Escolar Documentos

Profissional Documentos

Cultura Documentos

Base Metal (As Recevied) Base Metal (Micro Sample) Weld Area (Micro Sample)

Enviado por

Vasu RajaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Base Metal (As Recevied) Base Metal (Micro Sample) Weld Area (Micro Sample)

Enviado por

Vasu RajaDireitos autorais:

Formatos disponíveis

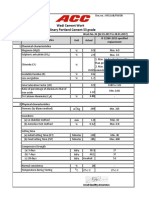

AMSTEEL Castings Pvt. Ltd., Hosur - 635 126.

ESSC : 5A Casting

Chemical test : Spectro analysis

5A Chemical Specification Sample 1 (Small) Sample 2 (Big)

C 0.03 max 0.030 0.022

Mn 1.50 max 0.970 0.950

Si 1.00 max 0.834 0.818

S 0.04 max 0.003 0.002

P 0.04 max 0.017 0.017

Cr 24 % to 26 % 24.861 25.008

Ni 6% to 8 % 6.862 6.746

Cu -- 0.508 0.507

Mo 4 % to 5% 4.385 4.383

N 0.1 % to 0.3 % 0.218 0.216

Pren 40 min. 42.816 42.931

Cr Eq 30.5 30.6

Ni Eq 11.8 11.5

% of Ferrite 58 65

(GIL Calculation)

Mechnaical tests :

Location Sample 1 (Small) Sample 2 (Big)

01. Charpy Impact test Base Metal 04,04,04 04,04,04

at -50°C

Weld area 02,02,04 04,06,04

Base Metal

(as recevied) 285 301

Base Metal

02. Brinell Hardness (HBW) (micro sample) 264 264

Weld area

(micro sample) 258 271

Base Metal 10.3 12

03. % of Ferrite (ASTM E562)

Weld area 12.5 14

Base Metal & Weld

04. % of Ferrite (Ferrito scope) 20% to 30% 20% to 30%

area

05. Microstructure Examination Base Metal & Weld Presence of Presence of

area Sigma phase(σ). Sigma phase(σ).

AMSTEEL Castings Pvt. Ltd., Hosur - 635 126.

ESSC : 5A Casting

Mechnaical tests after Solution Annealing :

Location Sample 1 (Small) Sample 2 (Big)

60,54,62

70,62,64

01. Charpy Impact test Base Metal (Avg: 65)

at -50°C (J) (Avg: 59)

50,54,56 56,62,58

Weld area (Avg: 59)

(Avg: 53)

Base Metal

02. Brinell Hardness (HBW) 248 252

Base Metal 44% 48%

03. % of Ferrite (ASTM E562)

Weld area 47% 45%

04. % of Ferrite Base Metal 60%to 65% 60%to 65%

(ASTM E1245) -

Image analyzer Weld area 60%to 65% 60%to 65%

Base Metal & No Sigma phase(σ). No Sigma phase(σ).

05. Microstructure Examination Weld area

Você também pode gostar

- Failure Analysis PDFDocumento26 páginasFailure Analysis PDFRahman AuliaAinda não há avaliações

- Materials Data for Cyclic Loading: Low-Alloy SteelsNo EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsNota: 5 de 5 estrelas5/5 (2)

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Documento2 páginasProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajAinda não há avaliações

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocumento3 páginasProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLAinda não há avaliações

- SilcoTek Coatings For High Purity ApplicationsDocumento30 páginasSilcoTek Coatings For High Purity ApplicationsKommu RohithAinda não há avaliações

- S-8018 B2Documento5 páginasS-8018 B2Abhishek AnandAinda não há avaliações

- Specification For Precipitation-Hardening Nickel Alloy Bars, Forgings, and Forging Stock For High-Temperature ServiceDocumento9 páginasSpecification For Precipitation-Hardening Nickel Alloy Bars, Forgings, and Forging Stock For High-Temperature ServicerbagriAinda não há avaliações

- 2.0550 - CW713R (CuZn40Al2)Documento1 página2.0550 - CW713R (CuZn40Al2)Eminent RishAinda não há avaliações

- Lincoln6011 AS ES-MX PDFDocumento2 páginasLincoln6011 AS ES-MX PDFJuan Novillo RamosAinda não há avaliações

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocumento1 páginaExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaAinda não há avaliações

- The US Particle Accelerator School Materials, Fabrication Techniques, and Joint DesignsDocumento46 páginasThe US Particle Accelerator School Materials, Fabrication Techniques, and Joint Designsgangappa birajadarAinda não há avaliações

- Arcaloy 430Nb (Rev.2)Documento2 páginasArcaloy 430Nb (Rev.2)RobertoAinda não há avaliações

- CW604N Leaded BrassDocumento2 páginasCW604N Leaded BrassJIGAR KATHIRIYAAinda não há avaliações

- Wiem 7024 Ecc: Type Rutile Shield Metal Arc Weld (SMAW) Classifications DescriptionDocumento1 páginaWiem 7024 Ecc: Type Rutile Shield Metal Arc Weld (SMAW) Classifications DescriptionagrinjoshAinda não há avaliações

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocumento1 páginaCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesXQAinda não há avaliações

- Sheet Coil & Plate Alloy 6061Documento2 páginasSheet Coil & Plate Alloy 6061Sarat SrinivasAinda não há avaliações

- Sheet Coil & Plate Alloy 6061Documento2 páginasSheet Coil & Plate Alloy 6061Sarat SrinivasAinda não há avaliações

- Kim HT - 1996 - Article - StudyOnTheSolidificationCracki - PDF - Borland EquationDocumento6 páginasKim HT - 1996 - Article - StudyOnTheSolidificationCracki - PDF - Borland Equation이상벽Ainda não há avaliações

- Ficha Tecnica Esab Electrodos EspecialesDocumento1 páginaFicha Tecnica Esab Electrodos EspecialesStanley RamirezAinda não há avaliações

- Basics of X-Ray Powder DiffractionDocumento82 páginasBasics of X-Ray Powder DiffractionJohn Gerald OdhiamboAinda não há avaliações

- Report On: "Characterization of Welded Clad Sample of Grade C276 + IS 2062, E250"Documento5 páginasReport On: "Characterization of Welded Clad Sample of Grade C276 + IS 2062, E250"sagarAinda não há avaliações

- Material Search Results - DETAILED REPORT: General Information MAT - ID 265Documento4 páginasMaterial Search Results - DETAILED REPORT: General Information MAT - ID 265Muhammad DiazAinda não há avaliações

- Optimization of Machining Parameters in Wire Cut Electric Discharge Machining of Inconel 600Documento24 páginasOptimization of Machining Parameters in Wire Cut Electric Discharge Machining of Inconel 600noble aAinda não há avaliações

- 1434529448155-Failure Investigation MetallurgicalDocumento51 páginas1434529448155-Failure Investigation MetallurgicalEmmanuel Kwesi ArthurAinda não há avaliações

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocumento2 páginasProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87Ainda não há avaliações

- OK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsDocumento1 páginaOK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsHusam AhmedAinda não há avaliações

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocumento1 páginaCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesMohammad AdilAinda não há avaliações

- Microsoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFDocumento56 páginasMicrosoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFamitAinda não há avaliações

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Documento3 páginasProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801Ainda não há avaliações

- 02112015000000B - Boehler FOX CEL Mo - CeDocumento1 página02112015000000B - Boehler FOX CEL Mo - CeOPAZOSCAinda não há avaliações

- Zinc AG40A (Zinc Alloy 3 Zn-4Al-0.4Mg Zamak 3), Cast - SAE 903Documento2 páginasZinc AG40A (Zinc Alloy 3 Zn-4Al-0.4Mg Zamak 3), Cast - SAE 903Hari Tej AvvaruAinda não há avaliações

- Lab Planning - EMMDocumento1 páginaLab Planning - EMMmarysudhakarAinda não há avaliações

- Localized TechniquesDocumento77 páginasLocalized TechniquestehtnicaAinda não há avaliações

- Copper Alloy C67500Documento10 páginasCopper Alloy C67500Kapil HarchekarAinda não há avaliações

- JIS G5131ï š2008 High Manganese Steel Castings PDFDocumento14 páginasJIS G5131ï š2008 High Manganese Steel Castings PDFsupendiAinda não há avaliações

- OK 63.30 (Inox 316)Documento1 páginaOK 63.30 (Inox 316)Tiberiu MunteanuAinda não há avaliações

- Chemical Composition: ASTM B103Documento1 páginaChemical Composition: ASTM B103MarcoAntonioAinda não há avaliações

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Documento2 páginasProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanAinda não há avaliações

- El Ement Al Analysis of Glass by SEM-EDS, X RF, LI BS and Laser Abl ation-ICP - MSDocumento66 páginasEl Ement Al Analysis of Glass by SEM-EDS, X RF, LI BS and Laser Abl ation-ICP - MSIpungAinda não há avaliações

- Case Studies in Engineering Failure Analysis: Soham Chattopadhyay, Piyas Palit, Nilotpal DeyDocumento6 páginasCase Studies in Engineering Failure Analysis: Soham Chattopadhyay, Piyas Palit, Nilotpal DeySebastian MorenoAinda não há avaliações

- Certificate of Conformance: Q1 Lot Number: 15163483Documento1 páginaCertificate of Conformance: Q1 Lot Number: 15163483interx00Ainda não há avaliações

- Quality Requirements For CrMo Alloys SAG Mill Liner and GratesDocumento16 páginasQuality Requirements For CrMo Alloys SAG Mill Liner and GratesFrancis ChavezAinda não há avaliações

- Mil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322Documento2 páginasMil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322FlavioAinda não há avaliações

- Esab, Ok 309L (29.12.16)Documento1 páginaEsab, Ok 309L (29.12.16)RodrigoAinda não há avaliações

- Wadi Cement Work Ordinary Portland Cement 53 Grade: Chemical CharacteristicsDocumento1 páginaWadi Cement Work Ordinary Portland Cement 53 Grade: Chemical CharacteristicsAshish SontakkeAinda não há avaliações

- 7 Tool Steels1Documento12 páginas7 Tool Steels1ontc0109Ainda não há avaliações

- Materials Science and Technology 11 (1995) 1046-1051Documento19 páginasMaterials Science and Technology 11 (1995) 1046-1051iqbal haiderAinda não há avaliações

- ESPARRAGO A-193 B7 3l4-10 X 3660Documento1 páginaESPARRAGO A-193 B7 3l4-10 X 3660Incoservspa cl100% (1)

- 8 FormulinoxUSDémoDocumento6 páginas8 FormulinoxUSDémoThe TechnicalsAinda não há avaliações

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Documento2 páginasProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffAinda não há avaliações

- Dmls Inconel 625Documento1 páginaDmls Inconel 625CRISTIANOAinda não há avaliações

- Shear DeformationDocumento12 páginasShear DeformationDurgesh KhannaAinda não há avaliações

- Application of The Modified ElectrochemicalDocumento8 páginasApplication of The Modified ElectrochemicalAlmerindo JuniorAinda não há avaliações

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocumento1 páginaPipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacAinda não há avaliações

- AMP16609P61Documento1 páginaAMP16609P61Gutha Giribabu NaiduAinda não há avaliações

- Jom Module IIDocumento138 páginasJom Module IIPrinceAinda não há avaliações

- Comparision of Three & Four Tandem Wire SystemDocumento15 páginasComparision of Three & Four Tandem Wire SystemKumawat PrakashAinda não há avaliações

- L11a Weld - DesignDocumento36 páginasL11a Weld - Designtan zhiyuAinda não há avaliações

- OK Tigrod NiCu-7Documento1 páginaOK Tigrod NiCu-7Ali VarmazyarAinda não há avaliações

- Process Parameter Optimization of CO2 MouldingDocumento4 páginasProcess Parameter Optimization of CO2 MouldingVasu RajaAinda não há avaliações

- Astm A 106 - A 106M-06Documento8 páginasAstm A 106 - A 106M-06Ramsi AnkziAinda não há avaliações

- United States Patent: (45) June 6, 1972Documento4 páginasUnited States Patent: (45) June 6, 1972Vasu RajaAinda não há avaliações

- US4089837Documento6 páginasUS4089837Vasu RajaAinda não há avaliações

- Shell Molding Process Guide - The Eagle GroupDocumento27 páginasShell Molding Process Guide - The Eagle GroupVasu RajaAinda não há avaliações

- Disclosure To Promote The Right To InformationDocumento34 páginasDisclosure To Promote The Right To InformationVasu RajaAinda não há avaliações

- Nabl 129 PDFDocumento135 páginasNabl 129 PDFDisha ShahAinda não há avaliações

- Elimination of Pinhole Porosity by Using Fe SeDocumento5 páginasElimination of Pinhole Porosity by Using Fe SeVasu RajaAinda não há avaliações

- Increasing of Reclamination Sand Compression StrengthDocumento6 páginasIncreasing of Reclamination Sand Compression StrengthVasu RajaAinda não há avaliações

- Er70s 6Documento2 páginasEr70s 6Carlos PadillaAinda não há avaliações

- Weldingguide ENGDocumento518 páginasWeldingguide ENGBoris Kozjan0% (1)

- Material Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: ApplicationDocumento2 páginasMaterial Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: Applicationshankarjb100% (1)

- Defects, Root Causes in Casting Process and Their Remedies: ReviewDocumento8 páginasDefects, Root Causes in Casting Process and Their Remedies: ReviewkoushikraoAinda não há avaliações

- Nabl 100Documento51 páginasNabl 100Vasu RajaAinda não há avaliações

- ACCAB - Corporate BrochureDocumento12 páginasACCAB - Corporate BrochureVasu RajaAinda não há avaliações

- ISO IEC 17025 2017 Transition TemplateDocumento8 páginasISO IEC 17025 2017 Transition TemplateVasu RajaAinda não há avaliações

- Nabl 191Documento87 páginasNabl 191Vasu RajaAinda não há avaliações

- Is 1917.1.1991Documento8 páginasIs 1917.1.1991gurushankarAinda não há avaliações

- Phosphorous Control in Induction Furnace Steel Melting Using LD Slag IJERTV5IS060791 PDFDocumento6 páginasPhosphorous Control in Induction Furnace Steel Melting Using LD Slag IJERTV5IS060791 PDFVasu RajaAinda não há avaliações

- Creehan RD 1984 PHD ThesisDocumento211 páginasCreehan RD 1984 PHD ThesisVasu RajaAinda não há avaliações

- Practice ASTM E691Documento22 páginasPractice ASTM E691Les Nataly Hernando JaqueAinda não há avaliações

- Risk ManagementDocumento19 páginasRisk ManagementChitu IulianAinda não há avaliações

- TensileDocumento7 páginasTensiledayglisAinda não há avaliações

- Turning Carbon Dioxide Into FuelDocumento22 páginasTurning Carbon Dioxide Into FuelVasu RajaAinda não há avaliações

- Disclosure To Promote The Right To Information: IS 1811 (1984) : Methods of Sampling Foundry Sands (MTD 14: Foundry)Documento17 páginasDisclosure To Promote The Right To Information: IS 1811 (1984) : Methods of Sampling Foundry Sands (MTD 14: Foundry)Vasu RajaAinda não há avaliações

- ISO31000yNS AustralianaDocumento61 páginasISO31000yNS AustralianaMarco Antonio GuillenAinda não há avaliações

- Astm A-29Documento16 páginasAstm A-29Jivi' Gernot DunckelAinda não há avaliações

- Failure Modesand Effects AnalysisDocumento3 páginasFailure Modesand Effects AnalysisVasu RajaAinda não há avaliações

- Risk Assessment in Analytical LaboratoriesDocumento7 páginasRisk Assessment in Analytical LaboratoriesVasu RajaAinda não há avaliações

- Nabl 216Documento17 páginasNabl 216Bhupendra KarandikarAinda não há avaliações

- Classical Encryption TechniqueDocumento18 páginasClassical Encryption TechniquetalebmuhsinAinda não há avaliações

- Bill - AKIJDocumento3 páginasBill - AKIJm.tanjil2005Ainda não há avaliações

- Risk Assessment For ExcavationDocumento6 páginasRisk Assessment For ExcavationAhmed GamalAinda não há avaliações

- 7273X 47 ITOW Mozart PDFDocumento3 páginas7273X 47 ITOW Mozart PDFAdrian KranjcevicAinda não há avaliações

- E Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersDocumento13 páginasE Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersRichard VillanuevaAinda não há avaliações

- Architecture of Neural NWDocumento79 páginasArchitecture of Neural NWapi-3798769Ainda não há avaliações

- Unseen Passage 2Documento6 páginasUnseen Passage 2Vinay OjhaAinda não há avaliações

- Ultimate Prime Sieve - Sieve of ZakiyaDocumento23 páginasUltimate Prime Sieve - Sieve of ZakiyaJabari ZakiyaAinda não há avaliações

- Classical School of Thought: Ms. Salma ShaheenDocumento62 páginasClassical School of Thought: Ms. Salma ShaheenQasim Ali100% (1)

- Towards A Brighter Ecological Future: Group 2Documento24 páginasTowards A Brighter Ecological Future: Group 2As YangAinda não há avaliações

- IPT .Quarter 2 (Grade 7-Mathematics, English &TLE)Documento2 páginasIPT .Quarter 2 (Grade 7-Mathematics, English &TLE)ARRIANE JOY TOLEDOAinda não há avaliações

- Fbla Scavenger Hunt 1Documento3 páginasFbla Scavenger Hunt 1api-472648158Ainda não há avaliações

- APS PresentationDocumento32 páginasAPS PresentationRozack Ya ZhackAinda não há avaliações

- 2019q123.ev3-Descon Engro Level Gauges-QDocumento7 páginas2019q123.ev3-Descon Engro Level Gauges-Qengr_umer_01Ainda não há avaliações

- Victaulic-FP-FireLock Fire-Pac Series 745 PreactionDocumento9 páginasVictaulic-FP-FireLock Fire-Pac Series 745 PreactionTấn ĐạtAinda não há avaliações

- Part 1. Question 1-7. Complete The Notes Below. Write NO MORE THAN THREE WORDS AND/OR A NUMBER For Each AnswerDocumento13 páginasPart 1. Question 1-7. Complete The Notes Below. Write NO MORE THAN THREE WORDS AND/OR A NUMBER For Each Answerahmad amdaAinda não há avaliações

- Chapter 3 Mine Ventialtion ProblemDocumento3 páginasChapter 3 Mine Ventialtion ProblemfahimAinda não há avaliações

- Construction of Perimeter Fence of BFP NHQ PDFDocumento133 páginasConstruction of Perimeter Fence of BFP NHQ PDFYalla ChaitanyaAinda não há avaliações

- Tyler & Wheeler Curriculum ModelDocumento8 páginasTyler & Wheeler Curriculum Modelliliyayanono100% (1)

- Evolution of Strategic HRM As Seen Through Two Founding Books A 30TH Anniversary Perspective On Development of The FieldDocumento20 páginasEvolution of Strategic HRM As Seen Through Two Founding Books A 30TH Anniversary Perspective On Development of The FieldJhon Alex ValenciaAinda não há avaliações

- Lecture 08Documento32 páginasLecture 08SusovanAinda não há avaliações

- Grade 7 First Quarter ExamDocumento3 páginasGrade 7 First Quarter ExamBILLY JOE ARELLANOAinda não há avaliações

- K To 12 Math 7 Curriculum Guide PDFDocumento15 páginasK To 12 Math 7 Curriculum Guide PDFEdmar Tan Fabi100% (1)

- Keira Knightley: Jump To Navigation Jump To SearchDocumento12 páginasKeira Knightley: Jump To Navigation Jump To SearchCrina LupuAinda não há avaliações

- CE Laws L8 L15Documento470 páginasCE Laws L8 L15Edwin BernatAinda não há avaliações

- A Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofDocumento65 páginasA Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofMadhavpokale100% (1)

- (Essential Skills For Nurses Series) Philippa Sully - Joan Dallas-Essential Communication Skills For Nursing and Midwifery-Mosby - Elsevier (2010) PDFDocumento250 páginas(Essential Skills For Nurses Series) Philippa Sully - Joan Dallas-Essential Communication Skills For Nursing and Midwifery-Mosby - Elsevier (2010) PDFRetno SumaraAinda não há avaliações

- Theben Timer SUL 181DDocumento2 páginasTheben Timer SUL 181DFerdiAinda não há avaliações

- KirbyDocumento3 páginasKirbyNorhassanah UtosabuayanAinda não há avaliações

- Day 1 Training Material FlowDocumento200 páginasDay 1 Training Material FlowGhazouani AymenAinda não há avaliações