Escolar Documentos

Profissional Documentos

Cultura Documentos

Ab 747

Enviado por

Ιάκωβος ΣαϊντDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ab 747

Enviado por

Ιάκωβος ΣαϊντDireitos autorais:

Formatos disponíveis

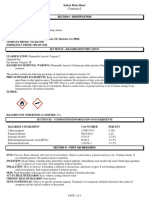

MATERIAL SAFETY DATA SHEET

PRODUCT NAME: ABRO SUPER GLUE HMIS CODES

HFRP

PRODUCT CODE: AB-747

DATE : 9/ 1/2018 2 2 2

===================== SECTION I - MANUFACTURER IDENTIFICATION =====================

MANUFACTURER'S NAME : ABRO INDUSTRIES, INC.

ADDRESS : 3580 Blackthorn Court

South Bend, IN 46628

COMPANY PHONE: 574-232-8289 NAME OF PREPARER : HOA

CHEMTREC TOLL-FREE 24 HOURS EMERGENCY PHONE: 800-424-9300

IN THE EVENT OF A CHEMICAL EMERGENCY INVOLVING A SPILL, LEAK, FIRE, EXPOSURE OR

ACCIDENT CONTACT: CHEMTREC INTERNATIONAL - 703-527-3887

============================ SECTION II - COMPOSITION =============================

Ethyl cyanoacrylate CAS No. 7085-85-0 93-100%

Poly Methyl Methacrylate CAS No. 9011-14-7 3-75

Hydroquinone CAS No. 123-31-9 0.1-0.5%

================== SECTION III - CHEMICAL AND PHYSICAL PROPERTIES ==================

Appearance: Clear liquid

Odor: Sharp, irritating

Boiling Point: More than 300 F

Solubility in Water: Polymerized

Specific gravity: 1.05 at 75F

VOC: 94.0%; 987g/l (EPA Method 24)

Vapor Pressure: Less than 0.2 mm at 75 F

Vapor Density: 3

INGREDIENTS WHICH HAVE EXPOSURE LIMITS:

Exposure Limits ACGIH OSHA OTHER

Ingredients (TLV) (PEL)

Ethyl cyanoacrylate None None 2ppm TWA

9.1 mg/m3

Hydroquinone 2 mg/m3 TWA 2mg/m3 TWA 2 mg/m3 TWA

4mg/m3 STEL

Exposure Limits (STEL)

Ethyl cyanoacrylate (4 ppm) (4 ppm)

(18 mg/m3) (16 mg/m3)

============= SECTION IV - FLAMMABILITY AND EXPLOSIVE PROPERTIES ====================

Flash point: 160-200F (TCC)

Extinguishing agents: Carbon dioxide, foam, dry chemical

Hazardous products formed by fire and thermal decomposition: irritating organic vapors.

===================== SECTION V - STABILITY AND REACTIVITY ===========================

Stability: Stable

Hazardous Polymerization: Will not occur

Incompatibility: Polymerized by contact with water, alcohols, amines, alkalies.

====================== SECTION VI - HEALTH HAZARD DATA ===========================

Toxicity: Skin contact may cause burns.

Bonds skin rapidly and strongly.

Skin and eye irritant.

Estimated oral LD50 more than 5000 mg/kg.

Estimated dermal LD50 more than 2000 mg/kg.

Primary routes of entry: None known.

Symptoms of exposure: Vapor is irritating to mucous membranes when above the TLV. Prolonged and repeated

overexposure to vapors may produce allergic reactions with asthma like symptoms in sensitive individuals.

======================= SECTION VII - PERSONAL PROTECTION =========================

Eyes: Safety glasses or goggles mandatory.

Skin: Polyethylene gloves and/or aprons. Do not use cotton.

Ventilation: Positive down draft exhaust ventilation should be provided to maintain vapor concentration below

TLV.

================ SECTION VIII - EMERGENCY TREATMENT PROCEDURES ==================

Inhalation: Remove to fresh air. If symptoms persist, obtain medical attention.

Skin contact: Soak in warm water.

Eye contact: Flush with water.

=================== SECTION IX - ACCIDENTAL RELEASE MEASURES=========================

If a spill or leak occurs, flood area with water to polymerize.

Soak up with an inert absorbent.

======================= SECTION X - DISPOSAL CONSIDERATIONS =======================

Dispose of following EPA, Federal, State, and Local regulations.

================ SECTION XI - HANDLING AND STORAGE INFORMATION ==================

Safe Storage: Store below 72 ΕF.

Handling: Avoid contact with skin and eyes. Avoid breathing vapors.

=========================== SECTION XII - SUPPLEMENT ==============================

SKIN ADHESION: First immerse the bonded surface in warm soapy water. Peel or roll the surface apart with the

aid of a blunt edge such as a pencil, spoon, handle, etc. Do this gradually, in a gentle fashion, with care not to be too

forceful. Then remove the adhesive from the skin with soap and water. DO NOT try to pull surface apart with a

direct opposing action.

EYELID TO EYE LID OR EYEBALL ADHESION: In the event that eyelids are stuck together or bonded to the

eyeball wash thoroughly with warm water and apply a gauze patch. The eye will open without further action,

typically in one to four days. There will be no residual damage. Do not try to open eyes by manipulation. Let eh

natural cleansing action of the eye take place.

ADHESIVE ON THE EYEBALL: Cyanoacrylate introduced into the eye will attach itself to the eye protein and will

disassociate from it over intermittent periods, generally covering several hours. This will cause periods of tearing

until clearance is achieved. The adhesive residue will flush out of the eye normally in a matter of hours.

MOUTH: If lips are accidentally stuck together, apply lots of warm water to the lips and encourage maximum

wetting and pressure from saliva inside the mouth. Peel or roll the lips apart. Do not try to pull the lips apart with a

direct opposing action. It is almost impossible to swallow cyanoacrylate. The adhesive solidifies and adheres in the

mouth. Saliva will lift the adhesive in 12 ro 48 hours.

BURNS: Cyanoacrylates give off heat in solidification. In rare cases a large amount will increase in temperature

enough to cause a burn. Should this occur treat using normal medical procedures.

Você também pode gostar

- Fevi KwikDocumento3 páginasFevi Kwiksuchisdhal100% (4)

- San Felipe Assembly Guide - Pack 1 PDFDocumento48 páginasSan Felipe Assembly Guide - Pack 1 PDFMarshall Moore100% (1)

- Farnworth ZuluTotorialDocumento11 páginasFarnworth ZuluTotorialfiachduhAinda não há avaliações

- FOWW Rules of Play Digital FinalDocumento60 páginasFOWW Rules of Play Digital FinalAnonymous PtMxUHm9Ro100% (6)

- Masking CanopiesDocumento5 páginasMasking CanopiesErisie100% (1)

- Product Portfolio of PidiliteDocumento2 páginasProduct Portfolio of PidiliteAKSHAY BHONDEAinda não há avaliações

- Material Safety Data SheetDocumento5 páginasMaterial Safety Data SheetBudi SantosoAinda não há avaliações

- Deck-O-Grip - MsdsDocumento2 páginasDeck-O-Grip - MsdshemantrulzAinda não há avaliações

- SDS Cold Galvanize SprayDocumento10 páginasSDS Cold Galvanize Sprayfarhahnadiah.mokhtarAinda não há avaliações

- MSDS CRC Red Urethane Seal CoatDocumento7 páginasMSDS CRC Red Urethane Seal CoatJACK GonzalezAinda não há avaliações

- MSDS Cyano AcrylateDocumento4 páginasMSDS Cyano AcrylateVIJAYAKUMAR K AAinda não há avaliações

- Centurion I - 2511Documento4 páginasCenturion I - 2511Ingo BohmerAinda não há avaliações

- 5844 Davis Traffic Paint BlackDocumento4 páginas5844 Davis Traffic Paint BlackcathleencatedelacruzAinda não há avaliações

- Super Glue - Rev 11 - 2010Documento2 páginasSuper Glue - Rev 11 - 2010Fatur RahmanAinda não há avaliações

- Material Safety Data SheetDocumento2 páginasMaterial Safety Data Sheetمحمد عزتAinda não há avaliações

- Safety Data Sheet: 1. Product and Company IdentificationDocumento5 páginasSafety Data Sheet: 1. Product and Company Identificationkei iswandaAinda não há avaliações

- Msds Colawet Ma-80 (16 Section)Documento6 páginasMsds Colawet Ma-80 (16 Section)mndmattAinda não há avaliações

- Lawson Products, Inc - Non-Chlorinated Brake CleanerDocumento4 páginasLawson Products, Inc - Non-Chlorinated Brake Cleanerjaredf@jfelectric.com100% (1)

- Material Safety Data Sheet: Product IdentificationDocumento4 páginasMaterial Safety Data Sheet: Product Identificationمحمد عزتAinda não há avaliações

- Msds-Dyrostain 4910103Documento2 páginasMsds-Dyrostain 4910103محمد عزتAinda não há avaliações

- ITW Performance Polymers - Devcon Material Safety Data SheetDocumento6 páginasITW Performance Polymers - Devcon Material Safety Data SheetNazirAhmadBashiriAinda não há avaliações

- Fendall - Best Vue Lense Cleaning StationDocumento3 páginasFendall - Best Vue Lense Cleaning Stationjaredf@jfelectric.comAinda não há avaliações

- Armaflex Adhesive 520 MSDS Front PageDocumento1 páginaArmaflex Adhesive 520 MSDS Front Pageum erAinda não há avaliações

- Joyforce SDS - PVA Pellet - r2.ENDocumento3 páginasJoyforce SDS - PVA Pellet - r2.ENjituniAinda não há avaliações

- FT Tracer Tinopal MSDSDocumento3 páginasFT Tracer Tinopal MSDSabhinavkushwaha2122Ainda não há avaliações

- Kaneka Kane Ace MX-257 SDSDocumento9 páginasKaneka Kane Ace MX-257 SDS黄利好Ainda não há avaliações

- Febolube Universal Issue 01.28.2008Documento3 páginasFebolube Universal Issue 01.28.2008Julio MendezAinda não há avaliações

- Epoxy Waterproofing Patching Compound Part AB SDSDocumento8 páginasEpoxy Waterproofing Patching Compound Part AB SDSRaju BiswasAinda não há avaliações

- Safety Data Sheet Chemical Aquatrol - 275-1Documento4 páginasSafety Data Sheet Chemical Aquatrol - 275-1nikoAinda não há avaliações

- Msds Colateric AP (16 Section)Documento6 páginasMsds Colateric AP (16 Section)mndmattAinda não há avaliações

- Material Safety Data SheetDocumento2 páginasMaterial Safety Data Sheetمحمد عزتAinda não há avaliações

- MSDS Stone Guard SealerDocumento10 páginasMSDS Stone Guard SealerRahul KumarAinda não há avaliações

- Clean R Carb Carburetor CleanerDocumento6 páginasClean R Carb Carburetor CleanerNabeel maqsoodAinda não há avaliações

- Eva MSDSDocumento8 páginasEva MSDStahiriqbalalviAinda não há avaliações

- Waxco TAR Bugs & Treesap RemoverDocumento5 páginasWaxco TAR Bugs & Treesap RemoverPLN UPT MAKASSARAinda não há avaliações

- Crude Tall OilDocumento8 páginasCrude Tall OilCarlos Andres Rios Barra100% (1)

- Material Safety Data Sheet: AES-A-315-RBDocumento8 páginasMaterial Safety Data Sheet: AES-A-315-RBSajidawan. OlineAinda não há avaliações

- MSDS AlkoholDocumento9 páginasMSDS AlkoholEris KurniawanAinda não há avaliações

- Sds Radiacwash 030620Documento7 páginasSds Radiacwash 030620Felipe Eduardo Zamorano LabbeAinda não há avaliações

- Ethyl AcetateDocumento8 páginasEthyl Acetatevighnesh kumarAinda não há avaliações

- Cat Yellow Paint High Gloss Fast DryingDocumento10 páginasCat Yellow Paint High Gloss Fast DryingClemente ZamudioAinda não há avaliações

- Nalco 7302Documento6 páginasNalco 7302Mohammed SamyAinda não há avaliações

- Blue Gold Industrial Cleaner 109 360 05 28 2019Documento6 páginasBlue Gold Industrial Cleaner 109 360 05 28 2019rajiv aryaAinda não há avaliações

- Lawson Products, Inc - ThreadlockDocumento7 páginasLawson Products, Inc - Threadlockjaredf@jfelectric.comAinda não há avaliações

- Cyclogen L Base Oil US 16 Point MSDSDocumento4 páginasCyclogen L Base Oil US 16 Point MSDSjuancarloscrsAinda não há avaliações

- MSDS-PSF-600,000cSt Silicone Damping Fluid PDFDocumento5 páginasMSDS-PSF-600,000cSt Silicone Damping Fluid PDFHugo CiprianiAinda não há avaliações

- Msds Colamulse Emultron PMDocumento4 páginasMsds Colamulse Emultron PMmndmatt100% (2)

- MSDS MX - 99 Gentian Blue PDFDocumento4 páginasMSDS MX - 99 Gentian Blue PDFrenitaAinda não há avaliações

- MSDS Colamulse SBCDocumento3 páginasMSDS Colamulse SBCmndmatt100% (2)

- Primer CC 200 Part B - NZL Sds - 31 07 2020Documento8 páginasPrimer CC 200 Part B - NZL Sds - 31 07 2020yaw shuAinda não há avaliações

- Msds-Thinnoxy - 4580114Documento2 páginasMsds-Thinnoxy - 4580114محمد عزتAinda não há avaliações

- 6640 MSDSDocumento4 páginas6640 MSDSShaikhRizwanAinda não há avaliações

- Cantesco SolventDocumento5 páginasCantesco Solventmasv792512Ainda não há avaliações

- Safety Data Sheet: 3M™ Machine Polish, PN 05986, 05996, 39009, 39809Documento8 páginasSafety Data Sheet: 3M™ Machine Polish, PN 05986, 05996, 39009, 39809Baladika Sukma ZufaraAinda não há avaliações

- Safety Data Sheet: Section 1 - Product IdentificationDocumento4 páginasSafety Data Sheet: Section 1 - Product IdentificationArpit SinghalAinda não há avaliações

- MSDS Food Grade Multi Purpose GreaseDocumento7 páginasMSDS Food Grade Multi Purpose Greaseayu laksitaAinda não há avaliações

- AltraWash Blue SDSDocumento5 páginasAltraWash Blue SDSkarirojas678Ainda não há avaliações

- Material Safety Data Sheet: Product IdentificationDocumento4 páginasMaterial Safety Data Sheet: Product Identificationمحمد عزتAinda não há avaliações

- MSDS For NC 14605Documento7 páginasMSDS For NC 14605محمد عزتAinda não há avaliações

- Material Safety Data Sheet: Product IdentificationDocumento4 páginasMaterial Safety Data Sheet: Product Identificationمحمد عزتAinda não há avaliações

- Aquapeel 510 MSDS PDFDocumento4 páginasAquapeel 510 MSDS PDFCHANDRAAinda não há avaliações

- MSDS Hoa Chat Phu Bong Be Mat San Klenco Super CoatingDocumento2 páginasMSDS Hoa Chat Phu Bong Be Mat San Klenco Super CoatingSPTC CORPAinda não há avaliações

- MSDS WD 40Documento2 páginasMSDS WD 40MeisusiloAinda não há avaliações

- MSDS 731Documento7 páginasMSDS 731GautamAinda não há avaliações

- Generic Msds Acrylic Lacquer AerosolDocumento4 páginasGeneric Msds Acrylic Lacquer AerosolPatt SaAinda não há avaliações

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEAinda não há avaliações

- (Original) Super Glue X2000 Multi Purpose Adhesive Adhesive Super Strong Liquid - Stick All Materials 50g - Lazada PHDocumento9 páginas(Original) Super Glue X2000 Multi Purpose Adhesive Adhesive Super Strong Liquid - Stick All Materials 50g - Lazada PHRene BesanaAinda não há avaliações

- Reference Loctite Vs ParsonDocumento9 páginasReference Loctite Vs ParsonKique AngelesAinda não há avaliações

- Laser Cutting Information 2015Documento5 páginasLaser Cutting Information 2015MageshwarAinda não há avaliações

- Cyanoacrylate AdhesiveDocumento4 páginasCyanoacrylate AdhesivePathan Sameer KhanAinda não há avaliações

- Orthodontics in 3 Millennia. Chapter 16: Late 20th-Century Fixed AppliancesDocumento4 páginasOrthodontics in 3 Millennia. Chapter 16: Late 20th-Century Fixed AppliancesDiego Andres Hincapie HerreraAinda não há avaliações

- Playmates Tricorder Upgrade Instruction Manual-2020-01aDocumento28 páginasPlaymates Tricorder Upgrade Instruction Manual-2020-01aRodger WeirAinda não há avaliações

- Loctite 416™: Technical Data SheetDocumento3 páginasLoctite 416™: Technical Data SheetJuanManuelPerillaAinda não há avaliações

- 2011 Devcon Permatex CatalogDocumento52 páginas2011 Devcon Permatex CatalogEBPENICHE6400Ainda não há avaliações

- Okra Glue ResearchDocumento35 páginasOkra Glue ResearchKyle BaltazarAinda não há avaliações

- Bow Head RepairDocumento16 páginasBow Head RepairMario ViolaAinda não há avaliações

- Organic Compounds With Description and ExamplesDocumento21 páginasOrganic Compounds With Description and ExamplesMikah SubaAinda não há avaliações

- Loctite 495: Technical Data SheetDocumento3 páginasLoctite 495: Technical Data SheetCơ Điện MáyAinda não há avaliações

- Rules & Regulations BDC NTUDocumento5 páginasRules & Regulations BDC NTUMohammad YasinAinda não há avaliações

- Applications of Nanotechnology in Forensic InvestigationDocumento6 páginasApplications of Nanotechnology in Forensic InvestigationMaraidAinda não há avaliações

- Loctite Guide 2008Documento184 páginasLoctite Guide 2008Shane AllenAinda não há avaliações

- Automotive Aftermarket: Adhesive and Sealants GuideDocumento48 páginasAutomotive Aftermarket: Adhesive and Sealants GuideFrancis MartinezAinda não há avaliações

- Model Laboratory 02Documento40 páginasModel Laboratory 02Manuel Ramírez Espíndola100% (3)

- LoxealDocumento16 páginasLoxealLeandro LibrandaAinda não há avaliações

- HATE Data Sheet PDFDocumento5 páginasHATE Data Sheet PDFSandipPatelAinda não há avaliações

- Manual PT 40 PDFDocumento64 páginasManual PT 40 PDFNicolas Higuera ManriqueAinda não há avaliações

- Fingerprinting PresentationDocumento47 páginasFingerprinting PresentationSo-Hee ParkAinda não há avaliações

- Technical Data Sheet Product 406: Worldwide Version, February 1996Documento3 páginasTechnical Data Sheet Product 406: Worldwide Version, February 1996Muhammad irtizaAinda não há avaliações

- Scotch-Weld: Cyanoacrylate Adhesive PR100Documento3 páginasScotch-Weld: Cyanoacrylate Adhesive PR100Marco AurélioAinda não há avaliações

- 4014 MSDSDocumento5 páginas4014 MSDSAhmed Emad AhmedAinda não há avaliações