Escolar Documentos

Profissional Documentos

Cultura Documentos

RF10 (A4)

Enviado por

Dewa Made Astika YathaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

RF10 (A4)

Enviado por

Dewa Made Astika YathaDireitos autorais:

Formatos disponíveis

SOLTEQ® Equipment for Engineering Education & Research

GAS ABSORPTION

REFRIGERATION UNIT

MODEL: RF 10

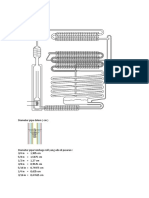

his Gas Absorption Refrigeration Unit (Model: RF 10) is a complete laboratory bench top unit for the

T demonstration of gas absorption refrigeration. The unit is a continuous absorption refrigeration system

operated by application of a heat source either electrically or furnished by fuel gas. No moving parts are

employed throughout the refrigeration unit. It consists of a boiler, condenser, evaporator, gas heat exchanger,

absorber and a liquid heat exchanger. The system is charged with a quantity of ammonia, water and hydrogen.

Absorption refrigeration systems are typically used in DESCRIPTION

conditions that favour lower power usage and no moving

parts as compared to the conventional mechanically The absorption refrigeration system charge contains

driven compression refrigeration systems. They are a quantity of ammonia, water, and hydrogen. The

widely used in domestic refrigerators, recreational gases are at a sufficient pressure to condense

vehicles, and also in year-round air conditioning of ammonia at room temperature. Heat is supplied to

homes and larger buildings. Due to their easy the vapour bubble pump system where bubbles of

adaptability to operate using either electricity or fuel gas, ammonia gas are produced from aqua ammonia. Here

they are useful in remote locations where the supply of any water vapor is condensed and runs back into the

electricity is not readily available. boiler system, leaving the dry ammonia vapor to pass

to the

SOLTEQ® Equipment for Engineering Education & Research

upstream condenser. Air circulating over the fins of the TECHNICAL SPECIFICATIONS

condenser removes heat from the ammonia vapor. It

SOLTEQ

condenses into liquid ammonia and then flows into the Refrigerant : Ammonia / water

evaporator. Auxiliary gas : Hydrogen

The evaporator is supplied with hydrogen. The hydrogen Generator : Insulated vapour bubble

passes across the surface of the ammonia. It lowers pump

the ammonia vapor pressure enough to allow the liquid Heat source : Electrical or fuel gas heater

ammonia to evaporate. The evaporation of the ammonia Fuel gas : Liquefied petroleum gas

extracts heat from the evaporator. This, in turn, extracts (LPG)

heat from the heat load. Fuel consumption : 0.3 g/min

The mixture of ammonia and hydrogen vapor passes Instrumentation and control:

from the evaporator to the absorber. A continuous trickle ♦ Temperature measurements: RTD sensors x 4

of weak ammonia solution enters the upper portion of ♦ Energy selector between electricity or fuel gas

the absorber. It is fed by gravity from the tube. This weak ♦ Thermostat for temperature control

solution flows down through the absorber. It comes into ♦ Piezoelectric igniter and safety button

contact with the mixed ammonia and hydrogen gases.

This readily absorbs the ammonia from the mixture. The

hydrogen is free to rise through the absorber coil and to UTILITY REQUIREMENTS

return to the evaporator. The hydrogen circulates

continuously between the absorber and the evaporator. Electricity : 240VAC/ 1-Phase / 50Hz

Fuel : LPG gas @ 30 mbar

The strong ammonia solution produced in the absorber

flows down to the absorber vessel. It passes on to the

vapour bubble pump system, thus completing the full OVERALL DIMENSION

cycle of operation. This cycle operates continuously as

long as the boiler is heated. Height : 2.00 m

Width : 2.00 m

Depth : 1.22 m

EXPERIMENTAL CAPABILITIES

♦ Principles of a gas absorption refrigeration system. MANUAL

♦ Familiarisation with the individual components of

the gas absorption refrigeration unit. The unit is supplied with Operating and Experiment

♦ Operation of a gas absorption refrigeration unit manuals in English.

using either electricity or fuel gas as the heat source.

♦ Demonstration of the refrigeration process.

♦ Measurement of temperature points along the

absorption refrigeration process.

♦ Effect of circulating air and thermostat control on

the process temperature.

SOLTEQ® Equipment for Engineering Education & Research

PROCESS FLOW DIAGRAM

SOLTEQ® Equipment for Engineering Education & Research

SOFTWARE & E-LEARNING

Our range of teaching equipment can be complemented with our

SOLDAS and SOLCAL software.

SOLDASTM - Supervisory Control & Data Acquisition

- Data Logging

- Signal Analysis

- Process Control

- Real-Time Display

- Tabulated Results

- Graph of Experiment Results

SOLCALTM - Computer Aided Learning

- Multimedia Features

- Interactive

- Graphic Simulation

- Samples of Experiment Result

- Full Experiment Manuals

Contact us for a catalog CD

SOLUTION ENGINEERING SDN. BHD. AGENT:

(Co. No. 174876-M)

Sales Office :

No.3, Jalan TPK 2/4, Taman Perindustrian Kinrara,

47100 Puchong, Selangor Darul Ehsan, Malaysia.

Tel. No. : +(603) 80758000

Fax. No. : +(603) 80755784

R&D Office :

G-2A, Incubator 3, Technology Park Malaysia,

Bukit Jalil, 57000 Kuala Lumpur, Malaysia.

Tel. No. : +(603) 8996 0023

Email : solution@solution.com.my

Web site : http//www.solution.com.my/ BUATAN MALAYSIA

Você também pode gostar

- Lab Report 6Documento18 páginasLab Report 6Idham ArifAinda não há avaliações

- Lab Gas Flow (Afif)Documento17 páginasLab Gas Flow (Afif)Nurshazwani syuhada bt al- badri100% (1)

- My Grandpa's FuneralDocumento1 páginaMy Grandpa's FuneralTSLB-0619 Salsabila Ainaa Binti RosliAinda não há avaliações

- MEC554 Lab HandoutDocumento60 páginasMEC554 Lab HandoutHilmiAhmadAinda não há avaliações

- Mec 424 - Laboratory Report Title:Introduction To Sample Preparation and Optical Microscope For Metallographic ObservationDocumento20 páginasMec 424 - Laboratory Report Title:Introduction To Sample Preparation and Optical Microscope For Metallographic ObservationTaufiq MahathirAinda não há avaliações

- 05 RefrigerationDocumento17 páginas05 RefrigerationApostolos AvraamidesAinda não há avaliações

- Proposal For Experiment 7 - Water Quality AnalysisDocumento12 páginasProposal For Experiment 7 - Water Quality AnalysisJasmine KangAinda não há avaliações

- Experiment 4 - Electrostatic PrecipitatorDocumento9 páginasExperiment 4 - Electrostatic PrecipitatorAzrol Azmir Long100% (5)

- (Finalized) Assignment Modelling CPE 603Documento48 páginas(Finalized) Assignment Modelling CPE 603Muhammad AshmanAinda não há avaliações

- MPU3242 IMjuly19Project BBMS L03F MiniaturePortableArtificalKidney Luqman 0133133922Documento36 páginasMPU3242 IMjuly19Project BBMS L03F MiniaturePortableArtificalKidney Luqman 0133133922Hema KuganAinda não há avaliações

- Analysis of Air Conditioning ProcessDocumento33 páginasAnalysis of Air Conditioning ProcessAmerul izwan AmiruddinAinda não há avaliações

- Carbon Zero Bio Char Production TechnologyDocumento10 páginasCarbon Zero Bio Char Production TechnologySandi ČretnikAinda não há avaliações

- Lab Gas FlowmeterDocumento7 páginasLab Gas Flowmeterazym94Ainda não há avaliações

- Lab 1 Cge617Documento9 páginasLab 1 Cge617wak syazwanAinda não há avaliações

- Surface Readout GyroDocumento2 páginasSurface Readout GyroSiti Nur IzzatyAinda não há avaliações

- Cge671 Mini ProjectDocumento42 páginasCge671 Mini ProjectEmilia StevenAinda não há avaliações

- CPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportDocumento9 páginasCPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportSiti Hajar MohamedAinda não há avaliações

- Mohd Amirul Hafifi Bin Asim Resign Letter PDFDocumento1 páginaMohd Amirul Hafifi Bin Asim Resign Letter PDFSlasherAinda não há avaliações

- CEV633 - ASGN 1 - Mar2018 - QuestionDocumento2 páginasCEV633 - ASGN 1 - Mar2018 - Questionbotakmbg6035Ainda não há avaliações

- Drag Force ReportDocumento15 páginasDrag Force ReportAmier KamilAinda não há avaliações

- Mini Project Reaction Engineering GROUP 9 (Stage 2)Documento41 páginasMini Project Reaction Engineering GROUP 9 (Stage 2)Syahmi Asraaf100% (3)

- Mec 531 Project Title Sept2013-Jan2014Documento3 páginasMec 531 Project Title Sept2013-Jan2014arina azharyAinda não há avaliações

- Ces511 - Structural Engineering Laboratory Lab Experiment: Indeterminate Truss (Co2:Po5) PEC2215B1Documento21 páginasCes511 - Structural Engineering Laboratory Lab Experiment: Indeterminate Truss (Co2:Po5) PEC2215B1elhammeAinda não há avaliações

- Lab Report 6Documento12 páginasLab Report 6Siti Nur Izzaty50% (2)

- CPB30004 Process Dynamics and Control Experiment 2: Liquid Flow Ratio Process Control Lab ReportDocumento11 páginasCPB30004 Process Dynamics and Control Experiment 2: Liquid Flow Ratio Process Control Lab ReportSiti Hajar Mohamed100% (1)

- SM Indi Assignment Bukit Tagar ReportDocumento13 páginasSM Indi Assignment Bukit Tagar ReportNor AmalinaAinda não há avaliações

- Pre-Lab PM10 Sampling in FoodCourtDocumento8 páginasPre-Lab PM10 Sampling in FoodCourtAjlaa RahimAinda não há avaliações

- Turbidity TestDocumento3 páginasTurbidity TestAnis NurdiniAinda não há avaliações

- Level Flow PCDocumento10 páginasLevel Flow PCMurali TharanAinda não há avaliações

- Total Iron TestDocumento5 páginasTotal Iron TestMuhammad FendiAinda não há avaliações

- HYDRAULIC Cqi QuestionsDocumento2 páginasHYDRAULIC Cqi QuestionsJibul temulakAinda não há avaliações

- CSTR UitmDocumento19 páginasCSTR UitmsaifulAinda não há avaliações

- Lab Manual Gas Pressure Process ControlDocumento10 páginasLab Manual Gas Pressure Process ControlAziemah AulanAinda não há avaliações

- Presentation Proposal (EWC661)Documento9 páginasPresentation Proposal (EWC661)fatin naddAinda não há avaliações

- Lab ManuDocumento12 páginasLab ManuMuhd Muzafar100% (1)

- Assignment Fluid 2 UitmDocumento19 páginasAssignment Fluid 2 UitmFirdaus AsryAinda não há avaliações

- Lab 6 - Growth Kinetics Study of Microorganism in Shake Flask PDFDocumento7 páginasLab 6 - Growth Kinetics Study of Microorganism in Shake Flask PDFJaymacAinda não há avaliações

- Process Instrumentation Lab Report 4Documento4 páginasProcess Instrumentation Lab Report 4Abu Rectify50% (4)

- MiniProject Stage 1 - Process Dynamic & ControlDocumento4 páginasMiniProject Stage 1 - Process Dynamic & ControlFarihah EyfaAinda não há avaliações

- Lab Pass FlowDocumento56 páginasLab Pass FlowloqmannazliAinda não há avaliações

- Group 1 - Lab Report Concept of Free VibrationDocumento15 páginasGroup 1 - Lab Report Concept of Free VibrationAmeer AimanAinda não há avaliações

- Strength Lab Report (Exp 2) Update 1Documento14 páginasStrength Lab Report (Exp 2) Update 1Syafiq RonaldoAinda não há avaliações

- (Project Eco) Latest Semifull Half Without Part RogerDocumento35 páginas(Project Eco) Latest Semifull Half Without Part RogerRoger FernandezAinda não há avaliações

- CPB 30103 Biochemical Engineering UniKL MICET Experiment 3: Immobilization of Enzymes by Gel Entrapment Full Lab ReportDocumento16 páginasCPB 30103 Biochemical Engineering UniKL MICET Experiment 3: Immobilization of Enzymes by Gel Entrapment Full Lab ReportSiti Hajar Mohamed100% (8)

- Assignment 2 Q2Documento2 páginasAssignment 2 Q2Johan Aliff0% (1)

- Universiti Teknologi Mara Faculty of Mechanical EngineeringDocumento4 páginasUniversiti Teknologi Mara Faculty of Mechanical Engineeringanis adilahAinda não há avaliações

- Abstract/Summary: V K M DP DLDocumento17 páginasAbstract/Summary: V K M DP DLAdnan Nanda100% (1)

- 600-FKM (FYP1-PR-Rev.1) - FYP Progress ReportDocumento37 páginas600-FKM (FYP1-PR-Rev.1) - FYP Progress ReportFad Tajudin100% (1)

- Abstract Lab 6Documento12 páginasAbstract Lab 6adib assoliAinda não há avaliações

- FYP Extended Proposal First DraftDocumento33 páginasFYP Extended Proposal First DraftEeHuey ChooAinda não há avaliações

- CPE501 - Lab Simulink Control Loop Syste PDFDocumento27 páginasCPE501 - Lab Simulink Control Loop Syste PDFJose Heli Vallejos CoronadoAinda não há avaliações

- Exp 4 Batch Evaporative Crystallization PDFDocumento9 páginasExp 4 Batch Evaporative Crystallization PDFmirza farhanAinda não há avaliações

- Topic 3 DCC 40152Documento27 páginasTopic 3 DCC 40152Sham AzrulAinda não há avaliações

- SWR Experiment 3 PDFDocumento9 páginasSWR Experiment 3 PDFwnay100% (1)

- Hse Assignment 24 JuneDocumento13 páginasHse Assignment 24 JuneJohan Aliff100% (1)

- Lab SprinklerDocumento8 páginasLab Sprinklerida hadi0% (1)

- Gas Meter CalibrationDocumento13 páginasGas Meter CalibrationMimi Hashim100% (1)

- TE-A-19 SanGFket Tekade (CIA 4)Documento10 páginasTE-A-19 SanGFket Tekade (CIA 4)jojoAinda não há avaliações

- 2 To Study VASDocumento5 páginas2 To Study VASAnand GujaratiAinda não há avaliações

- Domestic Electrolux Refrigeration SystemDocumento22 páginasDomestic Electrolux Refrigeration SystemTanviAinda não há avaliações

- Ammonia Sutrasno 2009Documento104 páginasAmmonia Sutrasno 2009dewi-kurniasari-6799Ainda não há avaliações

- RF10 (A4)Documento4 páginasRF10 (A4)Dewa Made Astika YathaAinda não há avaliações

- Modul Ignition SystemDocumento1 páginaModul Ignition SystemDewa Made Astika YathaAinda não há avaliações

- Ammonia Sutrasno 2009Documento104 páginasAmmonia Sutrasno 2009dewi-kurniasari-6799Ainda não há avaliações

- 托福阅读 - Arrival of Plant Life in HawaiiDocumento5 páginas托福阅读 - Arrival of Plant Life in HawaiiYongchang ChenAinda não há avaliações

- Evolution of The Arabian Plate PDFDocumento60 páginasEvolution of The Arabian Plate PDFscaldasoleAinda não há avaliações

- Green Chemistry - Wikipedia, The Free EncyclopediaDocumento3 páginasGreen Chemistry - Wikipedia, The Free Encyclopedia9894786946Ainda não há avaliações

- Soil Mechanics - Lab ManualDocumento205 páginasSoil Mechanics - Lab ManualJack Rasal94% (16)

- 019 Icges2012 S10007Documento5 páginas019 Icges2012 S10007Aditya PratamaAinda não há avaliações

- Pocket HabitatDocumento6 páginasPocket Habitatdanut_docAinda não há avaliações

- Rotor-Stator Spinning Disc ReactorDocumento145 páginasRotor-Stator Spinning Disc ReactorDes MshenguAinda não há avaliações

- Hype Cycle For Data Center P 263280Documento66 páginasHype Cycle For Data Center P 263280Hai Le HoangAinda não há avaliações

- Percentage of OxygenDocumento2 páginasPercentage of Oxygenmahdee khanAinda não há avaliações

- Solar PondsDocumento20 páginasSolar PondsAjoy RsAinda não há avaliações

- Ensayo Medio AmbienteDocumento2 páginasEnsayo Medio Ambientemrisel76Ainda não há avaliações

- PS PSSA Prep Physics ReviewDocumento30 páginasPS PSSA Prep Physics ReviewflyingmsAinda não há avaliações

- Past Papers IGCSE 2023 31Documento8 páginasPast Papers IGCSE 2023 31David ThydetAinda não há avaliações

- Partial Pressure DeterminationDocumento5 páginasPartial Pressure Determinationanon_378146815Ainda não há avaliações

- Sea of Souls Volume V (Extra Content)Documento51 páginasSea of Souls Volume V (Extra Content)Rafael Severino NomebostaAinda não há avaliações

- Chemical Bonding Shobhit NirwanDocumento17 páginasChemical Bonding Shobhit NirwanBhavya Goyal XI Non medAinda não há avaliações

- Chernobyl Disaster: The Worst Man-Made Disaster in Human HistoryDocumento13 páginasChernobyl Disaster: The Worst Man-Made Disaster in Human HistoryGowri ShankarAinda não há avaliações

- Interference and DiffractionDocumento30 páginasInterference and DiffractionSweeha PanwarAinda não há avaliações

- 2.3.5 Practice - Atomic Structure (Practice)Documento11 páginas2.3.5 Practice - Atomic Structure (Practice)damarionbryant46Ainda não há avaliações

- Geotechnical EngineeringDocumento3 páginasGeotechnical EngineeringJesus Ray M. Mansayon67% (3)

- Fuels & Combustion Technology (Major Elective Û I) (Chemical Group)Documento2 páginasFuels & Combustion Technology (Major Elective Û I) (Chemical Group)raumil123759033% (3)

- Nuclear Physics IgcseDocumento9 páginasNuclear Physics IgcseMuhammad asifAinda não há avaliações

- DRRR Reviewer: A Comprehensive Plan ShouldDocumento3 páginasDRRR Reviewer: A Comprehensive Plan ShouldJames BastesAinda não há avaliações

- Investigating The Parameters of Circular OrbitsDocumento4 páginasInvestigating The Parameters of Circular OrbitsPepe HandsAinda não há avaliações

- WavesDocumento8 páginasWavesMuneeb AnsariAinda não há avaliações

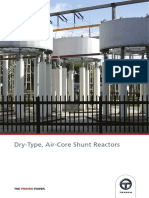

- Dry-Type, Air-Core Shunt Reactors: ProvenDocumento8 páginasDry-Type, Air-Core Shunt Reactors: ProvenWardencasianAlanisAinda não há avaliações

- NSTP Project FinalDocumento13 páginasNSTP Project FinalCHARIZE MAE NAVARROAinda não há avaliações

- Lecture 2: Material and Energy BalanceDocumento21 páginasLecture 2: Material and Energy BalanceTaytoAinda não há avaliações