Escolar Documentos

Profissional Documentos

Cultura Documentos

Solar Powered High Efficient Dual Buck Converter For Battery Charging

Enviado por

akp25iTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Solar Powered High Efficient Dual Buck Converter For Battery Charging

Enviado por

akp25iDireitos autorais:

Formatos disponíveis

Solar Powered High Efficient Dual Buck

Converter for Battery Charging

Esther Glory. S1, Dhivya. P.S2 and Sivaprakasam. T3

PG Scholar, Department of Electrical and Electronics Engineering, Sri Shakthi Instititute of Engineering and

Technology, Coimbatore, India1,2

Assistant Professor, Department of Electrical and Electronics Engineering, Sri Shakthi Instititute of ngineering and

Technology, Coimbatore, India3

Abstract: Photovoltaic power generation system implements an effective utilization of solar energy, but has very low

conversion efficiency. The major problem in solar photo-voltaic (SPV) system is to maintain the DC output power from

the panel as constant. Irradiation and temperature are the two factors, which will change the output power of the panel.

Maximum power point tracking (MPPT) is used in photovoltaic (PV) systems to regulate the photovoltaic array output.

MPPT controller typically consists of DC-DC converter with some duty cycle finding controller to maintain the output

power as constant. The power can be stored in battery and then utilized for the powering the DC and AC load through

inverter. In this project the dual buck converter has been proposed to track the maximum operating point of the Solar

PV. The switching losses have been reduced and converter efficiency is improved by using dual buck converter. The

modified perturb & observe (MPO) algorithm is used to provide suitable duty cycle to the dual buck converter. The

dual buck converter will provide the battery bank a large energy capacity, to run at 9V, and a large output current to

handle high power loads. Buck converters are used in controlling the charging current supplied to the battery based on

the power obtained from the PV system. The applications of this converter are hybrid electric vehicles, renewable

energy conversion system.

Keywords: Photovoltaic (PV) system, dual buck converter, MPPT, Battery Charger, MATLAB.

1. INTRODUCTION

The popular among the renewable energy sources is the used. a dual buck converter is used for efficient battery

solar energy. Solar energy is utilized by standalone charging and to control the power flow from the PV panel

photovoltaic PV system. Photovoltaic panels convert the to battery and load. It requires MPPT control algorithm to

solar energy into electrical energy. PV system has measure the power of the PV panel. Perturb and observe

nonlinear internal characteristics. Irradiation and algorithm (P & O) is used for MPP tracking. The complete

temperature in the solar PV system will affect the voltage system is simulated using MATLAB-SIMULINK and the

and power characteristics. As the cost of the PV panel is results are presented in this paper.

high maximum power point tracking (MPPT) is needed to

track maximum output power. DC to DC converter is 2. OVERVIEW OF EXCISTING SYSTEM

interfaced with the PV panel and the battery. Lead acid To increase the maximum power output from the solar

battery is mostly used because of its features such as wide panel MPP tracking systems are used. Even though the

operating temperature range, low self-discharge, long temperature, irradiation and the load characteristics varies

service life and maintenance free. The installation cost of it helps in maintain the output of the solar PV panel

the battery is low compared to PV panel. But the lifetime constant. For high efficiency output from the PV panel

cost of the battery is high compare to the PV installation buck converters are used for DC-DC power

because of its limited service time. Battery life time is transmission.[2]. In stand alone PV systems buck

reduced if there is low PV energy availability for longer converters are effective in dc-dc step down operation and

period or improper charging and discharging. The battery for battery storing operations. [3]. For battery charging

charging needs control for achieving high State of Charge application step down converters gives high efficiency.

(SOC) and longer battery life. For long battery life proper tracking solar power from PV panel many MPPT

battery charging is required. In standalone PV system the techniques are available, perturb and observe, incremental

main function of battery charging controller is to full conductance algorithm etc. among all the control

charge the battery without over charging, preventing algorithms the P&O algorithm is widely used and more

reverse current flow at night and deep discharge under effective with simple control algorithm. The insolation and

load conditions. temperature problems can be overcome by using P&O,

In this proposed system, the PV model, battery model and this is effective, flexible and earliest control algorithm.[7]

the battery charging system designed with buck converter [8] [9] [10]. Insolation (short for incident or incoming

is implemented. A popular single diode model of PV is solar radiation) is a measure of solar radiation energy

Copyright to IJIREEICE www.ijireeice.com 448

received on a given surface area and recorded during a The buck regulator circuit is a switching regulator. It uses

given time. Insolation expressed in watts per square meter an inductor and a capacitor as energy storage elements so

(W/m2). In photovoltaic a proportion of radiation that energy can be transferred from the input to the output

reflected or absorbed depends on the object's reflectivity. in discrete packets. The advantage of using switching

The insolation into a surface is largest when the surface regulators is that they offer higher efficiency than linear

directly faces the Sun. As the angle increases between the regulators. The one disadvantage is noise or ripple, the

direction at a right angle to the surface and the direction of ripple will need to be minimized through careful

the rays of sunlight, the insolation is reduced in proportion component selection. A requirement of the design is to

to the cosine of the angle.[3] The buck converter performs have high current slew rate (up to 930 A/μs) to increase

buck operation where voltage is stepped down, this can switching speed of microprocessor from one state to the

used for low power applications and battery charging. So a other but this causes voltage drop spikes at the processor

dual buck converter is capable of producing high buck power supply. To achieve high current slew rate the

operation useful in many systems.[1] inductor Lo should be as small as possible. This in turn

while achieving faster transient response will cause the

3. PROPOSED SYSTEM output voltage ripple to increase. To reduce output voltage

The power output of PV module varies continuously with ripple, the switching frequency should be increased but this

the variation of irradiation and temperature. The maximum lowers efficiency. This means that the selection of the

power point tracking (MPPT) algorithm is used for switching devices will be an important issue. The output

extracting the maximum power (Pm) from the solar PV voltage ripple can also be reduced by increasing the output

module and transferring that power to the load. A DC-DC capacitance, this means a large capacitor in practical

converter (Step down), serves the purpose of transferring design.

maximum power from the PV module to the load and acts

as an interface between the load and the module. the duty 1

cycle is changed by the PWM control signal, the load Total period =

impedance of the source varies and matches the point of f

the peak power of the source so as to transfer the maximum The circuit losses are associated with

power. 1. MOSFET ON time voltage drop

2. MOSFET switching losses

3.1 MPPT Algorithm

3. Diode voltage drop

Perturb and Observe algorithm is used to track maximum 4. Inductor effective resistance

power form the solar panel using MPPT. Perturb and

observe algorithm has a simple feedback structure and

requires less measured parameters. It operates by The average output voltage is given by

periodically perturbing (i.e. incrementing or decreasing) the

array terminal voltage and comparing the PV output power D Vo ton (1)

with that of the previous perturbation cycle. If the Vi T

perturbation leads to an increase (decrease) in array power,

the subsequent perturbation is made in the same (opposite) When the MOSFET is ON, current builds up in the

direction. In rapidly changing atmospheric conditions the inductor increasing its stored energy. When the MOSFET

peak power tracker continuously tracks maximum power is OFF the diode becomes forward bias and some of the

with considerable amount of time. stored energy is transferred to the load.

I

3.2 Buck Converter

Vin Vo L (2)

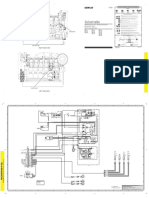

The most common power converter topology is the buck DT

power converter also called as step down power converter

is shown in fig1. Power supply designers choose the buck I 0.2Io (3)

power converter because the output voltage is always less

than the input voltage in the same polarity and is not The output current for a buck power converter is

isolated from the input. continuous because the output current is supplied by the

MOSFET

output inductor/capacitor combination; the output capacitor

L never supplies the entire load current for continuous

inductor current mode operationand is given by the equ (4).

diL I

Vi L Vo L Vo (4)

R dt DT

Vd D C

The input current for a buck power converter is

⁺ c

discontinuous due to the power switch, the current pulses

from 0 to Io every switching cycle and is given by equ(5).

Fig 1: dc-dc buck converter

⁻

Copyright to IJIREEICE www.ijireeice.com 449

diL I command is shifted to a higher level than the MPPT

0 Vo L Vo L (5) voltage. And finally, the generated PV power will

dt (1 D)T balance the load and battery charging.

Capacitor valur is given by 4.1 Dual Buck Converter

2 Dual buck converter is same as buck

Vo T

C (1 D) (6) converter, in dual buck 2 buck converters are connected in

Vo 8L parallel with each other. Both the converters are operated

simultaneously based on the input power availability from

Current Ripple ΔI the PV panel. The buck converters are operated in such a

Vi D (1 D) way that constant output power is supplied to the battery

I (7)

FL for charging. the effectiveness of the proposed controller

has been highlighted by checking the charging and

Voltage Ripple ΔV discharging currents of the battery. The circuit diagram of

When the switch is off during (1-D) T the current flowing dual buck converter is shown in figure 2.

in the capacitor is Ic-Io. We have now assumed that the

output current has no ripple so that the ripple voltage on The input voltage to battery may be will be maintained

the capacitor is entirely due to the inductor ripple current. constant and the input current supplied to battery may be

varying based on the power generated from the solar panel.

dQ I T Vi D (1 D) The dual buck converter is connected to the battery through

v a ON OFF switch which is turned ON when the power is

C 2 2 2 Co 8 L Co f f available from the solar panel and it is turned OFF when no

(8) generation from the PV panel.

4. PROPOSED SYSTEM

When Sunlight falls on the solar panel it cause generation

of electricity via the photoelectric effect. MPPT algorithm

is used to track maximum output power from the solar

panel. This unregulated power will feed into the charge

controller. The charge controller will measure the voltage

and current of both the solar panel and battery bank. Based

on the power availability from the solar panel the boost

converter switches are triggered at a desired firing angle

given by the controller. The MPPT controller monitors the

battery charge level and PV panel output, the output

voltage supplied to the battery is maintained constant to 9v

by the MPPT controller. Fig 2: Dual Buck Converter

The voltage is generated by combining both the MPPT

control and the Battery charging loop. The available PV Operation of a dual buck converter is same as buck

power is greater than the load power with which the converter in this when Q1 is conducting Q2 will be in off

battery gets charged. If the available maximum PV condition and when Q2 is on Q1 will be in off condition

power is less than the load power, the needed power will when high input power is supplied to the converter. Both

be supplied by the battery. But the charging current is still in positive and negative half cycle the conduction takes

less than the present value .At that instant the signal place. When low input is supplied to the dual buck

generated by the current controller will go positive and converter any one of the converter conducts and the other

limited to be zero. It results that the voltage command is will be turned off.

determined completely by the MPPT controller. If the

available peak power of the PV panel is greater than he The dual buck converter performs the step down operation

battery charging and load requirement, the battery for effective battery charging with the power generated

current will reach its command controller will go negative from the PV panel. A switch between the dual buck

which will add to the voltage generated by the MPPT converter and the battery helps in controlling the charging

controller. Consequently, the PV panel will discard the and the switch connected between the battery and the load

MPPT because the voltage command is shifted to a controls the power supplied to the load from the battery, it

higher level than the MPPT voltage. And finally, the also helps the battery from draining completely so that the

generated PV power will balance the load and battery life of the battery can be increased. By using dual buck

charging requirements. The signal generated by the converter and the MPPT controller effective battery

controller will go negative which will add to the voltage charging, long battery life and proper utilization of the

generated by the MPPT controller. Consequently, the PV power generated.

panel will discard the MPPT because the voltage

Copyright to IJIREEICE www.ijireeice.com 450

5. SIMULATION RESULT AND DISCUSSION

Table 1 – Design Parameters For Dual Buck Converter

Simulation is done using MATLAB/Simulink the entire

system is simulated. Here the maximum output power Dual buck converter

from solar PV is obtained by using P&O algorithm. Based S.No Parameter Values unit

the power generated from the PV panel the buck 1 Capacitors C1,C2 200 pF

converters are operated accordingly.

2 Inductor L1 145.83 µH

The simulink block diagram of the block parameters are 3 Inductor L2 20 µH

shown in Figure 3 below It provides the design and

simulations of the entire system, it discusses simulation of 4 Battery 9 v

the photovoltaic array, coding of the MPPT algorithm

Simulation of the dual buck converter

Figure 5: Output Voltage Current from PV Panel

Fig 3: Simulink model

The simulation model in figure 3 show the overall system,

it consists of the pv panel, dual buck converter, battery

bank, switches to control the power supplied to the battery

charging and the load. The power electronic switches are

chosen according to their maximum current and voltage Figure 6: Gate Pulse to Buck Converter Switch

they have to withstand The maximum power from the pv

panel is tracked using perturb and observe MPPT

algorithm.

Figure 4: Solar PV Module Figure 7: Voltage and Current Supplied to Battery

Copyright to IJIREEICE www.ijireeice.com 451

The input voltage to battery is maintained constant 9V and stand-alone applications,” Transactions On Industrial Electronics., vol.

55, no. 7, pp.2674–2683, July. 2008.

the input current supplied to battery is positive when

[4] Jae-Jung Yun, Hyung-Jin Choe, Young-Ho Hwang, Yong-Kyu

supplied to the battery. The current varies based on the Park, and Bongkoo Kang, Improvement of Power-Conversion Efficiency

power generation. And during discharging maximum of a DC–DC Boost Converter Using a Passive Snubber Circuit, IEEE

output current is obtained. Transactions On Industrial Electronics, VOL. 59, NO. 4, pp.1808-1841,

APRIL 2012.

.

[5] Liang Jia, Zhiyuan Hu, Yan-Fei Liu, and Paresh C. Sen, Predictable

Auxiliary Switching Strategy to Improve Unloading Transient Response

Performance or DC–DC Buck Converter, IEEE Transactions On

Industry Applications, VOL. 49, NO. 2, pp. 931-941, March/April 2013.

[6] F. Liu, S. Duan, F. Liu, and Y. Kang, “A variable step size INC

MPPT method for PV system,” IEEE Transactions On Industrial

Electronics., vol. 55, no. 7, pp. 2622–2628, July. 2008.

[7] Mohammed A. Elgendy, Bashar Zahawi, and David J. Atkin,

Assessment of Perturb and Observe MPPT Algorithm Implementation

Techniques for PV Pumping Applications IEEE Transactions On

Sustainable Energy, VOL. 3, NO. 1, pp.21-23, January 2012.

[8] Nicola Femia, Giovanni Petrone, Giovanni Spagnuolo, and

Massimo Vitelli, “Optimization of Perturb and Observe MaximumPower

Point Tracking Method”, IEEE Transactions On Industrial Electronics,

vol. 20, no. 4, pp 963-973, july2005.

[9] Trishan Esram, and Patrick L. Chapman, “Comparison of

Photovoltaic Array Maximum Power Point Tracking Techniques” IEEE

Transactions on energy conversion, vol. 22, no. 2, pp.439-447, June

Figure 8: Voltage And Current in Battery During charging 2007.

[10] Weidong Xiao, Nathan Ozog, and William G. Dunford, “Topology

6. CONCLUSION Study of Photovoltaic Interface for Maximum Power Point Tracking”

IEEE Transactions on industrial electronics, vol. 54, no. 3,pp.196-1704,

June 2007.

This paper presents a dual buck converter which provides [11] Xiaogao Xie, Chen Zhao, Lingwei Zheng, and Shirong Liu, An

the battery bank a large energy capacity, to run at 9V, and Improved Buck PFC Converter With High Power Factor, IEEE

a large output current to handle high power loads. The PV Transactions On Power Electronics, VOL. 28, NO. 5, pp. 2277-2284,

May 2013.

array is integrated with the load, the power conversion is [12] Ying-Chun Chuang, “High-Efficiency ZCS Buck Converter for

performed by the buck converter. The maximum power Rechargeable Batteries,” IEEE Transactions On Power Electronics, vol.

point tracking algorithm used is the perturb and observe 57, no. 7, pp.2463-2472, July 2010.

algorithm is coded in MATLAB, the amplitude of the

reference current which is used to control the switching of

buck converter .With the change in insolation the

amplitude of the reference current also changes.. The

algorithm would ensure maximum power point tracking

by controlling the MOSFET of the buck converters by

varying its duty cycle. The Simulink Model of the solar

array gives the output power and the output current. The

variation in solar insolation and the reference temperature

also gives a varying output power and output current.

Buck converters are used in controlling the charging

current supplied to the battery based on the power

obtained from the PV system. This proposed work can be

used in connecting directly to load or even connected to

appliances through inverter circuit. This will reduce the

pollution that results from burning of the fuels, The battery

life can be improved and constant power can be supplied

to the load.

REFERENCES

[1] Fellipe S. Garcia, José Antenor Pomilio, and Giorgio Spiazzi,

Modeling and Control Design of the Interleaved Double Dual Boost

Converter, IEEE Transactions On Industrial Electronics, Vol. 60, NO. 8,

pp. 3283-3290. August 2013.

[2] Eftichios Koutroulis, Kostas Kalaitzakis, and Nicholas C.

Voulgaris, Development of a Microcontroller-Based, Photovoltaic

Maximum Power Point Tracking Control System, IEEE Transactions On

Power Electronics, Vol. 16, No. 1, pp. 46-54, January 2001

[3] R. Gules, J. De Pellegrin Pacheco, H. L. Hey, and J. Rnhoff, “A

maximum power point tracking system with parallel connection for PV

Copyright to IJIREEICE www.ijireeice.com 452

Você também pode gostar

- SEPIC Converter Based Photovoltaic System With Particle Swarm Optimization MPPTDocumento6 páginasSEPIC Converter Based Photovoltaic System With Particle Swarm Optimization MPPTWARSE JournalsAinda não há avaliações

- Multiport DC-DC Converter For Power Management of Multiple Renewable Energy SourcesDocumento4 páginasMultiport DC-DC Converter For Power Management of Multiple Renewable Energy SourcesRasika PujareAinda não há avaliações

- Power Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesNo EverandPower Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesAinda não há avaliações

- Design of Photovoltaic System Using Buck-Boost Converter Based On MPPT With PID ControllerDocumento9 páginasDesign of Photovoltaic System Using Buck-Boost Converter Based On MPPT With PID ControllerL CHAinda não há avaliações

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Nota: 2.5 de 5 estrelas2.5/5 (3)

- A Seven Level Inverter Using A Solar Power Generation SystemDocumento7 páginasA Seven Level Inverter Using A Solar Power Generation Systemsasitharan33Ainda não há avaliações

- Design OF BUCK BOOST CONVERTERDocumento11 páginasDesign OF BUCK BOOST CONVERTERmithunprayagAinda não há avaliações

- Design and Implementation of Three Phase To Single Phase Solid State TransformerDocumento37 páginasDesign and Implementation of Three Phase To Single Phase Solid State TransformerUsha SreeAinda não há avaliações

- MPPT P&oDocumento7 páginasMPPT P&onoumsi briceAinda não há avaliações

- Design and Simulation of Solar PV SystemDocumento6 páginasDesign and Simulation of Solar PV SystemIndraneel ChapalaAinda não há avaliações

- Maximum Power Point Tracking of DC To DC Boost Converter Using Sliding Mode ControlDocumento6 páginasMaximum Power Point Tracking of DC To DC Boost Converter Using Sliding Mode ControlInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Paper 1Documento17 páginasPaper 1Shambhu SharanAinda não há avaliações

- Control of Grid Connected PV Array Using P&O MPPT AlgorithmDocumento7 páginasControl of Grid Connected PV Array Using P&O MPPT AlgorithmHương B DlightAinda não há avaliações

- M.tech ThesisDocumento59 páginasM.tech ThesisRama Krishna100% (1)

- Point Method The Photovoltaic System: Novel Maximum Power Tracking ForDocumento5 páginasPoint Method The Photovoltaic System: Novel Maximum Power Tracking Forramalakshmi_apsAinda não há avaliações

- A New Controller Scheme For Photovoltaics PowerDocumento10 páginasA New Controller Scheme For Photovoltaics PowerHakan PolatkanAinda não há avaliações

- Ijert Ijert: Implementation of Buck-Boost Converter For Remote Area Lighting SystemDocumento4 páginasIjert Ijert: Implementation of Buck-Boost Converter For Remote Area Lighting SystemSingam SridharAinda não há avaliações

- Solar Photovoltaic Power Conversion Using Modular Multilevel Converter PDFDocumento6 páginasSolar Photovoltaic Power Conversion Using Modular Multilevel Converter PDFMohan SriramAinda não há avaliações

- Design and Implementation of 12V/24V Closed Loop Boost Converter For Solar Powered LED Lighting SystemDocumento11 páginasDesign and Implementation of 12V/24V Closed Loop Boost Converter For Solar Powered LED Lighting Systemسعيد ابوسريعAinda não há avaliações

- Soft Switching Buck Converter For Battery Charging With MPPTDocumento7 páginasSoft Switching Buck Converter For Battery Charging With MPPTVenkanna BodigeAinda não há avaliações

- To Simulate, Design & Implementation of Maximum Power Harvesting of Solar Energy by Using DC-DC ConverterDocumento6 páginasTo Simulate, Design & Implementation of Maximum Power Harvesting of Solar Energy by Using DC-DC Convertershrawani rajputAinda não há avaliações

- MPPT Controller Based Solar Power Generation UsingDocumento9 páginasMPPT Controller Based Solar Power Generation UsingHarith HaikalAinda não há avaliações

- Photovoltaic Charge Controller Using MPPT AlgorithmDocumento4 páginasPhotovoltaic Charge Controller Using MPPT AlgorithmerpublicationAinda não há avaliações

- Maximum Power Point Tracking Controller For Photovoltaic System Using Sliding Mode ControlDocumento5 páginasMaximum Power Point Tracking Controller For Photovoltaic System Using Sliding Mode Controlt.benaissaAinda não há avaliações

- Enhancing Solar Photovoltaic System Efficiency A Comparative Analysis of Intelligent ANN PandO MPPT Controller Against Traditional AlgorithmsDocumento10 páginasEnhancing Solar Photovoltaic System Efficiency A Comparative Analysis of Intelligent ANN PandO MPPT Controller Against Traditional AlgorithmsEditor IJTSRDAinda não há avaliações

- Fig-II.1 (A) - Schematic Diagram of The PV SystemDocumento3 páginasFig-II.1 (A) - Schematic Diagram of The PV SystemAditi MishraAinda não há avaliações

- 14sepicconferencepaper PDFDocumento6 páginas14sepicconferencepaper PDFSherrinAinda não há avaliações

- An Interleaved Flyback Inverter For Grid Connected Photovoltaic SystemsDocumento7 páginasAn Interleaved Flyback Inverter For Grid Connected Photovoltaic SystemsBastianHerreraBugueñoAinda não há avaliações

- RP Report New Second One123Documento9 páginasRP Report New Second One123Electrio MurmuAinda não há avaliações

- Design and Implementation of Photo Voltaic System With Soft Switched Boost Converter Using Analog Fuzzy Based MPPTDocumento7 páginasDesign and Implementation of Photo Voltaic System With Soft Switched Boost Converter Using Analog Fuzzy Based MPPTskrtamilAinda não há avaliações

- Improved Single Stage Grid Connected Solar PV System Using Multilevel InverterDocumento6 páginasImproved Single Stage Grid Connected Solar PV System Using Multilevel InverterFaruq FaruqAinda não há avaliações

- Soft Switching Boost Converter With MPPT For Solar (1) 2233Documento29 páginasSoft Switching Boost Converter With MPPT For Solar (1) 2233satheesh_240Ainda não há avaliações

- Fuz MPPT PumpDocumento10 páginasFuz MPPT Pumpvintin4uAinda não há avaliações

- Zeta Converter For PV Applications Employing MPPTDocumento7 páginasZeta Converter For PV Applications Employing MPPTarattupuzhaAinda não há avaliações

- Solar PVDocumento8 páginasSolar PVmurthy237Ainda não há avaliações

- Design and Simulation of DC-DC Converter Used in Solar Charge ControllersDocumento4 páginasDesign and Simulation of DC-DC Converter Used in Solar Charge ControllersInternational Journal of Engineering Inventions (IJEI)Ainda não há avaliações

- An Isolated Series Resonant Converter For PV Application: Manalan108@gmailcomDocumento4 páginasAn Isolated Series Resonant Converter For PV Application: Manalan108@gmailcomRaja SajinAinda não há avaliações

- Solar PDFDocumento5 páginasSolar PDFjhony7373Ainda não há avaliações

- Abt 3747 PaperDocumento7 páginasAbt 3747 PaperhameeeeAinda não há avaliações

- Perturb and Observe Method MATLAB Simulink and Design of PV System Using Buck Boost ConverterDocumento5 páginasPerturb and Observe Method MATLAB Simulink and Design of PV System Using Buck Boost ConverterGss ChaitanyaAinda não há avaliações

- 2208EE006.ourside - GridsystemDocumento6 páginas2208EE006.ourside - GridsystemssAinda não há avaliações

- Simulation of A Solar MPPT Charger Using Cuk Converter For Standalone ApplicationDocumento6 páginasSimulation of A Solar MPPT Charger Using Cuk Converter For Standalone ApplicationcashnuiAinda não há avaliações

- Design and Implementation of A Low Cost MPPT Controller For Solar PV SystemDocumento6 páginasDesign and Implementation of A Low Cost MPPT Controller For Solar PV SystemAhmed ShoeebAinda não há avaliações

- Best Paper-4Documento20 páginasBest Paper-4padmavathiAinda não há avaliações

- Solar Powered Mobile Charger Using Buck Converter - PPTMDocumento14 páginasSolar Powered Mobile Charger Using Buck Converter - PPTMArvind RebelAinda não há avaliações

- High Voltage Gain Boost Converter Based On Three State Switching Cell For Solar Energy HarvestingDocumento5 páginasHigh Voltage Gain Boost Converter Based On Three State Switching Cell For Solar Energy HarvestingKarthik BossAinda não há avaliações

- Teardown: The Power Inverter - From Sunlight To Power Grid: Steve TaranovichDocumento14 páginasTeardown: The Power Inverter - From Sunlight To Power Grid: Steve TaranovichMinh PHAN THANHAinda não há avaliações

- RP Report New FourDocumento9 páginasRP Report New FourElectrio MurmuAinda não há avaliações

- Solar Powered Mobile Charger Using Buck ConverterDocumento4 páginasSolar Powered Mobile Charger Using Buck ConverterArvind RebelAinda não há avaliações

- Luo ConverterDocumento6 páginasLuo ConverterRagunathan NarayananAinda não há avaliações

- Regulated Output Voltage Double Switch Buck-Boost Converter For Photovoltaic Energy ApplicationDocumento11 páginasRegulated Output Voltage Double Switch Buck-Boost Converter For Photovoltaic Energy ApplicationEduardo Cairolli de NovaesAinda não há avaliações

- Design and Implementation of PV Fed Two Stage DC/DC Converter For Home ApplicationsDocumento6 páginasDesign and Implementation of PV Fed Two Stage DC/DC Converter For Home ApplicationsVishal KevatAinda não há avaliações

- Paper 02Documento4 páginasPaper 02Md ShafiullahAinda não há avaliações

- FinalDocumento53 páginasFinalKishore GvAinda não há avaliações

- Effect of Partial Shading in Grid Connected Solar PV System With FL ControllerDocumento10 páginasEffect of Partial Shading in Grid Connected Solar PV System With FL ControllerPtuan ThanhAinda não há avaliações

- Modelling of A Standalone Photovoltaic System With Charge Controller For Battery Energy Storage SystemDocumento10 páginasModelling of A Standalone Photovoltaic System With Charge Controller For Battery Energy Storage SystemHari KiranAinda não há avaliações

- IJRAR1ACP025Documento7 páginasIJRAR1ACP025Vignesh U PAinda não há avaliações

- SIM800C Hardware Design V1.02 PDFDocumento52 páginasSIM800C Hardware Design V1.02 PDFTuấnPhạmAinda não há avaliações

- 44-Pin Demo Board User S ManualDocumento18 páginas44-Pin Demo Board User S ManualjohanaceAinda não há avaliações

- Datasheet 2 N 3906Documento8 páginasDatasheet 2 N 3906Julian Alberto Chacon CaperaAinda não há avaliações

- Smartxs BRDocumento2 páginasSmartxs BRakp25iAinda não há avaliações

- Electrical Current Multiple ChoiceDocumento7 páginasElectrical Current Multiple ChoiceClaudio FacchineiAinda não há avaliações

- Light Rays and WavesDocumento33 páginasLight Rays and WavesElfrida Margaretha SitumeangAinda não há avaliações

- Practical Techniques For Designing Microstrip Filters On FR4Documento5 páginasPractical Techniques For Designing Microstrip Filters On FR4bayman66Ainda não há avaliações

- IS 8783 (Part-4-Sec.1) - 1995 - HR PVC Insulated - Winding Wires For Submersible MotorsDocumento10 páginasIS 8783 (Part-4-Sec.1) - 1995 - HR PVC Insulated - Winding Wires For Submersible Motorsshivam dwivediAinda não há avaliações

- Guia de Producto Rev615 - AbbDocumento60 páginasGuia de Producto Rev615 - Abbper47Ainda não há avaliações

- ADC Driver DesignDocumento32 páginasADC Driver Designchocobon_998078Ainda não há avaliações

- 1000 Electrical Maintenance Question and Answers PDFDocumento417 páginas1000 Electrical Maintenance Question and Answers PDFMikun SomAinda não há avaliações

- Experiment 3. Single Stage BJT Amplifiers: Names: 1. Buse YILBAŞ - 2376119 2. Elif CABRİ - 2374668 Section: 10Documento5 páginasExperiment 3. Single Stage BJT Amplifiers: Names: 1. Buse YILBAŞ - 2376119 2. Elif CABRİ - 2374668 Section: 10Buse YılbaşAinda não há avaliações

- NAD 2200 Service ManualDocumento12 páginasNAD 2200 Service ManualCameron001Ainda não há avaliações

- Presentation On Organic ChemistryDocumento44 páginasPresentation On Organic ChemistryKofi Frimpong-MansonAinda não há avaliações

- Chapter 4 Solutions: 4-1) LoadDocumento28 páginasChapter 4 Solutions: 4-1) Loadpaul kioiAinda não há avaliações

- Load Flow AnalysisDocumento79 páginasLoad Flow AnalysisKeshav ChanjalAinda não há avaliações

- HCDRX70 PDFDocumento113 páginasHCDRX70 PDFvyshyAinda não há avaliações

- SPM 2017 Paper 2Documento60 páginasSPM 2017 Paper 2Srikanth SagardevanAinda não há avaliações

- Comba RD-1932 DS 1-1-1Documento3 páginasComba RD-1932 DS 1-1-1Luis Alejandro LeonAinda não há avaliações

- CD Spectroscopy PPT FinalDocumento20 páginasCD Spectroscopy PPT FinalMukesh Yadav0% (1)

- ABB Electrical Installation Handbook 6th Edition2010Documento548 páginasABB Electrical Installation Handbook 6th Edition2010paratonerq100% (1)

- Et200sp Ai Energymeter 400vac ST Manual en-US en-USDocumento97 páginasEt200sp Ai Energymeter 400vac ST Manual en-US en-USHélio Dos SantosAinda não há avaliações

- KB6206 - Compatible Positive Voltage RegulatorsDocumento6 páginasKB6206 - Compatible Positive Voltage RegulatorsLangllyAinda não há avaliações

- A8 - Service Manual DetalladoDocumento46 páginasA8 - Service Manual DetalladoDiego MullerAinda não há avaliações

- Plano Grupo ElectrogenoDocumento2 páginasPlano Grupo Electrogenoluis alberto rodriguezAinda não há avaliações

- iNUKE NU6000DSP: Service ManualDocumento34 páginasiNUKE NU6000DSP: Service ManualMarcos E. Cuevas100% (1)

- RWS-375!6!433.92MHz ASK RF Receiver Module Data SheetDocumento4 páginasRWS-375!6!433.92MHz ASK RF Receiver Module Data SheetNivaldodeArrudaAinda não há avaliações

- Plastic Rod ExtensometerDocumento2 páginasPlastic Rod ExtensometerAnonymous qTP5oq7gAinda não há avaliações

- CMOS InverterDocumento16 páginasCMOS Invertersreekanthreddy peramAinda não há avaliações

- AlkatreszDocumento2 páginasAlkatreszgia maxniashviliAinda não há avaliações

- 1DPHYS - QUIZ1 (Electrostatics)Documento2 páginas1DPHYS - QUIZ1 (Electrostatics)Krishnaveni Subramani SAinda não há avaliações

- Instruction Manual: Installation - Operation - MaintenanceDocumento43 páginasInstruction Manual: Installation - Operation - Maintenancesujon_shinpowerAinda não há avaliações

- 13 - IRIS - NV - Error CodeDocumento53 páginas13 - IRIS - NV - Error Codesteve niereAinda não há avaliações

- Electrical: ElectronicDocumento250 páginasElectrical: ElectronicSaavedra LopezAinda não há avaliações

- Cyber War: The Next Threat to National Security and What to Do About ItNo EverandCyber War: The Next Threat to National Security and What to Do About ItNota: 3.5 de 5 estrelas3.5/5 (66)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityNo EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityNota: 5 de 5 estrelas5/5 (1)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveAinda não há avaliações

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldNo EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldNota: 4.5 de 5 estrelas4.5/5 (55)

- Algorithms to Live By: The Computer Science of Human DecisionsNo EverandAlgorithms to Live By: The Computer Science of Human DecisionsNota: 4.5 de 5 estrelas4.5/5 (722)

- Generative AI: The Insights You Need from Harvard Business ReviewNo EverandGenerative AI: The Insights You Need from Harvard Business ReviewNota: 4.5 de 5 estrelas4.5/5 (2)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessAinda não há avaliações

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyNo EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyNota: 3.5 de 5 estrelas3.5/5 (111)

- AI Prompting Mastery: Strategies and Techniques for Effective PromptingNo EverandAI Prompting Mastery: Strategies and Techniques for Effective PromptingAinda não há avaliações

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindAinda não há avaliações

- Chip War: The Quest to Dominate the World's Most Critical TechnologyNo EverandChip War: The Quest to Dominate the World's Most Critical TechnologyNota: 4.5 de 5 estrelas4.5/5 (227)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldNo EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldNota: 4.5 de 5 estrelas4.5/5 (107)

- The Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectNo EverandThe Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectNota: 4.5 de 5 estrelas4.5/5 (20)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideNo EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideNota: 5 de 5 estrelas5/5 (2)

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesNo EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesNota: 4.5 de 5 estrelas4.5/5 (13)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewNo EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewNota: 4.5 de 5 estrelas4.5/5 (104)

- The Internet Con: How to Seize the Means of ComputationNo EverandThe Internet Con: How to Seize the Means of ComputationNota: 5 de 5 estrelas5/5 (6)

- The AI Advantage: How to Put the Artificial Intelligence Revolution to WorkNo EverandThe AI Advantage: How to Put the Artificial Intelligence Revolution to WorkNota: 4 de 5 estrelas4/5 (7)

- Machine Learning: The Ultimate Beginner's Guide to Learn Machine Learning, Artificial Intelligence & Neural Networks Step by StepNo EverandMachine Learning: The Ultimate Beginner's Guide to Learn Machine Learning, Artificial Intelligence & Neural Networks Step by StepNota: 4.5 de 5 estrelas4.5/5 (19)