Escolar Documentos

Profissional Documentos

Cultura Documentos

Pipe Line Flexibility Manual Calculation

Enviado por

Kagira Drawing SoltuionDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pipe Line Flexibility Manual Calculation

Enviado por

Kagira Drawing SoltuionDireitos autorais:

Formatos disponíveis

Stress Analysis Of Hot Wall Flue Gas Piping At FCCU Plant, Reliance 27

Chapter 7 : MANUAL CALCULATIONS

Before we move on to the CAESAR results lets check the feasibility of the

software.

7.1 Considering a Cantilever pipe and calculating stresses due to self

weight and weight of water and comparing with CAESAR Output

Given :-

Leg 10-20 Length, L = 3500 mm

O.D. of pipe, Do = 275.05 mm

Thickness of pipe, t = 9.271 mm

Corrosion allowance, C.A = 1.6 mm

Design Temperature T1 = 350 ºC

Material :- A 106 Gr. B

Density of Pipe = 7833.1567 kg/m³.

According to ASME B31.3[8],

Allowable cold stress range at 21 º C = Sc = 137.9 N/mm²

Allowable hot stress range at 350 º C = Sh = 116.4 N/mm²

7.1.1 Solution :-

SA = Allowable stress range = f ( 1.25 Sc + 0.25 Sh )

= 1.0 ( 1.25 * 137.9 + 0.25 * 116.4 )

…..( where f = 1.0 for 7000 load cycles )

SA = 201.5 N/mm² …(7.1)

K.L.E. Society’s College Of Engineering and Technology, Belgaum

Stress Analysis Of Hot Wall Flue Gas Piping At FCCU Plant, Reliance 28

W1 = Weight of the pipe

= Density of Pipe material * Volume of pipe * 9.81

= 7833.1567 * { ( pi/4) * (Do² - Di²) } * L * 9.81

= 7833.1567 * { ( pi/4) * (0.27305 ² - 0.25451 ²) } * 3.5 * 9.81

W1= 2066 N …(7.2)

W2 = Weight of water

= Density of water * Volume of water in pipe * 9.81

= 1000 * { ( pi/4) * ( Di²) } * L * 9.81

= 1000 * { ( pi/4) * ( 0.25451 ²) } * 3.5 * 9.81

W2= 1746.8 N …(7.3)

Therefore,

Total weight, W = Weight of pipe (W1) + Weight of water (W2)

= 2066 + 1746.8

W = 3812.8 N …(7.4)

Therefore,

Shear force, Fs = 3812.8 N

Thus, Bending Moment, Mb = Fs * X c.g

= 3812.8 * ( 3.5 / 2 )

Mb = 6672.4 N-m …(7.5)

Considering, t = t actual - Corrosion allowance

= 9.271 – 1.6

t = 7.671 mm

Therefore, Di = Do – 2 * t

= 273.05 – 2 * 7.671

Di = 257.71 mm

K.L.E. Society’s College Of Engineering and Technology, Belgaum

Stress Analysis Of Hot Wall Flue Gas Piping At FCCU Plant, Reliance 29

Now calculating stresses and comparing with CAESAR OUTPUT. Detailed

CAESAR results are given in APPENDIX D.

1) Longitudinal stress or axial stress = ( P Di) / ( 4 * t )

= ( 0.4 * 257.71 ) / ( 4 * 7.671 )

Longitudinal stress or axial stress = 3.35 N/mm² …(7.6)

where as CAESAR output gives axial stress = 3.26 N/mm²

2) Bending stress = Mb / Z

Now,

Section Modulus, Z = {pi* (Do4- Di4)} / (32*Do)

= {pi* (0.273054- 0.2757714)} / (32*0.27305)

= 0.000412677 m³

Z = 412677 mm³ …(7.7)

Therefore from eqn.(7.5) & (7.7),

Bending Stress = (6672.4 * 10³ / 412677 )

Bending Stress = 16.16 N/mm² …(7.8)

where as CAESAR output gives Bending stress = 16.16 N/mm²

3) Hoop stress = ( P Di) / ( 2 * t )

= ( 0.4 * 257.71 ) / ( 2 * 7.671 )

Hoop stress = 6.72 N/mm² …(7.9)

where as CAESAR output gives Hoop stress = 6.72 N/mm²

4) Max 3D stress intensity

= Axial stress + {(Bending stress)² + 4(Torsional stress)² }^0.5

In this case Torsional stress = 0, as there is no Torsional moment acting on the

pipe.

Therefore from eqn.(6) & (7),

Max 3D stress intensity = 3.35 + {(16.16)² + 4(0)² }^0.5

Max 3D stress intensity = 19.51 N/mm² …(7.10)

where as CAESAR output gives Max 3D stress intensity = 19.42 N/mm²

K.L.E. Society’s College Of Engineering and Technology, Belgaum

Stress Analysis Of Hot Wall Flue Gas Piping At FCCU Plant, Reliance 30

Now Calculating Deflection of Pipe at node 20,

We have for Cantilever beam[10],

y = ( w * L4 ) / ( 8 * E * I )

From ASME B 31.3[8],

Modulus of Elasticity, E = 203391 N/mm² at 350 ºC …(7.11)

Moment of inertia, I = { pi* (Do4- Di4)} / 64

= { pi* (273.05 4- 254.51 4)} / 64

I = 66899732.1 mm4 …(7.12)

Weight per meter, w = W / L

= 3812.8 / 3500 = 1.08937 N/mm …(7.13)

Therefore from eqn. (7.11), (7.12) and (7.13),

y = ( 1.08937 * 3500 4 ) / ( 8 * 203391 * 66899732.1 )

y = 1.502 mm ( downward direction ) …(7.14)

where as CAESAR output gives deflection, y = - 1.523 mm i.e. in downward direction.

Thus it is seen that the result obtained by CAESAR and manual calculation

are nearly same.

K.L.E. Society’s College Of Engineering and Technology, Belgaum

Stress Analysis Of Hot Wall Flue Gas Piping At FCCU Plant, Reliance 31

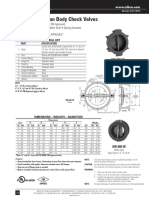

7.1.2 CAESAR OUTPUT

Figure 7-1

Figure 7-2

Figure 7-3

K.L.E. Society’s College Of Engineering and Technology, Belgaum

Stress Analysis Of Hot Wall Flue Gas Piping At FCCU Plant, Reliance 32

7.2 Considering a Cantilever pipe having perpendicular supporting pipe

and calculating expansion stress due to temperature and comparing

with CAESAR Output

Given :-

Leg 10-30 Length, L = 7500 mm

O.D. of pipe, Do = 275.05 mm

Thickness of pipe, t = 9.271 mm

Corrosion allowance, C.A = 1.6 mm

Design Temperature T1 = 350 ºC

Material :- A 106 Gr. B

Density of Pipe = 7833.1567 kg/m³.

According to ASME B31.3,

Allowable cold stress range at 21 º C = Sc = 137.9 N/mm²

Allowable hot stress range at 350 º C = Sh = 116.4 N/mm²

7.2.1 Solution :-

SA = Allowable stress range = f ( 1.25 Sc + 0.25 Sh )

= 1.0 ( 1.25 * 137.9 + 0.25 * 116.4 )

…..( where f = 1.0 for 7000 load cycles )

SA = 201.5 N/mm² …(7.15)

Calculation of expansion of leg 10-20,

L1 = 3.5 m

T1 = 350 ºC

T2 = 21 ºC = ambient temperature

Expansion ¨ 10-20 is calculated by formula[8],

¨ = Į . ¨T . L

where,

Į = Thermal Expansion coefficient m/m º C

¨T = Temperature difference = ( 350-21 ) = 329 º C

K.L.E. Society’s College Of Engineering and Technology, Belgaum

Stress Analysis Of Hot Wall Flue Gas Piping At FCCU Plant, Reliance 33

L = Leg length of 10-20 i.e. 3.5 m

From ASME B31.3[8],

Į = 13.194 * 10-6 m/m º C at 343.333 º C

Į = 13.284 * 10-6 m/m º C at 357.222 º C

Using interpolation method we get,

( Į - 13.194 * 10-6 ) = ( 13.284 – 13.194 ) * 10-6

( 350 – 343.333 ) ( 357.222 – 343.333 )

Solving the above eqn. we get,

Į =1.3237 * 10-5 m/m ºC at 350 °C …(7.16)

Now expansion of leg 10-20,

ǻ10-20 = Į . ¨T . L

= 1.3237 * 10-5 * 329 * 3.5 * 1000

ǻ10-20 = 15.242 mm …(7.17)

As node 10 is anchored, the expansion takes place near node 20 and as leg 10-20

is horizontal and parallel to X axis, the deflection is in X axis.

CAESAR output gives deflection, DX = 15.241 mm i.e. in positive X direction.

Similarly expansion of leg 20-30,

ǻ20-30 = Į . ¨T . L

= 1.3237 * 10-5 * 329 * 4.0 * 1000

ǻ20-30 = 17.42 mm …(7.18)

As node 30 is supported from below, the expansion takes place near node 20 and

as leg 20-30 is vertical and parallel to Y axis, the deflection is in + Y axis.

CAESAR output gives deflection, DY = 17. 376 mm i.e. in positive Y direction.

K.L.E. Society’s College Of Engineering and Technology, Belgaum

Você também pode gostar

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringNo EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillNota: 3.5 de 5 estrelas3.5/5 (3)

- Harmonic Analysis REV. 1Documento7 páginasHarmonic Analysis REV. 1Amro SalahAinda não há avaliações

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionAinda não há avaliações

- Caesar II TutorialDocumento35 páginasCaesar II TutorialzahoorAinda não há avaliações

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationNo EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationNota: 4 de 5 estrelas4/5 (18)

- Procedure For Pump Line Stress AnalysisDocumento9 páginasProcedure For Pump Line Stress AnalysisNilesh Gohel100% (1)

- NozzlePRO PDFDocumento185 páginasNozzlePRO PDFRagupathy KulandaisamyAinda não há avaliações

- Example From Theory To Caesar IIDocumento12 páginasExample From Theory To Caesar IITon Phichit100% (7)

- Asme B 31J SifDocumento6 páginasAsme B 31J SifVineesh Vs100% (1)

- Calculating Stresses PDFDocumento55 páginasCalculating Stresses PDFpilotte7Ainda não há avaliações

- Nozzle Movement CalculationDocumento23 páginasNozzle Movement CalculationPriyanathan Thayalan100% (4)

- Flange Leakage Evaluation Based On NC 3658 PDFDocumento3 páginasFlange Leakage Evaluation Based On NC 3658 PDFkaruna346Ainda não há avaliações

- Allowable Stress RangeDocumento2 páginasAllowable Stress RangeSharun SureshAinda não há avaliações

- Concepts of Pipe Stress AnalysisDocumento54 páginasConcepts of Pipe Stress AnalysisTejas Patel100% (12)

- A Finite Element-Based InvestigationDocumento7 páginasA Finite Element-Based InvestigationSteve IpAinda não há avaliações

- Vivek Paul Engineer (Tech.) KLG Systel LTDDocumento61 páginasVivek Paul Engineer (Tech.) KLG Systel LTDFirasat AliAinda não há avaliações

- Allowable Pipe Spans LoadsDocumento84 páginasAllowable Pipe Spans LoadsMalcolm Hutton100% (5)

- Spec Editor Pipe SupportsDocumento18 páginasSpec Editor Pipe SupportsGerry100% (1)

- Stress Analysis Specification: CONT. NO.: 1032/GC-GN/CON-EP09-00 DOC. NO.: 3607/34-78-ED-PI-SPDocumento23 páginasStress Analysis Specification: CONT. NO.: 1032/GC-GN/CON-EP09-00 DOC. NO.: 3607/34-78-ED-PI-SPhamedpdms100% (1)

- Piping Flexibility - A Detailed ApproachDocumento5 páginasPiping Flexibility - A Detailed ApproachRUDHRA DHANASEKARAinda não há avaliações

- Expansion Joint ModelDocumento1 páginaExpansion Joint ModelnirgaAinda não há avaliações

- Allowable Nozzle LoadsDocumento6 páginasAllowable Nozzle LoadskparthypanAinda não há avaliações

- Load CasesDocumento15 páginasLoad CasesVishnu Menon100% (1)

- Piping Stress AnalysisDocumento16 páginasPiping Stress Analysischikimkong80% (5)

- Expansion Loop CalculationDocumento2 páginasExpansion Loop Calculationsk130986100% (1)

- CAESAR II Flange CalcDocumento8 páginasCAESAR II Flange CalcDavid Fonseca100% (1)

- CaesarDocumento32 páginasCaesarAndi Pramana80% (5)

- Pipe Stress Analysis Using A Computer Model of The Piping SystemDocumento90 páginasPipe Stress Analysis Using A Computer Model of The Piping Systemmsdohar100% (1)

- Static & Dynamic Analysis of Piping SystemDocumento105 páginasStatic & Dynamic Analysis of Piping Systemkarthikeashwar100% (4)

- CAESAR II - Pipe Stress AnalysisDocumento6 páginasCAESAR II - Pipe Stress Analysisnguyentrungsonctm7Ainda não há avaliações

- Fluid Flow's Influence: On The Structural Response of Piping Systems and Their AnalysisDocumento19 páginasFluid Flow's Influence: On The Structural Response of Piping Systems and Their Analysisb4sukiAinda não há avaliações

- CAESAR II - Modeling Victaulic CouplingsDocumento5 páginasCAESAR II - Modeling Victaulic CouplingsDenny ThomasAinda não há avaliações

- Dynamic Analysis of PipeDocumento11 páginasDynamic Analysis of PipeAshok KsAinda não há avaliações

- Pipe Stress Manual CalcDocumento62 páginasPipe Stress Manual Calcpipestress100% (7)

- Richmond Stress NotesDocumento110 páginasRichmond Stress Notessateesh chand100% (1)

- Air Cooler Piping Stress Analysis Using Caesar IIDocumento5 páginasAir Cooler Piping Stress Analysis Using Caesar IIsemin prsesAinda não há avaliações

- Dynamic Load in Piping SystemDocumento3 páginasDynamic Load in Piping SystemAMITDEWANGAN1991100% (1)

- Design ChimneyDocumento30 páginasDesign ChimneyMeera R. JadhavAinda não há avaliações

- SCOPE:: Design Input DataDocumento7 páginasSCOPE:: Design Input DataEmmanuel LawrenceAinda não há avaliações

- Column LRFDshear (SI)Documento12 páginasColumn LRFDshear (SI)donnybtampubolonAinda não há avaliações

- Mechanical Design For Sieve Plate ColumnDocumento14 páginasMechanical Design For Sieve Plate ColumnIan Zuhair II100% (1)

- Verifica Giunto Secondo AsmeDocumento5 páginasVerifica Giunto Secondo AsmeFabio TemporiniAinda não há avaliações

- Design of Intze Tank Part 1Documento4 páginasDesign of Intze Tank Part 1iqramoyale022Ainda não há avaliações

- Oht - RDocumento93 páginasOht - RAnkur DubeyAinda não há avaliações

- Water TankDocumento22 páginasWater TankSamik SenAinda não há avaliações

- Slab Designer As Per IS 456-2000Documento7 páginasSlab Designer As Per IS 456-2000mofizahmed64% (11)

- Transmission Line Design CalcDocumento38 páginasTransmission Line Design CalcparmenderAinda não há avaliações

- Design of Cantilever BeamDocumento23 páginasDesign of Cantilever Beamjs kalyana rama83% (12)

- Strength of Materials-II 2-2 Set-4 (A)Documento10 páginasStrength of Materials-II 2-2 Set-4 (A)Sri DAinda não há avaliações

- Circular Water Tank With Domcal Top and BaseDocumento20 páginasCircular Water Tank With Domcal Top and BaseSourav Chandra83% (6)

- sm13 111Documento2 páginassm13 111Timothy JonesAinda não há avaliações

- Sol HW9Documento6 páginasSol HW9Jao Wei KuangAinda não há avaliações

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Documento12 páginasLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiAinda não há avaliações

- Strength of MatrialDocumento36 páginasStrength of MatrialahmedanyAinda não há avaliações

- Current and Resistance: Answers To QuestionsDocumento20 páginasCurrent and Resistance: Answers To QuestionsSamuel González MoralesAinda não há avaliações

- Example1 1-StraightsupportedDocumento7 páginasExample1 1-StraightsupportedOmar BayouAinda não há avaliações

- Penstock CaalculationDocumento3 páginasPenstock CaalculationGertjan DuniceriAinda não há avaliações

- Isodraft User GuideDocumento135 páginasIsodraft User GuideManny MendozaAinda não há avaliações

- Pipe Expansion and SupportDocumento10 páginasPipe Expansion and SupportKagira Drawing SoltuionAinda não há avaliações

- Introduction To Steam DistributionDocumento6 páginasIntroduction To Steam DistributionKagira Drawing SoltuionAinda não há avaliações

- Introduction Steam DrainDocumento14 páginasIntroduction Steam DrainKagira Drawing SoltuionAinda não há avaliações

- Pipes and Pipe Sizing: Block 10 Steam DistributionDocumento18 páginasPipes and Pipe Sizing: Block 10 Steam DistributionKagira Drawing SoltuionAinda não há avaliações

- Handbook of Planning Installations For BuildingsDocumento86 páginasHandbook of Planning Installations For BuildingsjakejohnsAinda não há avaliações

- Caesar II Applications GuideDocumento308 páginasCaesar II Applications Guidebanjinolimit8299100% (5)

- Piping Drafting GuideDocumento28 páginasPiping Drafting GuideKagira Drawing SoltuionAinda não há avaliações

- Marine Piping SystemDocumento233 páginasMarine Piping SystemKagira Drawing Soltuion67% (6)

- Off Shore Drilling GuideDocumento34 páginasOff Shore Drilling GuideKagira Drawing SoltuionAinda não há avaliações

- Piping DesignersDocumento60 páginasPiping DesignersKagira Drawing Soltuion100% (1)

- Jack Up PrimerDocumento24 páginasJack Up PrimerEsteban Gozalo100% (3)

- Piping Design Manual Training GuideDocumento78 páginasPiping Design Manual Training GuideKagira Drawing SoltuionAinda não há avaliações

- Deepwater Platforms (Offshore Drilling) Training GuideDocumento20 páginasDeepwater Platforms (Offshore Drilling) Training GuideKagira Drawing SoltuionAinda não há avaliações

- Piping Materials Selection TrainingDocumento60 páginasPiping Materials Selection TrainingKagira Drawing Soltuion100% (2)

- Off Shore Drilling User GuideDocumento676 páginasOff Shore Drilling User GuideKagira Drawing Soltuion100% (1)

- The Fundamentals of Heat ExchangersDocumento4 páginasThe Fundamentals of Heat ExchangersJojie-Ann AlabarcaAinda não há avaliações

- Piping Elements TrainingDocumento85 páginasPiping Elements TrainingKagira Drawing Soltuion100% (2)

- Piping Design Engineering BasisDocumento50 páginasPiping Design Engineering BasisKagira Drawing Soltuion100% (1)

- Pressure Testing SafetyDocumento4 páginasPressure Testing Safetyapi-26143956100% (2)

- Cooling Towers Design TrainingDocumento57 páginasCooling Towers Design TrainingKagira Drawing Soltuion100% (1)

- Codes and StandardsDocumento28 páginasCodes and StandardsKagira Drawing SoltuionAinda não há avaliações

- Piping Plot Plan and Layout EngineeringDocumento12 páginasPiping Plot Plan and Layout EngineeringKagira Drawing SoltuionAinda não há avaliações

- Valves Details and UsageDocumento72 páginasValves Details and UsageKagira Drawing Soltuion100% (1)

- E6 165 13 00Documento7 páginasE6 165 13 00Lucas BragaAinda não há avaliações

- Stress Analysis of Reactor Nozzle To HeadDocumento5 páginasStress Analysis of Reactor Nozzle To HeadKagira Drawing SoltuionAinda não há avaliações

- Piping EngineeringDocumento83 páginasPiping EngineeringKagira Drawing Soltuion100% (2)

- PDF Engineering) Esab Welding Handbook - 5 EditionDocumento143 páginasPDF Engineering) Esab Welding Handbook - 5 Editionmarshall, of course100% (3)

- Stress Analysis On Vesselnozzle IntersectionsDocumento8 páginasStress Analysis On Vesselnozzle IntersectionsKagira Drawing SoltuionAinda não há avaliações

- Nozzle PDFDocumento8 páginasNozzle PDFtavo1293Ainda não há avaliações

- Theory of Relativity - Wikipedia, The Free Encyclopedia PDFDocumento8 páginasTheory of Relativity - Wikipedia, The Free Encyclopedia PDFProf C.S.PurushothamanAinda não há avaliações

- Og Humwbp 02Documento8 páginasOg Humwbp 02Trash PandaAinda não há avaliações

- WWW - Manaresults.Co - In: B.Tech Ii Year I Semester (R13) Supplementary Examinations June 2016Documento2 páginasWWW - Manaresults.Co - In: B.Tech Ii Year I Semester (R13) Supplementary Examinations June 2016Noor IslamAinda não há avaliações

- Single Composite Beam With Deck Slab Design - ISMBDocumento94 páginasSingle Composite Beam With Deck Slab Design - ISMBHAZIRACFS SURAT100% (1)

- 5-Boilers and CondensersDocumento2 páginas5-Boilers and Condensersnagwaibrahim3132002Ainda não há avaliações

- MB Sprinter 903 Electrical DiagramsDocumento377 páginasMB Sprinter 903 Electrical DiagramsHarlinton descalzi100% (1)

- Henry Berger ResumeDocumento1 páginaHenry Berger Resumeapi-581806915Ainda não há avaliações

- Driver Manual Scania New - 1011 - en-GB PDFDocumento905 páginasDriver Manual Scania New - 1011 - en-GB PDFfajardiniant100% (7)

- Technical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1DB43-4AB4/IE3Documento3 páginasTechnical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1DB43-4AB4/IE3mahmadwasiAinda não há avaliações

- Conectores Rele Arranque Aveo 2005Documento3 páginasConectores Rele Arranque Aveo 2005Jose Luis Velasquez RomeroAinda não há avaliações

- History of Fluid MechanicsDocumento11 páginasHistory of Fluid MechanicsYash MenonAinda não há avaliações

- Rolling Element Bearing Failure AnalysisDocumento4 páginasRolling Element Bearing Failure AnalysisYanuar KrisnahadiAinda não há avaliações

- Instructions: Rotary Lobe BlowersDocumento15 páginasInstructions: Rotary Lobe BlowersKumarAinda não há avaliações

- Check Valves WaferDocumento1 páginaCheck Valves WaferwfjerrAinda não há avaliações

- Manual Source1 S1-TheC11NS Rev 4Documento25 páginasManual Source1 S1-TheC11NS Rev 4nichokolAinda não há avaliações

- Ivanov - Smolensky-Electrical Machines, Vol. 2Documento466 páginasIvanov - Smolensky-Electrical Machines, Vol. 2elmer100% (3)

- Intellisys SSR SeriesDocumento50 páginasIntellisys SSR SeriesJesus GCAinda não há avaliações

- IOM Manual C132355.SflbDocumento14 páginasIOM Manual C132355.SflbVenkat SubramanianAinda não há avaliações

- Supracell Circular Daf: Dissolved Air Flotation ClarifierDocumento2 páginasSupracell Circular Daf: Dissolved Air Flotation ClarifierKevin KeaneAinda não há avaliações

- Centripetal Acceleration On A TurntableDocumento3 páginasCentripetal Acceleration On A Turntablejobi-wan0% (1)

- ProjectDocumento17 páginasProjectRavi ChotaliyaAinda não há avaliações

- 8-Baf - DP 3045 MT 234 Motor 1,2kw AtexDocumento5 páginas8-Baf - DP 3045 MT 234 Motor 1,2kw AtexSantiago RodaAinda não há avaliações

- VPS 504Documento12 páginasVPS 504José Ginés Abellan GarciaAinda não há avaliações

- 6 - IPR Curve Construction ExercisesDocumento22 páginas6 - IPR Curve Construction Exercisesمرتضى عبد الباري خنوبةAinda não há avaliações

- Gelbart Course Notes Part 1Documento24 páginasGelbart Course Notes Part 1Maciek K.Ainda não há avaliações

- Kmk20003 (Chapter 2) Week 2Documento38 páginasKmk20003 (Chapter 2) Week 2mr bentoAinda não há avaliações

- Report On Engine LubricationDocumento9 páginasReport On Engine LubricationJitesh MhatreAinda não há avaliações

- AV Maintenance Manual - R1Documento15 páginasAV Maintenance Manual - R1Faiz MiserangAinda não há avaliações

- D475a-5gen00051 Fa-03Documento240 páginasD475a-5gen00051 Fa-03Gabo GaboAinda não há avaliações

- Manual Pump Down On An Air ConditioningDocumento7 páginasManual Pump Down On An Air ConditioningRay Ravel100% (1)