Escolar Documentos

Profissional Documentos

Cultura Documentos

Volvo Penta Genset

Enviado por

afandybaharuddin0 notas0% acharam este documento útil (0 voto)

255 visualizações4 páginasMarine Genset

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoMarine Genset

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

255 visualizações4 páginasVolvo Penta Genset

Enviado por

afandybaharuddinMarine Genset

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

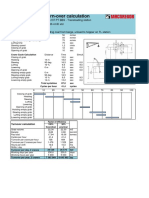

VOLVO PENTA MARINE GENSET

D7A TA

149–163 kVA (119–130 kWe) at 1500 rpm 50 Hz/400V, 156–174 kVA (125–139 kWe) at 1800 rpm 60 Hz/440V

Volvo Penta Genset System

The Volvo Penta Genset systems are the

complete solution for a ship’s onboard power

requirements. From a company dedicated to

the marine industry you not only get reliable

marine diesels, well-matched generators and

a monitoring system, but also a wide range of

other products and services to optimize your

investment.

Each Volvo Penta Genset is factory built

fully adapted to the customer’s requirements

and comes complete with engine, generator

and monitoring system, all tested and ready

for installation onboard. A complete set of

documentation will be delivered with the set

according to Volvo’s high quality publication

standard.

Reliable and powerful

The D7A TA is a highly reliable marine

Genset. The engine and generators are type

approved by all major classification societies

and the complete Genset can be delivered

with complete classification certificates

directly from factory. Well-matched compo-

nents combined with an injection system and

a turbo optimized for Genset applications

provides fast response to load variations.

Easily accessible maintenance points and Safely supported

Robust and silent single side servicing contribute to the ease Volvo Penta has a well-established, well-

A rigid in-line cylinder block with generously of servicing the engine. Liners of wet and trained, network of authorized service deal-

dimensioned crankshaft bearings, together replaceable type, inclined connecting rod ers in more than 100 countries throughout

with water-cooled exhaust manifold and caps and replaceable valve seats make the world. These service centers offer

turbo, are just some of the design features even major maintenance possible to carry Genuine Volvo Penta Parts as well as skilled

making this silent running and sturdy engine. out on-board. service personnel to help you protect your

The owner of a D7A TA not only benefits from investment.

many hours of trouble-free operation, but also

enjoys improved onboard comfort. Technical Data Engine

Engine designation . . . . . . . . . . . . . . . . . . . . . . . . . D7A TA

Economical and service friendly No. of cylinders and configuration. . . . . . . . . . . . . in-line 6

Price is not the only concern when investing Method of operation . . . . . . . . . . . . . . . . . . . . . . . . 4-stroke, direct-injected, turbocharged

in a new Genset. As confirmed by marine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . diesel engine with aftercooler

professionals, it is the operational costs, Bore, mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

such as cost for fuel, spare parts, service and Stroke, mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

maintenance, that make the real difference in Displacement, l . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.15

economy. Compression ratio. . . . . . . . . . . . . . . . . . . . . . . . . . 17.5:1

The D7A TA is equipped with unit pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500 rpm 1800 rpm

that control the fuel distribution for each cyl- Crankshaft Power HE Cooling, kW . . . . . . . . . . . 139 148

inder. Six-hole high-pressure injection nozzles Crankshaft Power KC Cooling, kW. . . . . . . . . . . . 139 148

optimize the fuel-air mixture. This improved Specific fuel consumption, g/kWh. . . . . . . . . . . . . 213 (50%) 220 (50%)

combustion results in high thermal efficiency, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209 (75%) 212 (75%)

low fuel consumption and reduced exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209 (100%) 213 (100%)

emissions. Recommended fuel to conform to. . . . . . . . . . . . . MDO-DMX or MDO-DMA acc. to ISO 8217

Engine certified for. . . . . . . . . . . . . . . . . . . . . . . . . . EU IWW and IMO NOx

10% overload available acc. to class requirements. Fuel temperature 40°C (104°F). Technical data according to ISO 3046 Fuel Stop

Power with a tolerance ±4%. Fuel with a lower calorific value of 42700 kJ/kg and density of 840 g/liter at 15°C (60°F). Merchant

fuel may differ from this specification which will influence engine power output and fuel consumption.

D7A TA

Technical description Keel cooled system (KC) Non classified control system

Complete Genset – 2-circuit keel cooling system – 2-pole 24V system including:

– High system efficiency as a result of well- – Gear-driven pump (LT circuit) – Oil pressure shutdown

matched components – Belt-driven pump (HT circuit) (not for emergency sets)

– Components of highest quality from well – Engine-mounted expansion tank (HT – Oil pressure gauge (optional)

reputed suppliers circuit) – Coolant temp shutdown

– Mono-block engine/generator rigidly Generator (not for emergency sets)

mounted on a common bed frame – Temperature rise class F – Coolant temp gauge (optional)

– Engine directly coupled to generator via a – Tropical insulation class H – Coolant level shutdown

flexplate – Generator equipped with spacious (not for emergency sets)

– Flexible mountings including welding terminal box – Overspeed shutdown

plates mounted under the frame – Stator winding as standard with short – Battery charging alarm

– Total torsion compatibility confirmed by 2/3 pitch winding, ideal for non-linear – Rpm gauge

advanced calculations load (thyristor load) – Hour counter

– Full protection of rotating parts – 4-pole, brushless, AC marine genera- – Instrument panel for second control station

– Set painted in Volvo Penta green tor – Extension cables in different lengths

Engine and block – Dynamically balanced rotor Classified control and monitoring system

– Cylinder block, head and flywheel hous- – Automatic Voltage Regulator (AVR) MCC

ing made of cast iron for accurate voltage regulation – Alarm and monitoring functions according to

– Belt guard – Permanent magnet mounted on gen- classification

– 11.5" flywheel with SAE 2 housing erator for independent power supply – Optional functions on request

– Nitrocarburized transmission gears to AVR – Modbus

– Press-hardened crankshaft – Permanent magnet system to obtain – Configurable inputs and outputs

– Forged aluminum pistons hard performance on motor start and – SDU, shutdown unit, includes all shutdown

– Cylinder liners of wet type to deliver stationary short circuit cur- functions required by classification societies

– Exhaust elbow, dry, with integrated flex- rent Generator

ible compensator – Heavy damper cage for parallel opera- – Air inlet filters according to IP23

Lubrication system tion and very low subtransient reac- – Droop-kit

– Oil filler in valve cover tance values – Thermistors mounted in generator (1 or 2

– Manual oil drain pump – Single bearing generator as standard per phase) for temperature measurement of

– Lubrication oil pump of rotor type – Windings are 12 wire reconnectable windings in generator including relays for

– Freshwater-cooled oil cooler – Voltage available range up to 690V potential free contacts

– Full flow oil filters of spin-on type – IP23 enclosure as standard – PT100 elements mounted in generator

– Closed crankcase ventilation system – Anti condensation heating (1 or 2 per phase) for temperature measure-

Fuel system Optional equipment ment of windings in generator

– Fuel feed pump Engine Miscellaneous

– Jacketed fuel pipes – Twin oil filter with change over valve – Engine heater 230V/820W

– Fine fuel filter of spin-on type – GAC electronic governor – Batteries 14V/140A

– Unit pumps – Single or twin fuel/water separating – Battery charger

– Six-hole injectors pre filter – Synchronization unit (for GAC system)

– Mechanical governor with smoke delimiter – Twin fuel filters – Load sharing unit (for GAC system)

– Fuel stopping solenoid 24V – Silencer, dry, with or without spark ar- – 2-pole 28V/55A alternator

Heat Exchanger cooled system (HE) restor – Spare parts according to classification rec-

– For seawater-cooled Gensets – Electrical or air starting systems avail- ommendations

– V-belt-driven freshwater pump able Contact your local Volvo Penta dealer for further information.

– Gear-driven seawater pump – Kit to connect both HT and LT togeth- Not all models, standard equipment and accessories are available in

all countries. All specifications are subject to change without notice.

– Engine-mounted tubular heat exchanger er into a 1.5-circuit system including The engine illustrated may not be entirely identical to production

with integrated expansion tank engine mounted expansion tank standard engines.

Control and monitoring system MCC

Volvo Penta MCC system is an engine control an RS232 port and a standard Modbus protocol

and monitoring system designed specially or via any of the large number of potential free

to meet the demanding needs of the marine contacts. All actions are displayed with text mes-

commercial market for both electronically and sages, in any specified language, and logged

mechanically controlled engines. The system is according to running hours of occurrence in a

easily integrated into the ship’s control system. non-erasable memory. The unit provides a highly

All readings are displayed both as horizontal flexible solution, featuring configurable inputs and

bars and as digital values on the MCU adjust- outputs, allowing the controller to be customized

able graphical LCD screen. The MCU interfac- to a particular application or requirement without

es with the ship’s computer system either via complicated programming.

D7A TA

Technical Data HE Genset

Power output at 1500 rpm 50Hz/400V, kVA (kWe) Dimensions L x W x H1/H2 (mm), not for installation

D7A TA / UCM274G-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . 149 (119) D7A TA / UCM274F-1. . . . . . . . . . . . . . 2191 x 1157 x 1275/1614

D7A TA / UCM274H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163 (130) D7A TA / UCM274G-1. . . . . . . . . . . . . . 2239 x 1157 x 1275/1614

Power output at 1800 rpm 60Hz/440V, kVA (kWe) D7A TA / UCM274H-1. . . . . . . . . . . . . . 2275 x 1157 x 1275/1614

D7A TA / UCM274F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 (125) Dry weight, kg

D7A TA / UCM274H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 (139) D7A TA / UCM274F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1560

10% overload available according to class requirements. D7A TA / UCM274G-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1610

Fuel temperature 40°C (104°F). Technical data according to ISO 3046 Fuel Stop Power and ISO

8665. Fuel with a lower calorific value of 42700 kJ/kg and density of 840 g/liter at 15°C (60°F). D7A TA / UCM274H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1660

Merchant fuel may differ from this specification which will influence engine power output and fuel H1 = Height including exhaust compensator

consumption. H2 = Total genset height including control box

Technical Data KC Genset

Power output at 1500 rpm 50Hz/400V, kVA (kWe) Dimensions L x W x H1/H2 (mm), not for installation

D7A TA / UCM274G-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . 149 (119) D7A TA / UCM274F-1. . . . . . . . . . . . . . 2154 x 1157 x 1275/1614

D7A TA / UCM274H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163 (130) D7A TA / UCM274G-1. . . . . . . . . . . . . . 2204 x 1157 x 1275/1614

Power output at 1800 rpm 60Hz/440V, kVA (kWe) D7A TA / UCM274H-1. . . . . . . . . . . . . . 2240 x 1157 x 1275/1614

D7A TA / UCM274F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 (125) Dry weight, kg

D7A TA / UCM274H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 (139) D7A TA / UCM274F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1540

10% overload available according to class requirements. D7A TA / UCM274G-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1590

Fuel temperature 40°C (104°F). Technical data according to ISO 3046 Fuel Stop Power and ISO

8665. Fuel with a lower calorific value of 42700 kJ/kg and density of 840 g/liter at 15°C (60°F). D7A TA / UCM274H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1640

Merchant fuel may differ from this specification which will influence engine power output and fuel H1 = Height including exhaust compensator

consumption. H2 = Total genset height including control box

D7A TA

7748596 English 06-2012. © 2012 AB Volvo Penta.

AB Volvo Penta

SE-405 08 Göteborg, Sweden

www.volvopenta.com

Você também pode gostar

- TAD1242GEDocumento14 páginasTAD1242GESIVARAMANJAGANATHANAinda não há avaliações

- Bollard Pull Test ProcedureDocumento8 páginasBollard Pull Test ProcedureMey Rudy100% (2)

- Volvo Penta D7 at GensetDocumento4 páginasVolvo Penta D7 at GensetEser75% (4)

- Datos Tecnicos de Proveedor - Volvo Penta TAMD122A PDFDocumento2 páginasDatos Tecnicos de Proveedor - Volvo Penta TAMD122A PDFErik Rosado Alvarado0% (1)

- Tad1241ge PDFDocumento14 páginasTad1241ge PDFMasum uddin mondolAinda não há avaliações

- 3406Documento4 páginas3406Ivan Morel100% (2)

- TAD1641GE: Volvo Penta Genset EngineDocumento2 páginasTAD1641GE: Volvo Penta Genset EnginesIMPEX sHARMAAinda não há avaliações

- Yanmar 6AYM WET DatasheetDocumento2 páginasYanmar 6AYM WET Datasheetafandybaharuddin100% (4)

- Electrical GuidelinesDocumento2 páginasElectrical GuidelinesDivyam KhandelwalAinda não há avaliações

- GenSet Velvo Penta D7A TDocumento4 páginasGenSet Velvo Penta D7A TPlingu Razvan100% (2)

- D7a Ta - Ucm274f - 3Documento4 páginasD7a Ta - Ucm274f - 3ozakyus100% (1)

- D5A-A T GensetDocumento4 páginasD5A-A T Gensetknp2809Ainda não há avaliações

- D9 MG GensetDocumento4 páginasD9 MG GensetAji HandokoAinda não há avaliações

- CAT Engine Specifications: 3516B Offshore Generator SetDocumento6 páginasCAT Engine Specifications: 3516B Offshore Generator SetKarel GómezAinda não há avaliações

- XQ Trailer Spec SheetDocumento6 páginasXQ Trailer Spec Sheetmohammad hazbehzadAinda não há avaliações

- Volvo TWD1643GE - 613 KW PDFDocumento2 páginasVolvo TWD1643GE - 613 KW PDFvictoros27Ainda não há avaliações

- Volvo Twd1643ge Technical Data PDFDocumento2 páginasVolvo Twd1643ge Technical Data PDFMuhammad rizkiAinda não há avaliações

- Volvo EngineDocumento63 páginasVolvo EngineFCDSGN100% (1)

- TAD941GEDocumento2 páginasTAD941GEjesus silvaAinda não há avaliações

- CAT Engine Specifications: 3508B Offshore Emergency Generator SetDocumento6 páginasCAT Engine Specifications: 3508B Offshore Emergency Generator SetGazAinda não há avaliações

- TAMD163PDocumento2 páginasTAMD163PdimasanggararobertsonAinda não há avaliações

- Lehw0067 01Documento6 páginasLehw0067 01majed al.madhajiAinda não há avaliações

- D5A Ta: Volvo Penta Inboard DieselDocumento2 páginasD5A Ta: Volvo Penta Inboard DieselTerah Pio100% (1)

- Tad 1240 GeDocumento2 páginasTad 1240 GeFedor GrigorievAinda não há avaliações

- Lehw0124 01Documento6 páginasLehw0124 01Hosam HamdyAinda não há avaliações

- TMD 22 PDocumento2 páginasTMD 22 PdeepakgkdAinda não há avaliações

- Tad1642ge PDFDocumento16 páginasTad1642ge PDFWallace Ferreira100% (1)

- Tad1242ge PDFDocumento2 páginasTad1242ge PDFCharl PietersenAinda não há avaliações

- TAD1241GE: Volvo Penta Genset EngineDocumento2 páginasTAD1241GE: Volvo Penta Genset EngineMuhammad rizki100% (1)

- TWD1240VE: Volvo Penta Industrial DieselDocumento2 páginasTWD1240VE: Volvo Penta Industrial DieseladiAinda não há avaliações

- TWD1643GE: Volvo Penta Genset EngineDocumento2 páginasTWD1643GE: Volvo Penta Genset Enginemohsen_cumminsAinda não há avaliações

- TAMD22P Specs SheetDocumento2 páginasTAMD22P Specs SheetdanielAinda não há avaliações

- Tamd 74 LDocumento2 páginasTamd 74 LNaresh SookdeoAinda não há avaliações

- Lehw0013 01Documento4 páginasLehw0013 01ingcalderonAinda não há avaliações

- 1010KVADocumento6 páginas1010KVAK RameshAinda não há avaliações

- Brochure TAD760VE VolvoDocumento2 páginasBrochure TAD760VE VolvoNoer RachAinda não há avaliações

- TAD760VE: Volvo Penta Industrial DieselDocumento2 páginasTAD760VE: Volvo Penta Industrial DieselDatAinda não há avaliações

- Volvo Penta Tamd74cedcDocumento2 páginasVolvo Penta Tamd74cedcElvys Jose Linares BriceñoAinda não há avaliações

- TAD1640GE: Volvo Penta Genset EngineDocumento2 páginasTAD1640GE: Volvo Penta Genset EngineRenzo zuñiga ahon100% (1)

- CAT Engine Specifications: C32 Acert Petroleum EngineDocumento4 páginasCAT Engine Specifications: C32 Acert Petroleum EngineArvind HarryAinda não há avaliações

- Tad1242ge Tad1242geDocumento2 páginasTad1242ge Tad1242gesabujAinda não há avaliações

- D7C Ta: Volvo Penta Inboard DieselDocumento2 páginasD7C Ta: Volvo Penta Inboard DieselAhmet GelisliAinda não há avaliações

- Engine Volvo Penta Tad1641veDocumento2 páginasEngine Volvo Penta Tad1641veRohit Om TiwariAinda não há avaliações

- Tad734ge PDFDocumento2 páginasTad734ge PDFmaherAinda não há avaliações

- 3512 Land Electric - LEHW0066-00 P2Documento4 páginas3512 Land Electric - LEHW0066-00 P2AustinAinda não há avaliações

- TAD1641GE: Volvo Penta Genset EngineDocumento2 páginasTAD1641GE: Volvo Penta Genset EngineHenry PabloAinda não há avaliações

- 3306 164-200KW PRDocumento4 páginas3306 164-200KW PRvanaselvan vpAinda não há avaliações

- Cartepillar C32 Diesel Oilfield Generator SetDocumento4 páginasCartepillar C32 Diesel Oilfield Generator SetJesus Enrique Figueroa GilAinda não há avaliações

- TAD941GE: Volvo Penta Industrial DieselDocumento2 páginasTAD941GE: Volvo Penta Industrial DieselGiangDoAinda não há avaliações

- A4-C13 Engine Aug2013Documento2 páginasA4-C13 Engine Aug2013Brayan Villanueva VillenaAinda não há avaliações

- CaterpillarDocumento4 páginasCaterpillarrobert_candra_tarunaAinda não há avaliações

- Tad1641ge PDFDocumento2 páginasTad1641ge PDFjuanAinda não há avaliações

- Generador Cat 3512bDocumento4 páginasGenerador Cat 3512bcarlucido247970Ainda não há avaliações

- Microsoft Word - 3516B XQ2000 Spec Sheet-Corpolec Rev3Documento9 páginasMicrosoft Word - 3516B XQ2000 Spec Sheet-Corpolec Rev3AlbertoAinda não há avaliações

- Datasheet G3516 1200 RPMDocumento4 páginasDatasheet G3516 1200 RPMVerita SanjuánAinda não há avaliações

- Caterpillar XQ600 Containerized Diesel Generator SetDocumento6 páginasCaterpillar XQ600 Containerized Diesel Generator SetMacAllister MachineryAinda não há avaliações

- TAD1343GE: Volvo Penta Genset EngineDocumento2 páginasTAD1343GE: Volvo Penta Genset EngineAndres SorinAinda não há avaliações

- Lehm4965-01 c9 Ficha TecnicaDocumento2 páginasLehm4965-01 c9 Ficha TecnicaDavid.QuijanoAinda não há avaliações

- VOLVO TAD 1341 GE 300 Kva PDFDocumento2 páginasVOLVO TAD 1341 GE 300 Kva PDFluislunar0% (2)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesAinda não há avaliações

- 6W126S Baudouin PDFDocumento95 páginas6W126S Baudouin PDFafandybaharuddinAinda não há avaliações

- We Supply Complete Transloading Solutions. Why Make Life Complicated?Documento1 páginaWe Supply Complete Transloading Solutions. Why Make Life Complicated?afandybaharuddinAinda não há avaliações

- Baudouin GensetDocumento2 páginasBaudouin GensetafandybaharuddinAinda não há avaliações

- Turnover and Load Cycle - Transloading Station 2xK3030 + SULDocumento1 páginaTurnover and Load Cycle - Transloading Station 2xK3030 + SULafandybaharuddinAinda não há avaliações

- Adaro Ship Plate WH Mill CertDocumento1 páginaAdaro Ship Plate WH Mill CertafandybaharuddinAinda não há avaliações

- Payload Calculation Adaro 250FTDocumento1 páginaPayload Calculation Adaro 250FTafandybaharuddinAinda não há avaliações

- 12aym WetDocumento2 páginas12aym Wetghyd artiagaAinda não há avaliações

- 12aym WetDocumento2 páginas12aym Wetghyd artiagaAinda não há avaliações

- List of Approved Manufacturer 871219 PopojiDocumento26 páginasList of Approved Manufacturer 871219 PopojiafandybaharuddinAinda não há avaliações

- I More QuestDocumento1 páginaI More QuestafandybaharuddinAinda não há avaliações

- A-1000 Series Amplifiers BrochureDocumento2 páginasA-1000 Series Amplifiers BrochureafandybaharuddinAinda não há avaliações

- Fast PlotDocumento2 páginasFast PlotafandybaharuddinAinda não há avaliações

- Piping MarkingDocumento18 páginasPiping MarkingafandybaharuddinAinda não há avaliações

- Yanmar Marine EngineDocumento2 páginasYanmar Marine EngineafandybaharuddinAinda não há avaliações

- Exam 2 Package ADocumento2 páginasExam 2 Package AafandybaharuddinAinda não há avaliações

- Call For Yanmar Solutions: Medium Speed Diesel EnginesDocumento44 páginasCall For Yanmar Solutions: Medium Speed Diesel EnginesBaher SalehAinda não há avaliações

- List Electrical Cable LCTDocumento1 páginaList Electrical Cable LCTafandybaharuddinAinda não há avaliações

- Request Sea Trial Hull 147Documento2 páginasRequest Sea Trial Hull 147afandybaharuddinAinda não há avaliações

- Hydrostatic and Bonjean CurveDocumento19 páginasHydrostatic and Bonjean CurveafandybaharuddinAinda não há avaliações

- Independent & Linked Rudders SystemDocumento1 páginaIndependent & Linked Rudders SystemafandybaharuddinAinda não há avaliações

- Configuring SQL Server 2005 For Use With ShipConstructor - ShipConstructor Knowledge Base - ShipConstructor KnowledgebaseDocumento8 páginasConfiguring SQL Server 2005 For Use With ShipConstructor - ShipConstructor Knowledge Base - ShipConstructor KnowledgebaseafandybaharuddinAinda não há avaliações

- Pedoman Gaji IDocumento28 páginasPedoman Gaji IRezi Darma SetiawanAinda não há avaliações

- Tech Specification 3500 MT SPOBDocumento26 páginasTech Specification 3500 MT SPOBafandybaharuddinAinda não há avaliações

- YANMAR marineAuxiliaryDieselEnginesDocumento4 páginasYANMAR marineAuxiliaryDieselEnginesafandybaharuddinAinda não há avaliações

- Pedoman Gaji IDocumento28 páginasPedoman Gaji IRezi Darma SetiawanAinda não há avaliações

- Request Leaking Test Pipa Hull 150Documento2 páginasRequest Leaking Test Pipa Hull 150afandybaharuddin100% (1)

- Detail of Flywheel: 4CHL-4CHL-TN - R2011-1.dwgDocumento1 páginaDetail of Flywheel: 4CHL-4CHL-TN - R2011-1.dwgafandybaharuddinAinda não há avaliações

- Short Circuit in Power System: Technical Colloquium Indonesia PLN - ABBDocumento43 páginasShort Circuit in Power System: Technical Colloquium Indonesia PLN - ABBCristian Aguilar QuintanillaAinda não há avaliações

- Evaluation The High Voltage Gas Insulated Substations (GIS) Based On Flashovers in The 220 KV SwitchgearsDocumento8 páginasEvaluation The High Voltage Gas Insulated Substations (GIS) Based On Flashovers in The 220 KV SwitchgearsAjay SantiAinda não há avaliações

- Electrical Engineering Portal - Com Principles For Controlling HarmonicsDocumento3 páginasElectrical Engineering Portal - Com Principles For Controlling HarmonicsRobert GalarzaAinda não há avaliações

- Byron Inspection 2018Documento32 páginasByron Inspection 2018FACULTY / LITAinda não há avaliações

- Target True Zero Foundations For Battery and Hydrogen Powered FlightDocumento31 páginasTarget True Zero Foundations For Battery and Hydrogen Powered FlightIoannis BoukisAinda não há avaliações

- Electrical DesignDocumento39 páginasElectrical DesignJemal Musa100% (1)

- V112-3.0 MW - VestasDocumento20 páginasV112-3.0 MW - Vestasjamesr277272Ainda não há avaliações

- Schneider Electric - PowerLogic-PM5000-series - METSEPM5310Documento4 páginasSchneider Electric - PowerLogic-PM5000-series - METSEPM5310X X ChongAinda não há avaliações

- Copenhagen Energy Vision 2050Documento126 páginasCopenhagen Energy Vision 2050Paula EscobarAinda não há avaliações

- Galaxy PW Muti Module Technical SpecsDocumento30 páginasGalaxy PW Muti Module Technical SpecsRUBEN LOZANOAinda não há avaliações

- Ee2302 - Electrical Machines Ii: Om SathiDocumento17 páginasEe2302 - Electrical Machines Ii: Om SathikesavantAinda não há avaliações

- Assessment of Solar and Wind Resource Synergy in AustraliaDocumento14 páginasAssessment of Solar and Wind Resource Synergy in AustraliaEbub eAinda não há avaliações

- Multifunction Power Supply For Embedded SystemDocumento16 páginasMultifunction Power Supply For Embedded SystemPrabhat PatelAinda não há avaliações

- DC Power SourcesDocumento50 páginasDC Power SourcesZay YarAinda não há avaliações

- A True History of Oil and GasDocumento2 páginasA True History of Oil and GasKaiysse YoukéAinda não há avaliações

- 2 Numericals On Energy Transfer in TMDocumento2 páginas2 Numericals On Energy Transfer in TMRahulAinda não há avaliações

- Work and EnergyDocumento14 páginasWork and Energyroque porcelAinda não há avaliações

- Ski Trip Guided Practice 3Documento3 páginasSki Trip Guided Practice 3api-3813919510% (1)

- Alex Epstein - Moral Case For Fossil Fuels SummaryDocumento2 páginasAlex Epstein - Moral Case For Fossil Fuels SummaryIsaac LewisAinda não há avaliações

- Power Generation & Water Balancing SystemDocumento20 páginasPower Generation & Water Balancing SystemnamakAinda não há avaliações

- 2 TTTGDocumento2 páginas2 TTTGAbebawBelayAinda não há avaliações

- Turbine Operation Manual QN1 SEC G 04 TP 002Documento173 páginasTurbine Operation Manual QN1 SEC G 04 TP 002Bui Vanluong100% (2)

- Materi Sosialisasi Juknis PTB - 0021 - 18102022 - ShareDocumento50 páginasMateri Sosialisasi Juknis PTB - 0021 - 18102022 - ShareUtomo FebbyAinda não há avaliações

- Madhya Pradesh Upkar Adhiniyam, 1981 PDFDocumento22 páginasMadhya Pradesh Upkar Adhiniyam, 1981 PDFLatest Laws TeamAinda não há avaliações

- UL 1077 Series: Miniatur e Cir Cuit BR EakersDocumento11 páginasUL 1077 Series: Miniatur e Cir Cuit BR EakersjohnAinda não há avaliações

- Geep 114Documento5 páginasGeep 114friendkwtAinda não há avaliações

- Zinc Oxide Surge Arrester PEXLIM Q-Y: Brief Performance DataDocumento7 páginasZinc Oxide Surge Arrester PEXLIM Q-Y: Brief Performance DatawiznuvAinda não há avaliações

- HW07Documento8 páginasHW07raulernesto28Ainda não há avaliações

- How Does A Wind Turbine Work - WRDocumento4 páginasHow Does A Wind Turbine Work - WRGillianne Mae VargasAinda não há avaliações