Escolar Documentos

Profissional Documentos

Cultura Documentos

30 23 K Lox Proofer

Enviado por

Firas_karboujDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

30 23 K Lox Proofer

Enviado por

Firas_karboujDireitos autorais:

Formatos disponíveis

K Lox Proofer

30-24, 30-26

▲ Automatic K Lox

Main Features

• Instant flexo proofs

• Easy to use – easy to clean

• Excellent repeatability

• Reduces press down-time

• Fully interchangeable rollers up to 500 screen

• Hand and automatic versions available

▲ Hand K Lox

The simplest method of applying flexo inks and other

fluid coatings onto any substrate to produce accurate

and repeatable proofs that closely resemble conven-

tional flexo printing. The K Lox Proofer is an essential

tool for ink makers and printers alike. Ideal for quality

control and presentation samples, R&D and computer

colour matching data.

K Lox Proofer

K Lox

A bead of ink is placed between an engraved anilox roller and a rubber

roller as illustrated below. It is essential to have constant pressure

between the rollers for consistent prints and this is ensured by two

weights. When the K Lox is drawn smoothly over the substrate an ac-

curate film of ink is printed producing a sample up to 4.5 in (115mm)

wide. After removing the weights, both rollers are easily cleaned.

Anilox rollers with screens for solid, line and half-tone printing may be

selected as required.

▲ Cleaning/storage rack

Hand K Lox Automatic K Lox

The Hand K Lox provides a cost-effective and simple With a little practice, the K Lox user is able to pro-

means of proofing flexo inks. It is available as a single duce consistent results with the hand unit. However,

unit or may be ordered as a comprehensive system. where a number of operators may be involved or when

The Hand K Lox system comes complete with 3 stan- the highest degree of repeatability is demanded (e.g.

dard engraved anilox rollers, 2 rubber rollers and a when using the prints for computer colour matching),

cleaning/storage rack. the Automatic K Lox is recommended. This machine

eliminates any variation in speed and pressure and an

Single Series, Catalog no. 30-23

accurate print is produced ever time. The unit operates

System Series, Catalog no. 30-24

at variable speeds up to 15m/min. The Automatic K

Lox is also available as a system. An air driven version

is available for use in hazardous areas.

Catalog no. 30-26-01

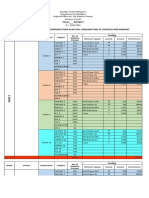

Standard Rollers Accessories

TYPE SCREEN CELL VOLUME • Cleaning/storage rack for up to 6 rollers.

CELLS/LINEAR CELLS/LINEAR CBM CM³/M²

INCH CM • Wide shouldered rubber roller (for use on

400/5 400 160 2.8 4.3 slippery substrates eg. polythene).

200/12 200 80 6.6 10.2

180/14 180 70 10.7 16.6

140/10 140 55 13.0 20.2

100/18 100 40 25.2 39.1

Other screens and wire wound rollers can be manufactured to

customer specification.

Main Headquarters

Testing Machines Inc. Messmer Instruments Büchel BV Lako Tool and Lawson Hemphill Adamel Lhomargy TMI Canada

2 Fleetwood Court Unit F1 Imperial Fokkerstrat 24, Manufacturing Inc. 1658 G A R Highway SARL P.O. Box 203

Ronkonkoma, NY 11779 Business Estate 3905 KV 7400 Ponderosa Road Swansea, MA 02777 Z.A. de l’Habitat, Pointe-Claire Dorval

Tel: (631) 439-5400 West Mill, Gravesend Veenendaal, Perrysburg, Ohio 43552 Tel: (508) 679-5364 Bâtiment 6 QC, H9R-4N9 CAN

Fax: (631) 439-5420 Kent DA11 0DL UK Netherlands Tel: (419) 662-5256 Fax: (508) 679-5396 Route d’Ozoir, 77680 Tel: (514) 426-5855

Info@testingmachines.com Tel:+44 (0) 1474 566488 Tel:+33 (0)318 521500 Fax: (419) 662-8225 Information@ Roissy en Brie, France Fax: (514) 426-1557

Fax:+44 (0) 1474 560310 Fax:+33 (0)318 5400358 lawsonhemphill.com Tel:+33 (0) 1 6440291

Fax:+33 (0) 1 64409211

www.testingmachines.com www.lakotool.com www.lawsonhemphill.com

Você também pode gostar

- John Meunier Cont-Flo Type CFDocumento4 páginasJohn Meunier Cont-Flo Type CFCarlos FrancoAinda não há avaliações

- P&C Documento Unico DEF WebDocumento2 páginasP&C Documento Unico DEF Webabdelaziz_ismail685662Ainda não há avaliações

- Sam McCoy MFG - Catalogue 2004 - 2Documento29 páginasSam McCoy MFG - Catalogue 2004 - 2Sam McCoy ManufacturingAinda não há avaliações

- Lotem 400 Lotem 400 Quantum: High-Throughput, High-Quality 4-Page CTPDocumento4 páginasLotem 400 Lotem 400 Quantum: High-Throughput, High-Quality 4-Page CTPnebiyouAinda não há avaliações

- XFlex X2 Cat 1marzoDocumento6 páginasXFlex X2 Cat 1marzoassistante embAinda não há avaliações

- 04DA KLoxProofer DDocumento2 páginas04DA KLoxProofer DChristian NunezAinda não há avaliações

- AXIOMDocumento3 páginasAXIOMPrejit RadhakrishnaAinda não há avaliações

- Kohler News-30 ENDocumento6 páginasKohler News-30 ENAli BÜLBÜLAinda não há avaliações

- Anilox SelectionDocumento2 páginasAnilox SelectionTanneru Hemanth KumarAinda não há avaliações

- Corrosion - Mapping Usign Phased Array - Olympus NDTDocumento3 páginasCorrosion - Mapping Usign Phased Array - Olympus NDTpokeboy19Ainda não há avaliações

- Atlas Copco Construction Tools - Facts BookDocumento144 páginasAtlas Copco Construction Tools - Facts Bookmnowaq100% (1)

- Kodak Veriset - T400-800Documento2 páginasKodak Veriset - T400-800RizwanAinda não há avaliações

- Crossheads For The Cable Industry: WWW - Unitek.at WWW - Unitek.atDocumento4 páginasCrossheads For The Cable Industry: WWW - Unitek.at WWW - Unitek.atAlyass EvanAinda não há avaliações

- SPX Flow Technology Overview - BrochureDocumento44 páginasSPX Flow Technology Overview - BrochureCentrifugal SeparatorAinda não há avaliações

- Flatbed and Rotary DieDocumento10 páginasFlatbed and Rotary DieAliArababadi100% (2)

- Elcometer 112 - 115 - 154 - 3230 - 3236 - 3238 Wet Film Combs and WheelDocumento12 páginasElcometer 112 - 115 - 154 - 3230 - 3236 - 3238 Wet Film Combs and WheelAshat Ul HaqAinda não há avaliações

- KHD Comflex April 2012Documento4 páginasKHD Comflex April 2012m_verma21Ainda não há avaliações

- Dot Pin Marking MachineDocumento9 páginasDot Pin Marking MachineilovemechAinda não há avaliações

- K Printing Proofer: The First Name in Sample Preparation EquipmentDocumento4 páginasK Printing Proofer: The First Name in Sample Preparation Equipmentfajar ramadhanAinda não há avaliações

- BM 2500 DLDocumento7 páginasBM 2500 DLanthonynr94Ainda não há avaliações

- Clamshell Telescopic Arm: Application & AttachmentDocumento12 páginasClamshell Telescopic Arm: Application & AttachmenttresspasseeAinda não há avaliações

- PRO DOC BRO Brochure Automotive 2022 No Price en ScreenDocumento36 páginasPRO DOC BRO Brochure Automotive 2022 No Price en Screenjazzmate003Ainda não há avaliações

- Series: Leaflet Folding MachineDocumento2 páginasSeries: Leaflet Folding MachineBineyamAinda não há avaliações

- Brochure Jenny Science EDocumento12 páginasBrochure Jenny Science EOLIVETOAinda não há avaliações

- Titan R50 Wagon LeafletDocumento24 páginasTitan R50 Wagon Leafletinfo48260% (1)

- KODAK ACHIEVE T400 T800 Platesetters Brochure ENDocumento4 páginasKODAK ACHIEVE T400 T800 Platesetters Brochure ENWilmer TasaycoAinda não há avaliações

- Lombardi Company PresentationDocumento35 páginasLombardi Company PresentationPam Landi0% (1)

- 5808A1291 - Bs - Cat - Rover K FT - Mag19 - ENG - LRDocumento40 páginas5808A1291 - Bs - Cat - Rover K FT - Mag19 - ENG - LRИвалин ДимитровAinda não há avaliações

- Anilox RollDocumento37 páginasAnilox RollSudhakar Joshi100% (4)

- Alcolor DampeningDocumento30 páginasAlcolor DampeningSaranovicu Krsto100% (3)

- Flexo. PrintingDocumento43 páginasFlexo. Printingahmed shamlawiAinda não há avaliações

- Moisture Separator - Brochure - 1521101259Documento16 páginasMoisture Separator - Brochure - 1521101259Hanhan Subhan UmbaraAinda não há avaliações

- Xpose! Flex: The CTP System With Maximum Efficiency and Flexibility Xpose! FlexDocumento2 páginasXpose! Flex: The CTP System With Maximum Efficiency and Flexibility Xpose! FlexEric FassoniAinda não há avaliações

- Filtomat M300Documento4 páginasFiltomat M300Sasa Jadrovski100% (1)

- Printing by The Flexography MethodDocumento7 páginasPrinting by The Flexography Methodrafael_faria_4Ainda não há avaliações

- Product Catalogue PC7 Web PDFDocumento15 páginasProduct Catalogue PC7 Web PDFjohnAinda não há avaliações

- Mtxflex12 1250 2500Documento23 páginasMtxflex12 1250 2500Jovan KostadinovicAinda não há avaliações

- Catalogo GeneralDocumento149 páginasCatalogo GeneralFrank HigueraAinda não há avaliações

- Batching PlantDocumento8 páginasBatching Plantsofyanshah100% (1)

- Automotive PDFDocumento2 páginasAutomotive PDFPc HealerAinda não há avaliações

- Wide Belt Sanding Machines SANDTEQ W 300 700 en PDFDocumento48 páginasWide Belt Sanding Machines SANDTEQ W 300 700 en PDFMesara Kod KokijaAinda não há avaliações

- Robofil x40 CC UsDocumento28 páginasRobofil x40 CC UsMahdi ElgolliAinda não há avaliações

- KodakFlexcelNX 100,1 BestPracticesDocumento7 páginasKodakFlexcelNX 100,1 BestPracticesMauMauAinda não há avaliações

- ASC 30-50 Single Drum RollersDocumento8 páginasASC 30-50 Single Drum RollersMuhaiminAinda não há avaliações

- BM 2500 T ModifiedDocumento8 páginasBM 2500 T Modifiedhungthienphu999Ainda não há avaliações

- Arc Welding PDFDocumento12 páginasArc Welding PDFInlaboAinda não há avaliações

- CNC RoutersDocumento2 páginasCNC RoutersPochoo AlexAinda não há avaliações

- Collar Load Support (CLS™)Documento1 páginaCollar Load Support (CLS™)tafhim rashidAinda não há avaliações

- ZX30, ZX35, ZX40, ZX50 EN Product Information ENDocumento42 páginasZX30, ZX35, ZX40, ZX50 EN Product Information ENАлексейAinda não há avaliações

- Dry Disconnects BrochureDocumento4 páginasDry Disconnects BrochureRicardo TurinAinda não há avaliações

- Blown Film CatalogueDocumento12 páginasBlown Film CatalogueMohammad-reza NabavinezhadAinda não há avaliações

- 2-8 Kodak Digital Imaging PlatesDocumento6 páginas2-8 Kodak Digital Imaging PlatesJayeshAinda não há avaliações

- Test EquipmentDocumento18 páginasTest EquipmentAliAinda não há avaliações

- Odmeter InformationDocumento144 páginasOdmeter InformationSachin KothariAinda não há avaliações

- Comby Plants Rct1: Machine DescriptionDocumento2 páginasComby Plants Rct1: Machine DescriptionFelipe BrainAinda não há avaliações

- Xes 3000 Series BrochureDocumento2 páginasXes 3000 Series BrochureJuju ButtAinda não há avaliações

- Sewage Disposal Works: Their Design and ConstructionNo EverandSewage Disposal Works: Their Design and ConstructionAinda não há avaliações

- EL119 Module 2Documento4 páginasEL119 Module 2Kristine CastleAinda não há avaliações

- Arhivska PraksaDocumento552 páginasArhivska PraksaABCAinda não há avaliações

- Key Word: Innovation, Marketing Plan, Marketing, Strategy: AbstractDocumento8 páginasKey Word: Innovation, Marketing Plan, Marketing, Strategy: AbstractabhiAinda não há avaliações

- In-Text Citations (Publication Manual, Pp. 174-179)Documento13 páginasIn-Text Citations (Publication Manual, Pp. 174-179)John Dave Sta AnaAinda não há avaliações

- The Worship Media Handbook Version 2Documento104 páginasThe Worship Media Handbook Version 2Cris AdonesAinda não há avaliações

- Creating A BibiliographyDocumento2 páginasCreating A BibiliographyDamian JuanAinda não há avaliações

- Natural Resources BiometricsDocumento181 páginasNatural Resources BiometricsNNA EFEAinda não há avaliações

- Steps To Effective CampaignDocumento29 páginasSteps To Effective CampaignIskandar Maulana Zulkarnain100% (1)

- Joachim Meyer, Munich Manuscript Raw TranscriptionDocumento75 páginasJoachim Meyer, Munich Manuscript Raw TranscriptionCarey MillhouseAinda não há avaliações

- D. Layout, Composing, Printing, Presses, Printed Books (Incl. Incunabula, Etc.)Documento94 páginasD. Layout, Composing, Printing, Presses, Printed Books (Incl. Incunabula, Etc.)anabelaanapaz0% (1)

- By: Devon Miller: @anotherdayin3rdgradeDocumento16 páginasBy: Devon Miller: @anotherdayin3rdgradeKeira GarruchoAinda não há avaliações

- Lesson 3-CITATION STYLESDocumento3 páginasLesson 3-CITATION STYLESDaniel KellyAinda não há avaliações

- The City in The Islamic World (2 Vols.)Documento1 páginaThe City in The Islamic World (2 Vols.)Nuri Zganka RekikAinda não há avaliações

- Book 1Documento12 páginasBook 1Zen M. De PaduaAinda não há avaliações

- Project Management Journal ListDocumento4 páginasProject Management Journal ListvicaschendeAinda não há avaliações

- OsoPandaColgado VitaliStore ParedDocumento24 páginasOsoPandaColgado VitaliStore ParedCristhian Velasquez PerezAinda não há avaliações

- Ma (MCJ)Documento12 páginasMa (MCJ)jcssraviAinda não há avaliações

- Music Magazine Front Cover Analysis - We Love PopDocumento2 páginasMusic Magazine Front Cover Analysis - We Love PopTom SolisAinda não há avaliações

- Advantages of Using The InternetDocumento4 páginasAdvantages of Using The InternetqiulimAinda não há avaliações

- I Got My Dream Job So Can YouDocumento9 páginasI Got My Dream Job So Can YouSteveMastersAinda não há avaliações

- IPL Batch 1 Case DigestDocumento8 páginasIPL Batch 1 Case DigestDaryl Noel TejanoAinda não há avaliações

- Dubai TV Coverage Summary March '09Documento58 páginasDubai TV Coverage Summary March '09api-27382426Ainda não há avaliações

- Copy Paste Fonts. Choose The Only Option To Retain Text Copy Paste Fonts. Choose The Only Option To Retain TextDocumento26 páginasCopy Paste Fonts. Choose The Only Option To Retain Text Copy Paste Fonts. Choose The Only Option To Retain TextBông BôngAinda não há avaliações

- BJ Alex Chapter 6: SearchDocumento78 páginasBJ Alex Chapter 6: SearchKoopieAinda não há avaliações

- License To Publish Agreement For Conference Proceedings: Author WarrantiesDocumento2 páginasLicense To Publish Agreement For Conference Proceedings: Author WarrantiesBudi AuliaAinda não há avaliações

- Palo - District: Week School Grade Level Subject No. of Modules PrintedDocumento5 páginasPalo - District: Week School Grade Level Subject No. of Modules PrintedEiddik ErepmasAinda não há avaliações

- The Social Groups of Dark Age GreeceDocumento17 páginasThe Social Groups of Dark Age GreeceNikos HarokoposAinda não há avaliações

- Brian Tracy No Excuses Power of Self-DisciplineDocumento4 páginasBrian Tracy No Excuses Power of Self-DisciplineVlad CotfasAinda não há avaliações

- Okir Insight First IssueDocumento100 páginasOkir Insight First IssueOkir Publishing Inc.Ainda não há avaliações

- Collectable SDocumento36 páginasCollectable SCarson Marshall100% (1)