Escolar Documentos

Profissional Documentos

Cultura Documentos

A5-11 Specification For Nickel and Nickel Alloy Wel - El For SMAW PDF

Enviado por

SenakeTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

A5-11 Specification For Nickel and Nickel Alloy Wel - El For SMAW PDF

Enviado por

SenakeDireitos autorais:

Formatos disponíveis

ANSVAWS A5.11/A5.

11M-97

An American National Standard

Specification for

Nickel and

Nickel-Alloy

Welding Electrodes

for Shielded Metal

Arc Welding

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

Key Words- Nickel, nickel-alloy weldingelectrodes, ANWAWS A5.11/A5.11 M-97

shielded metal arc welding electrodes, An American National Standard

welding electrodes

Approved by

American National StandardsInstitute

November 6,1997

Specification for

Nickel and Nickel-Alloy

Welding Electrodes for

Shielded Metal Arc Welding

Supersedes ANSI/AWS AS.ll-90

Prepared by

AWS Committee on Filler Metals

Under the Directionof

AWS Technical Activities Committee

Approved by

AWS Board of Directors

Abstract

This specification describes the composition, dimensions, soundness, and properties of weld metal from more than20

classifications of nickel and nickel-alloy covered electrodes. Major topics include general requirements, testing, manu-

facturing, identification, and packaging, A guide to using the specification is included in an annex.

This specification makes use of both U.S. Customary Units and the International Systemof Units (SI). Since these are

not equivalent, each system must be used independentlyof the other.

American Welding Society

550 N.W. LeJeune Road, Miami, Florida33 126

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

Statement on Use of AWS Standards

All standards (codes, specifications, recommended practices, methods, classifications, and guides) of the American

Welding Society are voluntary consensus standards that have beendeveloped in accordance with the rules of the Ameri-

can National Standards Institute. When AWS standards are either incorporated in, or made part of, documents that are

included in federal or state laws and regulations, or the regulations of other governmental bodies, their provisions carry

the full legal authority of the statute. In such cases, any changes in those AWS standards must be approved by the gov-

ernmental body having statutory jurisdiction before they can become a part of those laws and regulations. In all cases,

these standards carry the full legal authority of the contract or other document that invokes the AWS standards. Where

this contractual relationship exists, changes in or deviations from requirements of an AWS standard must be by agree-

ment betweenthe contracting parties.

International Standard Book Number:0-87 17 1-533-3

American Welding Society,550 N.W. LeJeune Road, Miami, FL 33126

O 1998 by American WeldingSociety. All rights reserved

Printed in the United States of America

Note: The primary purpose of AWS is to serve and benefit its members. To this end, AWS provides a forum for the ex-

change, consideration, and discussion of ideas and proposals that are relevant to the welding industry and the consensus

of which forms the basis for these standards. By providing such a forum, AWS does not assume any duties to which a

user of these standards may be required to adhere. By publishing this standard, the American Welding Society does not

insure anyone using the information it contains against any liability arising from that use. Publication of a standard by

the American Welding Society does not carry with it any right to make, use, or sell any patented items. Users of the in-

formation in this standard should make an independent, substantiating investigation of the validity of that information

for their particular use and thepatent status of any item referredto herein.

With regard to technical inquiries made concerning AWS standards, oral opinions on AWS standards may be rendered.

However, such opinions represent only the personal opinions of the particular individuals giving them. These individuals

do not speak on behalf of AWS, nor do these oral opinions constitute official or unofficial opinions or interpretations of

AWS. In addition, oral opinions are informal and should notbe used as a substitute for an official interpretation.

This standard is subject to revision at any time by the AWS Committee on Filler Metals. It must be reviewedevery five

years and if not revised, it must be either reapproved or withdrawn. Comments (recommendations, additions, or dele-

tions) and any pertinent data that may be of use in improving this standard are requested and should be addressed to

AWS Headquarters. Such comments will receive careful consideration by the AWS Committee on Filler Metals and the

author of the comments will be informed of the Committee's response to the comments. Guests are invited to attend all

meetings of the AWS Committee on Filler Metals to express their comments verbally. Procedures for appeal of an ad-

verse decision concerning all such comments are provided in the Rules of Operationof the Technical Activities Commit-

tee. A copy of these Rules can be obtained from the American Welding Society, 550 N.W. LeJeune Road, Miami, FL,

33 126.

Photocopy Rights

Authorization to photocopy items for internal, personal, or educational classroom use only, or the internal, personal, or

educational classroom use only of specific clients, is granted by the American WeldingSociety (AWS) provided thatthe

appropriate fee is paid to the Copyright Clearance Center, 222 Rosewood Drive, Danvers, MA 01923; Tel. (508) 750-

8400; online: http://www.copyright.com

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

Personnel

AWS Committee on Filler Metals

R. A. LaFave, Chair Elliott Company

J. R Hunt, 1st Vice Chair Consultant

D. A. Fink, 2nd Vice Chair The Lincoln Electric Company

H. M. Woodward, Secretary American Welding Society

*R. L. Bateman Electromanufacturas, S.A.

R. S. Brown Carpenter Technology Corporation

R. A. Bushey ESAB Welding and Cutting Products

J. Caprarola, JI: Consultant

*L. J. Christensen Consultant

R. J. Christoffel Consultant

D. D. Crockett The Lincoln Electric Company

R. A. Daemen Consultant

D. A. DelSignore Consultant

R. L. Drury I l l Caterpillar, Incorporated

H. W Ebert Exxon Research and Engineering Company

J. G. Feldstein Foster Wheeler Energy International

S. E. Ferree ESAB Welding and Cutting Products

L. Flasche Haynes International, Incorporated

R. S. Fuchs Böhler Thyssen Welding USA, Incorporated

C. E. Fuerstenau Alloy Ring Service

G. Hallstrom, JI: Hallstrom Consultants

R. B. Kadiyala Techalloy Company

D. J. Kotecki The Lincoln Electric Company

D. !I Ku American Bureau of Shipping

N. E. Larson Compressed Gas Industries

A. S. Laurenson Consultant

J. S. Lee Chicago Bridge and Iron Company

G. H. MucShane MAC Associates

W A. Marttila Chrysler Corporation

R. Menon Stoody Company

M. T. Merlo Select Arc, Incorporated

A. R. Mertes Ampco Metal, Incorporated

M. D. Morin ABB Power Generation

C. L, Null Department of the Navy

J. J. Payne Consultant

R. L. Peaslee Wall Colmonoy Corporation

E. W Pickering Consultant

M. A. Quintana The Lincoln Electric Company

*H. E Reid Consultant

*S. D. Reynolds, JI: Consultant

L. E Roberts Canadian Welding Bureau

P: K. Sulvesen Det Norske Veritas (DNV)

J. M. Suwhill, JI: Newport News Shipbuilding

A. P. Seidler Armco Steel Corporation

*Advisor

...

111

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services ~.

AWS Committee on Filler Metals (Continued)

W S. Severance ESAB Welding andCutting Products

*W A. Shopp Editorial Consultant

M. S. Sierdzinski ESAB Welding andCutting Products

*R. G. Sim The Lincoln Electric Company (Australia)

E. R. Stevens Fisher Controls International

*R. W Straiton Bechtel Corporation

R. A. Sulit Digital Systems Research

R. A. Swain Euroweld, Limited .

R. D. Thomas, J,: R. D. Thomas and Company

K. I? Thomberry J. W. Harris Company, Incorporated

*R. í'ïmerman Conarco, S.A.

*S. Tsutsumi Kobe Steel Limited-Welding Division

L.. T. Vernam AlcoTec Wire Company

G. J. vtanovych Mobil TechnologyCompany

T. R. Warren Ingalls Shipbuilding, Incorporated

H. D. Wehr Arcos Alloys

*E J. Winsor Consultant

K. G. Wold Siemens Power Corporation

AWS Subcommittee on Nickel and Nickel-Alloy Filler Metal

L. Flasche, Chair Haynes International, Incorporated

H. M. Woodward, Secretary American WeldingSociety

* E S. Babish Sandvik Steel Company

R. S. Brown Carpenter Technology Corporation

c. W cox Inco Alloys International, Incorporated

*D. A. DelSignore Consultant

*J. E Frawley General Electric Company

R. S. Fuchs Böhler Thyssen Welding USA, Incorporated

c! U! Hartmann Inco Alloys International, Incorporated

J. F! Hunt Consultant

R. B. Kadiyala Techalloy Company

E B. Luke ESAB Group, Incorporated

R. Menon Stoody Company

R. A. Swain Euroweld, Limited

*R. D. Thomas, J,: R. D. Thomas and Company

*J. W Tackett Consultant

*S. Tsutsumi Kobe Steel, Limited

J. E Tumer Consultant

H. D. Wehr Arcos Alloys

*Advisor

iv

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

Foreword

(This Foreword is not a part of ANSVAWS A5.11/A5.11M-97, Specification for Nickel and Nickel-Alloy Welding

Electrodesfor Shielded Metal Arc Welding,but is included for information purposes only.)

This documentis the first revision to A5.11 specificationsthat makes useof both U.S. Customary Units andthe Inter-

national System of Units(SI). The measurementsare not exact equivalents; therefore each system must be used indepen-

dently of the other, without combining values in any way. In selecting rational metric units, ANSVAWS Al . I , Metric

Practice Guide for the Welding Industry,and International Standard I S 0 544, Filler Metals for Manual Welding - Size

Requirements, are used where suitable. Tables andfigures make use of both U.S. Customary and SI units, which with the

application of the specified tolerances provides for interchangeability of products in both the U.S. Customary and SI

units.

The first specification for nickel and nickel-alloy covered electrodes was issued in 1954 by a joint committee of the

American Society for Testing and Materials and the American Welding Society. The first revision in 1964 was also the

result of the cooperativeeffort. This revision is the fifth prepared entirely by the AWS Committee on Filler Metals.

Document Development

ASTMB295-54T Tentative Specification for NickelandNickelBaseAlloyCoveredWeldingElectrodes

AWS A5.11-54T

AWS A5.11-64T Tentative Specification for NickelandNickelAlloyCoveredWeldingElectrodes

ASTM B295-64T

AWS A5.11-69 Specification for Nickel

andNickel

Alloy

Covered

Welding

Electrodes

ANSI W3.11-1973

AWSA5.11-Add 1-75 Addenda to Specification for NickelandNickelAlloyCoveredWeldingElectrodes

AWS

A5.11-76 Specification for Nickel

andNickel

Alloy

Covered

Welding

Electrodes

ANSVAWSA5.11-83 Specification for NickelandNickelAlloyCoveredWeldingElectrodes

ANSVAWSA5.11-90SpecificationforNickelandNickelAlloyWeldingElectrodesforShieldedMetalArcWelding

Comments and suggestionsfor the improvement of this standard are welcome. They should be sent to theSecretary,

Committee on Filler Metals, American Welding Society,550 N.W. LeJeune Road, Miami,FL 33126.

Official interpretations of any of the technical requirementsof this standard may be obtained by sendinga request, in

writing, to the Managing Director, Technical Services Division, American Welding Society. A formal reply will be

issued after it has been reviewed by the appropriate personnel following established procedures.

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

Table of Contents

Page No .

...

Personnel .................................................................................................................................................................... 111

Foreword ...................................................................................................................................................................

List of ..............................................................................................................................................................

Tables

..v

v11

List of Figures ............................................................................................................................................................

..

v11

1. Scope .................................................................................................................................................................... 1

Part A-General Requirements

2. Normative References.......................................................................................................................................... 1

3. Classification........................................................................................................................................................ 2

4. Acceptance ........................................................................................................................................................... 2

5. Certification ......................................................................................................................................................... 2

6. Units of Measure and Rounding-Off Procedure.................................................................................................. 2

Part B.Tests. Procedures. and Requirements

7. Summary of Tests ................................................................................................................................................. 2

8. Retest .................................................................................................................................................................... 7

9. Weld Test Assemblies.......................................................................................................................................... 7

10. Chemical Analysis ............................................................................................................................................... 7

11. Radiographic Test................................................................................................................................................. 8

12. Tension Test ....................................................................................................................................................... 12

13. Bend Test ............................................................................................................................................................ 12

Part C.Manufacture. Identification. and Packaging

14. Method of Manufacture ..................................................................................................................................... 17

15. Standard Sizes and Lengths ............................................................................................................................... 17

16. Core Wire and Covering .................................................................................................................................... 17

17. Exposed Core ..................................................................................................................................................... 18

18. Electrode Identification...................................................................................................................................... 18

19. Packaging ........................................................................................................................................................... 21

20. Marking of Packages .......................................................................................................................................... 21

Annex-Guide to AWS Specification for Nickel and Nickel-Alloy Welding Electrodes for

Shielded Metal Arc Welding

Al . Introduction...................................................................................................................................................... 23

A2 . Classification System ...................................................................................................................................... 23

A3 . Acceptance....................................................................................................................................................... 23

A4 . Certification..................................................................................................................................................... 24

A5 . Ventilation During Welding ............................................................................................................................. 25

A6 . Welding Considerations................................................................................................................................... 25

A7 . Description and Intended Useof Electrodes ................................................................................................... 25

A8 . Special Tests .................................................................................................................................................... 29

A9 . Discontinued Classifications ........................................................................................................................... 29

A10. Safety Considerations...................................................................................................................................... 29

AWS Filler Metal Specifications by Material and Welding Process .......................................................................... 33

AWS Filler Metal Spec@ationsand Related Documents ........................................................................................ 35

vi

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

List of Tables

Table Page No .

1 Chemical Composition Requirementsfor Undiluted Weld Metal ................................................................. 3

2 Required Tests andPositions ......................................................................................................................... 6

3 Base Metals for Test Assemblies ................................................................................................................. 11

4 All-Weld-Metal Tension Test Requirements................................................................................................ 18

5 Dimensions of Bend Test Specimens........................................................................................................... 18

6 Bend Test Requirements.............................................................................................................................. 20

7 Standard Sizes and Lengths ......................................................................................................................... 21

Al Comparison of Classifications ..................................................................................................................... 24

A2 Discontinued Classifications........................................................................................................................ 29

List of Figures

Figure Page No.

1 Pad for Chemical Analysisof Undiluted Weld Metal .................................................................................... 8

2 Groove Weld Test Assembly for Mechanical Properties and Soundness ...................................................... 9

3 Groove Weld Test Assemblyfor Radiographic Soundness Test.................................................................. IO

4 Radiographic Standardsfor 1/8 in . [3.2 mm] Test Assembly...................................................................... 12

5 Radiographic Standardsfor 1/4 in . [6.4 mm] Test Assembly...................................................................... 13

6 Radiographic Standardsfor 3/8 in . [9.5 mm] Test Assembly...................................................................... 14

7 Radiographic Standardsfor 1/2 in . [ 13 mm] Test Assembly....................................................................... 15

8 Radiographic Standardsfor 314 in . [19 mm] Test Assembly....................................................................... 16

9 Dimensions of All-Weld-Metal Tension Test Specimen .............................................................................. 17

10 Standard Bend TestJigs ............................................................................................................................... 19

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

Specification for Nickel and Nickel-Alloy

Welding Electrodes for Shielded MetalArc Welding

1. Scope (1) ASTM A I3 IIA I3 1M, Standard Specification for

Structural Steelfor Ships

This specification prescribes requirements for the classi- ( 2 ) ASTM A 240lA 240M,Standard Specification for

fication of nickel and nickel-alloy covered electrodes for Heat-Resisting Chromium and Chromium-Nickel Stain-

shielded metal arc welding. It includes those composi- less Steel Plate, Sheet,und Strip f o r Pressure Vessels

tions in which the nickel content exceeds that of any

other element. 3) ASTM A 285lA 285M, Standard Specification for

Pressure Vessel Plates, Carbon steel, Low- and Inter-

mediate-Tensile Strength

(4) ASTM A 5 151A 5 15M, Standard Specification for

Part A Pressure Vessel Plates, Carbon Steel,f o r Intermediate-

General Requirements and Higher-Temperature Service

(5) ASTM B 127, Standard Specification f o r Nickel-

2. Normative References Copper Alloy (UNS N04400)Plate, Sheet, and Strip

(6) ASTM B 160, Standard Specification f o r Nickel

2.1 The following ANSIIAWS standards2 are referenced Rod and Bar

in the mandatorysections of this document:

(7) ASTM B 162, Standard Specification f o r Nickel

(1) ANSIIAWS A1.1, Metric Practice Cuide for the

Plate, Sheet, and Strip

Welding Industry

( 2 ) ANSIIAWS A5.01, Filler Metal Procurement (8) ASTM B 164, Standard Specification f o r Nickel-

Guidelines Copper Alloy Rod,Bal; and Wire

( 3 ) ANSUAWS B4.0, Standard Methods for Mechani- (9) ASTM B 166, Standard Specification f o r Nickel-

cal Testing of Welds Chromium-Iron Alloys (UNSN06600, N06601, N06690,

N06025, and N06045) and Nickel-Chromium-Cobalt-

2.2 The following ASTM and I S 0 standards3 are refer- Molybdenum Alloy (UNSNO6617)Rod, Bal; and Wire

enced in the mandatory sections of this document:

( I O) ASTM B 167, Standard Specification for Nickel-

Chromium-Iron Alloys (UNSN06600, N06601, N06690,

1. Nickel-basecoveredelectrodes for weldingcastironsare N06025, and N06045) Seamless Pipe and Tube

treated separately in ANSYAWS A5.15, Specificationfor Weld- ( 1 1) ASTM B 168, Standard Specification for Nickel-

ing Electrodes and Rods for Cast Iron. This specification is Chromium-Iron Alloys (UNSN06600, N06601, N06690,

availablefromtheAmericanWeldingSociety, 550 N.W. N06025, and N0604.5) and Nickel-Chromium-Cobalt-

LeJeune Road, Miami, FL 33126. Molybdenum Alloy (UNS NO661 7 ) Plate, Sheet, and

2. AWS standards can be obtained from the American Welding Strip

Society, 550 N.W. LeJeune Road, Miami, FL 33126.

( 1 2) ASTM B 333, Standard Specifcation for Nickel-

3. ASTM standards canbe obtained from the American Society

for Testing and Materials, 100 Barr Harbor Drive, West Con- Molybdenum Alloy Plate, Sheet, and Strip

shohocken, PA 19428-2959. IS0 standards are available from (13) ASTM B 435, Standard Specification f o r U N S

AmericanNationalStandardsInstitute,ANSI, 11 West 42nd N06002, UNS N06230, UNS N12160, and UNS R30556

Street, 13th Floor, New York, NY 10036. Plate, Sheet, and Strip

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

L997 m 0719'42b5 0509'457

2

(14) ASTM B 443, Standard Specification for Nickel- 5. Certification

Chromium-Molybdenum-Columbium Alloy (UNS

N06625) Plate, Sheet, and Strip By affixing the AWS specification and classification

(15) ASTM B 446, Standard Specification for Nickel- designation to the packaging, or the classification to the

Chromium-Molybdenum-Columbium Alloy (UNS product, the manufacturer certifies that the product meets

N06625) Rod and Bar the requirements of this specification?

(16) ASTM B 575, Standard Specification f o r Low-

Carbon Nickel-Molybdenum- Chromium, Low-Carbon

Nickel-Chromium-Molybdenum, and Low-Carbon

Nickel-Chromium-Molybdenum-Tungsten Alloy Plate, 6. Units of Measure and

Sheet, and Strip Rounding-Off Procedure

(17) ASTM B 582, Standard Specification for Nickel-

Chromium-Iron-Molybdenum-Copper AlloyPlate, Sheet, 6.1 This specification makes use of both U.S. Customary

and Strip Units and the International System of Units (SI). The

measurements are not exact equivalents; therefore each

(1 8) ASTM E 29, Standard Practice for Using Signifi- system must be used independently of the other without

cant Digits in Test Data to Determine Conformance with combining values in any way. The specification with the

Specifications designation A5.11 uses the U.S. Customary Units. Speci-

(19) ASTM E 38, Standard Methods f o r Chemical fication A5.11M uses SI Units. The latter are shown in

Analysis of Nickel-Chromium and Nickel-Chromium- appropriate columns in tables and in figures, and within

Iron Alloys brackets [ ] when used in the text.

(20) ASTM E 76, Standard Methods for Chemical

Analysis of Nickel-Copper Alloys 6.2 For purposes of determining conformance with this

(21) ASTM E 142, Methods for Controlling Quality of specification, an observed or calculated value shall be

Radiographic Testing rounded to the nearest 1000 psi [lo MPa] used in ex-

(22) I S 0 544, Filler Metals for Manual Welding - pressing the limiting value for other quantities in accor-

Size Requirements dance with the rounding-off method given in ASTM

E29, Standard Practice for Using Significant Digits in

Tests to Determine Conformance with Specifications.

3. Classification

3.1 The welding electrodes covered by the A5.11/

A5.11M specification are classified using a system that is Part B

independent of U.S. Customary Units and the Interna-

tional System of Units(SI). Classification is according to

Tests, Procedures,

the chemical composition of their undiluted weld metal, and Requirements

as specified in Table1.

3.2 Electrodes classified under one classificationshall

not be classified under any other classification in this

specification.

7. Summary of Tests

The tests required for classification are specified in

Table 2. The purpose of these tests is to determine the

4. Acceptance chemical composition, the mechanical properties and

soundness of the weld metal, and the usability of the

Acceptance4 of the electrodes shall be in accordance electrode. The base metal for the weld test assemblies,

with the provisions of ANSVAWS A5.01, Filler Metal the welding and testing procedures to be employed, and

Procurement Guidelines. the results required are given in Section 9, Weld Test As-

semblies, through Section 13, Bend Test.

4. See Section A3. Acceptance (in

the Annex), for further infor-

mationconcerningacceptance and testingofthe material 5. See SectionA4.Certification(in the Annex), for further

shipped, as well as ANSYAWS A5.01, Filler Metal Pmcure- information concerning certification and the testing called for

ment Guidelines. to meet this requirement.

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

3

O

v!

O

"

O

O

O

I I I

9 o" 9 09 9 o?

--.N o-m -*m

O

2 I

m O

?

O 2 I

n

I V

o)

I

O O

v!

2 O

v, In

? Y

O O

m c1

8 9

O

O r-

2 2 O v,

2

o ó

r?

O 8 o 2 8

4 N m d

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

4

O O O O O O O

Y Y Y

Y

O 2 2 O O 2 O

O

\4

O

I I I I I I I I

I l I I I I

I I I I l I

O O O O

?

O

Y

O

?

"N

o?

2 2

v, v,

2 r:

O

9

3

9

3

Y

O

m 2 m m

8 8 8 z N

9

O

xo 2 B

o

B

o

8

O

e

2 ò

ò

z 6

.-

zi Ei

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

5

3 O O O O O O

r! Y Y Y 'c! Y Y

9 O O O O O O

vr

I 2 I I I

I o o N

Y U 9 I I

I I I I I

I I I l I

Y

N I 2 Y

N 2

O O

Y Y

O O

9

2 9

(ri N (ci 2 N

4

O 8 9

O 8 8

m m

B P; B

o 8 ò 8 d

9

4 -

9 -

Y

E! 2 2 N r4 m

ó o 9

O 8 8 8

2

6

F

U

5

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

6

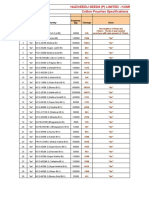

Table 2

Required Tests and Positions

Tests Required

Diameter

Electrode

Position

Radiographic

Chemical

Bend

Tension

Radiographic

AWS ClassificationTestc** Testin. Testb mm Test Analysis

ENi- 1

. r

1

ENiCrFe-1 5/64

ENiCrFe-2 3/32

ENiCrFe-3 - 2.5 Required

Required

Required

Required V

ENiCrFe-4 118 3.2

ENiCrFe-7

ENiCrFe-9 '

<

ENiCrFe-1O 5/32

ENiCrMo-3 3/16

ENiCrMo-6 - F Required

Required

Required

Required

5.0

ENiCrMo-1O 114'

ENiCrMo- 14

ENiCu-7 , L

5/64 2.0

ENiMo- 1 2.4= 3/32

ENiMo-3

ENiMo-7

- 2.5

ENiMo-8 1/8 3.2 F* Required

Required

Required

Required

miMo-9 5/32 4.0

ENiMo- 10 4.gC3116

- 5.0

5/64

3/32

1

-

RequiredRequiredRequiredRequired

2.5

V

ENiCrCoMo-1

3.2 1/8

/16

ENiCrMo-1

ENiCrMo-2

ENiCrMo-5

ENiCrMo-4

ENiCrMo-7

ENiCrMo-9

ENiCrMo-11

1 if 5/32

5/32

-

Required

4.0 Required

4.0

4.P

Required

Required

Required

Required

Required

Required

F

ENiCrMo- 13

5/64 2.0 I

3/32

-

RequiredRequiredRequiredRequired V

ENiCrMo- 12

3.2 1/8

5/32 F Required

4.0Required

Required

Required ì

I

Notes:

a. See Table 3 for base metals tobe used in these tests.

b. Three transverse side-bend test specimens are required except for 5/64 in. [2.0 mm] electrodes. For that size, two transverse face-bend specimens

are required.

c. The groove weld for mechanical properties (Figure 2) may also be used for the radiographic soundness test conducted in the flat position. In that

case, the test assemblyis radiographed before the couponsfor the tensileand bend test specimensare removed.

d. The position of welding shown in this column isonly for the radiographic soundness test(V = vertical with uphill progression,F = flat). All other

test assemblies ce welded in the flat position.

e. Metric sizes not shown inI S 0 544.

f. Applies only to ENiCu-7 classification.

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

7

8. Retest 9.3 Weld Pad. A weld pad shall be prepared as specified

in Table 2 and shownin Figure I , except when one of the

If the results of any test fail to meet the requirement, alternatives in 9.1 (taking the sample from the weld

that test shall be repeated twice. The results of both re- metal in the groove or from the tension test specimen) is

tests shall meet the requirement. Specimens for retest selected. Base metal of any convenient size, of the type

may be taken from the original test assembly, or from specified in Table 3, shall be used as the base for the

one or two new test assemblies. For chemical analysis, weld pad. The surface of the base metal on which the

retest need be onlyfor those specific elements that failed filler metal is deposited shall be clean. The pad shall be

to meet the test requirement. welded in the flat position with multiple beads and layers

If the results of one or both retests fail to meet the re- to obtain undiluted weld metal. The type of current and

quirement, the material under test shall be considered as range of amperage used for welding shall be as recom-

not meeting the requirements ofthis specification for that mended by the manufacturer. The preheat temperature

classification. shall be not less than 60°F [16"C] and the interpass tem-

In the event that, during preparation or after comple- perature shall not exceed 300°F [ 150"C]. The slag shall

tion of any test, it is clearly determined that prescribed or be removed after each pass. The pad may be quenched in

proper procedures were not followed in preparing the water (temperature above 60°F [ 16"C]) between passes.

weld test assembly or test specimen(s) or in conducting The dimensions of the completed pad shall be as shown

the test, the test shall be considered invalid, without re- in Figure 1 for each size of electrode. Testing of this

gard to whether the test was actually completed, or assembly shall be as specified in Section 10, Chemical

whether test results met, or failed to meet, the require- Analysis.

ment. That test shall be repeated, following proper pre- 9.4 Groove Weld

scribed procedures. In this case, the requirement for

doubling ofthe number of test specimens does not apply. 9.4.1 Mechanical Properties and Soundness.A test

assembly shall be prepared and welded as specified in

Figure 2 and Table 2 using base metal of an appropriate

type in Table 3. Testing of this assemblyshall be as spec-

9. Weld Test Assemblies ified in Section 12, Tension Test, and Section 13, Bend

Test. Additionally, this assembly may be used to satisfy

9.1 To perform all required tests as specified in Table 2, a the requirements of the flat position radiographic test

minimum of one weld test assembly is required. Two, or (Note c to Table 2). In that case, the assemblyshall be ra-

even three, may be necessary (according to the classifi- diographed as required in Section 11, Radiographic Test.

cation, size, and manner in which the testing is con- The assembly shall be tested in the as-welded condition.

ducted, i.e., with respect to alternative options).

9.4.2 Radiographic Soundness. A test assembly

The weld test assemblies are identified as follows: shall be prepared for electrodes of all classifications and

( I ) The weld pad in Figure 1 for chemical analysis of welded as shown in Figure 3. using base metal ofthe ap-

the undiluted weld metal propriate type specified in Table 3. The welding position

(2) The groove weld in Figure 2 for mechanical prop- shall be as specified in Table 2 for the different electrode

erties and soundness sizes and classifications. Testing of the assembly shall be

(3) The groove weld in Figure 3 for radiographic as specified in Section 11, Radiographic Test. The

soundness. groove weld in Figure 2 may be radiographed (for those

The sample for chemical analysis may be taken from a classifications for which the radiographic test is welded

low dilution area in the groove weldin Figure 2, or from i n the flat position), thus eliminating the need to make

the reduced section of the fractured tension test speci- the groove weld in Figure 3, in those cases.

men, thereby avoidingthe need to make the weld pad. In

case of dispute, the weld pad shall be the referee method.

10. Chemical Analysis

9.2 Preparation of each weld test assembly shall be as

prescribed in 9.3, 9.4.1, and 9.4.2. The base metal for 10.1The sample for analysis shall be taken from weld

each assembly shall meet the requirements of the appro- metal obtained from the weldpad, the reduced section of

priate ASTM specification shown in Table3 or an equiv- the fractured tension test specimen, or a low-dilution

alent specification. Testing of the assemblies shall be as area of the groove weld in Figure 2. The top surface of

prescribed in Section 10, Chemical Analysis, Section 11, the pad described in 9.3 and shown in Figure 1 (when the

Radiographic Test, Section 12, Tension Test, and Section pad is used), shall be removed and discarded. A sample

13, Bend Test. for analysis shall be obtained from the underlying metal

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

8

Electrode Size Weld Pad Size

mm, min. in., mm in.

5/64 2.0

L= 1-112 38

2.4’ 3/32

- 2.5 W=

H=

1-112

112

38

13

1I8 3.2

5/32 4.0

L= 2 50

4.8’ W1 6 W= 2 50

- 5.0 H= 718 22

1I4 6.4’

‘Metric sizes not shown in IS0 544.

General Notes:

1. The number and size of the beads will vary according to the size of the weave,as well as the amperage

of the electrode and the width

employed.

2. If carbon steelbase metal is used for the chemical analysis pad, the height

of the pad (dimensionH) shall be increased as required in

Note aof Table 3.

Figure 1-Pad for Chemical Analysisof Undiluted Weld Metal

by any appropriate mechanical means. The sample shall Standard Methods for Chemical Analysis of Nickel-

be freeof slag. Chromium and Nickel-Chromium-ZronAlloys, or ASTM

For electrodes smaller than 5/32 in. [4.0 mm], the E76,Standard Methodsfor Chemical Analysis of Nickel-

sample shall be taken at least 3/8 in. [9.5 mm] from the Copper Alloys,as appropriate.

nearest surface of the base metal. For electrodes 5/32 in.

10.3 The results of the analysis shallmeet the require-

[4.0 mm] and larger, the sample shall be taken at least

ments of Table 1 for the classification of electrode under

3/4 in. [19 mm] from that surface. If carbon-steel base

test.

metal is used in the chemical analysis test pad, see Note

“a” in Table 3. The sample from the reduced section of

the fractured tension test

specimen and the sample froma

low-dilution area of the groove weld shall be prepared 11. Radiographic Test

for analysisby any suitable mechanical means.

11.1The radiographic soundnesstest weld described in

10.2 The sample shall beanalyzed by accepted analytical 9.4.2 and shown in Figure 3 (or the groove weld de-

methods. The referee method shall be eitherASTM E38. scribed in 9.4.1 and shown in Figure 2, when that is de-

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

9

BUlTERING

c WELD

CENTERLINE

1 in. (25mm) LAYERS

MINIMUM

E BEND

T

'

1

'

TENSION

SPECIMEN SPECIMENS

LAYOUT OF TEST ASSEMBLY

I I LT/2

BUlTERlNG CONDITIONS FOR

CARBON STEELTEST PLATE ASSEMBLY

r

F{{

\rRlfli

5 deg. MAXIMUM

""

f

MATCHING COMPOSITION

TEST PLATE ASSEMBLY

AFTER

WELDING

BACKING

ANY

BE

MAY

BAR

SUITABLE DIMENSION BUlTERlNG CONDITIONS AND

TENSILE SPECIMEN LOCATION

GROOVE PREPARATION

(Thickness),

min. T Electrode

Size R (Root

Layers of

opening)a

Number

mm in.

5/64 10 2.0 318 3116 5 (b)

2.4c 3/32 13 1 /2 1 I4 7 (b)

- 2.5 1 /2 13 1 I4 7 (b)

118 3.2 19 1 12 1J4 7 (b)

4.0 5/32 W4 19 13 1 I2 6

316 4.8c W4 19 13 1 12 6

- 5.0 W4 19 13 1 12 6

114 19

6.4c 314 13 1 12 6

a. Tolerance: ilIl 6 in. [2mm].

b. Number of layers not specified, but pass and layer sequence shall

be recorded and reported.

c. Metric sizes not shown in IS0 544.

General Notes:

1. Base metal shallbe as specified inTable 3.

2. The surfaces to be welded shall be clean.

3. The minimum lengthof the test assemblyis 6 in. [150mm] but the assembly shall be as long as necessaryto provide the specimens

for the number and type of tests required. Minimum width6is in. [150 mm].

4. Prior to welding, the assembly may be preset so that the welded joint will be within

5 degrees of plane after welding. As an alternate,

restraint or a combinationof restraint and presetting may be used. A test assembly that is more5than degrees out of plane shall be

discarded. Straightening of the test assembly is prohibited.

5. Welding shall be performed in the flat position, using the type and range of current and welding technique recommended by the elec-

trode manufacturer.

6. The preheat temperature shall be60°F [16"C]. The interpass temperature shall not exceed 300°F [150°C].

7. The welds shallbe made with stringer beads or weave beads no wider than four times the diameter of the core wire. The completed

of the test plate.For electrodes larger than118 in. [3.2mm], the root beads may be depos-

weld shallbe at least flush with the surface

ited with3/32or 118 in. [2.4, or 3.2mm] electrodes.

2.5,

8. The tests shall be conducted without a postweld heat treatment.

Figure 2-Groove Weld Test Assembly for Mechanical Properties and Soundness

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

10

BUlTERING

LAYERS

BUlTERING

LAYERS BUTTER

LAYERS

BUTTERING CONDITIONSFOR

CARBON STEEL TEST PLATE ASSEMBLY

MATCHING COMPOSITION

TEST PLATE ASSEMBLY

r- 6 in. (150mm) MINIMUM

--i BUlTERING CONDmONSAND

TENSILE SPECIMEN LOCATION

L BACKING BAR MAY BE ANY

SUITABLE DIMENSION

Electrode Size T (Thickness), min. R (Root opening)a

in. in. mm mm in.

5/64 2.0 1 I8 3 1 18 3

3/32 2.4b 1 I4 7 1 I4 7

- 2.5 1I4 7 1I4 7

3.2 1 I8 318 10 5/1 6 8

5/32 4.0 W8 10 3/8 10

3/1 6 4.8b 1/2 13 1/2 13

- 13 5.0 1/2 1/2 13

6.4b 1 14 1/2 13 1/2 13

a. Tolerance: i1116 in. [2mm].

b. Metric sizes not shown in IS0 544.

General Notes:

1. Base metal shall beas specified in Table 3.

2. The surfaces to be welded shall be clean.

3. Welding shall be conducted in the vertical-up or flat position. as required in Table 2 (also see note c in Table 2) using the type and

range of current, and technique recommended by the electrode manufacturer.

4. The preheat temperature shallbe 60°F [16"C].The interpass temperatureshall not exceed300°F [150°C].

5. The welds shall be made with a stringer bead technique or a weave to produce a beadM wider than four times the diameter of the

core wire.The root layerin tests of electrodes larger than 1/8in. [3.2mm] diameter may be deposited with 3/32or 1/8in. [2.4, 2.5 or

3.2mm] electrodes of that same classification. In additionto the start and stop at the ends of the weld, each bead shall also contain a

start and astop somewhere in between.

6. A small amount of grinding between beadsis permissible for welds inthe vertical position, but an Inordinate amount should not be re-

quired to produce a satisfactory weld.

7. The completed weld shallbe at least flush with the surfaœ of the test plate.

8. The backing strip shall be removed, and the weld on both sides of the assembly shallbe machined or ground smooth and flush with

the original surfacesof the base plate.

9. The assembly shall be radiographed as specifiedin Section 11, Radiographic Test.

Figure 3-Groove Weld Test Assembly for Radiographic Soundness Test

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

Table 3

Base Metalsfor Test Assemblies

UNS

SpecificationsC

ASTM

AWS

Materialsa*b

Classification

~~

ENI- 1 Nickel B160, B162 N02200, NO2201

ENiCu-7 Nickel-Copper Alloy B127, B164 N04400

ENiCrFe-l,2,3,4,9, 10 Nickel-Chromium-Iron Alloy B166, B168 NO6600

ENiCrFe-7 Nickel-Chromium-Iron Alloy B166, B167, B168 NO6690

ENiMo-l,3.7,8,9, 10 Nickel-Molybdenum

B333 Alloy N10001, N10665, N10675

ENiCICoMo-

Nickel-Chromium-Cobalt-Molybdenum

1 168

Alloy

166,

BB NM617

ENiCrMo- 1,9, 1 1 Nickel-Chromium-Molybdenum

B582

Alloy N06007, N06985, NO6030

Nickel-Chromium-Molybdenum

B435

ENiCrMo-2Alloy NO6002

Nickel-Chromium-Molybdenum

ENiCrMo-3

B446 B443, Alloy NO6625

ENiCrMo-4,5,7, 10, 13,14Low-CarbonNickel-Chromium-MolybdenumB575 N10276, N06455, N06022,

Alloy N06059, NM686

ENiCrMo-6 Nickel-Chromium-Molybdenum Alloy B166, B168 NO6600

ENiCrMo- 12 Chromium-Nickel-Molybdenum Alloy A240 S3 1254

(Austenitic Stainless Steel)

Notes:

a. Either the base metals specifiedor carbon steel (A131, A285, A515) may be used. If carbon steel is used, two layers of buttering shall be applied to

the surface and the backing strip if appropriate. For chemical analysis, base metals other than those specified may

be used as the base for the undi-

luted weld pad provided that, for electrodes of the118 in. [3.2 mm] size and smaller, the minimum height shown in Figure 1 is 314 in. [ 19 mm] and

the sample for analysis is taken at least 5/8 in. [16 mm] from the nearest surface of the base metal. For electrode sizes 5/32 in. [4 mm] through

1/4 in. [6.4 mm], the dimensions are1 in. [25 mm] and 7/8 in. [22 mm], respectively.

b. All specified base metals shallbe in the annealed condition priorto welding.

c. Equivalent material specifications may be used.

sired and is permitted by Note c of Table 2), shall be (3) No rounded indications in excess of those permit-

radiographed toevaluate the usability of the electrode. In ted by the radiographic standards in Figures 4 through 8.

preparation for radiography, the backing shall be re- according to the thickness of the test assembly, or the

moved, and both surfaces of the weld shall be machined alternative method of evaluation in 11.3.1

or ground smooth and flush with the original surfaces of In evaluating the radiograph, 1 in. [25 mm] of the weld

the base metal. Both surfaces of the test assembly, in the on each endof the test assembly shall bedisregarded.

area of the weld, shall be smooth enough to avoid diffi-

culty in interpreting the radiograph. 11.3.1 The alternative method of evaluation involves

calculation of the total area of the rounded indications as

11.2 The weld shall be radiographed in accordance with they appear on the radiograph. This total area shall not

ASTM E142, Standard Method for Controlling Quality exceed 1 percent of the thickness of the test assembly

of Radiographic Testing. The quality level of inspection multiplied by the length of the weld used in the evalua-

shall be 2-2T. tion (length of the weld in the test assembly minus 1 in.

[25 mm] on eachend). The value given in Note 3 to each

11.3 The electrode meets the requirements of this specifi- of the Figures (4 through has been calculated for 6 in.

cation if the radiograph shows the following: [150 mm] of weld (an 8-in. [200-mm] long test assem-

( l ) No no fusion, and no bly). The value for weld lengths other than this will differ

plete penetration on a linearly proportional basis.

(2) No slag inclusions in excess of those permitted by

Note 4 to the radiographic standards inFigures 4 through 11.3.2 A rounded indication is an indication (on the

8, according to the size of the electrode radiograph)

whose

length is no

more

than three times its

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

12

I . * 0 . 9 ..

(A) MEDIUM ROUNDED INDICATIONS

SIZE PERMllTED IS 0.025 in. [0.6mm] MAXIMUM.

NUMBER PERMllTED INANY 6 in. [150 mm] OF WELD IS 14.

(B) SMALL ROUNDED INDICATIONS

SIZE PERMllTED IS 0.020 in. [0.5 mm] MAXIMUM.

NUMBER PERMllTED INANY 6 in. [150 mm]OF WELD IS 23.

General Notes:

1. The

. . chart

" ~~that is most remesentative of the size of the rounded indicationsin the radioaraph of the test assembly shall be used to

~

determine conformance with this specification. Rounded indications 1/64 in. [0.4 mm] a i d smaller shall be disregarded. The largest

dimension of the indication (including any is tail)

the size of the indication.

2. These radiographic requirementsare for test welds madein the laboratory specifically forclassification purposes. They are more

restrictive than those normally encountered in general fabrication.

3. When using the alternative method of evaluation describedI lin.3.1, the total cross-sectional areaof the rounded indications (calcu-

lated from measurements taken from the radiograph) shall not exceed 0.008in? [5.2 mm2] in any 6 in. [150 mm]of weld.

4. The acceptance standardfor slag inclusionsin this assemblyis the following:

(a) Length of each individual slag indication: 1/16[I in. .6mm] maximum

(b) Total length of all slag indications: 1/8 in. [3.2 mm] maximum

Figure 4-Radiographic Standards for 1/8 in. [3.2 mm] Test Assembly

width. Rounded indications may be circular, elliptical, 12.3 The results of the tension testshall meet the require-

conical, or irregular in shape, and they may have tails. ments specified in Table 4.

The size of a rounded indication is the largest dimension

of the indication including any tail that may be present.

The indications maybe of porosity or slag. The total area

of the rounded indications for the alternativemethod

13. Bend Test

shall not exceed the values given in Note 3 to the radio- 13.1 Three transverse side bend specimens (for elec-

graphic standards (Figures 4 through 8). Indications trodes larger than 5/64 in. [2.0 mm]) or two transverse

whose largest dimension does not exceed 1/64 in. face bend specimens (for 5/64 in. [2.0 mm] electrodes),

[0.40 mm] shall be disregarded. Test assemblies with as required in Table 2, shall be taken from the assembly

rounded indications larger than the largest indications described in 9.4.1 and shown in Figure 2. The dimen-

permitted in the radiographic standards do not meet the sions of the specimens shall be asshown in Table5.

requirements ofthis specification.

13.2 The specimens shall be bent uniformly through 180

degrees over 3/4-in.

a [19-mmI radius in any suitable jig.

Tb0 standard jigs are shown in Figure 10. Positioning of

12. Tension Test

the side bend specimensshall be such that the side of the

12.1 One all-weld-metal tensiontest specimen shall be bend withthe greater discontinuities, if any,is in tension.

machined from the groove weld describedin 9.4.1 and Positioning ofthe face bend specimens shall be such that

shown in Figure2. The dimensionsof the specimen shall the face of the weld is in tension.For both types of trans-

be as shown in Figure9. verse bend specimen, the weld shall be at the center of

the bend.

12.2 The specimen shall be tested in the manner de-

scribed in the tension test section of the latest edition of 13.3 Each specimen, after bending, shall conform to the

ANSIfAWS B4.0, Standard Methods for Mechanical 3/4-in. [ 19-mmI radius, with an appropriate allowance

Testing of Welds. for springback, and the weld metal shall not contain

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

13

1.. O

. . . . O

(A) ASSORTED ROUNDED INDICATIONS

SIZE PERMllTED IS 0.050 in. [1.3 mm] MAXIMUM.

NUMBER PERMITTED IN ANY 6 in. [150 mm] OF WELD IS 21, WITH THE FOLLOWINGRESTRICTIONS:

LARGE: UP TO 0.050in. [1.3 mm] - 4 PERMITTED

MEDIUM: UP TO 0.031 in. [0.8mm] - 5 PERMITTED

SMALL: UP TO 0.020in. [0.5 mm] - 12 PERMllTED

1. . . . . . . .

(B) LARGE ROUNDED INDICATIONS

SIZE PERMllTED IS 0.050 in. [1.3 mm] MAXIMUM.

NUMBER PERMITTED IN ANY 6 in. [150 mm] OF WELD IS 8.

I' . . . . *

. . . . . I

(C) MEDIUM ROUNDED INDICATIONS

SIZE PERMllTED IS 0.031 in.[0.8mm] MAXIMUM.

NUMBER PERMllTED IN ANY 6 in. [150 mm] OF WELD IS 19.

. . , . . . . . . . . . . .

. . a a . . . . * . *

(D) SMALL ROUNDED INDICATIONS

SIZE PERMITTED IS 0.020 in. [0.5 mm] MAXIMUM.

NUMBER PERMITTED IN ANY 6 in. [150mm] OF WELD IS 48.

General Notes:

1. The chart that is most representativeof the size of the rounded indicationsin the radiograph of the test assembly shall be used to de-

termine conformance with this specification. Rounded indications 1/64 in. [0.4 mm] and smaller shall be disregarded. The largest di-

mension of the indication (including any tail) is the size of the indication.

2. These radiographic requirements are for test welds made in the laboratory specifically for classification purposes. They are more re-

strictive than those normally encounteredin general fabrication.

3. When using the alternative method of evaluation described in 11.3.1, the total cross-sectional areaof the rounded indications (calcu-

lated from measurements taken from the radiograph) shall not exceed 0.015 in.2 [9.7 mm2] in any 6 in. [150 mm] of weld.

4. The acceptance standard for slag inclusions in this assembly is the following:

(a) Length of each individual slag indication:5/32 in. [4.0 mm] maximum

(b) Total length of all slag indications: 1/4 in. [6.4 mm] maximum

Figure 5-Radiographic Standards for 1/4 in. [6.4 mm] Test Assembly

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

14

I' * . 0 . . O

. O

I

(A) ASSORTED ROUNDED INDICATIONS

SIZE PERMITTED IS 0.075 in. [1.9mm] MAXIMUM.

NUMBER PERMllTED INANY 6 in. [150mm] OF WELD IS 17,WITH THE FOLLOWING RESTRICTIONS:

LARGE: UPTO 0.075in. [1.9mm] - 3 PERMllTED

-

MEDIUM: UP TO 0.049in. [1.3mm] 3 PERMllTED

SMALL: UP TO 0.020in. [0.5mm] - 11 PERMITTED

O O

O O

O

(B) LARGE ROUNDED INDICATIONS

..

SIZE PERMllTED IS 0.075in. [1.9mm] MAXIMUM.

NUMBER PERMllTED IN ANY 6 in. [I50mm] OF WELD IS 5.

. . . . . e

. ?

. .

(C) MEDIUM ROUNDED INDICATIONS

SIZE PERMllTED IS 0.049in. [1.3mm] MAXIMUM.

NUMBER PERMITTED IN ANY 6 in. [150mm] OF WELD IS Il.

-

. '

-

.. .

. S .

. *

..

. . . . .

. .

e .

a

*

m . . . m .

..

'

a

a

.

.

. ... . . .. . . '

(D) SMALL ROUNDED INDICATIONS

SIZE PERMllTED IS 0.020in. [0.5mm] MAXIMUM.

NUMBER PERMITTED IN ANY 6 in. [150mm] OF WELD IS 72.

General Notes:

1. The chart that is most representative of the size of the rounded indicationsin the radiographof the test assembly shall be used to de-

termine conformance with this specification. Rounded indications 1/64 in. [0.4mm] and smaller shallbe disregarded. The largest di-

mension of the indication (including any tail) is thesue of the indication.

2. These radiographic requirements arefor test welds made in the laboratory specificallyfor classification purposes. They are morere-

strictive than those normally encountered in general fabrication.

3. When using the alternative method of evaluation describedln 11.3.1,the total cross-sectlonal area of the rounded indications(calcu-

lated from measurements taken from the radiograph) shall not exceed 0.023in2 [14.8mm7 in any 6 in. [150 mm] of weld. ?

4. The acceptance standard for slag inclusionsin this assembly is thefolkwing:

(a) Lengthof each individual slag indication: 7/32 in. [5.6mm] maximum

(b) Total length of all slag indications: W8 in. [9.5mm] maximum

Figure 6-Radiographic Standards for 3/s in. [9.5 mm] Test Assembly

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

15

. . , * . .

.

* e

. .

O . .

’ .

(A) ASSORTED ROUNDED INDICATIONS

SIZE PERMllTED IS 0.10 in. [2.5mm] MAXIMUM.

NUMBER PERMllTED INANY 6 in. [150mm] OF WELD IS 45, WITH THE FOLLOWING RESTRICTIONS:

LARGE: UP TO 0.10 in. [2.5mm] - 1 PERMITTED

MEDIUM: UP TO 0.031 in. [0.8mm] - 9 PERMllTED

SMALL: UP TO0.019in. [0.5mm] - 35 PERMITTED

I O O I

I O O

I

(B) LARGE ROUNDED INDICATIONS

SIZE PERMllTED IS 0.10in. [2.5mm] MAXIMUM.

NUMBER PERMITTEDIN ANY 6 in. [I50mm] OF WELD IS 4.

. . .

. 0 . . . * . *

(C) MEDIUM ROUNDED INDICATIONS

SIZE PERMllTED IS 0.031 in. [OB mm] MAXIMUM.

NUMBER PERMITTEDIN ANY 6 in. [150mm] OF WELD IS 40.

. . .. . . -. . . . - . .

.. - .

S .

. .

. . . e

*

. . . . e - *

. . . .

*

. . . . .

.

. . . .

.. . . .

.

I

. . . - *

(D) SMALL ROUNDED INDICATIONS

SIZE PERMITTED IS 0.019in. [0.5mm] MAXIMUM.

NUMBER PERMITTEDIN ANY 6 in. I150 mm] OF WELD IS 101.

General Notes:

1. The chart thatis most representative of the size of the rounded indicationsin the radiograph of the test assembly shall be used to de-

termine conformance with this specification. Rounded indications1/64in. [0.4mm] and smaller shall be disregarded. The largest di-

mension of the indication (including any tail) is the size of the indication.

2. These radiographic requirements are for test welds made in the laboratory specifically for classification purposes. They are more re-

strictive than those normally encounteredin general fabrication.

3. When using the alternative method of evaluation described in 11.3.1,the total cross-sectional areaof the rounded indications (calcu-

lated from measurements taken from the radiograph) shall not exceed 0.030in.2[19.4mm2] in any 6 in. [150mm] of weld.

4. The acceptance standard for slag inclusions in this assembly is the following:

(a) Lengthof each individual slag indication:7/32 in. [5.6mm] maximum

(b) Total length of all slag indications: 7/16in. [ll mm] maximum

Figure 7-Radiographic Standards for 112 in. [13 mm] Test Assembly

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

I. ' . . . e

. . .

I * . 'O

(A) ASSORTED ROUNDED INDICATIONS

SIZE PERMITTEDIS 0.125 in. [3.2 mm] MAXIMUM.

NUMBER PERMITTEDIN ANY 6 in. [150 mm] OF WELD IS 53, WITH THE FOLLOWING RESTRICTIONS:

-

LARGE: UP TO 0.125 in. [3.2 mm] 1 PERMITTED

MEDIUM: UP TO0.034in. [0.9 mm] - 17 PERMllTED

-

SMALL: UP TO 0.024 in. [0.6 mm] 35 PERMITTED

e O

O

O

(B) LARGE ROUNDED INDICATIONS

SIZE PERMllTED IS 0.125 in. [3.2 mm] MAXIMUM.

NUMBER PERMITTEDIN ANY 6 in. [150 mm] OF WELD IS 4.

. .

. .

S .

(C) MEDIUM ROUNDED INDICATIONS

SIZE PERMITTEDIS 0.034in. [0.9 mm] MAXIMUM.

NUMBER PERMITTEDIN ANY 6 in. [150 mm] OF WELD IS 50.

. . . *

. . . ' . . .

..

0 .

. . . . e .

.. a .

(D) SMALL ROUNDED INDICATIONS

SIZE PERMllTED IS 0.024 in. [0.6 mm] MAXIMUM.

NUMBER PERMllTED IN ANY 6 in. [150 mm]OF WELD IS 90.

General Notes:

1. The chart thatis most representative of the size of the rounded indications be used to de-

in the radiograph of the test assembly shall

termine conformance with thisspecifition. Rounded indications 1/64in. [0.4 mm] and smaller shall be disregarded.The largest di-

mension ofthe indication (including any tail) is the sizeof the indication.

2. These radographic requirements are for test welds made in the laboratory specifically for classification purposes. They are more re-

strictive than those normally encountered in general fabrication.

3. When using the alternative methodof evaluation described in 11.3.1, the total cross-sectional area of the rounded indications (calcu-

lated from measurements taken from the radiograph) shall not exceed 0.045 in2 [29.0 mm7 in any 6 in. [150 mm] of weld.

4. The acceptance standard for slag inclusions in this assembly is the following:

(a) Length of each individual slag indication: 5/16 v.9

in. mm] maximum

(b) Total length of all slag indications: 15/32 in. [11.9 mm] maximum

Figure 8-Radiographic Standards for 3/4 in. [19 mm]Test Assembly

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

17

Dimensions of Specimens, in.

Test Assembly

(T) Thickness G C B F-min in.2

314 0.500f 0.010 2.000i 0.005 0.22-114

(318) 0.38 314

1 I2

0.250 i 0.005 1 .O00f 0.005 0.18

1-114 3.8 0.05

3/8 0.160i 0.003 0.640i 0.005 314 5116 0.15 0.02

Dimensions of Specimens, mm

Test

(T) Thickness G C B F-min mm2

12.7 19 0.25 19

50.8i 0.13 57 129 9.5

0.13 6.4 13 9.525.4f 0.13 32 4.6 32

4.110 f 0.08 7.916.3i 0.13 19 13 3.8

General Notes:

1. Dimensions C and G shall be as shown, but the ends may be of any shape required to fit the testing machine, as long as the load is

kept axial.

2. The diameter of the specimen (dimension D) within the gage length (dimension G) shall be slightly smaller at the center than at the

ends (controlling dimension). The difference shall not exceed1 percent of the diameter.

3. The finish of the surface withinthe C dimension shall be no rougher than63 pin. [1.6pm].

Figure 9-Dimensions of All-Weld-Metal Tension Test Specimen

fissures in excess of those permitted in Table6 when ex- 15.2 The diameter of the core wire shall not vary more

amined with the unaidedeye. than k0.003 in. [+O.OS mm] from the diameterspecified.

The length shall not vary more than +3/8 in. [*IO mm]

from that specified.

Part C

Manufacture, Identification,

and Packaging 16. Core Wire and Covering

16.1 The core wire and covering shall be free of defects

that would interfere with uniform deposition of the

14. Method of Manufacture electrode.

The welding electrodes classified according to this

16.2 The core wire and covering shall be concentric to

specification may be manufactured by any method that

will produceelectrodes that meet the requirements of this the extent that the maximum core-plus-one covering di-

specification. mension shall not exceed the minimum core-plus-one

covering dimensionby more than the following:

(1) Seven percent of the mean dimension i n sizes

15. Standard Sizes and Lengths 3/32 in. [2.5 mm] and smaller

15.1 Standard sizes (diameter of the core wire) and (2) Five percentof the mean dimension insizes 118 in.

lengths of electrodes are as shown in Table 7. [3.2 mm] and 5/32 in. [4.0 mm]

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

S T D - A W S AS.LL/AS-LLM-ENGL

18

Table 4 (3) Four percent of the mean dimension in sizes

3/16 in. [4.8 mm] and larger

All-Weld-Metal Tension Test Requirements

The concentricity may be measured by any suitable

Tensile Strength, min. means.

AWS Elongation*

MPa Classification

ksi Percent, min.

1 60 410 20

17. Exposed Core

ENiCu-7 30 70 480 17.1The grip end of each electrode shall bebare (free of

covering) for adistance of not lessthan 3/4 in. [ 19 mm],

ENiCrFe-1 nor more than1-1/4 in. [32 mm], to provide for electrical

ENiCrFe-2 30 80 550

ENiCrFe-3 contact with the holder.

ENiCrFe-7 17.2 The arc endof each electrode shallbe sufficiently

ENiCrFe-4 20 95 650 bare and the covering sufficiently tapered to permit easy

ENiCrFe- O 1

ENicrFe-9

ENMo- 1

I 25 95 650

striking of the arc. The length of the bare portion (mea-

sured from the end to the point where the full cross sec-

tion of the covering is obtained) shall not exceed 1/8 in.

ENiMo-3 [3 mm] or the diameter of the core wire, whichever is

25 100 690 less. Electrodes with chipped coverings near the arc end,

ENiMo-7

ENiMo-1O baring the core wire no more than the lesser of 1/4 in.

[6 mm] or twice the diameter of thecore wire meet there-

ENiMo-9 25 95 650 quirements of this specification, providedno chip uncov-

ENiCrCoMo-1 90 620 25

ers more than50 percent of thecircumferenceof the core.

ENiCrMo-1 20 90 620

ENiCrMo-2 20 95 650 18. Electrode Identification

ENiCrMo-3 110 760 30

All electrodes shall be identified as follows:

ENiCrMo-4

ENiCrMo-5 18.1 At least one legible imprint of the electrode classifi-

ENiCrMo-7 25 100 690 cation shall be applied to the electrode covering within

ENiCrMo-1O 2-1/2 in. [ 6 4 mm] of the grip end of the electrode.

ENiCrMo- 1 3

18.2 The numbers and letters of the imprint shallbe of

ENiCrMo-6 35 90 620

bold block type ofa sizelarge enough to be legible.

ENiCrMo-9 25 90 620

18.3 The ink used for imprinting shall provide sufficient

ENiCrMo- 1 1 25 85 585 contrast with the electrode coveringso that in normal

ENiCrMo- 12 95 650 > 35 use, the numbers and letters are legible both before and

ENiCrMo-14 100 690 30 after welding.

*The elongationshall be determined from the gage length

equal 18.4 The prefix letter “ E in the electrode classification

to four times the gage diameter. may be omitted from the imprint.

~~ ~~ ~ ~

Table 5

Dimensions of Bend Test Specimens

Width, min. Length, min. min. Thickness,

in. mm in. mm in. mm

150

Side. 6 (3) 9.5 0) 3/8

150

FaCe’ 6 1-ln 9.5 38 3/8

Notes:

a The radius of the corners of the specimen shall be 1/8 in. [3.2 mm] maximum.

b. The width of the Spezimen is the thickness of the test assembly from which the specimen is taken (seeFigure 2).

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

19

AS REQUIRED

TAPPED HOLE TO SUIT

TESTING MACHINE 7 r PLUNGER MEMBER

SHOULDERHARDENED

ANDGREASED

_"."_.

.""".

HARDENED ROLLERS

I I OF DIMENSION A IN

DIAMETER MAY BE

SUBSTITUTED FOR

JIG SHOULDERS

Standard Guided Bend Jig SPECIMEN THICKNESS + 1/16 in. (1.5 mm)

Figure Dimensions

in. mm

~~ ~ ~~ ~

1-112 A 38 r- ROLLER ANY DIAMETER

B 314 19

2-318 C 60

D 1-3116 30

E110 4-112

F 1-118 29

G 114 6.4

H 112 13

J 118 3.2 Wraparound Bend Jig

K 644 170 Figure Dimensions

L 3-718 98 mm in.

2 M 51

9 N 230 A 1-1/2 38

P 7- 112 190 B 314 19

Q 5-114 130

Notes:

1. Specimen thickness is 318 in. General Notes:

[9.5 mm] minimum. 1. Specimen thickness is 318 in. [9.5 mm] minimum.

2. Plunger and interior die sur- 2. Dimensions not shown are the optionof the designer; it is essential that the wrap-

faces shall be machine finished. around jig has adequate rigidityso the assembly will not spring during the bending

operation.

3. One end of the specimen shall be firmly clamped to the jig so the specimen does not

slide during bending.

Figure 10-Standard Bend Test Jigs

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

20

Table 6

Bend Test Requirementsa

Fissures Permitted

Maximum Size Electrode Lengthc

Maximum

AWS ClassificationNumberb mm in. in. mm

1}

5/64

3/32 118 3

- 2.5

ENi- 1 118 3.2

i:d

5/32

3/16 E d 4 118 3

- 5.0

5/64

3/32

- 2.5 2.5 3/32

3.2 118

ENiCu-7

5/32 4.0 'I

3/16

-

114

5

4J3d

6Ad

.o

J

1 3/32 2.5

\

ENiMo-1 ENiMo-3

Mo-8 ENiMo-7

ENiMo-9

ENiMo- 1O

ENiCrFe-1 ENiCrFe-2 2.0 5/64

ENiCrFe-7 ENiCrFe-4

ENiCrFe-9

ENiCrFe- 1O

ENiCrCoMo-

ENiCrMo-

1 1 > 3 3/32 2.5

ENiCrMo-3ENiCrMo-2 5/32 4.0

ENiCrMo-5ENiCrMo-4 3/16

ENiCrMo-7

ENiCrMo-6 5.0

ENiCrMo-9

ENiCrMo-

10

o}

ENiCrMo-11 ENiCrMo-

12

ENiCrMo-13 ENiCrMo-

14

5/64

3/32

ENiCrFe-3 -

118 2

2.5 3/32

5/32 4.0

3/16 4.gd

- 5.0

Notes:

a These requirements apply to both si& and face-bend specimens.

b. The value shown isthe maximum number of fissurespermitted in the weld metalon the tension sideof each bend specimen.The sizes of the fis-

sures are defined in Note c.

c. The numberof fissures referred to in Note b, is for fissures between1/64 in. [0.4 mm] and the length shownin the last column of the table. Those

less than 1/64 in. [0.4 mm] in length and thoseon the comers of the specimens shallbe disregarded. Bend specimens with fissures longer than the

length shown do not meet the tequirements of this specification.

d. Metric sizesnot shown inIS0 544.

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

21

Table 7

Standard Sizes and Lengths

Standard Lengthsa

ENiMo- 1 ENiMo-3

ENiMo-7 ENiMo-8

ENiCrFe- 1 ENiMo-9

ENiMo-

10

ENiCrFe-2 ENiCrCoMo-1 ENiCrMo-1

ENiCrMo-2 ENiCrMo-4 ENiCrFe-3

ENiCrFe-4 ENiCrMo-5

ENiCrMo-6

ENiCrMo-7 ENiCrMo-9 ENiCrFe-7

Electrode Size ENiCrFe-9 ENiCrMo- 1O ENiCrMo-1 1

(Core Wire ENiCrFe-10 ENiCrMo- 1ZC ENiCrMo- 13

Diameter) ENi- 1 ENiCrMo- ENiCu-7 ENiCrMo-3 14

in. mm in. mm in. mm in. mm in. mm

5/64 2.0

230 9 230 9 9 230 9 230

2.4b 3/32 9 or 12 230or300 9 o r 12 230or300 or 12 230or300 9 or 12 230 or 300

9

- 2.5 - 250 - 250 - 250 - 250

118 3.2 14 350 14 350 12 or 14 300 or 350 14 350

4.0 14 5/32 350 14 350 14 350 14 350

3/16‘ 4.8b*C 14 350 14 350 14 350 14 350

- 5.OC - - 350 350 - - - -

114 6.4b - - 14 350 - - - -

Notes:

a. Other sizes and lengths shall be as agreed upon by the purchaser and the supplier.

b. Metric sizes not shown inI S 0 544.

c. The 3/16 in. [4.8 or 5.0 m m ]diameter is not standardfor the ENiCrMo-12 classification.

19. Packaging

WARNING:

19.1 Electrodes shall be packaged to protect them from PROTECT yourself andothers. Read and understand this

damage during shipment and storage under normal label.

conditions. FUMES and GASES can be hazardousto your health.

19.2 Package weights shall be as agreed upon by supplier ARC RAYS can injure and burn skin.

and purchaser. ELECTRIC SHOCK can KILL.

o Before use, read and understand the manufacturer’s

instructions, Material Safety Data Sheets (MSDSs),

20. Marking of Packages and your employer’ssafety practices.

20.1 Thefollowingproductinformation (as a minimum) Keep your head out ofthe fumes.

shall belegiblymarkedontheoutside of each unit Use enough ventilation, exhaust at the arc, or both,

package: to keep fumes and gases away from your breathing

zone andthe general area.

(1) AWS specification and classification designations

(year of issue may be excluded) o Wear correct eye, ear, and body protection.

( 2 ) Supplier’s name and trade designation Do not touch live electrical parts.

weight net(3) Size and o See American National Standard ANSUASC249.1,

(4) Lot, control, or heat number Safety in Welding, Cutting, and Allied Processes, pub-

lished by the American Welding Society,550 N.W. Le-

20.2 The following precautionary information(as a mini- Jeune Road, Miami,FL 33 126; and OSHA Safety and

mum) shall be prominently displayed in legible print on Health Standards,29 CFR 1910,available from theU S .

all packages of electrodes, including individual unit Government PrintingOfice, Washington, DC20402.

packages enclosed withina larger package. DO NOT REMOVE THIS INFORMATION

COPYRIGHT American Welding Society, Inc.

Licensed by Information Handling Services

Annex

Guide to AWS Specification for Nickel and Nickel-Alloy

Welding Electrodes for Shielded Metal Arc Welding

(This Annex is not a part of ANSI/AWS A5.11IA5.11M-97, Specification for Nickel and Nickel-Alloy Welding Elec-

trodes for Shielded Meral Arc Welding,but is includedfor information purposes only.)

Al. Introduction A2.3 From an application point of view, the electrode

classifications in this specification have corresponding

The purpose of this guide is to correlate the electrode classifications in ANSUAWS A5.14/A5.14M, Specifica-

classifications with their intended applications so the tionfor Bare Nickel andNickel-Alloy Welding Electrodes

specification can be usedeffectively. Reference to appro- and Rods, for those cases in which there is a correspond-

priate base metal specifications is made whenever that ing application for a bare electrode or rod (ER). Table A 1

can be done and when it would be helpful. Such refer- correlates the covered electrode classifications in this

ences are intended onlyas examples rather than complete edition with the corresponding ER classification in

listings of the base metals for which each filler metal is ANSYAWS A5.14/A5.14M. It also lists the current des-

suitable. ignation for each classification as it is given in a promi-

nent and pertinent military specification, when such a

designation exists.

A2. Classification System A2.4 An international system for designating welding

filler metals is under development by the International

A2.1 The system for identifying the electrode classifica-

Institute of Welding (IIW)for use in future specifications

tions in this specification follows the standard pattern

to be issued by the International Standards Organization

used in other AWS filler metal specifications. The letter

(ISO). Table Al shows the proposed designations for

“ E ’ at the beginning of each classification designation

nickel-alloy filler metals. In that system. the initial “ E ’

stands for electrode.

designates a covered electrode, the letter “N” the alloy

A2.2 Since the electrodes are classified according to the system, followed by a four-digit number. For nickel al-

chemical compositionof the weld metal theydeposit, the loys, the four-digit number is based on the UNS number

chemical symbol “Ni” appears right after the “E,” as a (see Table l), one of the five digits of which has been

means of identifying the electrodes as nickel-base alloys. eliminated.

The other symbols (Cr, Cu, Fe, Mo, and Co) in the desig-

nations are intended to group the electrodes according to

their principal alloying elements. The individual desig- A3. Acceptance

nations are made up of these symbols and a number at

the end of the designation (ENiMo-1 and ENiMo-3, for Acceptance of all welding materials classified under

example). These numbersseparate one composition from this specification is in accordance with