Escolar Documentos

Profissional Documentos

Cultura Documentos

2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4

Enviado por

Mohamed HamedTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4

Enviado por

Mohamed HamedDireitos autorais:

Formatos disponíveis

INLET SYSTEM

SVG INLET AIRSHUT-OFF VALVE INCORPORATING INLET FLAMETRAP

AND BUTTERFLY VALVE (SVG-12, SVG-9.5, SVG-4)

DESCRIPTION

The inlet air shut-off valve uses a rotating disc ‘butterfly’ valve to provide intake air shut-off. The

valve employs a free flow design which provides very low pressure drop to minimise losses in

engine shaft horsepower. The valve is equipped with a pneumatic actuator, pressurized to run,

spring return to close. The recommended actuation pressure is 60 psi to 80 psi (414 kPa to 552

kPa), with minimum actuation pressure of 35 psi (241 kPa) and maximum actuation pressure of

100 psi (690 kPa). The working temperature range

The red plastic indicator on the end of the actuator spindle must not be used to turn the butterfly,

it is for position indication only. Check that it aligns with the direction of the butterfly plate.

Pneumatic Actuator

SVG Inlet Air Shut-Off Valve Installation

Direction of air flow

into engine

Air Supply

(female)

Securing Red

Thread Size

Screws* Indicator

G1/8

Copyright 2003 Issue 1

Pyroban Ltd, Endeavour Works, Dolphin Rd, Shoreham-by-Sea

West Sussex. BN43 6QG. United Kingdom.

Tel: +44(0) 1273 466200

INLET SYSTEM

INSTALLATION

Refer to assembly drawing for installation details.

Before installing the SVG inlet air shut-off valve, ensure any packing material is removed. The

SVG inlet air shut-off valve may be assembled in any orientation.

Fit with the inlet flametrap element on the engine side of the SVG inlet air shut-off valve. Refer to

the air flow direction arrow.

The entire inlet system between the SVG inlet air shut-off valve and the engine must be tested

and withstand 10 bar hydrostatic pressure. All other air inlets between the SVG inlet air shut-off

valve and the engine must be closed or rerouted to prevent ingress of air or gases after

shutdown.

An efficient dry type air filter must be fitted upstream of the SVG inlet air shut-off valve. Regular

servicing to the air filter will minimise fouling of the valve’s flametrap.

The control system pipework connection on the valve actuator is made with pipe thread fittings.

Any scale, dirt, etc. must be removed from the fittings and tubing before they are connected to

the valve. Apply a quality thread sealant to the threaded pipe connections. This sealant must not

be permitted to enter the valve actuator passages.

Alternatively, P.T.F.E. thread sealing tape may be used: but the tape must not be applied in a

manner that enables shreds of tape to enter the valve actuator.

MAINTENANCE

a) Maintenance

The air shut-off valve should be checked monthly for correct operation. Inspect the control

mechanism and ensure that it functions correctly.

Carry out an emergency stop test by cracking a pipe fitting to reduce system pressure below the

set trip pressure.

Ensure the SVG inlet air shut-off valve closes correctly and shuts down the engine.

If operation of the SVG inlet air shut-off valve appears to be satisfactory but the engine does not

stop within a few seconds then the inlet system including the inlet manifold should be checked for

leaks.

The valve shafts are permanently lubricated by the manufacturer. The 'O' rings within the valve

are used to seal in the lubricant and need not be serviced. If it is necessary to replace the 'O' ring

on the periphery of the butterfly plate, remove the two screws (see * on picture) securing the

mounting plate of the valve operator and rotate the disc 180° from its normal closed position.

Copyright 2003 Issue 1

Pyroban Ltd, Endeavour Works, Dolphin Rd, Shoreham-by-Sea

West Sussex. BN43 6QG. United Kingdom.

Tel: +44(0) 1273 466200

INLET SYSTEM

Remove the 'O' ring and replace. When the SVG inlet air shut-off valve is downstream of a

turbocharger the replacement 'O' ring must be Viton. Reverse the above sequence to

reassemble.

Mark the plate for correct positioning. Make sure

the plate is clean from dust and dirt. Apply

silicone grease (DOW Corning DC4) and fit large

‘O’ ring to the plate.

Slide shaft through and fit the smaller ‘O’ rings in

the same way (these act as dust seals) until they

sit within the housing.

Tip plate up (vertical position), rotate shaft

carefully whilst maintaining ‘O’ ring in

housing. Previous marks should line up. Fit

new stainless steel pin through plate and

shaft. Repeat process for other hole.

The actuator with its bracket is then

positioned on to the shaft. Finally, fit the

coil pin through the hole back into shaft

and fit fixing screws.

At this point the butterfly plate should be in

an horizontal position.

b) Lubrication

Periodically, apply a suitable light grease (e.g. Dow Corning MS4 or equivalent) to the 'O' ring in

the periphery of the butterfly plate and to the mating conical surface inside the casting.

Note that the SVG inlet air shut-off valve shafts are permanently lubricated by the manufacturer.

Cleaning the Exhaust Flametrap Inlet Flame Arrester Element:

Do not attempt to remove the flame arrester element from the SVG valve.

Do not clean by inserting probes as the fine passages could be enlarged thereby impairing the

flametrap performance.

Provided the maintenance and servicing of the induction air filter is carried out regularly, the inlet

flametrap should not require cleaning. However, if engine performance deteriorates due to a

partially blocked inlet flame arrester, the inlet flame arrester can be washed with mild solvent and

blown through with compressed air. Ensure the element is dry before re-assembling on engine.

Copyright 2003 Issue 1

Pyroban Ltd, Endeavour Works, Dolphin Rd, Shoreham-by-Sea

West Sussex. BN43 6QG. United Kingdom.

Tel: +44(0) 1273 466200

INLET SYSTEM

OPERATING INSTRUCTIONS

To Start the Engine:

Carry out operator checks as defined in the Servicing section.

Ensure that the clean air supply is applied to the Pyroban SVG inlet air shut-off valve. If the safety

control system has not actuated, the SVG inlet shut-off valve will open, the red indicator will show

the plate orientation. Carry out pre-start checks as defined by engine manufacturer. Start engine

in accordance with installer’s instructions.

To Stop the Engine:

Stop the engine in accordance with the original engine manufacturers instructions. Only shut

down the engine on the SVG inlet air shut-off valve an emergency or for test purposes.

Stopping the engine using the SVG inlet shutdown valve will create a vacuum with the inlet

system. This vacuum must dissipate before the inlet valve can be opened. Allow minimum 5

minutes before attempting to open valve.

Copyright 2003 Issue 1

Pyroban Ltd, Endeavour Works, Dolphin Rd, Shoreham-by-Sea

West Sussex. BN43 6QG. United Kingdom.

Tel: +44(0) 1273 466200

Você também pode gostar

- Pyroban CDRom Installation & Technical ManualDocumento10 páginasPyroban CDRom Installation & Technical ManualMohamed HamedAinda não há avaliações

- Hose Hanger Installation Operating Procedures Rev.1Documento9 páginasHose Hanger Installation Operating Procedures Rev.1HSE PULAI AAinda não há avaliações

- Manual CD 1400 DgasserDocumento91 páginasManual CD 1400 DgasserLuis Alfredo Mean LaraAinda não há avaliações

- 2014 Dropsafe CatalogueDocumento15 páginas2014 Dropsafe CataloguehamzadarbarAinda não há avaliações

- Caja de Cambio John DeereDocumento52 páginasCaja de Cambio John Deerenelson.oyanadel21Ainda não há avaliações

- Batch Mixer Skid Details 001280 - Rev1Documento1 páginaBatch Mixer Skid Details 001280 - Rev1kiranvar13Ainda não há avaliações

- Heavy-Duty ROV Spec Sheet with LARSDocumento2 páginasHeavy-Duty ROV Spec Sheet with LARSJen QianhuiAinda não há avaliações

- Diaphragm AccumulatorDocumento4 páginasDiaphragm AccumulatorRupeshPandyaAinda não há avaliações

- Hyd Inc SwivelsDocumento140 páginasHyd Inc SwivelsCentral HydraulicsAinda não há avaliações

- CD 1400 Centrifugal D GasserDocumento2 páginasCD 1400 Centrifugal D Gasserciucalata88Ainda não há avaliações

- G Lake TravelliftDocumento2 páginasG Lake TravelliftabdulanisAinda não há avaliações

- Air-Winch Manual PDFDocumento56 páginasAir-Winch Manual PDFQuyet Nguyen0% (1)

- HL-ADS compressed air dryer packagesDocumento17 páginasHL-ADS compressed air dryer packagesMarcoAlbaAinda não há avaliações

- V1S3 Traveling Block Manual 2015.4.17Documento6 páginasV1S3 Traveling Block Manual 2015.4.17tavingus2Ainda não há avaliações

- Grove g4n Gate Valve BrochureDocumento24 páginasGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- McCoyDrillingCompletionsCatalog LowResDocumento65 páginasMcCoyDrillingCompletionsCatalog LowResAlvin Garcia PalancaAinda não há avaliações

- DE1000 GBD LP Derick CentrifugeDocumento4 páginasDE1000 GBD LP Derick CentrifugePETROPATH FLUIDS INDIA PVT. LTD.Ainda não há avaliações

- M60es44 P449y Man 001Documento23 páginasM60es44 P449y Man 001Riski Kurniawan100% (1)

- Main Rig Components and SpecificationsDocumento1 páginaMain Rig Components and SpecificationsHarits PamitranAinda não há avaliações

- FranksDocumento3 páginasFranksNawab Muhammad Ibrahim100% (1)

- Back PoshtDocumento2 páginasBack Poshtmhn yAinda não há avaliações

- 250 HMI 475 SpecsDocumento3 páginas250 HMI 475 SpecsProyectil De Proyecto100% (1)

- Circulating SwagesDocumento1 páginaCirculating Swageskaveh-bahiraeeAinda não há avaliações

- Wireline Depth CountersDocumento1 páginaWireline Depth CounterssitaAinda não há avaliações

- 7.6 SingleDocumento226 páginas7.6 Singlewuillian barretoAinda não há avaliações

- Transfluid Fluid Coupling CatalougeDocumento32 páginasTransfluid Fluid Coupling CatalougeNaeem KhanAinda não há avaliações

- Ingersoll Rand FA10 Popeye Winch Air Tugger ManualDocumento85 páginasIngersoll Rand FA10 Popeye Winch Air Tugger ManualAleksei ChernozhukovAinda não há avaliações

- Heavilift JacksDocumento12 páginasHeavilift JacksAziz ul HakeemAinda não há avaliações

- Bwmetals1 PDFDocumento2 páginasBwmetals1 PDFDian SikumbangAinda não há avaliações

- Flexible Balflex - Hoses - Catalogue - 2019Documento181 páginasFlexible Balflex - Hoses - Catalogue - 2019zephyrinAinda não há avaliações

- Oil States Swab Cups PDFDocumento2 páginasOil States Swab Cups PDFramudo ZAinda não há avaliações

- 4 - Drawing &datasheet 20-10kDocumento131 páginas4 - Drawing &datasheet 20-10kAnonymous 1ykzuaxWgYAinda não há avaliações

- DHV 6a Catalogue-FinalDocumento16 páginasDHV 6a Catalogue-FinalJohn UrdanetaAinda não há avaliações

- Combined Marine Safety Catalogue PDFDocumento277 páginasCombined Marine Safety Catalogue PDFJeffry KarundengAinda não há avaliações

- Double Disc Gate ValveDocumento12 páginasDouble Disc Gate Valveshafeeqm3086Ainda não há avaliações

- 1-Axial Piston Pumps and Motors-HydromobilDocumento8 páginas1-Axial Piston Pumps and Motors-HydromobilSocaciu VioricaAinda não há avaliações

- FC-FXX - 8 Parts List PDFDocumento28 páginasFC-FXX - 8 Parts List PDFjulioramcaAinda não há avaliações

- Berkeley Ownwes ManualDocumento28 páginasBerkeley Ownwes ManualMoses Alvarado100% (1)

- 使用说明书Operation ManualDocumento84 páginas使用说明书Operation ManualMohamed el attarAinda não há avaliações

- Agitator NJ 15c2Documento1 páginaAgitator NJ 15c2Khaled AmmarAinda não há avaliações

- BD 165 PDFDocumento2 páginasBD 165 PDFAndres NavarroAinda não há avaliações

- SPE - 22559 Advancements in Dynamic-Kill Calculations For Blowout Wells - G E KoubaDocumento10 páginasSPE - 22559 Advancements in Dynamic-Kill Calculations For Blowout Wells - G E KoubaAsahel NuñezAinda não há avaliações

- Degasser CD-1400Documento3 páginasDegasser CD-1400Ruslan ZakirovAinda não há avaliações

- PSC Ergodyne Range 2021Documento45 páginasPSC Ergodyne Range 2021Project Sales CorpAinda não há avaliações

- Aot GG (350 Ton) Bottleneck ElevatorDocumento1 páginaAot GG (350 Ton) Bottleneck ElevatorCarlig Radu MihaiAinda não há avaliações

- Donaldson Differential Pressure Switches & Gauges GuideDocumento2 páginasDonaldson Differential Pressure Switches & Gauges GuideManikandan SenthilAinda não há avaliações

- Hydraulic Cylinder Parker 3lDocumento48 páginasHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- KL150 Detailed SpecsDocumento3 páginasKL150 Detailed Specsben100% (1)

- Ingersoll Rand Air Motors PDFDocumento98 páginasIngersoll Rand Air Motors PDFVicctor PiñaAinda não há avaliações

- Bridon Offshore ExplorationDocumento44 páginasBridon Offshore ExplorationAthox QhurienAinda não há avaliações

- JWS-340 Well Servicing Pump BrochureDocumento4 páginasJWS-340 Well Servicing Pump BrochureCesar MoraAinda não há avaliações

- Ees ExampleDocumento12 páginasEes ExamplesbjAinda não há avaliações

- 5650 TechDocumento7 páginas5650 Techamjath584Ainda não há avaliações

- GEQParts CatalogDocumento7 páginasGEQParts CatalogIRWIN_DSOUZAAinda não há avaliações

- ELECTRIC MOTORS TYPE 3SIE IE3 FOR 50/60HZ OPERATIONDocumento9 páginasELECTRIC MOTORS TYPE 3SIE IE3 FOR 50/60HZ OPERATIONAmandaAinda não há avaliações

- SOP 829-009 Nipple Up BOPs.Documento2 páginasSOP 829-009 Nipple Up BOPs.Anonymous XbmoAFtIAinda não há avaliações

- Pumping Unit T75 Manual 107072Documento32 páginasPumping Unit T75 Manual 107072reinaldopf2012Ainda não há avaliações

- 2B) Inlet Air Shut-Off ValveDocumento2 páginas2B) Inlet Air Shut-Off ValveMohamed HamedAinda não há avaliações

- Mercer 9100 ManualDocumento11 páginasMercer 9100 Manualanara.aidAinda não há avaliações

- IR Turbine Power Starters TS700Documento20 páginasIR Turbine Power Starters TS700andistwn99Ainda não há avaliações

- Lecture 10 - Ex NDocumento11 páginasLecture 10 - Ex NMohamed HamedAinda não há avaliações

- Glanding: Glands Must Maintain Integrity of EnclosureDocumento11 páginasGlanding: Glands Must Maintain Integrity of EnclosureMohamed HamedAinda não há avaliações

- Principles of Intrinsic SafetyDocumento14 páginasPrinciples of Intrinsic SafetyMohamed HamedAinda não há avaliações

- 6E) Exhaust Gas Temperature Gauge InstallationDocumento1 página6E) Exhaust Gas Temperature Gauge InstallationMohamed HamedAinda não há avaliações

- 6D) Coolant Temperature Gauge InstallationDocumento1 página6D) Coolant Temperature Gauge InstallationMohamed HamedAinda não há avaliações

- Lecture 09 - Ex PDocumento8 páginasLecture 09 - Ex PMohamed HamedAinda não há avaliações

- JSA Form DraftDocumento1 páginaJSA Form DraftMohamed HamedAinda não há avaliações

- Apsey Application Form en r10 0Documento3 páginasApsey Application Form en r10 0Mohamed HamedAinda não há avaliações

- Pre - Run Check ListDocumento2 páginasPre - Run Check ListMohamed HamedAinda não há avaliações

- Hazard Identification Prompt CDocumento2 páginasHazard Identification Prompt CMohamed HamedAinda não há avaliações

- 6F) Oil Pressure Gauge and Pipe Kit InstallationDocumento1 página6F) Oil Pressure Gauge and Pipe Kit InstallationMohamed HamedAinda não há avaliações

- Miscellaneous Items: Screw Secured Engine Oil Filler CapDocumento1 páginaMiscellaneous Items: Screw Secured Engine Oil Filler CapMohamed HamedAinda não há avaliações

- Heat Rejection and Coolant NotesDocumento1 páginaHeat Rejection and Coolant NotesMohamed HamedAinda não há avaliações

- 2B) Inlet Air Shut-Off ValveDocumento2 páginas2B) Inlet Air Shut-Off ValveMohamed HamedAinda não há avaliações

- Cooling Circuit Installation and MaintenanceDocumento1 páginaCooling Circuit Installation and MaintenanceMohamed HamedAinda não há avaliações

- Ensco Work Instruction and JSA ProceduresDocumento18 páginasEnsco Work Instruction and JSA ProceduresMohamed HamedAinda não há avaliações

- 2I) ServicingDocumento1 página2I) ServicingMohamed HamedAinda não há avaliações

- 2G) SVF Inlet Oil ValveDocumento1 página2G) SVF Inlet Oil ValveMohamed HamedAinda não há avaliações

- Battery SpecsDocumento2 páginasBattery SpecsAbraham SaucedoAinda não há avaliações

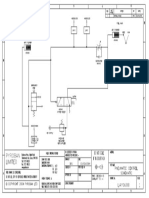

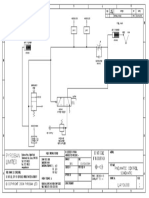

- Control Schematic PDFDocumento1 páginaControl Schematic PDFMohamed HamedAinda não há avaliações

- Heat Rejection and Coolant NotesDocumento1 páginaHeat Rejection and Coolant NotesMohamed HamedAinda não há avaliações

- Control SchematicDocumento1 páginaControl SchematicMohamed HamedAinda não há avaliações

- Observe The Employee: Safe Act/ConditionDocumento3 páginasObserve The Employee: Safe Act/ConditionMohamed HamedAinda não há avaliações

- K06952 BomDocumento2 páginasK06952 BomMohamed HamedAinda não há avaliações

- Cleaning Galley Fryer WIDocumento2 páginasCleaning Galley Fryer WIMohamed HamedAinda não há avaliações

- Field DataDocumento1 páginaField DataMohamed HamedAinda não há avaliações

- Working With KnifesDocumento2 páginasWorking With KnifesMohamed HamedAinda não há avaliações

- Cleaning Galley Fryer WIDocumento2 páginasCleaning Galley Fryer WIMohamed HamedAinda não há avaliações

- Fill Stop Fill ValveDocumento1 páginaFill Stop Fill ValveDenier RubianoAinda não há avaliações

- en - e - R45ie R55-75i R44-75N - Maintenance Manual-1Documento16 páginasen - e - R45ie R55-75i R44-75N - Maintenance Manual-1Susilo purwanggiAinda não há avaliações

- Home Experiment 4: Hp145 Compact Reciprocating Pump Test SetDocumento9 páginasHome Experiment 4: Hp145 Compact Reciprocating Pump Test SetPietro Ian AbdonAinda não há avaliações

- Master Document Register for Majnoon ME&I ProjectDocumento15 páginasMaster Document Register for Majnoon ME&I ProjectAbdullah Abdullah100% (1)

- As 2118.1-1999 Automatic Fire Sprinkler Systems General RequirementsDocumento10 páginasAs 2118.1-1999 Automatic Fire Sprinkler Systems General RequirementsSAI Global - APAC100% (1)

- Packing of ValvesDocumento4 páginasPacking of ValvesNaved HavaAinda não há avaliações

- B1000R C64.eng PDFDocumento31 páginasB1000R C64.eng PDFRajan MullappillyAinda não há avaliações

- Butterfly Valve Catalogue //: The Fort Vale Range of Butterfly ValvesDocumento22 páginasButterfly Valve Catalogue //: The Fort Vale Range of Butterfly ValvesrohandiAinda não há avaliações

- Bomba de Espumador PartesDocumento4 páginasBomba de Espumador PartesRafael IbarraAinda não há avaliações

- Pilot Pressure Proportional Control (PPC)Documento16 páginasPilot Pressure Proportional Control (PPC)EkoAinda não há avaliações

- PV 48Documento12 páginasPV 48thierrylindoAinda não há avaliações

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Documento2 páginasAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiAinda não há avaliações

- Functional location mapping of Cikampek tissue mill siteDocumento24 páginasFunctional location mapping of Cikampek tissue mill siteRian AprianaAinda não há avaliações

- Daeju heavy duty quarter turn actuatorsDocumento16 páginasDaeju heavy duty quarter turn actuatorssujiv_sujiv1278Ainda não há avaliações

- Report On PHBPL HaldiaDocumento37 páginasReport On PHBPL HaldiaINCREDIBLE ADIONUAinda não há avaliações

- 09 Cat BHL B&C Hydsys3Documento15 páginas09 Cat BHL B&C Hydsys3Mahmmod Al-QawasmehAinda não há avaliações

- Instructions For Installation, Operation, Care and MaintenanceDocumento10 páginasInstructions For Installation, Operation, Care and MaintenanceAdi HardiansyahAinda não há avaliações

- 3/2-Solenoid Directional Valve Poppet Type - Direct-Acting Normally Open Metric Cartridge - 350 BarDocumento2 páginas3/2-Solenoid Directional Valve Poppet Type - Direct-Acting Normally Open Metric Cartridge - 350 Barandri putrantoAinda não há avaliações

- Peract Pi Q23 DW 0004 PDFDocumento5 páginasPeract Pi Q23 DW 0004 PDFGAinda não há avaliações

- Bobcat S300 PDFDocumento56 páginasBobcat S300 PDFRodolfo Baccaglini100% (2)

- لقطة شاشة 2023-12-21 في 7.24.27 مDocumento45 páginasلقطة شاشة 2023-12-21 في 7.24.27 مhamza.nasser091Ainda não há avaliações

- Honeywell - 63-2515 - ML7421 - Data Sheet PDFDocumento8 páginasHoneywell - 63-2515 - ML7421 - Data Sheet PDFMarcello PorrinoAinda não há avaliações

- 200RD4S3 SHOWN: Major Per Sep 200-7 Critical Per Sep 200-7Documento3 páginas200RD4S3 SHOWN: Major Per Sep 200-7 Critical Per Sep 200-7DianaAinda não há avaliações

- Plano Hidraulico Cat 314c 5Documento7 páginasPlano Hidraulico Cat 314c 5galvis1020100% (1)

- AM-07 Vacuum Toilet SystemDocumento111 páginasAM-07 Vacuum Toilet SystemAlexandru Alex100% (2)

- Safety Features of Acetylene Cylinders and Bundles - Ernest Khoo - Web VersDocumento38 páginasSafety Features of Acetylene Cylinders and Bundles - Ernest Khoo - Web VersLisa FosterAinda não há avaliações

- Product Catalogue August 2018Documento73 páginasProduct Catalogue August 2018Wylbert ConsueloAinda não há avaliações

- TDS11 Training Manual PDFDocumento264 páginasTDS11 Training Manual PDFNelson AlvarezAinda não há avaliações

- Service Manual: Automatic Changeover ManifoldDocumento51 páginasService Manual: Automatic Changeover ManifoldServicios Generales CMOAinda não há avaliações

- 2214 With Hino 6ETI BS II EngineDocumento249 páginas2214 With Hino 6ETI BS II EngineBhawani Copy0% (1)