Escolar Documentos

Profissional Documentos

Cultura Documentos

Work Experience Sample2

Enviado por

ziadddDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Work Experience Sample2

Enviado por

ziadddDireitos autorais:

Formatos disponíveis

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No Effective Date Review Date Total Page

Drafted by Approved by 7

Authorised by

Introduction:

Today the risk management in Pharmaceuticals manufacturing and Control has become

important consideration. The cGMP norms require proper identification, assessment,

Page | 1 mitigation and prevention of the risk in all areas. Followings are the few potentially risky

situations.

1. Lack of standard operating procedures

2. Abrupt unwarranted changes in process and analytical methods

3. Changing the source of raw materials abruptly

4. Incomplelete specifications of Raw materials/Finished Goods, unwarranted procedures

5. Unknown personnel disabilities

6. Employing untrained persons in production/QC/QA

7. System failures

8. Inappropriately designed machines and systems

9. Un-validated Process and methods

10. Poor maintenance

11. The management interference and ignorance

12. Missing links in the organization

13. Low management commitments

14. Poor man and material flow

15. Cross contamination in production areas

16. Undue microbial contamination in Purified water

17. Inappropriate cleaning procedures

18. Working in laboratory/production areas in street clothes

19. Observation of rodent excreta in manufacturing and storage area

20. Undue filth and microbial contamination

21. Manufacturing Lactam products and non beta Lactam products side by side Cross

contamination issues

22. Open access to computerized data system

23. Negligence

24. Insufficient cleaning of equipments during product changeover

25 Poor vision (disability to see clearly ) of final inspection staff

26 Ill health of the personnel in general

Prepared By Checked By Approved By Released By

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No Effective Date Review Date Total Page

Drafted by Approved by 7

Authorised by

27 Improper validation of EDP system involved in data entry and data maintenance

In addition to manufacturing preclinical studies, bio studies, clinical trials and marketing

authorization applications also involve considerable risks.

Page | 2

This SOP is intended to provide a procedure to identify, mitigate and prevent all the risks

associated over life history of the pharmaceutical products.

1.0 Responsibilities

Risk management is not a one man show. It requires active involvement of Manufacturing,

Quality Control, Quality Assurance and Maintenance department.

Sometimes even the external agencies are involved in the risk management

Personnel Responsibilities

Risk Assessment Officer To identify the risk

Manufacturing In charge To report all deviations and unwarranted results in production

Maintenance In charge To report equipment limitations and deficiencies

Quality Control In charge To test the products

Quality Assurance To control the entire process and to mitigate the situation

2.0 Scope

This protocol is applicable to all functions/procedures related to receipt, storage, release,

manufacturing, packaging, maintenance, distribution, data handling, documentation, assay,

impurity profiling, stability studies and bio studies as performed at pharmaceutical sites.

This SOP will facilitate identification, classification, mitigation and prevention of risk during

manufacturing of following products …………………………………………………..at

………………………………………………………………………………………………

Prepared By Checked By Approved By Released By

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No Effective Date Review Date Total Page

Drafted by Approved by 7

Authorised by

Procedure

The risk management shall involve the following functions:

Page | 3 Risk identification

Risk Assessment

Risk Mitigation and prevention

Risk closure

Risk Identification

Risk

Risk Closure Analysis/Assess‐

ment

Risk

Risk Mitigation

Mitigation/Preven

Monitoring

tion

3.

Prepared By Checked By Approved By Released By

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No Effective Date Review Date Total Page

Drafted by Approved by 7

Authorised by

3.1 Risk Identification:

Page | 4

Each and every procedure involved in manufacturing or analysis of the product shall be

assessed for the possible risk involved. The particular step of operation which is vulnerable to

being wrong shall be identified and controlled

The observations shall be recorded as per follows against each SOP

No The major system / component/ subsystem /SOP Probability of risk factor

which carries risk. (high ,medium or low)

1

2

3

4

5

6

7

3.2 Risk Assessment

Risk assessment involves assessing the effect of risk on the purity, identity, efficacy,

appearance, safety and yield of the product. Theoretically, following are the probabilities if

the risk is not controlled

1. The product may not comply with Compendial specifications

2. The product may not withstand the stability

3. The product may lose the identity

4. The colour and appearance of the product may change

5. The product may develop undue impurities

6. The product may develop undue bacterial/viral load

7. The product may not comply with TSE/BSE

8. The product may fail in sterility

Prepared By Checked By Approved By Released By

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No Effective Date Review Date Total Page

Drafted by Approved by 7

Authorised by

9. The product may carry particulate matter

10. The product may fail in absorption/distribution as intended

11. The product may induce toxic reactions or undue side effects.

12. The product yield may be reduced

Page | 5

13. The product may fail to crystallize in required polymorphic form such as form1, form 2

14. The product may fail in enantiomeric purity

Risk Assessment Table

SOP No: SOP Clause No which Risk Impact (Critical, Subcritical,

Title: carries Risk medium , Low)

Version No

Effective Date:

Review date:

Identify any other subsystem or subsequent processing steps which may get affected by the

risk.

Prepared By Checked By Approved By Released By

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No Effective Date Review Date Total Page

Drafted by Approved by 7

Authorised by

4. Risk Mitigation

Ideally, the risk mitigation and prevention shall be done till the risk is minimized to zero level.

It shall be noted that the risk mitigation is not a onetime process. The new risks are born by

Page | 6 changes at site, introduction of new products and updating of the regulation.

Following protocol may be followed for risk prevention/mitigation

Mitigation Plan Description Action Taken

1. Describe what updating will

be required in the process to

minimize the risk

2. Describe the plan/in process

tests to monitor the risk

3. Review the few batches for

efficacy of risk control

measures

4. Provide the frequency or exact

dates for reviewing the risk

control activities

5. Provide Risk Closing

Rationale

Conclusion:

The pharmaceutical Manufacturing requires suitable risk management plan over the life

history of the products manufactured at the site. The plans shall be live to accommodate

changes in regulations, updating in product standards and the changes at the site.

Prepared By Checked By Approved By Released By

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No Effective Date Review Date Total Page

Drafted by Approved by 7

Authorised by

References

Structured Approach to Benefit-Risk Assessment in Drug

www.fda.gov/downloads/ForIndustry/UserFees/.../UCM329758.pdf

GMP: Risk analysis in pharmaceutical production

Page | 7 apps.who.int/prequal/.../pq.../1-4d_Qualiy-Risk-Management.ppt

Who guideline on quality risk management - World Health Organization

www.who.int/.../QualityRiskManagement-QAS10-376_18082010.pd

Quality risk management - European Medicines Agency

www.ema.europa.eu/docs/en_GB/document.../WC500002873.pdf

Notes:

The present protocol is a basic version. The same may be customized as per specific

requirements. The readers are invited to post their queries on risk management at

guptarmg1952@gmail.com

Mr. R.M. Gupta (M. Pharm.) is a free lancer consultant for US DMF, COS, ANDA, ACTD,

CTD, eCTD and other regulatory submissions. guptarmg1952@gmail.com

He is associated with Perfect Pharmaceutical Consultants Pvt. Limited and Global Institute of

Regulatory affairs (Pune, India). He has filed a very large number of US DMF, CEP,

APIDMF, ANDA and CTD Dossiers in various countries over the globe. He is constantly

contributing to Pharma Profession by authoring useful guidelines and review articles on

regulatory issues.

Prepared By Checked By Approved By Released By

Você também pode gostar

- Risk Assessment Template 1.2 PDFDocumento5 páginasRisk Assessment Template 1.2 PDFGanesh KashinathAinda não há avaliações

- Risk Assessment Template 1.2Documento5 páginasRisk Assessment Template 1.2Jorge Humberto Herrera100% (1)

- PFI SOP For Actions To Address Risks & OpportunitiesDocumento11 páginasPFI SOP For Actions To Address Risks & OpportunitiesRugadya PaulAinda não há avaliações

- Financial Uncertainty, Legal Liabilities, Strategic Management Errors, Accidents and Natural DisastersDocumento10 páginasFinancial Uncertainty, Legal Liabilities, Strategic Management Errors, Accidents and Natural Disastersrajan mishraAinda não há avaliações

- Rakhmat Budi Yuwono Quality Risk Management An Implementation in IndustriDocumento38 páginasRakhmat Budi Yuwono Quality Risk Management An Implementation in IndustriAbdul NasirAinda não há avaliações

- Antonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Documento52 páginasAntonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Kim Cyrelle Samson Umbalin100% (2)

- ##-QSP-05 Risk Assessment and ManagementDocumento11 páginas##-QSP-05 Risk Assessment and Managementrajiv100% (1)

- Compliance TestingDocumento17 páginasCompliance TestingRBR SISONAinda não há avaliações

- Template ProcedureDocumento4 páginasTemplate ProcedureRobbyTeresaAinda não há avaliações

- Session5 Amer Gamal PresDocumento83 páginasSession5 Amer Gamal Presreymon taroAinda não há avaliações

- TOPIC 3e - Risk and MaterialityDocumento33 páginasTOPIC 3e - Risk and MaterialityLANGITBIRUAinda não há avaliações

- Risk Management Requirement Under ISO 17025-2017: November 2019Documento14 páginasRisk Management Requirement Under ISO 17025-2017: November 2019Royal BimhahAinda não há avaliações

- RA 20mar2022 vAHDocumento8 páginasRA 20mar2022 vAHAbdellatef HossamAinda não há avaliações

- UntitledDocumento9 páginasUntitledJinna SmaAinda não há avaliações

- Cleaning Validation & Regulatory Compliance: An Introduction & OverviewDocumento8 páginasCleaning Validation & Regulatory Compliance: An Introduction & Overviewsasirkumar1Ainda não há avaliações

- Risk GuidebookDocumento16 páginasRisk GuidebookNEOQUALITYAinda não há avaliações

- ISO 13485:2016 Compliance: Embedding Risk in Your Quality Management ProcessesDocumento48 páginasISO 13485:2016 Compliance: Embedding Risk in Your Quality Management ProcessesHilario AlinabonAinda não há avaliações

- Understanding QA System in Pharma Industry - 23092020Documento31 páginasUnderstanding QA System in Pharma Industry - 23092020Anggia Bia Amanda100% (1)

- QMS-135 Quality Risk Management Techniques SampleDocumento14 páginasQMS-135 Quality Risk Management Techniques Samplefaisal abbas100% (1)

- Risk AssessmentDocumento13 páginasRisk AssessmentYJ OoiAinda não há avaliações

- Audit Methodology FS 10 PDFDocumento114 páginasAudit Methodology FS 10 PDFKelvin Lim Wei Liang0% (1)

- 15JF Brady PDFDocumento8 páginas15JF Brady PDFitung23Ainda não há avaliações

- Rely On Laboratory Recognition by Conformity Assessment BodiesDocumento4 páginasRely On Laboratory Recognition by Conformity Assessment BodiesANU M AAinda não há avaliações

- Session 1 2 3Documento65 páginasSession 1 2 3rajesh shekarAinda não há avaliações

- Msa - QSP - 01 - Risk Assessment and Mitigation PlanDocumento11 páginasMsa - QSP - 01 - Risk Assessment and Mitigation PlanVasudevan GovindarajAinda não há avaliações

- T09-MOTIVA Sample Continual Improvement ProcedureDocumento9 páginasT09-MOTIVA Sample Continual Improvement ProcedurefarheenAinda não há avaliações

- Quality Risk Management PlanDocumento9 páginasQuality Risk Management Plansakib445Ainda não há avaliações

- Draftauditreporttemplate Revision 2015forreviewDocumento11 páginasDraftauditreporttemplate Revision 2015forreviewalias brownAinda não há avaliações

- Risk Management PlanDocumento13 páginasRisk Management PlanConrado Juisan CrisostomoAinda não há avaliações

- Pertemuan 7Documento19 páginasPertemuan 7Melia FaniAinda não há avaliações

- Preview Web VersionDocumento6 páginasPreview Web VersionOsman AitaAinda não há avaliações

- Draftauditreporttemplate Revision 2015forreviewDocumento11 páginasDraftauditreporttemplate Revision 2015forreviewalias brownAinda não há avaliações

- Cordero - Jorge - Pres - Learn How To Perform A Risk-Based Impact AssessmentDocumento25 páginasCordero - Jorge - Pres - Learn How To Perform A Risk-Based Impact AssessmentwahAinda não há avaliações

- Naturecare Products: Risk Management PlanDocumento7 páginasNaturecare Products: Risk Management PlanIkramAinda não há avaliações

- BSBOPS504 Assessment Task 1Documento4 páginasBSBOPS504 Assessment Task 1tuners baluarte100% (1)

- Manejo de Desviaciones OMSDocumento28 páginasManejo de Desviaciones OMSBrian SerranoAinda não há avaliações

- IT Audit FormatDocumento15 páginasIT Audit FormatAnonymous 9d1jFvAinda não há avaliações

- Kitcb D01.nhóm 7Documento44 páginasKitcb D01.nhóm 7Mạnh hưng LêAinda não há avaliações

- Risk Assesment Sample ProtocolDocumento20 páginasRisk Assesment Sample ProtocolPraveenAinda não há avaliações

- Operational Key Risk IndicatorsDocumento24 páginasOperational Key Risk IndicatorssjvrAinda não há avaliações

- Quality Risk Management Plan: ApprovalsDocumento8 páginasQuality Risk Management Plan: Approvalsnsk79in@gmail.comAinda não há avaliações

- Risk Based Audit - ISA 315 Risk AssessmentDocumento21 páginasRisk Based Audit - ISA 315 Risk AssessmentFachrurroziAinda não há avaliações

- 74937bos60526-Cp4 UnlockedDocumento72 páginas74937bos60526-Cp4 Unlockedhrudaya boysAinda não há avaliações

- Plantilla para Procedimientos - Risk ManagementDocumento9 páginasPlantilla para Procedimientos - Risk ManagementMacky321Ainda não há avaliações

- Risk Based ThinkingDocumento31 páginasRisk Based ThinkingMahender Kumar100% (2)

- ISO/IEC 17025:2017 Risk Analysis: Sumaira Nosheen Scientific Officer/Asst. Quality Manager Pcsir-LlcDocumento40 páginasISO/IEC 17025:2017 Risk Analysis: Sumaira Nosheen Scientific Officer/Asst. Quality Manager Pcsir-LlcKhalid JavedAinda não há avaliações

- Isolation of Errors On Materials - A Comprehensive AnalysisDocumento13 páginasIsolation of Errors On Materials - A Comprehensive AnalysisprinceyahweAinda não há avaliações

- BSBMGT517 SD Operational Plan - TemplateDocumento7 páginasBSBMGT517 SD Operational Plan - TemplateMousumi Mridha0% (1)

- GTAG 3 Continuous Auditing Implications For Assurance Monitoring and Risk AssessmentDocumento41 páginasGTAG 3 Continuous Auditing Implications For Assurance Monitoring and Risk AssessmentGurcan KarayelAinda não há avaliações

- 005 Procedure For Risk ManagementDocumento10 páginas005 Procedure For Risk ManagementRizwan KaziAinda não há avaliações

- Annex 3 Auditing Guide Audit Report TemplateDocumento11 páginasAnnex 3 Auditing Guide Audit Report TemplateAlejandroAinda não há avaliações

- Risk Based Auditing Ebook PDFDocumento11 páginasRisk Based Auditing Ebook PDFAsepWahyuPrabowoAinda não há avaliações

- RiskDocumento14 páginasRiskAHMAD ALIAinda não há avaliações

- Risk & Opportunity ManagementDocumento20 páginasRisk & Opportunity ManagementIshara Praneeth Wijesuriya100% (1)

- HSMS Hazard Identification & Risk Assessment ProcedureDocumento5 páginasHSMS Hazard Identification & Risk Assessment ProcedureOsama SharafAinda não há avaliações

- Standard Procedure - Risk and Opportunities ManagementDocumento25 páginasStandard Procedure - Risk and Opportunities ManagementShahzad Khan100% (1)

- Environment, Health, Safety and Sustainability Application SolutionDocumento4 páginasEnvironment, Health, Safety and Sustainability Application SolutionCompliance QuestAinda não há avaliações

- Internal Controls: Guidance for Private, Government, and Nonprofit EntitiesNo EverandInternal Controls: Guidance for Private, Government, and Nonprofit EntitiesAinda não há avaliações

- Risk Management Applications in Pharmaceutical and Biopharmaceutical ManufacturingNo EverandRisk Management Applications in Pharmaceutical and Biopharmaceutical ManufacturingHamid MollahAinda não há avaliações

- Guidelines for Hazard Evaluation ProceduresNo EverandGuidelines for Hazard Evaluation ProceduresNota: 5 de 5 estrelas5/5 (4)

- Protocol 1 Cease Itm Are 2Documento6 páginasProtocol 1 Cease Itm Are 2ziadddAinda não há avaliações

- My uPLODocumento10 páginasMy uPLOziadddAinda não há avaliações

- B) - For Rinse Sampling:: Through Whatman No. 2 Filter PaperDocumento6 páginasB) - For Rinse Sampling:: Through Whatman No. 2 Filter PaperziadddAinda não há avaliações

- Sampling Procedures & Sampling Plan: I. Sampling Procedure: A) - For Swab SamplingDocumento7 páginasSampling Procedures & Sampling Plan: I. Sampling Procedure: A) - For Swab SamplingziadddAinda não há avaliações

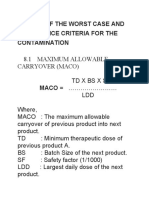

- Selection of The Worst Case and Acceptance Criteria For The ContaminationDocumento11 páginasSelection of The Worst Case and Acceptance Criteria For The ContaminationziadddAinda não há avaliações

- Acceptance Criteria: A. For Visual Inspection CriteriaDocumento9 páginasAcceptance Criteria: A. For Visual Inspection CriteriaziadddAinda não há avaliações

- Cream HvacDocumento3 páginasCream HvacziadddAinda não há avaliações

- Protocol 1 Cease Itm Are 4Documento4 páginasProtocol 1 Cease Itm Are 4ziadddAinda não há avaliações

- Protocol 1 Cease Itm Are 1Documento7 páginasProtocol 1 Cease Itm Are 1ziadddAinda não há avaliações

- List Cap IletDocumento4 páginasList Cap IletziadddAinda não há avaliações

- Azithromycin 250mg TabletDocumento12 páginasAzithromycin 250mg TabletziadddAinda não há avaliações

- Hold Time 1Documento11 páginasHold Time 1ziadddAinda não há avaliações

- Protocol 1 Cease Itm AreDocumento3 páginasProtocol 1 Cease Itm AreziadddAinda não há avaliações

- Equipment List QCDocumento1 páginaEquipment List QCziadddAinda não há avaliações

- Observational Cam DiSP July 02Documento29 páginasObservational Cam DiSP July 02ziadddAinda não há avaliações

- Aseptic Process Validation (By Media Fill Trial)Documento19 páginasAseptic Process Validation (By Media Fill Trial)ziaddd100% (2)

- Reference Regulatory AuthoritiesDocumento2 páginasReference Regulatory AuthoritiesziadddAinda não há avaliações

- PS W 01 2011 Questionnaire For AssessmentDocumento13 páginasPS W 01 2011 Questionnaire For AssessmentsfgvsdfrbhAinda não há avaliações

- CleanRoom TechnologyDocumento109 páginasCleanRoom TechnologysarathsreekumarAinda não há avaliações

- Integrity SOPs For VeinDocumento3 páginasIntegrity SOPs For VeinziadddAinda não há avaliações

- 62 Vol. 5 Issue 5 May 2014IJPSR RA 3367 Paper 62Documento10 páginas62 Vol. 5 Issue 5 May 2014IJPSR RA 3367 Paper 62ziadddAinda não há avaliações

- 37163893-1c1d-44b9-ac25-3c467ed44cbfDocumento10 páginas37163893-1c1d-44b9-ac25-3c467ed44cbfziadddAinda não há avaliações

- Cleanroom Users Manual: Georgia Tech Microelectronics Research CenterDocumento43 páginasCleanroom Users Manual: Georgia Tech Microelectronics Research Centeromayoral100% (1)

- SopsDocumento35 páginasSopsziaddd86% (14)

- Mycophenolate Mofetil: A New Therapeutic Option in DermatologyDocumento7 páginasMycophenolate Mofetil: A New Therapeutic Option in DermatologyziadddAinda não há avaliações

- Mycophenolate Mofetil: A New Therapeutic Option in DermatologyDocumento7 páginasMycophenolate Mofetil: A New Therapeutic Option in DermatologyziadddAinda não há avaliações

- 124 Vol. 5 Issue 8 IJPSR 2014 RA 3721 Paper 14Documento4 páginas124 Vol. 5 Issue 8 IJPSR 2014 RA 3721 Paper 14ziadddAinda não há avaliações

- 4파키스탄 Korea (Pakintan)Documento45 páginas4파키스탄 Korea (Pakintan)ziadddAinda não há avaliações

- Good StorageDocumento20 páginasGood Storageziaddd100% (1)

- ProAim InstructionsDocumento1 páginaProAim Instructionsfeli24arias06Ainda não há avaliações

- Carelink Connect: User GuideDocumento41 páginasCarelink Connect: User GuideMiha SoicaAinda não há avaliações

- Eclipsecon MQTT Dashboard SessionDocumento82 páginasEclipsecon MQTT Dashboard Sessionoscar.diciomma8446Ainda não há avaliações

- Elb v2 ApiDocumento180 páginasElb v2 ApikhalandharAinda não há avaliações

- WVU's Response Letter To Campbell Regarding HugginsDocumento4 páginasWVU's Response Letter To Campbell Regarding HugginsJosh JarnaginAinda não há avaliações

- Sem 4 - Minor 2Documento6 páginasSem 4 - Minor 2Shashank Mani TripathiAinda não há avaliações

- Financial StatementDocumento8 páginasFinancial StatementDarwin Dionisio ClementeAinda não há avaliações

- VoIP Testing With TEMS InvestigationDocumento20 páginasVoIP Testing With TEMS Investigationquantum3510Ainda não há avaliações

- Rideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardDocumento45 páginasRideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardpaolaAinda não há avaliações

- Ambient Lighting Vol 6 CompressedDocumento156 páginasAmbient Lighting Vol 6 Compressedadvait_etcAinda não há avaliações

- Optimization of Crude Oil DistillationDocumento8 páginasOptimization of Crude Oil DistillationJar RSAinda não há avaliações

- Business Plan GROUP 10Documento35 páginasBusiness Plan GROUP 10Sofia GarciaAinda não há avaliações

- Vylto Seed DeckDocumento17 páginasVylto Seed DeckBear MatthewsAinda não há avaliações

- SKF LGMT-2 Data SheetDocumento2 páginasSKF LGMT-2 Data SheetRahul SharmaAinda não há avaliações

- Catalogue of The Herbert Allen Collection of English PorcelainDocumento298 páginasCatalogue of The Herbert Allen Collection of English PorcelainPuiu Vasile ChiojdoiuAinda não há avaliações

- Oops in PythonDocumento64 páginasOops in PythonSyed SalmanAinda não há avaliações

- Emco - Unimat 3 - Unimat 4 LathesDocumento23 páginasEmco - Unimat 3 - Unimat 4 LathesEnrique LueraAinda não há avaliações

- Nasoya FoodsDocumento2 páginasNasoya Foodsanamta100% (1)

- E OfficeDocumento3 páginasE Officeஊக்கமது கைவிடேல்Ainda não há avaliações

- Criminal Law I Green Notes PDFDocumento105 páginasCriminal Law I Green Notes PDFNewCovenantChurchAinda não há avaliações

- CE5215-Theory and Applications of Cement CompositesDocumento10 páginasCE5215-Theory and Applications of Cement CompositesSivaramakrishnaNalluriAinda não há avaliações

- Frito Lay AssignmentDocumento14 páginasFrito Lay AssignmentSamarth Anand100% (1)

- Statable 1Documento350 páginasStatable 1Shelly SantiagoAinda não há avaliações

- Risk and Uncertainty in Estimating and TenderingDocumento16 páginasRisk and Uncertainty in Estimating and TenderingHaneefa ChAinda não há avaliações

- Strength and Microscale Properties of Bamboo FiberDocumento14 páginasStrength and Microscale Properties of Bamboo FiberDm EerzaAinda não há avaliações

- Integrated Building Managemnt SystemDocumento8 páginasIntegrated Building Managemnt SystemRitikaAinda não há avaliações

- On Applied EthicsDocumento34 páginasOn Applied Ethicsamanpatel78667% (3)

- Questionnaire: ON Measures For Employee Welfare in HCL InfosystemsDocumento3 páginasQuestionnaire: ON Measures For Employee Welfare in HCL Infosystemsseelam manoj sai kumarAinda não há avaliações

- Math 1 6Documento45 páginasMath 1 6Dhamar Hanania Ashari100% (1)

- Flyer Manuale - CON WATERMARK PAGINE SINGOLEDocumento6 páginasFlyer Manuale - CON WATERMARK PAGINE SINGOLEjscmtAinda não há avaliações