Escolar Documentos

Profissional Documentos

Cultura Documentos

Corrosion Rings

Enviado por

Anonymous JMuM0E5YODescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Corrosion Rings

Enviado por

Anonymous JMuM0E5YODireitos autorais:

Formatos disponíveis

Corrosion Rings

GENERAL SPECIFICATIONS

Corrosion rings are designed to measure the Typically manufactured from steel with similar

corrosive effects of drilling fluid environments on drill chemical and mechanical properties as drill pipe,

pipe. Due to the extremely corrosive conditions every ring has a machined finish and a stamped serial

present when drilling, including erosion from high number linking it to its initial weight stored in the

sand content, sudden wall failures leading to blowouts Caproco database. Each corrosion ring comes

can occur. They are particularly valuable in locations individually packaged in a vapor-inhibiting envelope

containing sour gas, oxygenated fluids and salt water. to prevent atmospheric corrosion. Plastic insulated

rings are also available upon request.

Corrosion rings are an economical and accurate

method of monitoring drill pipe condition during

drilling operations, and help in evaluating the

effectiveness of corrosion inhibitor treatment

programs. Examining scale and pitting on the

exposed rings can help in identifying the causes of

corrosion and aid in selecting proper mitigation

techniques.

APPLICATION Due to the variation in drill pipe box sizes,

Caproco offers corrosion rings in a variety of sizes

It is recommended to use corrosion rings in sets

and will custom manufacture rings to customer

of two, locating them at the top and bottom of the drill

specifications. Post-exposure corrosion ring analysis

string. The first ring is sized to fit in the tool box

is available, which includes accurate re-weighing,

recess of the first single above the crossover sub.

visual and pitting analysis and mpy wall-loss

The second ring is placed in the box end of the first

calculations provided in a concise report.

single below the kelly saver sub. Note that both

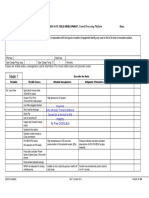

boxes should be cleaned and clean dry gloves used DRILL PIPE SIZE & TYPE PART NUMBER

during installation of the corrosion rings. The rings 2 f" SL-H90 35010

are sized to have the same bore as that of the tool

joint to minimize turbulence effects. 2 f" Internal Flush &

35005

3 ½" Slim Hole

Corrosion rings should be kept in the drill string for 3 ½" Extra Hole &

a minimum of 40 hours, as exposure periods shorter 35007

3 ½" Full Hole

than this may show unusually high initial corrosion

3 ½" Internal Flush &

rates. They can be left in for more than one bit run. 11523

3 ½" Extra Hole

Rings are typically in place for two to ten days,

depending on the corrosiveness of the environment. 4" Full Hole 35004

4" Internal Flush &

Drilling conditions during exposure should be 11526

4 ½" Extra Hole

recorded, including: ring serial number, drilling fluid

properties, chemicals additives, location of ring in the 4 ½" Full Hole 35002

drill string, initial weight, time in, depth in, depth out, 4 ½" Internal Flush &

35003

time out, % of sand and solids, color of scale and any 5" Extra Hole

general remarks. Once removed, the rings should be 9

5 /16" & 5 ½" API Regular &

placed in their original envelopes and sent in for 35006

Full Hole 6 e" API Regular

analysis.

5" XH Tool Joint 35009

CONTACT CAPROCO FOR ALTERNATE SIZING & MATERIAL OPTIONS

Você também pode gostar

- Flat RheologyDocumento16 páginasFlat RheologyAnonymous JMuM0E5YOAinda não há avaliações

- Shearing Blind Rams SBRDocumento8 páginasShearing Blind Rams SBRDavid OrtegaAinda não há avaliações

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- SA Roofing Cladding Section 3 PDFDocumento37 páginasSA Roofing Cladding Section 3 PDFharishram123456Ainda não há avaliações

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopNo EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopNota: 4.5 de 5 estrelas4.5/5 (2)

- Horizontal Well Drill String DesignDocumento27 páginasHorizontal Well Drill String DesignTarek HassanAinda não há avaliações

- CAT Hydraulic SystemsDocumento4 páginasCAT Hydraulic Systemsjimmy gomezAinda não há avaliações

- H2S Contingency PlanDocumento33 páginasH2S Contingency PlanAnonymous JMuM0E5YO100% (1)

- Bomba Vertical Krebs 3x3Documento48 páginasBomba Vertical Krebs 3x3juan carrizoAinda não há avaliações

- GASKET - DESIGN - & - BOLTING Kamprofile PDFDocumento77 páginasGASKET - DESIGN - & - BOLTING Kamprofile PDFPranpath NarupantawartAinda não há avaliações

- Swagelok ValveDocumento24 páginasSwagelok ValveSyahirul AlimAinda não há avaliações

- Catalogue - VIT PDFDocumento69 páginasCatalogue - VIT PDFNam Hoàng VõAinda não há avaliações

- Well Control HamiltonDocumento80 páginasWell Control HamiltonAnonymous JMuM0E5YO100% (2)

- 30 Mainline Hydrotesting 111Documento25 páginas30 Mainline Hydrotesting 111rexAinda não há avaliações

- Completion Fluids Displacement and Cementing SpacersDocumento18 páginasCompletion Fluids Displacement and Cementing SpacersAnonymous JMuM0E5YOAinda não há avaliações

- Hazop Worksheet Suggested ScenariosDocumento16 páginasHazop Worksheet Suggested ScenariosJagan BoseAinda não há avaliações

- Rockwool 159Documento37 páginasRockwool 159ashish2783Ainda não há avaliações

- Bowel Mill Inspection Guide LineDocumento10 páginasBowel Mill Inspection Guide Linesen_subhasis_58Ainda não há avaliações

- HPWBM Exceeds SBMDocumento7 páginasHPWBM Exceeds SBMAnonymous JMuM0E5YOAinda não há avaliações

- Catalogo 3700-8th Iom LoresDocumento80 páginasCatalogo 3700-8th Iom LoresChristian Fabian Altahona Piñeres100% (1)

- Plugs and Profiles: - Types - Running - Pulling - ProblemsDocumento43 páginasPlugs and Profiles: - Types - Running - Pulling - Problemsdriller22Ainda não há avaliações

- AUH Cabinet Decision No. 13 of 2009 - EN PDFDocumento26 páginasAUH Cabinet Decision No. 13 of 2009 - EN PDFmohamednavavi50% (2)

- Broco ExplaningDocumento3 páginasBroco Explaningsequeiradiver1Ainda não há avaliações

- Tubulars and Tubular Services Catalog: DrilcoDocumento29 páginasTubulars and Tubular Services Catalog: DrilcoDoni KurniawanAinda não há avaliações

- Barrenas e Hidraulica de Perforación PDFDocumento143 páginasBarrenas e Hidraulica de Perforación PDFAnonymous JMuM0E5YOAinda não há avaliações

- Redpath Raisedrill Brochure LowresDocumento24 páginasRedpath Raisedrill Brochure Lowresluis100% (1)

- Copper-Nickel Seawater Piping SystemsDocumento48 páginasCopper-Nickel Seawater Piping Systemsdandiar1100% (1)

- 2 140716021917 Phpapp01Documento87 páginas2 140716021917 Phpapp01LK AnhDungAinda não há avaliações

- Tubulars Tubular Services Catalog PDFDocumento29 páginasTubulars Tubular Services Catalog PDFHERNANDO CASTILLO100% (1)

- AISE No. 7 Specifications For Ladle HooksDocumento7 páginasAISE No. 7 Specifications For Ladle HookscadyfemAinda não há avaliações

- Corrosion RingsDocumento1 páginaCorrosion RingsAhmed Al-TememiAinda não há avaliações

- Corrosion RingsDocumento1 páginaCorrosion RingsRichard More LeonAinda não há avaliações

- Torus Blowout Preventers & Well Control ProductsDocumento8 páginasTorus Blowout Preventers & Well Control Productsgustavo rivasAinda não há avaliações

- Bi-Directional Overdriven / Unstable Detonation Flame ArrestersDocumento2 páginasBi-Directional Overdriven / Unstable Detonation Flame ArrestersHector Flores MarcosAinda não há avaliações

- 3.2. Flowstrong Yellowbox - Product SpecsDocumento16 páginas3.2. Flowstrong Yellowbox - Product SpecsHussain Al SanonaAinda não há avaliações

- Secoroc Omega: Sealed Bearing Tricone Rotary Drill BitsDocumento8 páginasSecoroc Omega: Sealed Bearing Tricone Rotary Drill BitsSandoval Ramos EddyAinda não há avaliações

- TF100-17G - Rynglok Tube Repair SystemDocumento8 páginasTF100-17G - Rynglok Tube Repair Systemairbuk doeingAinda não há avaliações

- Sample Cylinders: SC and MC SeriesDocumento5 páginasSample Cylinders: SC and MC SeriessbyeAinda não há avaliações

- Civil QualityDocumento89 páginasCivil QualitymithileshAinda não há avaliações

- TF100 17D Rynglok Tube Repair SystemDocumento8 páginasTF100 17D Rynglok Tube Repair SystemAnup DahalAinda não há avaliações

- Mod 10 DRLG BasicsDocumento13 páginasMod 10 DRLG BasicsMin Thant MaungAinda não há avaliações

- SMSGutter System Installation SpecificationDocumento13 páginasSMSGutter System Installation SpecificationChristan Daniel RestorAinda não há avaliações

- Carboguard 893: Selection & Specification DataDocumento5 páginasCarboguard 893: Selection & Specification DataQuy RomAinda não há avaliações

- Pasco Catalog eDocumento9 páginasPasco Catalog eClementine JsotoAinda não há avaliações

- Richpac® Spiral Wound Gask ETDocumento13 páginasRichpac® Spiral Wound Gask ETIgor NircaAinda não há avaliações

- Carboguard 893 SG MIO PDSDocumento4 páginasCarboguard 893 SG MIO PDSMuthuKumarAinda não há avaliações

- Filter ElsterDocumento4 páginasFilter ElsterkuwatiAinda não há avaliações

- Nitoflor Tf120 UbDocumento3 páginasNitoflor Tf120 UbtalatzahoorAinda não há avaliações

- Fishing Part 3Documento21 páginasFishing Part 3Farouq EngAinda não há avaliações

- Carboguard 504 PDSDocumento4 páginasCarboguard 504 PDSNicholas ColesAinda não há avaliações

- Data Sheet Multi-Channel Duct: Doc. No. DIPL-M/QA/PDS/FPF/693 Rev. 00, Issue: 1 - Issue Date: 09 - Aug, 2017Documento2 páginasData Sheet Multi-Channel Duct: Doc. No. DIPL-M/QA/PDS/FPF/693 Rev. 00, Issue: 1 - Issue Date: 09 - Aug, 2017Murali KrishnaAinda não há avaliações

- XOMOXPlugvalvesEurope BrochureDocumento12 páginasXOMOXPlugvalvesEurope BrochureAnonymous ItzBhUGoiAinda não há avaliações

- Surface Mining Brochure 2 PDFDocumento25 páginasSurface Mining Brochure 2 PDFhugo sobrinoAinda não há avaliações

- Cylinders 2007-04 Lo PDFDocumento14 páginasCylinders 2007-04 Lo PDFXaviAinda não há avaliações

- View DocumentDocumento2 páginasView DocumentIsmael VelascoAinda não há avaliações

- Drilling Parameter Analysis in Solving Pipe Sticking in A Total Loss Circulation Zone Case Study: Well "X" and Well "Y" Geothermal Well Ulubelu FieldDocumento21 páginasDrilling Parameter Analysis in Solving Pipe Sticking in A Total Loss Circulation Zone Case Study: Well "X" and Well "Y" Geothermal Well Ulubelu FieldJeva VienaAinda não há avaliações

- Marine PDFDocumento578 páginasMarine PDFNizar BouchaalaAinda não há avaliações

- Check Valve - Position IndicatorDocumento2 páginasCheck Valve - Position Indicatorunibalaji_05Ainda não há avaliações

- Design RSS Lined Globe ValveDocumento12 páginasDesign RSS Lined Globe Valveyenifer garciaAinda não há avaliações

- FDA Family of Dynamic Sealing Products: Leaders in Sealing IntegrityDocumento12 páginasFDA Family of Dynamic Sealing Products: Leaders in Sealing IntegrityUday GokhaleAinda não há avaliações

- MP Safety Heads and Rupture Discs PDFDocumento1 páginaMP Safety Heads and Rupture Discs PDFAnonymous OcbdpBFbxAinda não há avaliações

- Replaceable Solid Core Filter Driers CHAP. 9Documento11 páginasReplaceable Solid Core Filter Driers CHAP. 9Frédéric Fawa VellaAinda não há avaliações

- Tyco TY8281 TFP680 - 03 - 2023Documento17 páginasTyco TY8281 TFP680 - 03 - 2023First LAstAinda não há avaliações

- Carboguard 893 PDSDocumento5 páginasCarboguard 893 PDSUtomoAinda não há avaliações

- Cmats Lab4Documento8 páginasCmats Lab4Lorraine CustodioAinda não há avaliações

- 23145879Documento5 páginas23145879Ali Ben AmorAinda não há avaliações

- Cexhib PDFDocumento5 páginasCexhib PDFAli Ben AmorAinda não há avaliações

- Fertilizer Industry Valve Solutions: Upstream Midstream Downstream Chemical Valve ApplicationsDocumento20 páginasFertilizer Industry Valve Solutions: Upstream Midstream Downstream Chemical Valve ApplicationsSyed Zayne Syed KadirAinda não há avaliações

- D3 Spray Nozzle PDFDocumento6 páginasD3 Spray Nozzle PDFwahyuAinda não há avaliações

- Anchor-Profile SSPC SPDocumento9 páginasAnchor-Profile SSPC SPandy100% (1)

- RASCOflex Americas SpecSheetDocumento4 páginasRASCOflex Americas SpecSheetJohn loboAinda não há avaliações

- Carboguard 636 XT PDSDocumento4 páginasCarboguard 636 XT PDSCarlos Rojas HandalAinda não há avaliações

- Carbozinc 11Documento4 páginasCarbozinc 11DuongthithuydungAinda não há avaliações

- AISE No7 Ladle Hooks 1991Documento9 páginasAISE No7 Ladle Hooks 1991Zhifan FuAinda não há avaliações

- Pasco CatalogDocumento7 páginasPasco CatalogItx MinhasAinda não há avaliações

- ZRC GALVILITE Galvanizing Repair CompoundDocumento2 páginasZRC GALVILITE Galvanizing Repair CompoundRaymond LalumiereAinda não há avaliações

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Ainda não há avaliações

- Completion Fluids and Formation DamageDocumento6 páginasCompletion Fluids and Formation DamageAnonymous JMuM0E5YOAinda não há avaliações

- Analysis MacondoDocumento13 páginasAnalysis MacondoAnonymous JMuM0E5YOAinda não há avaliações

- ThixotropyDocumento13 páginasThixotropyAnonymous JMuM0E5YOAinda não há avaliações

- Alcomer 74 TDSDocumento1 páginaAlcomer 74 TDSAnonymous JMuM0E5YOAinda não há avaliações

- CST and AphronsDocumento15 páginasCST and AphronsAnonymous JMuM0E5YOAinda não há avaliações

- Aade-14-Ftce-25 LCMDocumento9 páginasAade-14-Ftce-25 LCMAnonymous JMuM0E5YOAinda não há avaliações

- Mud Agitator Manual PDFDocumento7 páginasMud Agitator Manual PDFAnonymous JMuM0E5YOAinda não há avaliações

- Canola OilDocumento9 páginasCanola OilAnonymous JMuM0E5YOAinda não há avaliações

- Q'Max Technical Bulletin #6 Viscosity Modification in Oil MudsDocumento6 páginasQ'Max Technical Bulletin #6 Viscosity Modification in Oil MudsAnonymous JMuM0E5YOAinda não há avaliações

- Qaqc Notes Over AllDocumento34 páginasQaqc Notes Over AllmohdAinda não há avaliações

- Santhosh.K.P: Curriculum VitaeDocumento3 páginasSanthosh.K.P: Curriculum VitaeAl Manar PetroleumAinda não há avaliações

- Installation Operation Maintenance: Light Commercial Split System 5-20 Tons TTH Model 50 HZDocumento16 páginasInstallation Operation Maintenance: Light Commercial Split System 5-20 Tons TTH Model 50 HZViệt Đặng XuânAinda não há avaliações

- Crisis Management at Blast FurnaceDocumento17 páginasCrisis Management at Blast FurnaceSanjay Kumar DokaniaAinda não há avaliações

- Ap Series Split Instal ManualDocumento24 páginasAp Series Split Instal ManualGhiban ConstantinAinda não há avaliações

- Epcot Building Codes 2015 Edition Code Change Submittals Effective 10/01/2015Documento48 páginasEpcot Building Codes 2015 Edition Code Change Submittals Effective 10/01/2015LALA0% (1)

- WS Fixture Flow Rates PDFDocumento1 páginaWS Fixture Flow Rates PDFbilal almelegyAinda não há avaliações

- Satellite EcolabDocumento2 páginasSatellite EcolabAndré BnuAinda não há avaliações

- Prince MRP List 02.07.2022Documento17 páginasPrince MRP List 02.07.2022Rachit SharmaAinda não há avaliações

- Electric Hot Water Boiler: Operation and Maintenance ManualDocumento12 páginasElectric Hot Water Boiler: Operation and Maintenance Manualabu7omar-1Ainda não há avaliações

- Butterfly MTD, GTDDocumento12 páginasButterfly MTD, GTDNaser JahangiriAinda não há avaliações

- Check Valve DSDocumento2 páginasCheck Valve DSsinamicsAinda não há avaliações

- General Shop ToolsDocumento8 páginasGeneral Shop ToolsCarlos veraAinda não há avaliações

- CFD Analysis of Fluid Flow Parameters Within A Y-Shaped Branched PipeDocumento5 páginasCFD Analysis of Fluid Flow Parameters Within A Y-Shaped Branched PipeHemant SharmaAinda não há avaliações

- Gatic CatalogueDocumento32 páginasGatic CatalogueriandiAinda não há avaliações

- ASME B31.3 - Interpretations No.31 - 2008 EditionDocumento235 páginasASME B31.3 - Interpretations No.31 - 2008 Editionmohammad kassarAinda não há avaliações

- N H S Office Complex: 3100 S. Figueroa Street Los Angeles, Ca 90007Documento1 páginaN H S Office Complex: 3100 S. Figueroa Street Los Angeles, Ca 90007Rafael SathlerAinda não há avaliações

- 5-6 Univer PDFDocumento2 páginas5-6 Univer PDFGLITZ ELEKTRO BUILDERS CDO BRANCHAinda não há avaliações

- Manuali Bosch I Instalimit Te Pom Pave Termike GjeotermaleDocumento46 páginasManuali Bosch I Instalimit Te Pom Pave Termike GjeotermaleLavdërim SalihuAinda não há avaliações