Escolar Documentos

Profissional Documentos

Cultura Documentos

NAS 1832 Insert Technical Specifications

Enviado por

staedtlerpDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

NAS 1832 Insert Technical Specifications

Enviado por

staedtlerpDireitos autorais:

Formatos disponíveis

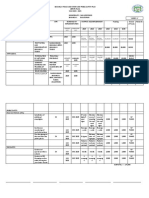

NAS 1832

SHEET 1OF 3

NAS 1832

INSERT, MOLDED IN, THREADED, SANDWICH PANEL

APPLICATIONS: SELF LOCKING AND NON SELF LOCKING THREADS

K

J 2 X .092 - .097 MIN

POTTING & VENT

15 8 SLOTS

2X .092 -.097 POTTING

AND VENT HOLES

(OPTIONAL SLOTS)

TYPICAL ALL STYLES

2X FULL R

OPTIONAL

"E"

Ø F MAX D

13 12

C 7 12

B

BOTTOM VIEW

(TYPICAL ALL STYLES) C

H(a)

L

L

14

B

.030 MIN

.030 MIN

ALL STEEL 13 "E"

ALUMINUM SELF-LOCKING OR ALTERNATE

NONSELF-LOCKING ALUMINUM STYLE

TABLE 1

FIRST THREAD ØA ØF H(a) J K L(B) INSTALLATION

DASH CLASS 3B +.000 ØB C ØD E MAX MIN BASIC MIN MIN HOLE SIZE

NO. MINOR DIA -.010

.1380-32

-06 .560 .300 .12 .375 .400 .560 .250 .367 .260 .37 .561 - .566

UNJC

.1640-32

-08 .560 .300 .12 .375 .400 .560 .250 .367 .260 .37 .561 - .566

UNJC

.1900-32

-3 .560 .300 .12 .375 .400 .560 .250 .367 .260 .37 .561 - .566

UNJF

.2500-28

-4 .685 .375 .14 .440 .520 .685 .310 .467 .360 .50 .686 - .691

UNJF

.3125-24

-5 .685 .475 .16 .500 .520 .685 .310 .467 .360 .50 .686 - .691

UNJF

.3750-24

-6 .841 .500 .22 .550 .560 .841 .370 .591 .484 .50 .842 - .847

UNJF

(a) MINIMUM THREAD "H" IN SHORT LENGTHS. MINIMUM THREAD "H" WHERE LENGTH PERMITS

SHALL BE 2X DIAMETER OF THREAD.

(b) MINIMUM LENGTH WHICH MAY BE SPECIFIED.

MATERIAL: CARBON STEEL PER ASTM-A-108. ASTM-A-576 OR MATERIAL COMPOSTION PER

FED-STD-66, ULTIMATE TENSILE STRENGTH 85 KSI MINIMUM. ALUMINUM ALLOY , GRADE 2024

(UNS AS2024), TEMPER T4 OR T351 PER QQ-A-225/6.

CORROSION RESISTANT STEEL, TYPE 303 (UNS 30300 PER ASTM-A-582. NONMETALLIC LOCKING

ELEMENT - POLYAMIDE PER FED SPEC L-P-410.

WITTEN COMPANY INC

918.272.9567

REV: - 8/24/09 IULLSTRATION BY WR.ELSWICK IN SOLIDWORKS 2009

NAS 1832

SHEET 2 OF 3

NAS 1832

INSERT, MOLDED IN, BLIND THREADED, SELF-LOCKING,

NON SELF-LOCKING, SANDWICH PANEL

FINISH: CARBON STEEL - CADMIUM PLATE PER SAE-AMS QQ-P-416, TYPE 2, CLASS 2.

ALUMINUM ALLOY - ANODIZE PER MIL-A-8625 TYPE 1, CLASS OPTIONAL.

CRES - PASSIVATE PER ASTM-A-967, SILVER PLATE PER AMS2410 OR AMS2411

OR CADMIUM PLATE PER SAE-AMS-QQ-P-416, TYPE 2, CLASS 2.

SOLID FILM LUBRICANT PER AS5272, TYPE 1, APPLIED TO THREADS ONLY.

CODING: NO LETTER AFTER BASIC NUMBER INDICATES CARBON STEEL, CADMIUM PLATED.

SUFFIX A TO BASIC NUMBER INDICATES AL ALLOY, ANODIZED.

SUFFIX C TO BASIC NUMBER INDICATES CRES. PASSIVATED.

FIRST DASH NUMBER INDICATES NOMINAL THREAD SIZE, SEE TABLE 1.

SUFFIX N TO FIRST DASH NUMBER INDICATES NON SELF-LOCKING.

SECOND DASH NUMBER INDICATES LENGTH IN .125 INCREMENTS. SEE NOTE 6.

NO LETTER AFTER SECOND DASH NUMBER FOR CRES INDICATES PASSIVATE ONLY.

SEE NOTE 5.

SUFFIX M TO SECOND DASH NUMBER INDICATES SOLID FILM LUBRICANT.

SEE NOTE 5.

SUFFIX P TO SECOND DASH NUMBER INDICATES CADMIUM PLATE ON CRES INSERT.

SEE NOTE 5.

SUFFIX S TO SECOND DASH NUMBER INDICATES SILVER PLATE ON CRES INSERT.

SEE NOTE 5.

EXAMPLE OF PART NUMBER:

NAS 1832-3-4M .1900-32 UNJF -3B THREAD,CARBON STEEL, CADMIUM PLATED

WITH MOLYCOAT 3402C LUBRICANT, .500 LONG, SELF-LOCKING.

NAS 1832A3N4 .1900-32 UNJF -3B THREAD, ALUMINUM ALLOY, ANODIZED, .500 LONG

NONSELF LOCKING.

NAS 1832CO8-3S .1640-32 UNJC -3B THREAD, CRES, SILVER PLATED, .375 LONG.

SELF-LOCKING.

NAS 1832C08-3P .2500-28 UNJF -3B THREAD, CRES, PASSIVATED, .625 LONG

NONSELF-LOCKING

NAS 1832C4N5 .2500-28 UNJF -3B THREAD, CARBON STEEL, CADMIUM PLATED,1.250

LONG, SELF-LOCKING.

NOTES:

1. THREADS PER MIL-S-8879.

2. LOCKING TORQUE PER MIL-DTL 25027 EXCEPT SELF-LOCKING. CORROSION RESISTANT STEEL

INSERT WITHOUT PLATING OR LUBRICANT WILL BE TESTED USING A SILVER PLATED BOLT OR

SCREW.

WITTEN COMPANY INC

918.272.9567

REV: - 8/24/09

NAS 1832

SHEET 3 OF 3

NAS 1832

INSERT, MOLDED IN, THREADED, SANDWICH PANEL

NOTES CON'TD:

3. TOLERANCES UNLESS OTHERWISE SPECIFIED:

XXX = ±.010

XX = ±.02

4. AN ADHESIVE-BACKED INSTALLATION TAB NAS 1837 (PLASTIC PER WITTEN 2007) SHALL BE

FURNISHED WITH EACH INSERT.

5. PLATING OR SOLID FILM LUBRICANT IS RECOMMENDED ON SELF-LOCKING CRES INSERTS.

6. SELECT A LENGTH WHICH WILL ALLOW A MINIMUM OF .040 CLEARANCE BETWEEN BOTTOM

OF INSERT AND INSIDE SURFACE OF BOTTOM SKIN.

7 NONMETALLIC THREAD LOCK WHEN APPLICABLE. LOCATE A PELLET NO CLOSER THAN 10°

FROM EDGE OF EITHER POTTING HOLE OR SLOT.

8 BURRS CAUSED BY MACHINING POTTING HOLES OR SLOTS PERMISSIBLE UNDER FLANGE.

9. DIMENSIONING AND TOLERANCING PER ANSI Y 14.5M-1982.

10. DIMENSIONS IN INCHES UNLESS OTHERWISE NOTED.

11. NOT USED.

12 MINIMUM "GO" THREAD GAGE PENETRATION SHALL BE ONE HALF REVOLUTION BEFORE

LUBRICATION. MINIMUM BOLT THREAD THREAD PENETRATION SHALL BE THREE QUARTER

REVOLUTION AFTER LUBRICATION.

13 CENTERLINE OF THREAD LOCK WHEN APPLICABLE.

14 SHANK DEFORMED IN THIS AREA TO PROVIDE THREAD LOCK WHEN APPLICABLE.

15 POTTING & VENT HOLES OR SLOTS (MANUFACTURER'S OPTION).

16. ALL DIAMETERS SHALL BE WITHIN .010 CIRCULAR RUNOUT TO DATUM A.

17. DIMENSIONAL LIMITS APPLY AFTER PLATING, PRIOR TO SOLID FILM LUBE.

WITTEN COMPANY INC

918.272.9567

REV: - 8/24/09

Você também pode gostar

- ITNC 530 HSCI Service Manual - 02 - 2012 - enDocumento654 páginasITNC 530 HSCI Service Manual - 02 - 2012 - enWaldemarAinda não há avaliações

- Yaskawa CACR-HR Series ManualDocumento122 páginasYaskawa CACR-HR Series ManualsunhuynhAinda não há avaliações

- 1 Smart HW IntroductionDocumento13 páginas1 Smart HW Introductiongopikrishna.schunkAinda não há avaliações

- Technical Manual: TNC 426 CB/PB/M TNC 430 CA/PA/MDocumento1.129 páginasTechnical Manual: TNC 426 CB/PB/M TNC 430 CA/PA/MRafal FoxAinda não há avaliações

- M700V/M70 Series PLC Programming ManualDocumento835 páginasM700V/M70 Series PLC Programming ManualAce RimmerAinda não há avaliações

- EP3 Use ManualDocumento321 páginasEP3 Use Manualalejandro becerraAinda não há avaliações

- KellenbergerDocumento44 páginasKellenbergerAminAinda não há avaliações

- B-65012E03 AC Spindle Motor Series (SPVH) Descriptions 1987Documento322 páginasB-65012E03 AC Spindle Motor Series (SPVH) Descriptions 1987John BacsikAinda não há avaliações

- MAT1020Documento8 páginasMAT1020Rodolfo NallisAinda não há avaliações

- 63003en-1 01Documento1.417 páginas63003en-1 01Bobert HAinda não há avaliações

- M800 - M80 - E80 - C80 Series Specifications Manual (Hardware) Ib1501506engc PDFDocumento284 páginasM800 - M80 - E80 - C80 Series Specifications Manual (Hardware) Ib1501506engc PDFKuanTing KuoAinda não há avaliações

- M800-M80 Series PLC Programming Manual - IB1501271-C (ENG) PDFDocumento780 páginasM800-M80 Series PLC Programming Manual - IB1501271-C (ENG) PDFXavier TorrasAinda não há avaliações

- VM1 PLWD r02x2-304Documento241 páginasVM1 PLWD r02x2-304ag cnc & wedm machining shopAinda não há avaliações

- DualCheckSafetyMan B-64004EN 03 070508Documento268 páginasDualCheckSafetyMan B-64004EN 03 070508Thiago SalesAinda não há avaliações

- The Caution of Rate Feed Function in FANUC Power Mate-MODEL E OPERATOR’S MANUALDocumento183 páginasThe Caution of Rate Feed Function in FANUC Power Mate-MODEL E OPERATOR’S MANUALCONG TRAN NGOCAinda não há avaliações

- 196 - GEA32677 - MV3000 Delta Module Retrofit Factsheet PDFDocumento2 páginas196 - GEA32677 - MV3000 Delta Module Retrofit Factsheet PDFAdson GomesAinda não há avaliações

- User GuideDocumento13 páginasUser Guidejfcastro2011Ainda não há avaliações

- TS27R User Guide (H-2000-5018-06-D)Documento76 páginasTS27R User Guide (H-2000-5018-06-D)Felipe SchiehllAinda não há avaliações

- PMC Supplemental Programming ManualDocumento88 páginasPMC Supplemental Programming ManualTien Nguyen VanAinda não há avaliações

- 9513 OptoDocumento18 páginas9513 OptoCatalina MuneraAinda não há avaliações

- 896096-25 iTNC530 OEM HSCI PDFDocumento112 páginas896096-25 iTNC530 OEM HSCI PDFalanrinAinda não há avaliações

- 802Dsl AlarmesDocumento438 páginas802Dsl AlarmesWagner Rodolfo da SilvaAinda não há avaliações

- TFP3051 Demo SpecSheetDocumento2 páginasTFP3051 Demo SpecSheetAlexandr KorolevAinda não há avaliações

- MR J4 CatalogueDocumento302 páginasMR J4 CatalogueGiang BùiAinda não há avaliações

- JJ/JJJ-3x8000-XXX-KT-RDB G25-16-130211-8: Project Description Drawing Number Company / CustomerDocumento23 páginasJJ/JJJ-3x8000-XXX-KT-RDB G25-16-130211-8: Project Description Drawing Number Company / CustomerМилен НиколовAinda não há avaliações

- FANUC control history in North AmericaDocumento1 páginaFANUC control history in North AmericaVaibhav ChaudhariAinda não há avaliações

- Doosan HC II SeriesDocumento20 páginasDoosan HC II SeriesBow LinAinda não há avaliações

- 66184en-Fapt Fladder II Opretion Manual PDFDocumento560 páginas66184en-Fapt Fladder II Opretion Manual PDFCuốn Theo Chiều GióAinda não há avaliações

- Inverter Sumitomo Af3100Documento20 páginasInverter Sumitomo Af3100FarizAinda não há avaliações

- Base PMC: User ManualDocumento31 páginasBase PMC: User ManualeletropaulomococaAinda não há avaliações

- Manual FanucDocumento6 páginasManual FanucWermeson SousaAinda não há avaliações

- Vt-1150 User ManualDocumento22 páginasVt-1150 User ManualAnne RodriguesAinda não há avaliações

- 6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Documento18 páginas6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Stefan IstratescuAinda não há avaliações

- Fan Uc Manuals 1790Documento213 páginasFan Uc Manuals 1790Somchai SompongpuangAinda não há avaliações

- Complete Operating and Programming 802Dsl en A TM Sw1 4Documento447 páginasComplete Operating and Programming 802Dsl en A TM Sw1 4Freddy Mamani AtayupanquiAinda não há avaliações

- DMU 70 Mechanik iTNC530Documento74 páginasDMU 70 Mechanik iTNC530tolik19731Ainda não há avaliações

- MAZAK Nexus 410A-II 00092Documento4 páginasMAZAK Nexus 410A-II 00092tiuganstefanAinda não há avaliações

- Connection Manual (Hardware) : Fanuc Series 0 - Model C FANUC Series 0 Mate-MODEL CDocumento370 páginasConnection Manual (Hardware) : Fanuc Series 0 - Model C FANUC Series 0 Mate-MODEL CTrương Vũ Jr.100% (1)

- Technical Manual for Inverter Systems and MotorsDocumento655 páginasTechnical Manual for Inverter Systems and MotorsSlawaAinda não há avaliações

- 04018E - A-77223E@02 Bis IO Link DescriptionDocumento80 páginas04018E - A-77223E@02 Bis IO Link DescriptionSagarAinda não há avaliações

- Fanuc SPM PDFDocumento2 páginasFanuc SPM PDFBrianAinda não há avaliações

- Surfcom 130 ADocumento6 páginasSurfcom 130 ABhargav ParsaAinda não há avaliações

- B 64304en 3 - 01 - V2008 09 02Documento68 páginasB 64304en 3 - 01 - V2008 09 02Ferenc UngváriAinda não há avaliações

- Fanuc Fanuc Fanuc Fanuc Fanuc: Series 16 Series 18 Series 20 Series 21 Series 0Documento612 páginasFanuc Fanuc Fanuc Fanuc Fanuc: Series 16 Series 18 Series 20 Series 21 Series 0CLAUDIOAinda não há avaliações

- Delcam DuctPost User Guide enDocumento219 páginasDelcam DuctPost User Guide enEntonyAinda não há avaliações

- BNP B2202Documento10 páginasBNP B2202hanhvannguyentranAinda não há avaliações

- 66234en PDFDocumento532 páginas66234en PDFMarian ButerchiAinda não há avaliações

- Meldas c6-c64 Network ManualDocumento208 páginasMeldas c6-c64 Network ManualsunhuynhAinda não há avaliações

- 3HAC026871-020 Rev09Documento117 páginas3HAC026871-020 Rev09kukaAinda não há avaliações

- Fanuc Series 10 11 12Documento28 páginasFanuc Series 10 11 12AlbertoQuezadaAinda não há avaliações

- Ge Fanuc Automation: Powermotion ProductsDocumento113 páginasGe Fanuc Automation: Powermotion ProductsEDUARDO PERFECTOAinda não há avaliações

- Gv-500&780 Operation Manual 04 VerDocumento395 páginasGv-500&780 Operation Manual 04 VersunhuynhAinda não há avaliações

- B-85444EN-3_03_Custom PMC FunctionDocumento392 páginasB-85444EN-3_03_Custom PMC FunctionKonrad WolnyAinda não há avaliações

- Siemense SM 06 04 23 76Documento17 páginasSiemense SM 06 04 23 76skidamdnevnoAinda não há avaliações

- B-65302en 03-04 100922Documento7 páginasB-65302en 03-04 100922Xavier TorrasAinda não há avaliações

- 63090en 02Documento376 páginas63090en 02Samuel MarquezAinda não há avaliações

- Details PDF: Image Part Number Description Manufacturer QtyDocumento1 páginaDetails PDF: Image Part Number Description Manufacturer QtyPaulo Henrique Valério100% (1)

- NAS1836Documento3 páginasNAS1836Ray DutchmanAinda não há avaliações

- Ed1801 MFG DWG of Ladder Grating Handrail in Shaft R (Partial DK)Documento15 páginasEd1801 MFG DWG of Ladder Grating Handrail in Shaft R (Partial DK)luisAinda não há avaliações

- NASA Stress Analysis Report Format RequirementsDocumento14 páginasNASA Stress Analysis Report Format RequirementsdouglascoombsAinda não há avaliações

- CS-29 Amendment 7Documento225 páginasCS-29 Amendment 7staedtlerpAinda não há avaliações

- D 6641 - D 6641M - 01 - Rdy2ndevrdy2ndfn PDFDocumento9 páginasD 6641 - D 6641M - 01 - Rdy2ndevrdy2ndfn PDFstaedtlerpAinda não há avaliações

- Click BondDocumento4 páginasClick BondstaedtlerpAinda não há avaliações

- Quasi-Static Three-Point Beniding of Carbon Fiber Sandwich Beams With Square Honeycomb CoresDocumento15 páginasQuasi-Static Three-Point Beniding of Carbon Fiber Sandwich Beams With Square Honeycomb CoresstaedtlerpAinda não há avaliações

- Numerical Modelling of Nomex Honeycomb C PDFDocumento12 páginasNumerical Modelling of Nomex Honeycomb C PDFstaedtlerpAinda não há avaliações

- Composites Design Manual 3 EdDocumento184 páginasComposites Design Manual 3 EdSérgio Patinha100% (5)

- CS-29 Amendment 7Documento225 páginasCS-29 Amendment 7staedtlerpAinda não há avaliações

- Metric Conversion TableDocumento2 páginasMetric Conversion TablestaedtlerpAinda não há avaliações

- Basic Stress EquationDocumento5 páginasBasic Stress EquationtankimsinAinda não há avaliações

- Click BondDocumento4 páginasClick BondstaedtlerpAinda não há avaliações

- Bending Stress of BeamsDocumento18 páginasBending Stress of BeamsRambabu RAinda não há avaliações

- Fan Supersonic Flutter: Prediction and Test Ar A Ys S: Procurement Executive, Ministry of DefenceDocumento24 páginasFan Supersonic Flutter: Prediction and Test Ar A Ys S: Procurement Executive, Ministry of DefencestaedtlerpAinda não há avaliações

- Cycom-919 CM en PDFDocumento7 páginasCycom-919 CM en PDFstaedtlerpAinda não há avaliações

- AN3-3A SpecDocumento2 páginasAN3-3A Specstaedtlerp100% (1)

- A Beginners Guide To Literature in The Field of AeroelasticityDocumento33 páginasA Beginners Guide To Literature in The Field of AeroelasticitystaedtlerpAinda não há avaliações

- FSI in VWT 2017Documento23 páginasFSI in VWT 2017staedtlerpAinda não há avaliações

- Applied FemDocumento30 páginasApplied FemAniket ThakurAinda não há avaliações

- Structural Analysis of Aircraft Wing J Nose Panel Using Mono and Multi Core Composite MaterialsDocumento6 páginasStructural Analysis of Aircraft Wing J Nose Panel Using Mono and Multi Core Composite MaterialsstaedtlerpAinda não há avaliações

- Numerical Modelling of Nomex Honeycomb C PDFDocumento12 páginasNumerical Modelling of Nomex Honeycomb C PDFstaedtlerpAinda não há avaliações

- PDFDocumento221 páginasPDFstaedtlerpAinda não há avaliações

- A One-Equation Turbulence Model For Aerodynamic Flows: January 1992Documento18 páginasA One-Equation Turbulence Model For Aerodynamic Flows: January 1992Asma KhanAinda não há avaliações

- Adhesive Bonding ECSS E HB 32 21A 20march2011Documento461 páginasAdhesive Bonding ECSS E HB 32 21A 20march2011Li-chung Jea100% (1)

- Spiralock Wire Thread Insert Hole Drilling Specifications 0Documento2 páginasSpiralock Wire Thread Insert Hole Drilling Specifications 0staedtlerpAinda não há avaliações

- HexPly M2626T Eu DataSheetDocumento4 páginasHexPly M2626T Eu DataSheetstaedtlerpAinda não há avaliações

- Ms33537e PDFDocumento11 páginasMs33537e PDFstaedtlerpAinda não há avaliações

- Mil S 7742DDocumento17 páginasMil S 7742DstaedtlerpAinda não há avaliações

- HexPly M2626T Eu DataSheetDocumento4 páginasHexPly M2626T Eu DataSheetstaedtlerpAinda não há avaliações

- Nasm21209 AiaDocumento8 páginasNasm21209 Aiastaedtlerp100% (3)

- Ms33537e PDFDocumento11 páginasMs33537e PDFstaedtlerpAinda não há avaliações

- Transpo Printable Lecture4Documento10 páginasTranspo Printable Lecture4Jabin Sta. TeresaAinda não há avaliações

- Akron Grad School Statement of Purpose PDFDocumento2 páginasAkron Grad School Statement of Purpose PDFapi-406039291Ainda não há avaliações

- Us Errata Document 11-14-13Documento12 páginasUs Errata Document 11-14-13H VAinda não há avaliações

- Computed Tomography (CT) - BodyDocumento7 páginasComputed Tomography (CT) - Bodyfery oktoraAinda não há avaliações

- Sodium Chloride MSDSDocumento5 páginasSodium Chloride MSDSIbaharmovic LpuAinda não há avaliações

- embragues-INTORK KBK14800 Erhsa2013 PDFDocumento56 páginasembragues-INTORK KBK14800 Erhsa2013 PDFPablo RuizAinda não há avaliações

- 23soft Starter HandbookDocumento36 páginas23soft Starter HandbookCarlos_Duque1958Ainda não há avaliações

- WASA Wastewater and Potable Water Design Requirements PDFDocumento233 páginasWASA Wastewater and Potable Water Design Requirements PDFYassin AlkadyAinda não há avaliações

- 310 Ta PDFDocumento8 páginas310 Ta PDFVincent GomuliaAinda não há avaliações

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADocumento3 páginasBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaAinda não há avaliações

- Being ProfessionalDocumento3 páginasBeing ProfessionalPutra SyahrezaAinda não há avaliações

- Reducing Malaria Infections in Sub-Saharan AfricaDocumento2 páginasReducing Malaria Infections in Sub-Saharan AfricaStansa SeniaAinda não há avaliações

- Lesson 1:: Introduction To Science, Technology and SocietyDocumento17 páginasLesson 1:: Introduction To Science, Technology and SocietyAlexis A. AguilarAinda não há avaliações

- Respiration PHYSIODocumento23 páginasRespiration PHYSIOTauseef AfridiAinda não há avaliações

- Technical Bulletins Miglow Underwater12Documento1 páginaTechnical Bulletins Miglow Underwater12Arnaud PoliAinda não há avaliações

- Calculate Size of Transformer / Fuse / Circuit Breaker: Connected Equipment To TransformerDocumento16 páginasCalculate Size of Transformer / Fuse / Circuit Breaker: Connected Equipment To TransformerHari OM MishraAinda não há avaliações

- F 204 (AutoRecovered)Documento27 páginasF 204 (AutoRecovered)safiqulislam100% (1)

- Osteo Book Final 2014Documento51 páginasOsteo Book Final 2014hyanandAinda não há avaliações

- What is Intermodulation InterferenceDocumento3 páginasWhat is Intermodulation InterferencedekcarcAinda não há avaliações

- CASE Study PTBDocumento53 páginasCASE Study PTBmeleanaquino94% (16)

- Chapter 3 NotesDocumento10 páginasChapter 3 Notesmjamie12345Ainda não há avaliações

- P1007 PPPS For Raw Milk 1AR SD3 Cheese Risk AssessmentDocumento304 páginasP1007 PPPS For Raw Milk 1AR SD3 Cheese Risk AssessmentNicholasAinda não há avaliações

- Exudate Detection For Diabetic Retinopathy With Circular HoughDocumento7 páginasExudate Detection For Diabetic Retinopathy With Circular HoughAshif MahbubAinda não há avaliações

- Registration Hike2help 15Documento2 páginasRegistration Hike2help 15api-275580337Ainda não há avaliações

- Polymer MaterialsDocumento31 páginasPolymer MaterialsDaithi Mac DomhnaillAinda não há avaliações

- MIDWIFE1115ra Tugue e PDFDocumento9 páginasMIDWIFE1115ra Tugue e PDFPhilBoardResultsAinda não há avaliações

- Cobb 500 PDFDocumento14 páginasCobb 500 PDFNeil Ryan100% (1)

- Technical Information Bulletins Ajax # 010717Documento28 páginasTechnical Information Bulletins Ajax # 010717harley florezAinda não há avaliações

- Statistics of Design Error in The Process IndustriesDocumento13 páginasStatistics of Design Error in The Process IndustriesEmmanuel Osorno CaroAinda não há avaliações

- Glulam Wood BeamsDocumento37 páginasGlulam Wood Beamsu16sr6Ainda não há avaliações