Escolar Documentos

Profissional Documentos

Cultura Documentos

AWS D1.1 Page 6

Enviado por

ksuscribdacct0 notas0% acharam este documento útil (0 voto)

19 visualizações1 páginaPage 6 of the AWS D1.1 Welding Code

Título original

AWS D1.1 page 6

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoPage 6 of the AWS D1.1 Welding Code

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

19 visualizações1 páginaAWS D1.1 Page 6

Enviado por

ksuscribdacctPage 6 of the AWS D1.1 Welding Code

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 1

‘CUUSED. DESIGN OF WELDED CONNECTIONS

245 Shop Drawing Requlments, Shop davinss

‘hl cleanly ine by welding spb oe Wich the

Akal f groove welded jin and the preparation af

ee met eid a make ther, Beth with and ck

nes of steel hacking sal Be dete

2.48.1 PP Groove Welds. Shop dev ings saline

cate the Weld roe dophs “Sneed 1 an welt

Sine "(Ered forthe welding proces an pon of

welding tobe we

2.3.52 File Welds and Wels in Skewed Tots.

‘The owing sl be provided a he op aig

(1 Porfiet welds between pans with sacs me

ing a an angle between WO" and 10°. shop ering

fl sw the let weld ep se

(2) Fe woli between pus wih sie esting

tan ale Less than AU” oF geste tan 10% the Sop

Swings shall show the dete aangement of welds

tl vaulted espe o acu Toffee of jot gore

try and, where appropiate. te Zo eduction fo the

proves to be used and the sgl

(2) God rts an hold tacks

263 Welding Symbols. The contract documents

Stal show CIP ar PIP grooke weld reiemens. Co

tract docaent da aot ead to show groove pe oF

rave dimensions The welling symbol witont dm

Sons nd with “CHP inthe al dengnstoes COP weld ae

ar

The woling symbol wot dimension and witha CP

ine i desis 3 wed tt il Sveop te aes

De met stength ia coin an shea. A welding sy

bel for uP roe sal sow dimension croc

inpaenteses blow (Ene shoe (Eth fer

hee lint indice the roe well sizes. the ar

Biter sides o the weld jim, especie, a8 show

eo

ae

2.354 Prequalified Detail Dimensons. The jot

eis seria ia 3.12 (PAP) and 3.13 (CHP) hae

‘Sondions and clearances necessary for depeiing td

‘of hese details shal or be inteepeted as plying con

Sideraon of th elete nt weling process on Base

Pas

6

wa. 101.46 2019

tryond the fasion boundary nor sity of dhe joint

el fora given application,

2.45 Special etal, When special rome details

are equied, they shall be deed inthe conrct

2358p Iepeton Requirements. Any spi

fnxgetion rooiements sll Benn) on the Conant

document

24 Effective Areas

2.4.1 Groove Welds

2.1L Umeetive Length. The maxim effesive

‘weld length of any groove weld, regu of ets

‘in, sal the with ofthe pone, perpendclar

10 the dicion of tnsle ww comprenive sess For

sore welds wansiting shea, te efective Length is

The length pid

2.4.2 Etfetve Sie of CJP Groove Welds The

weld size of «CHP groove wel hl be the hes oF

the thier par joined. Aa incre inthe efletive area

for design calculations for well rinfoncement all

be prohibited, Groove weld sies foe T, Yat K

oahections in tubular comsroton ar shown in Table

36

2.41.3 Minimum Size of P4P Groove Welds PIP

grove welds sll be equal too greater ta he ie

"(EF specied in 3.12.21 unos the WES fs quai in

confonnance with Cae.

2UL1A bffective Site of Flare-Groove Welds. The

lle size of Maregroove weld whe filled Hash

Shall be as shown in Table 2.1, excep allowed by

S115. For aregroove wel oiled nh, the ame

SITU sal be det, For Maree growve weks tose

faces wi ferent adi the slr R shal an

For fre proove wes retangulr ub etons, R

sal eke a two times the wl kes,

1.5 keting Area of Groove Welds The ef:

tive area of groove Wek sul he he eflecdve length

‘tpi bythe eects we sie,

2 Fite Welds

24421 fective Langs (Straight). The afocive

len ofa srsih il weld le the ovr gah

the al ie ile, ocaig end eta, No reduction

in effecive length sal be nsomed indesign calcul

tions tallow forthe stat or stop ertr ofthe weld

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- RAM Structural System TutorialDocumento234 páginasRAM Structural System Tutorialksuscribdacct100% (1)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hollow Sections 2nd EdtDocumento240 páginasHollow Sections 2nd Edtksuscribdacct100% (2)

- SSMA Product Technical Guide 2014Documento72 páginasSSMA Product Technical Guide 2014Diego PovedaAinda não há avaliações

- Brokers Market Analysis and Strategy Report PDFDocumento6 páginasBrokers Market Analysis and Strategy Report PDFksuscribdacct100% (2)

- Ocean Network Conference ScheduleDocumento2 páginasOcean Network Conference ScheduleksuscribdacctAinda não há avaliações

- Haydon Catalog 9-10 PDFDocumento148 páginasHaydon Catalog 9-10 PDFksuscribdacctAinda não há avaliações

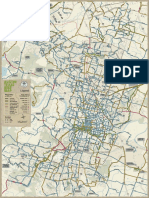

- COA Bike Map v12 FULL Web PDFDocumento1 páginaCOA Bike Map v12 FULL Web PDFksuscribdacctAinda não há avaliações

- Pages From ManualDocumento1 páginaPages From ManualksuscribdacctAinda não há avaliações

- Rules Sparks Games 092013Documento17 páginasRules Sparks Games 092013ksuscribdacctAinda não há avaliações

- Kanvinde - Shear Transfer in Exposed Column Base PlatesDocumento159 páginasKanvinde - Shear Transfer in Exposed Column Base PlatesksuscribdacctAinda não há avaliações

- Page 16 From Unistrut Catalog 17Documento1 páginaPage 16 From Unistrut Catalog 17ksuscribdacctAinda não há avaliações