Escolar Documentos

Profissional Documentos

Cultura Documentos

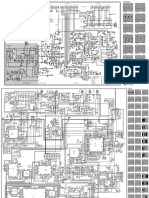

Control system for bilge wells

Enviado por

Arrijal PratamaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Control system for bilge wells

Enviado por

Arrijal PratamaDireitos autorais:

Formatos disponíveis

1 2 3 4 5 6 7 8 9 10 11 12

DETAIL CONTROL SYSTEM AT BILGE WELL

BILGE SYSTEM

A

LINE INSTRUMENTS SYMBOL A

: Main Line (Main Pipe)

: Branch Pipe FIC LIC LAH LIT LG

GS-P00

: Electrical Signal

: Pneumatic Signal

Dwg.No.02 - 42 18 DP03 - BG 1

001 001 001 001 001 Bilge Well

FIT

NOTE : 001

B 1. Bilge Pump use Centrifugal Pump, Self- Primming type.

B

I/P

Fluid Out

GS-OB 2 FV

001

GS-SRV 3

C Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well

C

14 (P.S) 13 (P.S) 12 (P.S) 11 (P.S) 10 (P.S) 9 (P.S) 8 (P.S) 7 (P.S) 6 (P.S) 5 (P.S) 4 (P.S) 3 (P.S)

GS-LAH 25 LAH GS-LAH 24 LAH GS-LAH 23 LAH GS-LAH 22 LAH GS-LAH 21 LAH GS-LAH 20 LAH GS-LAH 19 LAH GS-LAH 18 LAH GS-LAH 17 LAH GS-LAH 16 LAH GS-LAH 15 LAH GS-LAH 14 LAH

Bilge Suction LAH GS-LAH 29

JIS G 3452 - 200A

GS-BLM 25 GS-BLM 24 GS-BLM 23 GS-BLM 22 GS-BLM 21 GS-BLM 20 GS-BLM 19 GS-BLM 18 GS-BLM 17 GS-BLM 16 GS-BLM 15 GS-BLM 14

In E/R GS-BLM 29

GS-STR 25 GS-STR 24 GS-STR 23 GS-STR 22 GS-STR 21 GS-STR 20 GS-STR 19 GS-STR 18 GS-STR 17 GS-STR 16 GS-STR 15 GS-STR 14

GS-STR 29 GS-NRV 25 GS-NRV 24 GS-NRV 23 GS-NRV 22 GS-NRV 21 GS-NRV 20 GS-NRV 19 GS-NRV 18 GS-NRV 17 GS-NRV 16 GS-NRV 15 GS-NRV 14

GS-NRV 29

To Emergency Bilge Pump

( Cooling System )

GS-BV 14

(See Dwg no.09 - 42 18 GS-FLX 31 GS-FLX 30 GS-FLX 29 GS-FLX 28 GS-FLX 27 GS-FLX 26 GS-FLX 25 GS-FLX 24 GS-FLX 23 GS-FLX 22 GS-FLX 21 GS-FLX 20 GS-FLX 19 GS-FLX 18 GS-FLX 17

DP03 - CO)

D From Ballast see DWG no. 05 - 42 18 DP03 - BL

JIS G 3452 - 200A JIS G 3452 - 200A JIS G 3452 - 200A JIS G 3452 - 200A D

JIS G 3452 - 200A

GS-BV 13 GS-BV 12

GS-PI 3 GS-PI 3 GS-BV 11

GS-SV 2

To Ballast see DWG no. 05 - 42 18 DP03 - BL

GS-STR 31 GS-SRV 2

JIS G 3452 - 200A

GS-P00

GS-BV 10 SLOP

JIS G 3452 - 200A

2 TANK

E E

JIS G 3452 - 200A

C.O.T 14 C.O.T 13 C.O.T 12 C.O.T 11 C.O.T 10 C.O.T 9 C.O.T 8 C.O.T 7 C.O.T 6 C.O.T 5 C.O.T 4 C.O.T 3 C.O.T 2 C.O.T 1

(P.S) (P.S) (P.S) (P.S) (P.S) (P.S) (P.S) (P.S) (P.S) (P.S) (P.S) (P.S) (P.S) (P.S)

Suction In AP

GS-LAH 28 GS-STR 28

LAH

COFFERDAM

GS-BV 8

FOREPEAK

JIS G 3452 - 200A

GS-BLM 28

TANK

GS-BV 9 GS-FLX 32 GS-FLX 16

F Bilge

F

JIS G 3452 - 200A JIS G 3452 - 200A JIS G 3452 - 90A GS-NRV 13

Suction

JIS G 3452 - 200A

GS-STR 13

C.O.T 14 C.O.T 13 C.O.T 12 C.O.T 11 C.O.T 10 C.O.T 9 C.O.T 8 C.O.T 7 C.O.T 6 C.O.T 5 C.O.T 4 C.O.T 3 C.O.T 2 C.O.T 1 In FP

Direct Suction in E/R (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) (S.S) GS-BLM 13

LAH

GS-PI 1 GS-PI 2 GS-LAH 13

GS-NRV 27 GS-SV 1

GS-BV 7

JIS G 3452 - 200A

GS-LAH 27 LAH

GS-STR 27JIS G 3452 - 200A To Ballast see DWG no. 05 - 42 18 DP03 - BL

GS-BLM 27 GS-BV 2

GS-STR 30 GS-SRV 1

GS-BV 5 GS-P00

GS-BV 1 1

G SLOP

G

GS-BV 6 TANK

JIS G 3452 - 200A

GS-BV 3

From Ballast see DWG no. 05 - 42 18 DP03 - BL JIS G 3452 - 200A JIS G 3452 - 200A JIS G 3452 - 200A JIS G 3452 - 200A

JIS G 3452 - 200A GS-FLX 1 GS-FLX 2 GS-FLX 3 GS-FLX 4 GS-FLX 5 GS-FLX 6 GS-FLX 7 GS-FLX 8 GS-FLX 9 GS-FLX 10 GS-FLX 11 GS-FLX 12 GS-FLX 13 GS-FLX 14 GS-FLX 15

JIS G 3452 - 200A

GS-BV 4

GS-NRV 26

GS-STR 26 To Emergency Bilge Pump GS-NRV 1 GS-NRV 2 GS-NRV 3 GS-NRV 4 GS-NRV 5 GS-NRV 6 GS-NRV 7 GS-NRV 8 GS-NRV 9 GS-NRV 10 GS-NRV 11 GS-NRV 12

GS-BLM 26 ( Cooling System ) GS-STR 1 GS-STR 2 GS-STR 3 GS-STR 4 GS-STR 5 GS-STR 6 GS-STR 7 GS-STR 8 GS-STR 9 GS-STR 10 GS-STR 11 GS-STR 12

H Bilge Suction (See Dwg no.09 - 42 18 DP03 - CO) H

GS-BLM 1 GS-BLM 2 GS-BLM 3 GS-BLM 4 GS-BLM 5 GS-BLM 6 GS-BLM 7 GS-BLM 8 GS-BLM 9 GS-BLM 10 GS-BLM 11 GS-BLM 12

In E/R LAH GS-LAH 26 LAH

GS-LAH 1 LAH

GS-LAH 2 LAH

GS-LAH 3 LAH

GS-LAH 4 LAH

GS-LAH 5 LAH

GS-LAH 6 LAH

GS-LAH 7 LAH

GS-LAH 8 LAH

GS-LAH 9 LAH

GS-LAH 10 LAH

GS-LAH 11 LAH

GS-LAH 12

Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well Cargo Bilge Well

14 (S.S) 13 (S.S) 12 (S.S) 11 (S.S) 10 (S.S) 9 (S.S) 8 (S.S) 7 (S.S) 6 (S.S) 5 (S.S) 4 (S.S) 3 (S.S)

GS-SRV 4

GS-OB 1

I DEPARTEMENT OF MARINE ENGINEERING - ITS

I

NO SYMBOL EQUIPMENT QTY SPECIFICATION NO SYMBOL EQUIPMENT QTY SPECIFICATION NO SYMBOL EQUIPMENT QTY SPECIFICATION Pipe Specification :

1. Main Pipe :

PRINCIPLE DIMENSION

Institut

IV DESIGN - MACHINERY AND ELECTRICAL SYSTEM

Nominal Size : 200A Teknologi

Flanged Conection, Material Bronze, Material Stainless Steel, Max. Pressure LEVEL INDICATOR AND Inside Diameter : 200 mm Sepuluh Nopember EVEN SEMESTER 2018/2019

1 NON RETURN VALVE, STRAIGHT,

4 Temperature up to 200°C, Max. 7 FILTER/STRAINER 31 10 Bar, Temperature 80°C 13 LIT

29 LPP 174,0 m Cb 0,782

SCREW DOWN 001 TRANSMITTER Outside Diameter : 216,4mm

Pressure 10 Bar

Wafer Type, Material Ductile Iron, Centrifugal Pump, Material Bronze, Cap. On Monitor

Schedule Number : 40 DANADYAKSA

LIC LEVEL INDICATOR AND Thickness : 8,2 mm Lwl 0,791 CRUDE OIL CARRIER

2 BUTTERFLY VALVE 15 Temperature up to 95°C, Max. 8 GS BILGE PUMP 1 220 m3/h, Head 80 m, Max. 14 001 CONTROLLER 29 179,2 m Cp

Pressure 10 Bar Temperature 75°C Material : Steel Pipe ABS Classification ✠A1, OIL CARRIER, E , ✠ AMS, ACCU

Flanged Conection, Material Bronze, PVC, Temperature up to 60°C, Max. On Monitor Industri Standard : JIS G3452

NON RETURN VALVE, STRAIGHT, 32 FIC FLOW INDICATOR AND 29 Ldis PREPARED BY : SIGNED :

3 29 Temperature up to 200°C, Max. 9 FLEXIBLE COUPLING Pressure 43 bar 15 001 CONTROLLER

176,6 m Cm 0,989

SCREW DOWN, REMOTELY Okta Rijal Nur Pratama (04211540000044)

Pressure 16 Bar 2. Branch Pipe :

Welding Neck Flange, Material Magnetic Float and Reed Switch, FLOW INDICATOR AND Nominal Size : 90A

4 BULKHEAD FITTING WATERTIGHT, 40 Carbon Steel, Max. Pressure 10 Bar 10 LAH

LEVEL ALARM HEIGHT 29 SUS316l, Max. Pressure 50 bar 16 FIT

29 B 30,6 m Vs 14,2 knot CHECKED BY : SIGNED :

J FLANGE 001 TRANSMITTER Inside Diameter

Outside Diameter

:

:

92,6 mm

101,6mm

Bilge System Ramzy Chandra Muzaffar (04211540000050) J

Material : Copper Nickel Cu-Alloy, Temperature -20° - 60°C, TRANSDUCER Schedule Number : 20 SIGNED :

5 BELLMOUTHED 29 11 PRESSURE INDICATOR 4 Pressure range 0 - 10 bar 17 29 H 13,5 m Vs/√Ldis 0,589 APPROVED BY :

CURRENT TO PNEUMATIC Thickness : 4,5 mm Ir.Dwi Priyanta, M.SE

Material : Steel Pipe

Material Stainless Steel, Temperature Diel e 150, Length of Capillary 5 meter

6 SAFETY VALVE 2 up to 400°C, Max. Pressure 40 Bar 12 LG

LEVEL GAUGE 29 18 Industri Standard : JIS G3452 T 9,2 m Type Oil Carrier DWG NO. DATE : SCALE : REV :

001 02 - 42 18 DP03 - BG 13/10/2018 - 0

1 2 3 4 5 6 7 8 9 10 11 12

Você também pode gostar

- Bilge SistemDocumento1 páginaBilge Sistemhimmawan aan listyantoAinda não há avaliações

- Desain Bilga KapalDocumento1 páginaDesain Bilga Kapalhimmawan aan listyantoAinda não há avaliações

- Bilge System Function and RequirementsDocumento11 páginasBilge System Function and RequirementsSsplMacusang100% (1)

- SOLAS Bilge Pumping Rules for Merchant ShipsDocumento2 páginasSOLAS Bilge Pumping Rules for Merchant ShipsKhaing26Ainda não há avaliações

- 310-1512715 Bilge System H01Documento11 páginas310-1512715 Bilge System H01buturca sorinAinda não há avaliações

- Bilge System: Is A Drainage System That HandlesDocumento46 páginasBilge System: Is A Drainage System That HandlesSiskal Dd100% (3)

- 14m Crew Boat 355Documento6 páginas14m Crew Boat 355Roy FloAinda não há avaliações

- Ship Piping SystemDocumento19 páginasShip Piping SystemAtandho Gama MagwasyarAinda não há avaliações

- Bilge Pump - SOLAS Regulations For Merchant ShipsDocumento2 páginasBilge Pump - SOLAS Regulations For Merchant ShipssimAinda não há avaliações

- SPEC of Pipes For ShipbuildingDocumento13 páginasSPEC of Pipes For ShipbuildinggopaltryAinda não há avaliações

- Marine Bilge and Ballast SystemsDocumento17 páginasMarine Bilge and Ballast SystemsRyanAinda não há avaliações

- 02 Bilge Pumping Systems: Manual Diaphragm PumpsDocumento24 páginas02 Bilge Pumping Systems: Manual Diaphragm PumpsAli QomariahAinda não há avaliações

- Jacket Water SystemDocumento2 páginasJacket Water SystemJitendra KumarAinda não há avaliações

- Bilge System CalculationDocumento12 páginasBilge System CalculationMuhammad Habib100% (1)

- Operating Manual - Quick-Closing Valve SystemDocumento14 páginasOperating Manual - Quick-Closing Valve SystemFreeman MorganAinda não há avaliações

- Sili Pump: Marine Pump Specialist in ChinaDocumento0 páginaSili Pump: Marine Pump Specialist in ChinaRizky Aprianto SetiawanAinda não há avaliações

- 3590 - Marine Piping Systems - VALVES On Shipbuilding ApplicationDocumento14 páginas3590 - Marine Piping Systems - VALVES On Shipbuilding ApplicationZhafira OspAinda não há avaliações

- Bilge Suction StrainerDocumento7 páginasBilge Suction StrainerdbahidbAinda não há avaliações

- Central Cooling Water SystemsDocumento3 páginasCentral Cooling Water SystemsreachpdAinda não há avaliações

- FW System Hydrophore Tank PDFDocumento10 páginasFW System Hydrophore Tank PDFAnoop VijayakumarAinda não há avaliações

- Bilge Pumping System StudyDocumento3 páginasBilge Pumping System StudyAayush AgrawalAinda não há avaliações

- Kuliah Turbine Gas STT 1Documento123 páginasKuliah Turbine Gas STT 1Kristian d hAinda não há avaliações

- 1 Piping Systems On ShipsDocumento9 páginas1 Piping Systems On ShipsBang NielAinda não há avaliações

- FWG TroubleshootingDocumento7 páginasFWG TroubleshootingMariappan Na100% (5)

- Boiler D' Type: Team GroupingDocumento10 páginasBoiler D' Type: Team Groupingayie_38Ainda não há avaliações

- Cylinder Liner and Cooling Jacket Plate: 90302-122 S50MC-CDocumento2 páginasCylinder Liner and Cooling Jacket Plate: 90302-122 S50MC-CRM HaroonAinda não há avaliações

- Ship system keyplans and diagramsDocumento9 páginasShip system keyplans and diagramsIndra HazamiAinda não há avaliações

- Ballast DWGDocumento1 páginaBallast DWGIndra HazamiAinda não há avaliações

- Sili Pump CL PDFDocumento3 páginasSili Pump CL PDFGyda GydaAinda não há avaliações

- Lec 2 Bilge SystemDocumento19 páginasLec 2 Bilge SystemArwa Hussein100% (1)

- Diagram of Filling Drain Pipes ForDocumento9 páginasDiagram of Filling Drain Pipes ForCornel CrlAinda não há avaliações

- Desain Ulang Pompa Eletrical SubmersibleDocumento30 páginasDesain Ulang Pompa Eletrical SubmersibleSena gilang AndreanAinda não há avaliações

- Catalogue Card: Hydroster LTDDocumento50 páginasCatalogue Card: Hydroster LTDNur SalimAinda não há avaliações

- Ships PipingDocumento25 páginasShips Pipinggopaltry100% (1)

- Panduan Buat Lines PlanDocumento58 páginasPanduan Buat Lines Planwilson1007Ainda não há avaliações

- PUMPING SYSTEMSDocumento28 páginasPUMPING SYSTEMSJayvee Mauricio100% (1)

- Technical specification of fuel oil systemDocumento28 páginasTechnical specification of fuel oil systemPanji Kresno WijanarkoAinda não há avaliações

- Bilge N Ballast SystemDocumento2 páginasBilge N Ballast SystemAayush AgrawalAinda não há avaliações

- Large Marine Diesel Engines Are Started Using High Pressure Compressed AirDocumento4 páginasLarge Marine Diesel Engines Are Started Using High Pressure Compressed Airaerocristian12345Ainda não há avaliações

- Mechanical Foam Fire Extinguisher MaintenanceDocumento2 páginasMechanical Foam Fire Extinguisher MaintenanceAayush AgrawalAinda não há avaliações

- Marine Engineering System CODAG and SystemDocumento9 páginasMarine Engineering System CODAG and SystemIkhwan Azizie100% (2)

- SHIP Piping SystemDocumento5 páginasSHIP Piping Systemsurnaik100% (1)

- CLH Vertical SilipumpDocumento13 páginasCLH Vertical SilipumpTelly Fahrul100% (1)

- CBZ Horizontal Self-Priming Centrifugal Pump SpecsDocumento2 páginasCBZ Horizontal Self-Priming Centrifugal Pump Specsrio100% (1)

- Fixed Co2 Fire Fighting SystemDocumento20 páginasFixed Co2 Fire Fighting SystemMagesh ShanmughamAinda não há avaliações

- Bilge System and Ows SystemDocumento49 páginasBilge System and Ows SystemFajar Rizcy EAinda não há avaliações

- Stern Tubes PDFDocumento8 páginasStern Tubes PDFrajishrrr100% (1)

- 7.1 - Cooling Water SystemDocumento8 páginas7.1 - Cooling Water SystemSayem kaifAinda não há avaliações

- Eerl 72-23 Project TugboatDocumento219 páginasEerl 72-23 Project TugboatMisterSpacerockAinda não há avaliações

- DNV Marpol Annex VI Guide Lines LSHFO PositionsDocumento32 páginasDNV Marpol Annex VI Guide Lines LSHFO Positionsch3g44Ainda não há avaliações

- Donghwa CompressorDocumento2 páginasDonghwa CompressorSergei KurpishAinda não há avaliações

- Scotch BoilerDocumento52 páginasScotch Boilerrajishrrr100% (1)

- VLCCDocumento9 páginasVLCCAnonymous b68EQRAinda não há avaliações

- Design Piping for KM Ethes Artha 7Documento14 páginasDesign Piping for KM Ethes Artha 7Dhitya Agil Harnowo100% (1)

- m023 - 3u2400103 Rev.100 Piping System Diagram in ErDocumento80 páginasm023 - 3u2400103 Rev.100 Piping System Diagram in ErDamir Rubelj100% (1)

- An7348s-E1 Q1017 B1aarc000003Documento1 páginaAn7348s-E1 Q1017 B1aarc000003wilfreddelgadoAinda não há avaliações

- A2400 ChassisDocumento29 páginasA2400 ChassisdoomanAinda não há avaliações

- Bhatinda R 2 SLDDocumento1 páginaBhatinda R 2 SLDvineets058Ainda não há avaliações

- COPIER (B264/B265) Point To Point Diagram: Bicu PCB 1Documento14 páginasCOPIER (B264/B265) Point To Point Diagram: Bicu PCB 1josdavisAinda não há avaliações

- Mccauley Constant Speed Propellers: Threaded Series Threadless Series Retention Nut Split Retainer RingDocumento10 páginasMccauley Constant Speed Propellers: Threaded Series Threadless Series Retention Nut Split Retainer Ringcam cotAinda não há avaliações

- Analysis of Water Hammering in Pipeline and Its CFD SimulationDocumento6 páginasAnalysis of Water Hammering in Pipeline and Its CFD SimulationDuzzysAinda não há avaliações

- A Study of Liquid Metal AtomizationDocumento22 páginasA Study of Liquid Metal AtomizationAlisha Allison0% (1)

- Guide to Selecting Artificial Lift for Gas WellsDocumento20 páginasGuide to Selecting Artificial Lift for Gas WellsRaymundo Leonardo Pérez SierraAinda não há avaliações

- Manual Hélice Hartzell 139-0000-A PDFDocumento202 páginasManual Hélice Hartzell 139-0000-A PDFjojo4761Ainda não há avaliações

- Experiment 104 Torque: 2 Condition of Equilibrium: PhysicsDocumento4 páginasExperiment 104 Torque: 2 Condition of Equilibrium: PhysicsJag MasterAinda não há avaliações

- Alli 15Documento2 páginasAlli 15Robson belchiorAinda não há avaliações

- Automotive Equipment Training Programme 2013Documento52 páginasAutomotive Equipment Training Programme 20132791957Ainda não há avaliações

- Dinamika - 1 Kinematika Benda TegarDocumento36 páginasDinamika - 1 Kinematika Benda TegarFirman Ali NuryantoAinda não há avaliações

- 3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsDocumento8 páginas3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsengkjAinda não há avaliações

- A Natural Gas Fired Duplex Stirling For Domestic RefrigeratiDocumento11 páginasA Natural Gas Fired Duplex Stirling For Domestic RefrigeratiditoAinda não há avaliações

- Brake SystemDocumento7 páginasBrake SystemJavier GarciaAinda não há avaliações

- As (One Touch)Documento105 páginasAs (One Touch)carlos223344Ainda não há avaliações

- Measuring Distance of Heavenly BodyDocumento28 páginasMeasuring Distance of Heavenly BodykhanAinda não há avaliações

- (865 VHP) - Motor Grader Tier 3 (Na) - Asn N8AF04429 (7/05-12/08) (02-16 (01) ) - AIR CLEANER - ASSEMBLY Case ConstructuionDocumento3 páginas(865 VHP) - Motor Grader Tier 3 (Na) - Asn N8AF04429 (7/05-12/08) (02-16 (01) ) - AIR CLEANER - ASSEMBLY Case ConstructuionRjg EarthmoversAinda não há avaliações

- 87 s10Documento12 páginas87 s10carlosestayAinda não há avaliações

- Demolition Robot (Brokk 500) (Brochure) - 1Documento2 páginasDemolition Robot (Brokk 500) (Brochure) - 1Julius GatchalianAinda não há avaliações

- Angular Momentum (Momen Anguler)Documento35 páginasAngular Momentum (Momen Anguler)bat.laugh100% (1)

- ActSafe PME Manual ENGDocumento32 páginasActSafe PME Manual ENGpnsanatAinda não há avaliações

- ExDocumento2 páginasExSinggih KurniawanAinda não há avaliações

- To11c5 e 00 PDFDocumento526 páginasTo11c5 e 00 PDFGradimir MilanovicAinda não há avaliações

- 3 HvacDocumento32 páginas3 HvacLawrence ConananAinda não há avaliações

- Preliminary Heat Exchanger Sizing: These Calculations Are Provided For Educational Use Only - USE AT YOUR OWN RISKDocumento4 páginasPreliminary Heat Exchanger Sizing: These Calculations Are Provided For Educational Use Only - USE AT YOUR OWN RISKRaol VarshabenAinda não há avaliações

- Screw Compressors: Boge Air. The Air To WorkDocumento52 páginasScrew Compressors: Boge Air. The Air To WorkAndy KershawAinda não há avaliações

- QB. PPDocumento15 páginasQB. PPRajib MandalAinda não há avaliações

- Manual Recambios 3.152.4 (CM51027) PDFDocumento149 páginasManual Recambios 3.152.4 (CM51027) PDFValoys MirandaAinda não há avaliações

- Dytran Reference ManualDocumento866 páginasDytran Reference ManualDon100% (2)

- Conservation of Energy Worksheet #1 - 1Documento3 páginasConservation of Energy Worksheet #1 - 1Alyssa ColeAinda não há avaliações

- Lecture 28 Thermal Engineering II (09.09.2020)Documento71 páginasLecture 28 Thermal Engineering II (09.09.2020)Dr. BIBIN CHIDAMBARANATHANAinda não há avaliações

- Ruukki 41338 Instructiuni de Montaj Placarea Fatadei Peste PanouriDocumento12 páginasRuukki 41338 Instructiuni de Montaj Placarea Fatadei Peste PanouriGhenoiu PaulAinda não há avaliações