 3 days

Notes:

- Premature exposure to water will lead to whitening of dark colours when applied between tides on jetties, piling etc. this will not affect

anticorrosive properties of the coating

- Adequate ventilation must be maintained during application and curing (please refer to INFORMATION SHEETS 1433 and 1434)

Pot life (at application viscosity)

Mixed product temperature Pot life

10°C (50°F) 2 hours

20°C (68°F) 1.5 hours

30°C (86°F) 1 hour

SAFETY PRECAUTIONS

• For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

• This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact

between the wet paint and exposed skin or eyes

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

Ref. P565 Page 4/5

PRODUCT DATA SHEET April 13, 2018 (Revision of October 2, 2017)

AMERLOCK® 880 HS

REFERENCES

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

• SAFETY INDICATIONS INFORMATION SHEET 1430

• SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD – INFORMATION SHEET 1431

TOXIC HAZARD

• SAFE WORKING IN CONFINED SPACES INFORMATION SHEET 1433

• DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the

rightful claim of any third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER

STATUTE OR ARISING OTHERWISE IN LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE,

ARE DISCLAIMED BY PPG. Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the

applicable shelf life of the product, or one year from the date of the delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar

Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon

laboratory tests that PPG believes to be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or

suggestions relating to the use of the PPG product, whether in technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own

particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and

application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or the contents of this information (unless there are written agreements

stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This sheet supersedes all previous versions and it is the

Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

The PPG logo, and all other PPG marks are property of the PPG group of companies. All other third-party marks are property of their respective owners.

Ref. P565 Page 5/5

Você também pode gostar

- Creep Behavior of A New Cast Austenitic AlloyDocumento12 páginasCreep Behavior of A New Cast Austenitic AlloyAbdulAinda não há avaliações

- Laser-Beam Welding Impact On The Deformation Properties of Stainless Steels When Used For Automotive ApplicationsDocumento6 páginasLaser-Beam Welding Impact On The Deformation Properties of Stainless Steels When Used For Automotive ApplicationsAbdulAinda não há avaliações

- ASTM A29 Standard Specification Steel Bars Carbon and Alloy Hot Wrought General RequirementsDocumento16 páginasASTM A29 Standard Specification Steel Bars Carbon and Alloy Hot Wrought General RequirementsAndrés Molina100% (2)

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocumento12 páginas253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulAinda não há avaliações

- Cast BronzesDocumento6 páginasCast BronzesAbdulAinda não há avaliações

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocumento12 páginas253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulAinda não há avaliações

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocumento12 páginas253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulAinda não há avaliações

- Kingspan MEATI Coatings BrochureDocumento14 páginasKingspan MEATI Coatings BrochureAbhishek Y MAinda não há avaliações

- Klinger Spiral Wound Gaskets: Klingermaxiflex Mounting InstructionsDocumento16 páginasKlinger Spiral Wound Gaskets: Klingermaxiflex Mounting InstructionsrizwankhanzhiAinda não há avaliações

- Winch Skid 2Documento1 páginaWinch Skid 2AbdulAinda não há avaliações

- Technut Astm A563 PDFDocumento14 páginasTechnut Astm A563 PDFINGYARQAinda não há avaliações

- My WorkDocumento1 páginaMy WorkAbdulAinda não há avaliações

- Capital Spare PartsDocumento2 páginasCapital Spare PartsAbdulAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Internationa Paint - Thinner SpecsDocumento2 páginasInternationa Paint - Thinner SpecsAshta VakrAinda não há avaliações

- Julabo FL300 9660003 en UsDocumento4 páginasJulabo FL300 9660003 en Usrizky andrianAinda não há avaliações

- Application Guide Jotun Super Durable Tcm180 142472Documento8 páginasApplication Guide Jotun Super Durable Tcm180 142472Mrk KhanAinda não há avaliações

- Locks and Keys Specification v1Documento8 páginasLocks and Keys Specification v1Lucho DomAinda não há avaliações

- Tankguard DW Jotun PaintDocumento6 páginasTankguard DW Jotun PaintGurdeep Sungh AroraAinda não há avaliações

- 1N4148 Diode Pinout, Equivalents & DatasheetDocumento3 páginas1N4148 Diode Pinout, Equivalents & DatasheetmanguesAinda não há avaliações

- Xylene T1404 TDS - 10-3-2016Documento2 páginasXylene T1404 TDS - 10-3-2016Faez Ahammad MazumderAinda não há avaliações

- Ep 08 030 37Documento18 páginasEp 08 030 37Muhammad AwaluddinAinda não há avaliações

- DBB Datasheet WHRP PDFDocumento48 páginasDBB Datasheet WHRP PDFRajendraAinda não há avaliações

- Linux ProposalDocumento10 páginasLinux ProposalOng Xuan YaoAinda não há avaliações

- SW5094ADocumento1 páginaSW5094AAnthon Per CovaAinda não há avaliações

- BC547 PDFDocumento7 páginasBC547 PDFToño ParodAinda não há avaliações

- Datasheet PDFDocumento8 páginasDatasheet PDFVenkatesh VakamulluAinda não há avaliações

- Et 314 PDFDocumento2 páginasEt 314 PDFPrettyAinda não há avaliações

- Manual 1024 RS - GBDocumento67 páginasManual 1024 RS - GBAlejandro Mira EstradaAinda não há avaliações

- Kidde Fenwal - 93-002009-004 Electronic Initiator Assembly - 10012015 - GHSDocumento7 páginasKidde Fenwal - 93-002009-004 Electronic Initiator Assembly - 10012015 - GHSSaleh El-hawaryAinda não há avaliações

- GM ImdsDocumento8 páginasGM Imdsloko99Ainda não há avaliações

- Planitop HDM RestauroDocumento4 páginasPlanitop HDM RestaurodraganugAinda não há avaliações

- R Series RP RH AnalogDocumento14 páginasR Series RP RH AnaloghaggAinda não há avaliações

- Datasheet Borne SiemensDocumento3 páginasDatasheet Borne Siemenslorentz franklinAinda não há avaliações

- PTDS Sicomet 100 v2 190615Documento2 páginasPTDS Sicomet 100 v2 190615nhnamAinda não há avaliações

- Technical Data Sheet: Hlx-Nel (Narrow Edge Leading)Documento3 páginasTechnical Data Sheet: Hlx-Nel (Narrow Edge Leading)khaldoun samiAinda não há avaliações

- Technical Specification for Diesel Engine Operated Emergency PumpDocumento66 páginasTechnical Specification for Diesel Engine Operated Emergency PumpKg SubramanianAinda não há avaliações

- WATLUBE - Material Safety Data SheetDocumento2 páginasWATLUBE - Material Safety Data SheetJohn Jairo CelisAinda não há avaliações

- Pghsaw33 01BKDocumento2 páginasPghsaw33 01BKRanjan GnanaoliAinda não há avaliações

- DataSheets TipsDocumento3 páginasDataSheets TipsChem.Engg100% (1)

- 3500 SIL Functional Safety Datasheet - 162242Documento5 páginas3500 SIL Functional Safety Datasheet - 162242Rabah AmidiAinda não há avaliações

- CP75WH12 DatasheetDocumento1 páginaCP75WH12 DatasheetKal Al-SaleemAinda não há avaliações

- Line Pipes Factory Acceptance Test ChecklistDocumento1 páginaLine Pipes Factory Acceptance Test ChecklistIdaba100% (3)

- Sika Backing RodDocumento2 páginasSika Backing Rodthe pilotAinda não há avaliações