Escolar Documentos

Profissional Documentos

Cultura Documentos

Reactomate Valve

Enviado por

ibkhiDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Reactomate Valve

Enviado por

ibkhiDireitos autorais:

Formatos disponíveis

Data Sheet 810183-01

Issue Date: 04/06

Continuous Blowdown Valves

Reactomats

BA 28, BA 29, BA 210, BA 211

PN 63 – 320, DN 25 mm (1")

Description Connections

The valve is connected to the water space of the boiler. Butt-weld ends for pipe according to DIN 2448:

Precise adjustment of blowdown rate by turning regulating 30 x 2.6 to 4.5

lever on the calibrated scale plate (see charts on back page). 31.8 x 2.6 to 5

With the regulating lever in blow-off position the capacity is 33.7 x 3.6 to 6.3

approximately three times the capacity at scale division 100. 38 x 5.6 to 8

The BA includes a sampling valve for checking the boiler-wa- ANSI B 36.10: 1" Schedule 80 and 160

ter concentration. Other dimensions or weld-neck flanges on request at extra

cost.

Application

Continuous blowdown of steam boilers, evaporators, quench Design

coolers and similar installations. Regulating or dosing valve Straight-through valves with butt-weld ends, weld-neck

for all industries. flanges at extra cost. With GESTRA stage-nozzle, regulating

BA 28 – BA 211 lever, calibrated scale and sampling valve.

On request with electric actuator as BAE 28 – 211.

Range

If used as continuous blowdown valve (at saturation temperature):

BA 28 max. 63 bar g (915 psig)

BA 29 max. 94 bar g (1360 psig)

BA 210 max. 142 bar g (2060 psig)

BA 211 max. 226 bar g (3280 psig)

Max. temperature °C 120 200 250 300 350 400 450 500 530

BA 28 PN 63/100 barg 100 80 70 60 56 50 – – –

psig 1450 1160 1015 870 810 725 – – –

Max.

BA 29 PN 160*) barg 160 130 112 96 90 80 – – –

service

psig 2320 1885 1625 1390 1305 1160 – – –

pressure

BA 210 PN 250*) barg 250 200 175 150 140 125 – – –

psig 3625 2900 2540 2175 2030 1810 – – –

BA 211 PN 320*) barg 320 320 320 320 304 292 278 237 124

psig 4640 4640 4640 4640 4410 4235 4030 3435 1800

*) For relatively small capacities (see charts) use BA 29k, 210k or 211k with special stage nozzle.

Materials Order Specifications

BA 28 Valve type, nominal pressure (PN), nominal size (DN), c apacity,

Body (two parts): forged steel C 22.8 (No. 1.0460 DIN) service pressure, back pressure, fluid, application (e.g. type

Nozzle insert: cast stainless steel G-X 22 CrMoV 12 1 of boiler).

(1.4931) The following test certificates can be issued on request, at

Stage nozzle: stainless steel C 20 Cr 13 (1.4021) extra cost:

BA 29 In accordance with EN 10204-2.1, -2.2, -3.1A, -3.1B and

Body (two parts): C 22.8 (1.0460) -3.1C.

Nozzle insert*): G-X 22 CrMoV 12 1 (1.4931)

All inspection requirements have to be stated with the order.

Stage nozzle*): stainless steel X 8 CrTi 17 (1.4510)

After supply of the equipment certification cannot be esta-

BA 210 blished. For tests and inspection charges please consult us.

Lower-body part: C 22.8 (1.0460)

Upper-body part*): C 22.8 (1.0460) Enquiry Specification

Nozzle insert*): G-X 22 CrMoV 12 1 (1.4931)

Stage nozzle*): X 8 CrTi 17 (1.4510) Reactomats (continuous blowdown valves) with GESTRA

stage nozzle, regulating lever, calibrated scale and sampling

BA 211

valve.

Lower-body part: forged alloy steel 13 CrMo 44 (1.7335)

Upper-body part*): 13 CrMo 44 (1.7335) Application (optional) as continuous blowdown valve for steam

Nozzle insert*): G-X 22 CrMoV 12 1 (1.4931) boilers, evaporators and similar installations or as regulating/

Stage nozzle*): X 8 CrTi 17 (1.4510) dosing valve.

Indications on nominal pressure (PN), nominal size (DN), type

*) additionally armoured of connection, service pressure, back pressure, temperature,

fluid, application (e.g. type of boiler).

Continuous Blowdown Valves Types, Capacity, Scale Division Scale divisions for required capacity (blow-down quantity)

see charts.

Reactomats In blow-off position (regulating lever against stop) the ca-

BA 28, BA 29, BA 210, BA 211 Selection of valve type according to pressure and temperature pacity is approximately three times the capacity at scale

see under “Range”. division 100.

PN 63 – 320, DN 25 mm (1")

Chart 1: BA 28, 29, 210, 211 Differential pressure *)

Dimensions

BA 28 – 211 (approx. weight 21 kg)

max. 285

Hot-water capacity

Scale divisions

180

300 1)

For relatively small quantities (see dotted lines in chart) use BA 29k, 210k or 211k (with special stage nozzle).

Scale divisions according to chart 2.

2)

If the quantity of boiler water to be discharged is higher than the values covered by chart 1, GESTRA Reactomats

BA 39 with radial stage nozzle should be used.

128

Chart 2: BA 29k, 210k, 211k Differential pressure *)

Sampling valve with compression fitting 8 mm O.D.

∅ 120

220

Hot-water capacity

Scale divisions

*) Differential pressure (working pressure) = Inlet minus outlet pressure.

If the boiler water is lifted after the Reactomat, the differential pressure is reduced by approximately 1 bar for 7 m

(or 2 psi for 3 feet) in lift.

Supply in accordance with our general terms of business.

GESTRA AG

Münchener Straße 77, 28215 Bremen, Germany

Telefon +49 421 3503-0, Telefax +49 421 3503-393

E-mail info@de.gestra.com, Web www.gestra.de

810183-01/406cm · © 1977 GESTRA AG · Bremen · Printed in Germany

Você também pode gostar

- 2018 COE Troubleshooting 1 - ENG PDFDocumento886 páginas2018 COE Troubleshooting 1 - ENG PDFThanh Hoang67% (3)

- Lateral Earth Pressure Due To Vibratory Rollers PDFDocumento11 páginasLateral Earth Pressure Due To Vibratory Rollers PDFchutton681Ainda não há avaliações

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- Swimming Pool Calculation: To Calculate Pipe SizingDocumento2 páginasSwimming Pool Calculation: To Calculate Pipe SizingBenjamin YusuphAinda não há avaliações

- Checklist for Separator Tank DrawingDocumento5 páginasChecklist for Separator Tank DrawingRamalingam PrabhakaranAinda não há avaliações

- Keystone Actuator Fig F79U 036Documento8 páginasKeystone Actuator Fig F79U 036Edu SilvaAinda não há avaliações

- Econ Gate ValvesDocumento22 páginasEcon Gate ValvesRiyas Udheen100% (1)

- Machine Installation - Shaft AlignmentDocumento17 páginasMachine Installation - Shaft AlignmentD.b. Tampubolon100% (1)

- Asme B18.2.1 PDFDocumento37 páginasAsme B18.2.1 PDFJUAN C100% (1)

- Process Control Fundamentals 2Documento73 páginasProcess Control Fundamentals 2Otuekong Ukpong100% (2)

- LPG - Pump CatalogueDocumento19 páginasLPG - Pump CataloguepomaukAinda não há avaliações

- Main air compressor specificationsDocumento37 páginasMain air compressor specificationsRK Panchal100% (2)

- PRV - CatalogueDocumento6 páginasPRV - CatalogueSarbendu PaulAinda não há avaliações

- B 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerDocumento11 páginasB 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerpragatheeskAinda não há avaliações

- Centrifugal Pump BrochuresDocumento16 páginasCentrifugal Pump BrochuresAbsar Mamun100% (3)

- m0072942-04 (En-Us) - 00 - Manuals-Service-Modules - SpecificationsDocumento268 páginasm0072942-04 (En-Us) - 00 - Manuals-Service-Modules - Specificationsmostafa aliAinda não há avaliações

- Multistage Centrifugal Pumps HEGA 2502 ... 8009: Technical DataDocumento17 páginasMultistage Centrifugal Pumps HEGA 2502 ... 8009: Technical Datajairo ardilaAinda não há avaliações

- The AICHE Student Pocket HandbookDocumento68 páginasThe AICHE Student Pocket Handbookpapaas100% (1)

- Válvula ContrabalanceDocumento16 páginasVálvula ContrabalanceMauricio Ariel H. Orellana100% (1)

- ZK 29 Control Valve ZK 29 With Radial Stage Nozzle PN 160 DN 25, 50, 80, 100, 150 MM (1, 2, 3, 4, 6")Documento4 páginasZK 29 Control Valve ZK 29 With Radial Stage Nozzle PN 160 DN 25, 50, 80, 100, 150 MM (1, 2, 3, 4, 6")Ilic SlobodanAinda não há avaliações

- Medidor Caudal Kobold BGFDocumento6 páginasMedidor Caudal Kobold BGFBase SistemasAinda não há avaliações

- Data - Sheet Hora CV Act DetailsDocumento2 páginasData - Sheet Hora CV Act DetailsAnand K. MouryaAinda não há avaliações

- Sterling PumpeDocumento20 páginasSterling PumpesrdzaAinda não há avaliações

- Ode Solenoid Valve 21wa3z0b130 - 21wa4z0b130Documento2 páginasOde Solenoid Valve 21wa3z0b130 - 21wa4z0b130Uno MariconAinda não há avaliações

- Bullet Valve Series GuideDocumento2 páginasBullet Valve Series GuideAnthony PecorinoAinda não há avaliações

- HYDAC Pressure Relief Valve Poppet Type, Direct-Acting SAE-8 Cartridge - 420 BarDocumento2 páginasHYDAC Pressure Relief Valve Poppet Type, Direct-Acting SAE-8 Cartridge - 420 Barliftery100% (1)

- 084519xyz Re18307-49Documento2 páginas084519xyz Re18307-49NABEILAinda não há avaliações

- Dfu Ti D148 01 BRDocumento2 páginasDfu Ti D148 01 BRNoo SokiAinda não há avaliações

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDocumento4 páginasData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990Ainda não há avaliações

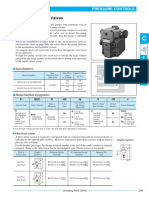

- Unloading Relief Valves: Pressure ControlsDocumento6 páginasUnloading Relief Valves: Pressure ControlsmdkhandaveAinda não há avaliações

- 9900 Series DatasheetDocumento3 páginas9900 Series DatasheetHans HongAinda não há avaliações

- Purga Fondo BBV 980 A PDFDocumento2 páginasPurga Fondo BBV 980 A PDFaugusto7777Ainda não há avaliações

- Swing Check Valve Data Sheet: Comision Federal de ElectricidadDocumento1 páginaSwing Check Valve Data Sheet: Comision Federal de Electricidadjos ToricesAinda não há avaliações

- What does "COLD STRETCHING 冷拉伸"mean?Documento10 páginasWhat does "COLD STRETCHING 冷拉伸"mean?dhaktodesatyajitAinda não há avaliações

- Instruction Manual For Air ReservoirDocumento52 páginasInstruction Manual For Air ReservoirFlo MarineAinda não há avaliações

- KAT A 2410 PA ZETA Pneumatic Edition7!31!01 2013 enDocumento3 páginasKAT A 2410 PA ZETA Pneumatic Edition7!31!01 2013 enGabriela AxinteAinda não há avaliações

- PRV C 101 Data SheetDocumento1 páginaPRV C 101 Data SheetDevit FitriyantoAinda não há avaliações

- Volute Pumps Sihi: SupernovaDocumento10 páginasVolute Pumps Sihi: SupernovaLuis Fernando collazosAinda não há avaliações

- Water Sewage Gas: Plus Gate ValveDocumento4 páginasWater Sewage Gas: Plus Gate ValveAhmedRamadanAinda não há avaliações

- Final Dwg-Sludge Pump-4178Documento93 páginasFinal Dwg-Sludge Pump-4178erol100% (1)

- p128 22 PDFDocumento3 páginasp128 22 PDFFernando CeballosAinda não há avaliações

- Air Trap RL1090 - RL1290Documento2 páginasAir Trap RL1090 - RL1290satphoenixAinda não há avaliações

- Single Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - ZDocumento2 páginasSingle Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - Znemi90Ainda não há avaliações

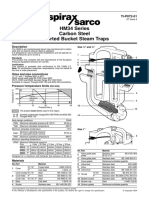

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocumento2 páginasHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaAinda não há avaliações

- Filter Regulator SMC PDFDocumento27 páginasFilter Regulator SMC PDFTuấn Anh NguyễnAinda não há avaliações

- Cryogenic Valves For Industrial Gas Applications-43-44Documento2 páginasCryogenic Valves For Industrial Gas Applications-43-44Abdul Hadi RashidAinda não há avaliações

- Cryogenic Pressure Regulator GuideDocumento4 páginasCryogenic Pressure Regulator GuidedhaktodesatyajitAinda não há avaliações

- Bombas SterlingDocumento19 páginasBombas SterlingGenrry EchaccayaAinda não há avaliações

- Armstrong International SA - Com 80-DC Series Automatic Differential Condensate ControllersDocumento2 páginasArmstrong International SA - Com 80-DC Series Automatic Differential Condensate ControllersWalid SaifAinda não há avaliações

- Sauter B6R Three-Way Valve With Female Thread, PN 16Documento4 páginasSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991Ainda não há avaliações

- ARI StobuDocumento2 páginasARI StobuMoonzeAinda não há avaliações

- 3 Way Sauter ValveDocumento8 páginas3 Way Sauter ValverkssAinda não há avaliações

- Sample Gas Cooler EGK 1/2: Bühler Constant Regulating SystemDocumento4 páginasSample Gas Cooler EGK 1/2: Bühler Constant Regulating SystemFrank LuizAinda não há avaliações

- Bang Head Here PDFDocumento12 páginasBang Head Here PDFhalackAinda não há avaliações

- BMS Safety Controllers and Ignition Components Product Reference GuideDocumento5 páginasBMS Safety Controllers and Ignition Components Product Reference GuideMantproca ComercioAinda não há avaliações

- Bd18 Ficha TecnicaDocumento2 páginasBd18 Ficha TecnicaGorch MarrokoAinda não há avaliações

- Design E-100 GT PMB N GN Kemala 15 MM Main CaseDocumento103 páginasDesign E-100 GT PMB N GN Kemala 15 MM Main Casewahyu hidayatAinda não há avaliações

- Liquip TrapDocumento1 páginaLiquip TrapKhánh TrầnAinda não há avaliações

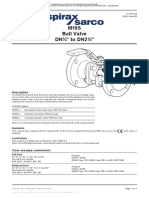

- M10S Ball Valve DN " To DN2 ": DescriptionDocumento7 páginasM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalAinda não há avaliações

- Product Data Sheet WB14 - ENDocumento10 páginasProduct Data Sheet WB14 - ENJairo Javier Díaz MontenegroAinda não há avaliações

- KSB Globe ValvesDocumento2 páginasKSB Globe ValvesvttneverloseAinda não há avaliações

- Wouter Witzel - ECV: Product Data SheetDocumento3 páginasWouter Witzel - ECV: Product Data SheetKristinAinda não há avaliações

- Main Oil PumpsDocumento61 páginasMain Oil PumpsysabeleleuterioAinda não há avaliações

- Valvula Fisher 3490Documento18 páginasValvula Fisher 3490adalberto89Ainda não há avaliações

- Ari Checko V Pn63 - 160Documento8 páginasAri Checko V Pn63 - 160Josue MorenoAinda não há avaliações

- Exhaust Back Pressure CalculationDocumento1 páginaExhaust Back Pressure Calculationccssaa123Ainda não há avaliações

- C PT Catalyst Process Technology: Gerard B. Hawkins Managing Director, CEODocumento24 páginasC PT Catalyst Process Technology: Gerard B. Hawkins Managing Director, CEOibkhiAinda não há avaliações

- Isentropic Process PDFDocumento2 páginasIsentropic Process PDFJeebee Logroño AloAinda não há avaliações

- Benfield SimulationDocumento5 páginasBenfield SimulationDian Risti PurwantiAinda não há avaliações

- Flaring Up World FertilizerDocumento3 páginasFlaring Up World FertilizeribkhiAinda não há avaliações

- Industry Risk Tolerance Criteria Data BenchmarkDocumento3 páginasIndustry Risk Tolerance Criteria Data BenchmarkibkhiAinda não há avaliações

- Una25 PK Ps - enDocumento1 páginaUna25 PK Ps - enhamid vahedil larijaniAinda não há avaliações

- ABB Technical Note - Cooling SystemsDocumento2 páginasABB Technical Note - Cooling SystemsibkhiAinda não há avaliações

- UhdeDocumento9 páginasUhdeibkhiAinda não há avaliações

- Industrial Eng Standards - SCEDocumento12 páginasIndustrial Eng Standards - SCEimran_chaudhryAinda não há avaliações

- ABB Technical Note - Cooling Systems - Lowresf PDFDocumento2 páginasABB Technical Note - Cooling Systems - Lowresf PDFrad1962Ainda não há avaliações

- Storage & TransportationDocumento21 páginasStorage & TransportationibkhiAinda não há avaliações

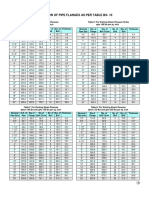

- TablesDocumento17 páginasTablesibkhiAinda não há avaliações

- Game Rules Freshhh 2014Documento33 páginasGame Rules Freshhh 2014kopamkanaleAinda não há avaliações

- Seminarprogramm 1510 enDocumento15 páginasSeminarprogramm 1510 enibkhiAinda não há avaliações

- Mu Basher 20160907 Mop Co Company NoteDocumento8 páginasMu Basher 20160907 Mop Co Company NoteibkhiAinda não há avaliações

- Hydraulic FittingDocumento124 páginasHydraulic FittingDhanraj PatilAinda não há avaliações

- Module 2Documento59 páginasModule 2STEPHEN VILLARUZAinda não há avaliações

- High Head Drainage PumpsDocumento9 páginasHigh Head Drainage PumpsEnrique MurgiaAinda não há avaliações

- 6M33 Maintain ManualDocumento116 páginas6M33 Maintain Manualteknisijarummas1Ainda não há avaliações

- SB E082qbebiconDocumento8 páginasSB E082qbebiconMAZENAinda não há avaliações

- Report 37Documento5 páginasReport 37Abanoub ShakerAinda não há avaliações

- 05 2013 1072 Sredanovic 04 PDFDocumento7 páginas05 2013 1072 Sredanovic 04 PDFOcta RioAinda não há avaliações

- Tugas 07Documento6 páginasTugas 07aingAinda não há avaliações

- Grade Markings For Steel Bolts and ScrewsDocumento3 páginasGrade Markings For Steel Bolts and Screwsrexie2canos8964Ainda não há avaliações

- Speed of Sound Increases With TemperatureDocumento12 páginasSpeed of Sound Increases With TemperatureAdjazent BuildersAinda não há avaliações

- NO. Nama Alat Keterangan Gambar Alat: 1. Actuator PneumaticDocumento28 páginasNO. Nama Alat Keterangan Gambar Alat: 1. Actuator PneumaticVeronica Nina Miyora SitumorangAinda não há avaliações

- Proof Squash BallsDocumento8 páginasProof Squash BallsMarshAinda não há avaliações

- Sarjana Site Visit Schedule-CPPDocumento13 páginasSarjana Site Visit Schedule-CPPSanjay GuptaAinda não há avaliações

- Conveyor ExercisesDocumento26 páginasConveyor ExercisesdanerdrrellAinda não há avaliações

- Konceptualni - Titranje I ValoviDocumento44 páginasKonceptualni - Titranje I ValoviNikolinaAinda não há avaliações

- Final Copy Specific Heat Capacity ExperimentDocumento3 páginasFinal Copy Specific Heat Capacity Experimentjoevic torrecampoAinda não há avaliações

- AMSOIL MCF - Synthetic 10W-40 Motorcycle OilDocumento2 páginasAMSOIL MCF - Synthetic 10W-40 Motorcycle OilamsoildealerAinda não há avaliações

- 15A03402 Kinematics of MachinesDocumento3 páginas15A03402 Kinematics of Machinesrammohan reddyAinda não há avaliações

- PIPE FLANGE DIMENSIONSDocumento5 páginasPIPE FLANGE DIMENSIONSViral ParmarAinda não há avaliações

- Local Scouring Around A Circular Pier in Open ChannelDocumento5 páginasLocal Scouring Around A Circular Pier in Open Channelomed muhammadAinda não há avaliações

- ColumnsDocumento66 páginasColumnsArchana GSAinda não há avaliações

- Liebherr Model 64 GrappleDocumento14 páginasLiebherr Model 64 GrappleLiebherr100% (1)

- Article 162Documento10 páginasArticle 162Zoran PanicAinda não há avaliações