Escolar Documentos

Profissional Documentos

Cultura Documentos

BrightLeadedFreeCuttingSteelAISI12L14 - En1A LEADED

Enviado por

jaymuscatTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

BrightLeadedFreeCuttingSteelAISI12L14 - En1A LEADED

Enviado por

jaymuscatDireitos autorais:

Formatos disponíveis

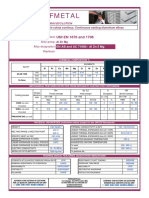

BRIGHT LEADED FREE CUTTING STEEL

– AISI 12L14

AISI 12L14 Low Carbon Leaded Free TYPICAL CHEMICAL ANALYSIS

Carbon 0.07%

Cutting Steel, bright drawn or smooth

Silicon 0.01%

turned with a consistently excellent

Manganese 1.00%

level of machinability. The lead

Phosphorus 0.05%

improves machinability greatly with

Sulphur 0.30%

little effect on the mechanical

Lead 0.25%

properties.

Manganese/Sulphides plus the lead addition

TYPICAL APPLICATIONS:

assist chip formation, friction and wear on cutting

Very heavily machined components or parts tool is reduced, allowing higher feeds and/or

subject to low stress levels, low shock loading, speeds.

limited forming and very limited welding.

Hot or cold forming is limited due to the high

sulphur content.

RELATED SPECIFICATIONS:

AS 1443-1994 12L14 Not suitable for through hardening flame or

induction hardening due to the low carbon

BS 970-3-1991 230M07Pb content.

EN 10277 1.0718 11SMn30Pb

Will Carburise or Carbonitride –

JIS G 4804 SUM22L / SUM23L Typical surface hardness to HRC 58.

SAE & UNS 12L14 & G12144

Ref AISI 1215 for details

.

DIMENSIONAL TOLERANCES: PLATING:

Bright drawn / Smooth turned: h10 Will electroplate but not suitable for hot dip

galvanizing

WELDING: Must be carried out in a well-ventilated environment or avoided as the lead will give off toxic

fumes. Ref AISI 1215 for details

TYPICAL MECHANICAL PROPERTIES - for guidance only

Finish Yield Strength Tensile Strength Elongation Hardness

MPa MPa % HB

Bright Drawn 290 – 550 400 – 650 7 min 115 – 200

Smooth Turned 230 – 310 370 – 500 17 min 100 – 150

Material supplied to chemical analysis only

Você também pode gostar

- MildSteel AISI 1018Documento2 páginasMildSteel AISI 1018ramanamurtytv7176Ainda não há avaliações

- High Tensile Steel 4140Documento2 páginasHigh Tensile Steel 4140Lazzarus Az GunawanAinda não há avaliações

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Documento2 páginasAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984Ainda não há avaliações

- AISI 4140 Chrome Molybdenum High Tensile Steel: Topics CoveredDocumento6 páginasAISI 4140 Chrome Molybdenum High Tensile Steel: Topics CoveredCristina NicheAinda não há avaliações

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Documento2 páginasAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisAinda não há avaliações

- Aalco Metals LTD Stainless Steel 14021 Bar 311Documento2 páginasAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaAinda não há avaliações

- Steel PropertiesDocumento22 páginasSteel PropertiesMOHD SALMANAinda não há avaliações

- Phosphor Bronze To Bs 1400: Pb1Documento1 páginaPhosphor Bronze To Bs 1400: Pb1Rohan ShiyaniAinda não há avaliações

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocumento3 páginasAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahAinda não há avaliações

- Incorporating CuZn10 AlloyDocumento1 páginaIncorporating CuZn10 AlloySara RiddleAinda não há avaliações

- RAFFMETAL: THE ALUMINIUM EVOLUTIONDocumento2 páginasRAFFMETAL: THE ALUMINIUM EVOLUTIONAmandeep SinghAinda não há avaliações

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocumento3 páginasAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesMellierAinda não há avaliações

- aluminium-alloy-7075-data-sheetDocumento1 páginaaluminium-alloy-7075-data-sheetFaris AlmarshadAinda não há avaliações

- 14 CR MoDocumento6 páginas14 CR Mozd55h2754kAinda não há avaliações

- 1022 Carbon Steel Bar PDFDocumento3 páginas1022 Carbon Steel Bar PDFjeyakumarAinda não há avaliações

- Aalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144Documento2 páginasAalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144anilbabu4Ainda não há avaliações

- Phosphor Bronze To Bs 1400: Pb2Documento1 páginaPhosphor Bronze To Bs 1400: Pb2Suresh NairAinda não há avaliações

- Copper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsDocumento2 páginasCopper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsAnonymous v7XdaQuAinda não há avaliações

- EN71000 From ReinferdenDocumento2 páginasEN71000 From ReinferdenJason WuAinda não há avaliações

- BronzeLG2LeadedGunmetalBronze PDFDocumento2 páginasBronzeLG2LeadedGunmetalBronze PDFAnthonyAinda não há avaliações

- Chemical Composition: LM6 LM4Documento2 páginasChemical Composition: LM6 LM4SiDdu KalashettiAinda não há avaliações

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Documento3 páginasAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouAinda não há avaliações

- 1018 SteelDocumento4 páginas1018 SteelAleeFloresAinda não há avaliações

- Copper and Copper Alloys CW614N Brass Rod: Specifications Supplied FormsDocumento2 páginasCopper and Copper Alloys CW614N Brass Rod: Specifications Supplied Formsdipesh6030Ainda não há avaliações

- Alloy M30 DatasheetDocumento1 páginaAlloy M30 DatasheetAperez_1990Ainda não há avaliações

- Sae 5160 VBDocumento2 páginasSae 5160 VBBarron ValentinAinda não há avaliações

- Din 1Documento1 páginaDin 1ttpatelAinda não há avaliações

- Stainless Steel 1.4462 Sheet & PlateDocumento3 páginasStainless Steel 1.4462 Sheet & PlatePaulAinda não há avaliações

- Carbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)Documento7 páginasCarbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)alvida pramudiantiAinda não há avaliações

- Phosphor Bronze To Bs 1400: Pb2Documento1 páginaPhosphor Bronze To Bs 1400: Pb2Santanu Chakraborty100% (1)

- Material - (1 4462)Documento2 páginasMaterial - (1 4462)Ashutosh PathakAinda não há avaliações

- AISI 1020 Low Carbon/Low Tensile SteelDocumento4 páginasAISI 1020 Low Carbon/Low Tensile Steeldofan thrimavithanaAinda não há avaliações

- Free Cutting Mild Steel: Chemical Composition in Volume PercentageDocumento1 páginaFree Cutting Mild Steel: Chemical Composition in Volume PercentageGANESH KUMARAinda não há avaliações

- CuZn15-convertedDocumento2 páginasCuZn15-convertedwjjt6chgtmAinda não há avaliações

- 20050602014857.orion AlloysDocumento25 páginas20050602014857.orion AlloysdtweetyAinda não há avaliações

- AB2 Aluminium Bronze PropertiesDocumento1 páginaAB2 Aluminium Bronze PropertiesSharad KokateAinda não há avaliações

- Raffmetal: UNI EN 1676 and 1706Documento2 páginasRaffmetal: UNI EN 1676 and 1706Martin DuarteAinda não há avaliações

- EASA Module 6 - Detailed NotesDocumento37 páginasEASA Module 6 - Detailed NotesSteven J. SelcukAinda não há avaliações

- kme_STOL76_C19010_enDocumento1 páginakme_STOL76_C19010_enMattia Terri TerrandoAinda não há avaliações

- Raffmetal: UNI EN 1676 and 1706Documento2 páginasRaffmetal: UNI EN 1676 and 1706Hareth MRAIDIAinda não há avaliações

- AISI 1018 Mild Low Carbon Steel PDFDocumento3 páginasAISI 1018 Mild Low Carbon Steel PDFYogesh ChaudhariAinda não há avaliações

- AISI 1018 Mild Low Carbon Steel PDFDocumento3 páginasAISI 1018 Mild Low Carbon Steel PDFbbbAinda não há avaliações

- AISI 1018 Mild Low Carbon Steel PDFDocumento3 páginasAISI 1018 Mild Low Carbon Steel PDFMayand DuaAinda não há avaliações

- Mild Steel PDFDocumento3 páginasMild Steel PDFHardikAinda não há avaliações

- AISI 1018 Mild Low Carbon Steel PDFDocumento3 páginasAISI 1018 Mild Low Carbon Steel PDFHardikAinda não há avaliações

- AISI 1018 Mild Low Carbon Steel PDFDocumento3 páginasAISI 1018 Mild Low Carbon Steel PDFFebrian JhaAinda não há avaliações

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Documento2 páginasAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloAinda não há avaliações

- EN47100Documento2 páginasEN47100tsonjayaAinda não há avaliações

- Selection of NodularizersDocumento2 páginasSelection of Nodularizersarnaldorcr8646100% (2)

- An Overview of Carbon Steel - Chemical Composition & Application SummaryDocumento11 páginasAn Overview of Carbon Steel - Chemical Composition & Application SummaryLutfi ArdiansyahAinda não há avaliações

- Material Groups Chart with Properties for Steel, Stainless Steel, Cast Iron and MoreDocumento1 páginaMaterial Groups Chart with Properties for Steel, Stainless Steel, Cast Iron and Moreedvinas dubinskasAinda não há avaliações

- CuZn20-convertedDocumento2 páginasCuZn20-convertedwjjt6chgtmAinda não há avaliações

- AISI 1018 MildLow Carbon SteelDocumento3 páginasAISI 1018 MildLow Carbon SteelDodi SuhendraAinda não há avaliações

- EN19 - 709M40 Black (As Rolled, Forged or Heat Treated) (ALLOY STEEL) (Direct Hardening or Nitriding)Documento1 páginaEN19 - 709M40 Black (As Rolled, Forged or Heat Treated) (ALLOY STEEL) (Direct Hardening or Nitriding)Raja Sekaran SajjaAinda não há avaliações

- Aluminium Alloy 5754 Data SheetDocumento1 páginaAluminium Alloy 5754 Data Sheetprasanth cpAinda não há avaliações

- F316L Austenitic Stainless Steel: Related SpecificationsDocumento2 páginasF316L Austenitic Stainless Steel: Related SpecificationsRAVIKIRAN BARDEAinda não há avaliações

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocumento2 páginasStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdAinda não há avaliações

- Process Suitability. Plasma Thermal Hvof: ISSUE: 04/15-1 SupercedesDocumento3 páginasProcess Suitability. Plasma Thermal Hvof: ISSUE: 04/15-1 SupercedesphuongAinda não há avaliações

- Offline Work Rules English - 50 and AboveDocumento2 páginasOffline Work Rules English - 50 and AbovejaymuscatAinda não há avaliações

- Normal Typeing Page in Notepad DemoDocumento2 páginasNormal Typeing Page in Notepad DemojaymuscatAinda não há avaliações

- Carshuw Image File Type in NotepadDocumento2 páginasCarshuw Image File Type in NotepadjaymuscatAinda não há avaliações

- Whitepaper How Can ISO 9001 Help Your Business Grow enDocumento13 páginasWhitepaper How Can ISO 9001 Help Your Business Grow enjaymuscatAinda não há avaliações

- Down FileDocumento8 páginasDown FileTomAinda não há avaliações

- DS-1 Volume 3 Addendum 1 - 16-AUG-2021Documento5 páginasDS-1 Volume 3 Addendum 1 - 16-AUG-2021jaymuscat100% (3)

- Subject:: Seal-Lock Apex AncillaryDocumento9 páginasSubject:: Seal-Lock Apex AncillaryjaymuscatAinda não há avaliações

- Cursive Offline Work Rules EnglishDocumento2 páginasCursive Offline Work Rules EnglishjaymuscatAinda não há avaliações

- API Advisory 10 Invoicing and Payment Terms English Translation 20191220Documento2 páginasAPI Advisory 10 Invoicing and Payment Terms English Translation 20191220jaymuscatAinda não há avaliações

- 20E 1st Edition Purch Guidelines R0 20130225 PDFDocumento7 páginas20E 1st Edition Purch Guidelines R0 20130225 PDFmohitcool019Ainda não há avaliações

- APV Test Procedure API 6DDocumento7 páginasAPV Test Procedure API 6Ddevadoss kishoreAinda não há avaliações

- API Spec 7-1 Errata 1 Updates Standard ReferencesDocumento5 páginasAPI Spec 7-1 Errata 1 Updates Standard ReferencesLatif QaiserAinda não há avaliações

- 20F E2 Errata 1Documento2 páginas20F E2 Errata 1jaymuscatAinda não há avaliações

- API 6A Spec Errata 2 SummaryDocumento4 páginasAPI 6A Spec Errata 2 SummaryjaymuscatAinda não há avaliações

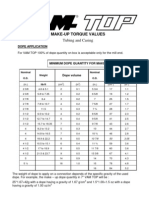

- VAM TOP Torque TableDocumento25 páginasVAM TOP Torque TableRafael Silva75% (4)

- PMET 720-420 StainlessDocumento1 páginaPMET 720-420 Stainless.xAinda não há avaliações

- Wilhelmsen Ships Service - Unitor Welding Handbook PDFDocumento561 páginasWilhelmsen Ships Service - Unitor Welding Handbook PDFNaseer HydenAinda não há avaliações

- PMET-885-Nickel-5-Aluminum - 75BDocumento1 páginaPMET-885-Nickel-5-Aluminum - 75BjaymuscatAinda não há avaliações

- From A Quality Management System (QMS) To A Lean Quality Management System (LQMS)Documento24 páginasFrom A Quality Management System (QMS) To A Lean Quality Management System (LQMS)jaymuscatAinda não há avaliações

- Safety Data Sheet: 1. IdentificationDocumento9 páginasSafety Data Sheet: 1. IdentificationjaymuscatAinda não há avaliações

- Marine-MP TDS EnglishDocumento1 páginaMarine-MP TDS EnglishjaymuscatAinda não há avaliações

- Nickel-Free Manganese Phosphate Processes: Product InfoDocumento2 páginasNickel-Free Manganese Phosphate Processes: Product InfojaymuscatAinda não há avaliações

- State Wise Quarantine Regulations: Dhs - Idspdatam@hry - Nic.inDocumento10 páginasState Wise Quarantine Regulations: Dhs - Idspdatam@hry - Nic.inAmit PaulAinda não há avaliações

- Technical Data Sheet Gardobond G 4040Documento5 páginasTechnical Data Sheet Gardobond G 4040jaymuscatAinda não há avaliações

- G2593R9Documento21 páginasG2593R9TanaAinda não há avaliações

- Running Manual - Handling - and - Storage - Guidelines PDFDocumento4 páginasRunning Manual - Handling - and - Storage - Guidelines PDFmark_vyzAinda não há avaliações

- Loctite 496-En PDFDocumento3 páginasLoctite 496-En PDFjaymuscatAinda não há avaliações

- Safety Data Sheet: Section 1. Identification Penguard Enamel Comp ADocumento11 páginasSafety Data Sheet: Section 1. Identification Penguard Enamel Comp AjaymuscatAinda não há avaliações

- 20E 1st Edition Purch Guidelines R0 20130225 PDFDocumento7 páginas20E 1st Edition Purch Guidelines R0 20130225 PDFmohitcool019Ainda não há avaliações

- Poka Yoke BDocumento31 páginasPoka Yoke BjaymuscatAinda não há avaliações

- 2x2 OHS Wall Connection DetailsDocumento1 página2x2 OHS Wall Connection DetailsSatria EkoAinda não há avaliações

- Sample Master CamDocumento86 páginasSample Master Camlionlionsher100% (2)

- A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedDocumento8 páginasA E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedMiller Andres Ladino Fernandez100% (1)

- Polishing Film Lestar 209-210-002Documento1 páginaPolishing Film Lestar 209-210-002Tomy GeorgeAinda não há avaliações

- BMT WeldingGuide 1017 2Documento8 páginasBMT WeldingGuide 1017 2kcarmachAinda não há avaliações

- Aisi 3215Documento1 páginaAisi 3215luis_dominguezeAinda não há avaliações

- Ch09 ME 406 Grinding and NTM With ProblemsDocumento44 páginasCh09 ME 406 Grinding and NTM With ProblemsKhaled HassanAinda não há avaliações

- 5112Documento3 páginas5112goldencometAinda não há avaliações

- FITTERDocumento43 páginasFITTERsuchi987Ainda não há avaliações

- Visit To Induction HardeningDocumento9 páginasVisit To Induction Hardeningdada kolekarAinda não há avaliações

- AMCAN THREADED PRODUCTS INC. Structural Fasteners CatalogDocumento78 páginasAMCAN THREADED PRODUCTS INC. Structural Fasteners CatalograffyphAinda não há avaliações

- SPACE TURN LB3000 EX-E - (3) - 500 (Mar08) A3 PDFDocumento13 páginasSPACE TURN LB3000 EX-E - (3) - 500 (Mar08) A3 PDFCorlat MihailAinda não há avaliações

- MoriSeikiSLSeriesProgrammingManual2008PMNLTMSC518I1ENL12002H02 PDFDocumento570 páginasMoriSeikiSLSeriesProgrammingManual2008PMNLTMSC518I1ENL12002H02 PDFmarkoskitp100% (3)

- New Microsoft Word DocumentDocumento19 páginasNew Microsoft Word DocumentŤhåýğųŢjAinda não há avaliações

- 004 Gtaw P5aDocumento16 páginas004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Design Guide Galvanized Steel StructuresDocumento28 páginasDesign Guide Galvanized Steel Structuresshoaib1985100% (1)

- OPTI Drill B17 PRO ManualDocumento86 páginasOPTI Drill B17 PRO ManualCharu NavneetAinda não há avaliações

- 0511 Grob PDFDocumento7 páginas0511 Grob PDFJ VeluAinda não há avaliações

- Search Results: Unified Thread Standard - WikipediaDocumento3 páginasSearch Results: Unified Thread Standard - WikipediaDineshkumarAinda não há avaliações

- IEM Accu Bend - 2Documento16 páginasIEM Accu Bend - 2khudhayer1970Ainda não há avaliações

- Module Manufacturing TechnologyDocumento5 páginasModule Manufacturing TechnologyJeshua IgnacioAinda não há avaliações

- Tool Design TerminologyDocumento5 páginasTool Design Terminologyanmol6237Ainda não há avaliações

- Knife Deburring Book PDFDocumento24 páginasKnife Deburring Book PDFDavid M.V.67% (3)

- Tugas Si SadeDocumento25 páginasTugas Si SadeNabil SatriaAinda não há avaliações

- Classic Leg Vise InstructionsDocumento34 páginasClassic Leg Vise InstructionsIulian MihaiAinda não há avaliações

- Turning and Machining CentresDocumento26 páginasTurning and Machining CentresBhado GagoAinda não há avaliações

- Sheetmetal FundamentalsDocumento81 páginasSheetmetal Fundamentalsramkishore_87100% (1)

- Flange ManagementDocumento95 páginasFlange ManagementVictor Biacolo100% (2)

- Assignment On Non-Traditional Manufacturing Processes SubjectDocumento18 páginasAssignment On Non-Traditional Manufacturing Processes SubjectAhmed EzwaiAinda não há avaliações

- BDSsteelhandbookDocumento80 páginasBDSsteelhandbookVeeraiah AnbuAinda não há avaliações