Escolar Documentos

Profissional Documentos

Cultura Documentos

2G & 5G

Enviado por

Rahul Moottolikandy0 notas0% acharam este documento útil (0 voto)

109 visualizações2 páginasa

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOC, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoa

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOC, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

109 visualizações2 páginas2G & 5G

Enviado por

Rahul Moottolikandya

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOC, PDF, TXT ou leia online no Scribd

Você está na página 1de 2

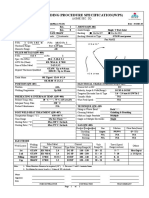

Welding Procedure Specifications (WPS)

Reference :ASME B31.3,ASME Sec IX and E.S.5.14.0010RA

KRANTZ ENGINEERS W.L.L

WPS NO. :WPS-KE-001 Rev : 1 Date :22-05-11

POSITIONS (QW-405) POSTWELD HEAT TREATMENT(QW-407)

Position (s) of Groove : All Temperature Range : None

Welding Progression : Up hill Time Range : None

Position (s) of Fillet: All Rate of Heating : None

Rate of cooling : None

PREHEAT (QW-406) GAS (QW-408)

Preheat Temp. Min : To remove moisture or 20 ˚C Shielding Gas : Argon

(Preheat to 40˚C if metal Temp.<20˚C) Percent Composition : 99.99%

Interpass Temp. Max : Max 181 ˚C Flow Rate : 8-12 LPM

Method of heating : LPG/Propane Gas Heating Torch Gas Backing : NA

Temp. Monitoring Method : Thermo melt crayons/Digital Trailing Shielding Gas : NA

thermometer.

ELECTRICAL CHARACTERISTICS (QW-410)

Current : DC Polarity : EN (GTAW ) & EP (SMAW)

Amps (Range) : 50Amps – 160 Amps(GTAW) Volts ( Range ) : 7V – 12V(GTAW)

70Amps-135Amps (SMAW) 18V-27V(SMAW)

Tungsten Electrode Size and Type : 2.4 mm, EW Th 2

Pulsing Current : None.

Mode of Metal Transfer for GMAW : NA

Electrode Wire feed speed range : NA

TECHNIQUE (QW-408)

String or Weave Bead : String –Root Pass, Weave –Fill & Cap

Orifice or gas Cup Size :4/6/8

Initial and interface Cleaning : Wire brushing /Grinding

Method of back gouging : NA

Oscillation : NA

Contact tube to work distance : NA

Multiple or Single Pass (per side) : Multiple passes.

Multiple or Single Electrodes : Single Electrode.

Travel Speed :50-120 mm/min(GTAW) & 90 – 130mm/min(SMAW)

Peening : NONE.

OTHERS:

Filter Metal Current Travel

Heat Input

Weld Pass Process Class Dia.mm Polarity Amps Volt Range Speed

KJ/mm

Range mm/min

Root GTAW ER70S3 2.4 DCEN 90-110 08-11 50-90 0.5-0.9

Hot GTAW ER70S3 2.4 DCEN 110-140 8-11 90-120 0.5-0.9

FILL SMAW E7018 2.5/3.2 DCEP 80-110 20-27 90-125 1.1-2.2

CAP1 SMAW E7018 2.5 DCEP 80-120 20-27 100-130 1.1-1.4

CAP2

Notes :

1. The number of passes may vary depending on actual thickness of the joint.

2. Maximum weaving permitted is 9mm for GTAW and 2.5 times electrode for SMAW.

3. Bridge/Bar tack shall be used for tacking.

KRANTZ TPI CLIENT

NAME

SIGNATURE

DATE

Welding Procedure Specifications (WPS)

Reference :ASME B31.3,ASME Sec IX and E.S.5.14.0010RA

KRANTZ ENGINEERS W.L.L

Você também pode gostar

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Documento1 páginaWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaAinda não há avaliações

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocumento1 páginaWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiAinda não há avaliações

- Pressure Vessel Hydrotest Procedure - Google SearchDocumento3 páginasPressure Vessel Hydrotest Procedure - Google SearchAsad KhanAinda não há avaliações

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocumento5 páginasSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalAinda não há avaliações

- PWHT Procedure For Petrol Steel - CoreDocumento9 páginasPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluAinda não há avaliações

- CPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingDocumento18 páginasCPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingAdil Ijaz100% (1)

- How To Calculate Hydrostatic Test Height in TanksDocumento4 páginasHow To Calculate Hydrostatic Test Height in TanksEric MagnayeAinda não há avaliações

- ITP Low Tempt Test - RevDocumento6 páginasITP Low Tempt Test - RevAgus GunawanAinda não há avaliações

- Table of Content: SR. TitleDocumento2 páginasTable of Content: SR. TitlePratik KarekarAinda não há avaliações

- Occpl: Hydro & Pneumatic Test ProcedureDocumento3 páginasOccpl: Hydro & Pneumatic Test ProcedureNupesh katreAinda não há avaliações

- QAP For Conical StrainerDocumento2 páginasQAP For Conical StrainersatishchidrewarAinda não há avaliações

- Itp Electrical SwitchgearDocumento4 páginasItp Electrical SwitchgearpertmasterAinda não há avaliações

- Test Pack Clearance FormatDocumento2 páginasTest Pack Clearance FormatKarthikAinda não há avaliações

- PQR REV. 2010a Interactive FormDocumento2 páginasPQR REV. 2010a Interactive FormcosmicbunnyAinda não há avaliações

- Hydrotest QI304-sampleDocumento3 páginasHydrotest QI304-sampleHanuman Rao100% (1)

- Circularity Inspection Report: Shell Course (LW) CW CWDocumento14 páginasCircularity Inspection Report: Shell Course (LW) CW CWaszlizaAinda não há avaliações

- Painting Procedure Rev.ADocumento12 páginasPainting Procedure Rev.Aคุณพ่อน้อง บิ๊กบอสAinda não há avaliações

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocumento4 páginasProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarAinda não há avaliações

- Factors Contributing To Foarming Crude OilDocumento11 páginasFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- Test Pack ProcedureDocumento10 páginasTest Pack ProcedureDaengkulle Firmansyah PuteraAinda não há avaliações

- Instrumentation and ControlsDocumento2 páginasInstrumentation and ControlsTrí NguyễnAinda não há avaliações

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocumento18 páginas4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuAinda não há avaliações

- Wps Mig PDF FreeDocumento3 páginasWps Mig PDF Freehanz bermejoAinda não há avaliações

- 1.13 Inspection & Test PlansDocumento1 página1.13 Inspection & Test Plansabimanyubawono100% (2)

- WPS Sa 517Documento2 páginasWPS Sa 517DHANANNJAI SINGH -Ainda não há avaliações

- ITP For Piping SystemsDocumento6 páginasITP For Piping SystemsGia Minh Tieu TuAinda não há avaliações

- Chemical Resistance (LLDPE) PDFDocumento24 páginasChemical Resistance (LLDPE) PDFrubyshreeAinda não há avaliações

- Cold Tap Coating Report 2Documento1 páginaCold Tap Coating Report 2Jamal BakhtAinda não há avaliações

- 22.MS For HydrotestDocumento9 páginas22.MS For HydrotestASHWANIAinda não há avaliações

- Pressure Vessel Dimension Inspection PDFDocumento17 páginasPressure Vessel Dimension Inspection PDFEqubal KhanAinda não há avaliações

- GMCo - WPSDocumento8 páginasGMCo - WPSMohamed AtefAinda não há avaliações

- Proposed WPS For API 5LDocumento1 páginaProposed WPS For API 5LMecon HyderabadAinda não há avaliações

- Radiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0Documento13 páginasRadiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0BCE DeAinda não há avaliações

- Approved Itp-Dss - 28 Sep 2016Documento4 páginasApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianAinda não há avaliações

- Painting ReportDocumento29 páginasPainting ReportDimas Afiefan AmirAinda não há avaliações

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDocumento1 páginaNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Blasting and Painting Procedure: Petronas Rapid Project Package 14 - Utilities, Interconnecting, Offsite UnitsDocumento52 páginasBlasting and Painting Procedure: Petronas Rapid Project Package 14 - Utilities, Interconnecting, Offsite UnitsYo Wee Liam100% (1)

- Cable Tray InstallationDocumento1 páginaCable Tray InstallationNaeemAinda não há avaliações

- Welding Procedure Specification For Storage Tank & Piping SystemDocumento3 páginasWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadAinda não há avaliações

- Sample WPS 1Documento13 páginasSample WPS 1waqas pirachaAinda não há avaliações

- Re-Welding, Expansion & HT ProcedureDocumento6 páginasRe-Welding, Expansion & HT Proceduresuria qaqcAinda não há avaliações

- TP-01Hydrostatic Test Cover SheetDocumento4 páginasTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Field Hydrotest Manual UndergroundDocumento8 páginasField Hydrotest Manual UndergroundPhuoc PhuAinda não há avaliações

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocumento1 páginaWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedAinda não há avaliações

- Consumable Spec Rev 12Documento24 páginasConsumable Spec Rev 12megastar0604Ainda não há avaliações

- Welding Procedure Specification For GTAWDocumento9 páginasWelding Procedure Specification For GTAWraja reyhanAinda não há avaliações

- Hydro Test ReportDocumento2 páginasHydro Test ReportAnonymous a8oga83Ainda não há avaliações

- A-Qac-Pro-730-38930 Rev ADocumento10 páginasA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiAinda não há avaliações

- Hydro Test ProcedureDocumento11 páginasHydro Test ProcedureRohit SharmaAinda não há avaliações

- Doc. No Revision No Revision DateDocumento6 páginasDoc. No Revision No Revision DateShyam SinghAinda não há avaliações

- QA-R-04 - Visual Inspection ReportDocumento1 páginaQA-R-04 - Visual Inspection ReportvinothAinda não há avaliações

- Pig Launcher Fabrication Activity PlanDocumento1 páginaPig Launcher Fabrication Activity PlanbeqsAinda não há avaliações

- Field Hydrostatic Testing of Piping Systems-EGDocumento9 páginasField Hydrostatic Testing of Piping Systems-EGYusufAinda não há avaliações

- 0.hydro Test Package Index - 2Documento13 páginas0.hydro Test Package Index - 2VISHNUPRASAD ARAKKAL MOHANDASAinda não há avaliações

- Activity Report Running WPS & PQRDocumento3 páginasActivity Report Running WPS & PQRAndre Brama AlvariAinda não há avaliações

- Hardness Pro Form1Documento2 páginasHardness Pro Form1gst ajah100% (1)

- Lot Inspection Report For LPG New CylindersDocumento3 páginasLot Inspection Report For LPG New CylindersJagannath MajhiAinda não há avaliações

- Tech SpecDocumento16 páginasTech SpecKingston RivingtonAinda não há avaliações

- Hydrostatic Test Procedure For Ug Non-Metallic Piping SystemDocumento16 páginasHydrostatic Test Procedure For Ug Non-Metallic Piping SystemabrayalamAinda não há avaliações

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Documento1 páginaWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyAinda não há avaliações

- Presented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaDocumento6 páginasPresented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaRahul MoottolikandyAinda não há avaliações

- Need of Surface TreatmentDocumento6 páginasNeed of Surface TreatmentRahul MoottolikandyAinda não há avaliações

- Mass Earth's Atmosphere: DensityDocumento23 páginasMass Earth's Atmosphere: DensityRahul MoottolikandyAinda não há avaliações

- Inspection NotesDocumento1 páginaInspection NotesRahul MoottolikandyAinda não há avaliações

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocumento3 páginasItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocumento3 páginasMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocumento3 páginasMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyAinda não há avaliações

- 026 To 033test ReportsDocumento40 páginas026 To 033test ReportsRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocumento5 páginasMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyAinda não há avaliações

- Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocumento5 páginasMarking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyAinda não há avaliações

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDocumento1 páginaDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyAinda não há avaliações

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocumento7 páginasMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyAinda não há avaliações

- Industrial Hose: Formerly Black Gold Choke & Kill HoseDocumento4 páginasIndustrial Hose: Formerly Black Gold Choke & Kill HoseRahul MoottolikandyAinda não há avaliações

- Mandays 100Documento1 páginaMandays 100Rahul MoottolikandyAinda não há avaliações

- IZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportDocumento1 páginaIZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportRahul MoottolikandyAinda não há avaliações

- Gate Pass Request FormDocumento38 páginasGate Pass Request FormRahul MoottolikandyAinda não há avaliações

- Gate Pass Request Form: Requested Date: Reference NoDocumento1 páginaGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyAinda não há avaliações

- Date Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Documento1 páginaDate Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Rahul MoottolikandyAinda não há avaliações

- New Process Performance IE4 Motors: Product NotesDocumento2 páginasNew Process Performance IE4 Motors: Product NotesCali MelendezAinda não há avaliações

- David Beard Composer CV ShortDocumento2 páginasDavid Beard Composer CV ShortEhsan KarimyAinda não há avaliações

- Profile of The Aerospace Industry in Greater MontrealDocumento48 páginasProfile of The Aerospace Industry in Greater Montrealvigneshkumar rajanAinda não há avaliações

- High Performance HTP eDocumento14 páginasHigh Performance HTP ejohnny_cashedAinda não há avaliações

- VbeltDocumento7 páginasVbeltMinaBasconAinda não há avaliações

- Mmro C 053 MD 0357 Interior PL DrawingsDocumento82 páginasMmro C 053 MD 0357 Interior PL DrawingsAnonymous 4Ts8UBFwzAinda não há avaliações

- 2501 Solid Drawn Copper Tubes For General Engineering PurposesDocumento8 páginas2501 Solid Drawn Copper Tubes For General Engineering PurposesKaushik SenguptaAinda não há avaliações

- Tycs AcDocumento38 páginasTycs Acvarshamore123Ainda não há avaliações

- Nexus 1262 & 1272 CatalogueDocumento12 páginasNexus 1262 & 1272 CataloguenaveenAinda não há avaliações

- InternshipDocumento14 páginasInternshipMohammed Shaheeruddin0% (1)

- BOB SO Information HandoutDocumento5 páginasBOB SO Information HandoutKabya SrivastavaAinda não há avaliações

- Bhopal Gas TragedyDocumento25 páginasBhopal Gas TragedyHarry AroraAinda não há avaliações

- Alexandria University Faculty of Engineering: Electromechanical Engineering Sheet 1 (Synchronous Machine)Documento5 páginasAlexandria University Faculty of Engineering: Electromechanical Engineering Sheet 1 (Synchronous Machine)Mahmoud EltawabAinda não há avaliações

- Awareness and Application of Ms Iec - Iso 31010 - 2011 Risk Assessment Techniques1 PDFDocumento21 páginasAwareness and Application of Ms Iec - Iso 31010 - 2011 Risk Assessment Techniques1 PDFasushk0% (1)

- 5 CombiflameDocumento8 páginas5 CombiflamenitantharaniAinda não há avaliações

- Mahindra08 Tractor 2Documento5 páginasMahindra08 Tractor 2Pawan SinghAinda não há avaliações

- ExcavationDocumento18 páginasExcavationBogdan-Gabriel SchiopuAinda não há avaliações

- Remote SensingDocumento30 páginasRemote SensingAdeel AhmedAinda não há avaliações

- Lab 7Documento12 páginasLab 7api-25252422380% (5)

- Average - Aptitude MCQ Questions and Solutions Wit - 1597107113795Documento6 páginasAverage - Aptitude MCQ Questions and Solutions Wit - 1597107113795Manish ChavannavarAinda não há avaliações

- 800ma Low Dropout Positive Regulator: Features DescriptionDocumento12 páginas800ma Low Dropout Positive Regulator: Features DescriptionmarcianocalviAinda não há avaliações

- Advanced English Communication Skills LaDocumento5 páginasAdvanced English Communication Skills LaMadjid MouffokiAinda não há avaliações

- 7sd610 CatalogueDocumento35 páginas7sd610 CatalogueTntngn Petualang100% (1)

- 09931374A Clarus 690 User's GuideDocumento244 páginas09931374A Clarus 690 User's GuideLuz Idalia Ibarra Rodriguez0% (1)

- Case StudyDocumento80 páginasCase Studybravo deltafoxAinda não há avaliações

- 1 Chapter1 Introduction V5.5a1Documento13 páginas1 Chapter1 Introduction V5.5a1Alejandro LaraAinda não há avaliações

- Dr. Ambedkar Institute of Technology: Mandatory Non-Credit NSS Course (22NSN310) Bachelor of Engineering inDocumento4 páginasDr. Ambedkar Institute of Technology: Mandatory Non-Credit NSS Course (22NSN310) Bachelor of Engineering inshamalac2004Ainda não há avaliações

- Mathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringDocumento40 páginasMathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringVishal ShasiAinda não há avaliações

- Congelador - Frigidaire GLFC1326FW1 - Man - Eng - PartsDocumento7 páginasCongelador - Frigidaire GLFC1326FW1 - Man - Eng - Partsfelix bazanAinda não há avaliações

- Sandisk X400 SSD (Solid State Drive) : The World'S First 1Tb, Single-Sided SSDDocumento2 páginasSandisk X400 SSD (Solid State Drive) : The World'S First 1Tb, Single-Sided SSDlechurzAinda não há avaliações