Escolar Documentos

Profissional Documentos

Cultura Documentos

A General Shear Design Method PDF

Enviado por

Wilfredo Neyra Cisneros0 notas0% acharam este documento útil (0 voto)

48 visualizações12 páginasTítulo original

A General Shear Design Method.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

48 visualizações12 páginasA General Shear Design Method PDF

Enviado por

Wilfredo Neyra CisnerosDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 12

Title no. 93-85

TECHNICAL PAPER

A General Shear Design Method

wes

by Michael P. Collins, Denis Mitchell, Perry Adebar, and Frank J. Vecchio

A simple, unified method is presented for the shear design of both pre

stressed concrete members and nonpresirssed concrete members. The

‘method can treat members subjected 10 axial tension or axial compression

‘and treats members with and without web reinforcement. The derivation of

the method is summarized and the predictions ofthe method are compared

with those of the current ACI Code

Keywords: aggregate interlock: axial loads: building codes; erack width

and spacing; reinforced concrete; shear stength; structural design.

‘The shear design provisions of the 1995 ACI Code! con-

sist of about 43 empirical equations for different types of

‘members and different types of loading, some of which are

illustrated in Fig. 1. In 1973, the ACI-ASCE Shear

Committee? expressed the hope that these “design regula-

tions for shear strength can be integrated, simplified, and

given a physical significance.” As shown by the growth in

the number of ACI shear design equations (see Fig. 2), the

‘code has not met this desirable goal. Iti interesting to note

that, prior to 1963, the ACI shear design procedure was so

simple that only four equations were required.

Most of the shear design equations given in Fig. 1 were in

troduced in either the 1963 or 1971 edition of the ACI Code."

‘These design equations were developed in the period follow-

ing the 1955 air-force warehouse shear failures® and rely on

the traditional concept of adding a concrete contribution V, to

the shear reinforcement contribution V, calculated on the basis,

of the 45 deg truss equation.

Since 1971 there has been an intensive research effort aimed

at improving design methods for shear (see Fig. 3), The re~

search has shown that, in general, the angle of inclination of

the concrete compression is not 45 deg, and that equations

based on a variable angle truss provide a more realistic basis

for shear design. In addition, tests of reinforced concrete pan-

els subjected to pure shear improved the understanding of the

stress-strain characteristics of diagonally cracked concrete,

‘These stress-strain relationships made it possible to develop

‘an analytical model, called the modified compression field

theory, that proved capable of accurately predicting the re-

sponse of reinforced concrete subjected to shear.

36

The objective of this paper is to present briefly a simple,

general shear design method based on the modified compres-

sion field theory. This design method, recently introduced by

Collins and Mitchell,’ has been adopted by the Ontario

Highway Bridge Design Code,* the Canadian Standards As-

sociation Concrete Design Code,’ and the AASHTO LRFD

specifications." The method is summarized in Fig. 1

SHEAR RESPONSE OF CRACKED CONCRETE

‘Tests of reinforced concrete panels subjected to pure shear

(see Fig. 4) demonstrated that even after cracking, tensile

stresses exist in the concrete and that these stresses can sig

nificantly increase the ability of reinforced concrete to resist

shear stresses,

Cracked reinforced concrete transmits load in a relatively

complex manner involving opening or closing of pre-exist-

ing cracks, formation of new cracks, interface shear transfer

fat rough crack surfaces, and significant variation of the

stresses in reinforcing bars due to bond, with the highest

steel stresses occurring at crack locations. The modified

compression field model attempts to capture the essential

features of this behavior without considering all of the de-

tails. The crack pattem is idealized as a series of parallel

cracks all occurring at angle @ to the longitudinal direction

In lieu of following the complex stress variations in the

cracked concrete, only the average stress state and the stress

state at a crack are considered [see Fig. 4(b) and 4(c)]. As

these two states of stress are statically equivalent, the loss of

tensile stresses in the concrete at the crack must be replaced

by increased steel stresses or, after yielding of some of the

reinforcement at the crack, by shear stresses on the crack in-

terface. The shear stress that can be transmitted across the

crack will be a function of the crack width, Note that shear

stress on the crack implies that the direction of principal

stresses in the concrete changes at the crack location,

ACI Sractaral Journal ¥.93, No.1 Januaey-ebuary 1996

Reveved June 17, 198 and revived under Institute publication polices. Copy.

right © 1993, American Concrete Institue. Allright eseved.tcludg he Mak.

‘oFeopes unless permission band from te copyright propetors.Ferinent ds

‘ston wil be publsd in the November December 1996 ACT Srcturol Journal

‘vce by Jay 196,

ACI Structural Journal / January-Febuary 1996

‘Michael PColing, FAC. ie Ban Tanenbaum Professor of Ci Engineering ot he

Univers of Toronto, Toronto, Canada. He is a member of ACI Commitee 388. Con

‘rete Guida the ACI Technical Actisties Commie subcommice on High Per

formance Concrete and joint ACEASCE Commitee 445 Shear and Torsion He is

member ofthe Canadien Standards Arsociation Commie forthe Design of Com

free Scares

Denis Michell, ACI, is a profesor in the Department of Cit Enginering and

Applied Mechance at McGill University He i @ member of ACI Commer 408,

Bond and Developmen of Reinforcement. and ACFASCE Commitee 445, Shear and

Torsion He is Chairman of the Canadian Standards Association Commie forthe

Design of Concrete Sucre

ACI memberBerry Adebar i an axsociete professor inthe Deparment of iil Engi

reering othe University of British Columbia, Voncowver Canada, He i Secretary of

JACK Commie 341, Earths Resistant Concrete Bridges and joint ACLASCE

‘computraded design of wnforced concrete

ACI member Frank J. Vecchio is a professor in the Department of Ci Enginering

‘atthe Univers Tron, Hes a member of ACI Commatees 441 Reinforced Con

‘rete Cols and 47, Finite Element Aalyis. and ofthe CEB Comniter on Com

stave Modeling.

‘The average principal tensile strain e, in the cracked con-

crete is used as a “damage indicator” that controls the aver

age tensile stress fin the cracked concrete, the ability of the

diagonally cracked concrete to carry compressive stresses f;,

and the shear stress v,; that can be transmitted across a crack.

‘The principal compressive stress in the concrete fis relat-

ed to both the principal compressive strain €, and the princi-

pal tensile strain e, in the following manner [see Fig. 5(a)]

h ay

where

Pamax = 4.7 (08 + 1108,) $f.’ S

ACI Method

General Method

¥,

naVet%

y,

ve, +¥,

¥, (191 + 2500, %

¥, 538 0E ba ot ¥,

¥ < 81h bya

o

vent = 08[Fibyd + y+

yA ol na

Ana oa

2\E ba

(00 = MoM oe on 2 r0 9, « IE

ce oe

™,

and, < Yeu = (980 + 03%,) te ¥,

ons,

Sh ae

where 8 and 8 are functions

of the strain, ¢,, shear stress, »,

and crack spacing s,

where

M,

=

a

= pu vy AT bd

1.9 fff + 2500p,

Axial Tension

and Shear

: :

Detailing Rules

© Feintorcement shall extend

© shear at cutoff < 2/3 shear permitted, or

8 tirup a

4, 60

f, 8 § d/8By, OF

teinforcemen shall be inited so that

es eitle

beyond the pont at which its no longer required to resist exure

fora distance equal fo the eflecive depth ofthe member or 124, ahichis greater,

(© Flexural reinforcement shall not be terminated in a tension zone unless

in excess of that required for shear and torsion, is provided

© for #11 bars or smaller: shear atthe cutofl 3/4 shear permitted and continuing

reinforcement provices double the area required for flexure a the cutot,

© At simple supports and points of inflection, the diameter ofthe positive moment tension

Detailing Rules

Longitudinal steo! must be

Setalled so that

+ -05u- soso

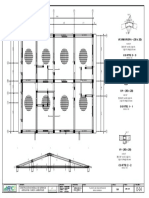

Fig. I Comparison of ACI and proposed shear design approaches

ACI Structural Journal / January-Febuary 1996

37

50

of

10

4900 191010201000

[NUMBER OF EQUATIONS FOR SHEAR DESIGN IN ACI CODE

1940

Fig. 2—Number of ACI shear design equations

1950 1960 197019801980

seo 1810 a0 100

180 1950 1960 197019001000

Fig. 3—Research into shear design methods

(©) Catcutated average stresses __(¢) Local stresses at crack

Fig. 4—Reinforced concrete panels subjected 10 shear

From Eq, (I) the principal compressive strain for the loading

portion ofthe stress-strain relationship is

0.002 (1 = {1 2/famax)

3)

where €;” has been taken as -0.002.

‘After cracking, the principal tensile stress in the conerete fis

related to the principal tensile strain ¢, as follows [see Fig. 5(b)]

Ser

1+ /500e,

where the cracking stress f,, can be taken as 4,/7," psi

(0.33 ff,’ MPa). For large values of €,, the cracks will become

and the magnitude of f, wll be controlled by the yielding,

of the reinforcement atthe crack and by the ability to transmit

shear stresses v; across the cracked interface (see Fig. 5(b)]

‘The shear stress that can be transmitted across the crack is a

function of the crack width w and the aggregate size a [see Fig.

4()}, as given by

216K"

~ aw

oT 08

fi “

psi and in,

For MPa and mm units, replace the 2.16 by 0.18 and the

0.63 by 16.

ACI Structural Journal / January-Febuary 1996

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- 01 Arquitectura-A-01Documento1 página01 Arquitectura-A-01Wilfredo Neyra CisnerosAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Planos MetalicosDocumento5 páginasPlanos MetalicosWilfredo Neyra CisnerosAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- 06 Encofrados-E-04Documento1 página06 Encofrados-E-04Wilfredo Neyra CisnerosAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- 01 Arquitectura A-01Documento1 página01 Arquitectura A-01Wilfredo Neyra CisnerosAinda não há avaliações

- 4 Plan de Seguridad - Caja de LaminacionDocumento16 páginas4 Plan de Seguridad - Caja de LaminacionWilfredo Neyra CisnerosAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Diseño de Reservorio Con GeomembranaDocumento2 páginasDiseño de Reservorio Con GeomembranaManuel Gonzales91% (11)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Chapihual El AjonDocumento23 páginasChapihual El AjonWilfredo Neyra CisnerosAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Decreto Legislativo 1354Documento40 páginasDecreto Legislativo 1354Wilfredo Neyra CisnerosAinda não há avaliações

- DISEÑO DE PAVIMENTOS Afirmado PDFDocumento107 páginasDISEÑO DE PAVIMENTOS Afirmado PDFWilfredo Neyra CisnerosAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)