Escolar Documentos

Profissional Documentos

Cultura Documentos

Preview DRST PDF

Enviado por

Hamed NazariTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Preview DRST PDF

Enviado por

Hamed NazariDireitos autorais:

Formatos disponíveis

DRILL STRING DS–1

Drill string and components Table DS-1: Drill pipe grades.

This chapter of the IADC Drilling Manual is concerned with Current Grades Grade Code Minimum Yield (psi)

the specifications, operating data, and the care and handling

E-75 E 75,000

of drill string. It will also discuss troubleshooting of the prob-

lems that may occur. X-95 X 95,000

G-105 G 105,000

The IADC definition of a drill string is drillpipe with tool S-135 S 135,000

joints attached. Drill stem is all those members between

Z-140* Z 140,000

the swivel and the bit, and it includes drill string, kelly or top

drive, subs, drill collars, heavy weight drillpipe, stabilizers, V-150* V 150,000

shock absorbers, reamers and any other in-hole equipment U-165* U 165,000

used generally or part-time during drilling operations.

Drill pipe tubes are furnished in the following API length

ranges:

API/ISO specifications

• Range 1: 18-22 ft;

In the worldwide oil industry today, an overwhelming major-

• Range 2: 27-30 ft;

ity of all tubular goods are manufactured to specifications

• Range 3: 38-45 ft.

developed and approved by the American Petroleum Insti-

tute. These specifications cover the mechanical properties

of the steel, the details of manufacture and physical dimen- includes mechanical properties of the steel and physical di-

sions of the pipe. The latter include internal and external mensions of the tubes and their upsets.

diameters, wall thickness, and upset dimensions for each

nominal size, weight and grade, as well as tool joint type, Normal tolerance on yield strength of drillpipe tubes is plus

OD and ID, and length. API Specification 5DP covers drill- 30,000 psi. All grades above E-75 are referred to as high

pipe. Bulletins 5A2, 5C2, and 5C3 cover aspects of the use of strength. Grades marked with an asterisk have been used

and care of drillpipe wall thickness or that joints would mate ,but not been formally recognized.

with similar products manufactured by different companies.

The production of high-strength drill-pipe tube began in the

To mitigate the resulting confusion and loss of time, the API was 1950s. When high strength tubes were accepted by API some

induced to undertake a program of standardization and mark- 10 years later, tool joint dimensions (ODs and IDs) were those

ing. This program is a continuing one which enables changes commonly used on E75 tubes. A committee was appointed,

to occur based upon improved technology and the needs of and tool-joint dimensions recommended, with the result that

users and manufacturers to be disseminated to the industry in the torsional yield of the tool-joint pin was at least 80% as

a minimum amount of time and with a high degree of accuracy. strong as the tube to which it was to be attached.

API Specifications and Recommended Practices cover a wide

range of oilfield equipment in addition to tubular goods. These Good practice is for the tool-joint box to be stronger than

publications are revised as necessary and constitute one of the pin initially, because wear will ultimately make the box

the best sources of information on the design, manufacture, the weaker member.

care, and use of drilling and production equipment.

The attaching of tool joints to upset drillpipe tubes by flash

This section of the Drilling Manual relates not only to the welding was replaced in the 1970s by inertia and friction

API 5DP specifications, but also to Recommended Practice welding. API/ISO specifications require the weld to be

RP7G and RP7A1. These publications relate to the connec- stronger than the tube body, have good ductility, and not be

tions for the drill string and also to the design and operating harder than 37 Rockwell C.

limits of the drill stem.

Most sizes of drill-pipe tubes come in light weight, standard

This section of the Drilling Manual discusses drill string care weight, and one or more heavier than standard weights.

and use and gives examples of the types of problems usually Both the grade code and the weight code should be sten-

encountered when the drill string is improperly used or used ciled on the pin base for finished drill string assemblies. It is

beyond its physical capabilities. This section also recom- recommended that these two codes (grade and weight) also

mends practices which will overcome or eliminate the prob- be stenciled on a milled flat on the pin tong surface for quick

lems often encountered when using the drill stem. identification. The numeric code is 1 for a light-weight tube

and 2 for a standard weight tube. Heavier-than-standard

In the oil industry today, most drillpipe is manufactured to tubes receive a 3, 4, or 5. Most of the tubes today are stan-

specifications developed and approved by API/ISO. This dard weight, and these receive the 2 designation. A complete

IADC Drilling Manual Copyright © 2015

DS–2 DRILL STRING

Table DS-2: Tool joint connections.

Grade code Description

IF Internal Flush

EH or XH Extra Hole Figure DS-1: Weld-on tool joint. The

SH Slim Hole flash-welded tool joint, introduced

in 1938, was the industry’s first

OH Open Hole weld-on tool. Inertia welding was

introduced in 1974 and continuous-

SL - H-90 Slim Line-Hughes-90

drive friction welding in 1978.

FH Full Hole

H-90 Hughes-90

WO Wide Open

NC Numbered Connection

list of these may be found in API 5DP in Table C-12. Drill string

Table DS-3: Interchangeability chart for tool joints.

nomenclature and abbreviations are detailed in Table DS-2.

NC NC26 NC31 NC38 NC40 NC46 NC50

Internal flush 2 3/8 2 7/8 3 1/2 4 4 1/2

Drillpipe description and basic theory Full hole 4

Extra hole 3 1/2 4 1/2 5

General information Wide open 3 1/2 4 5

The drill string is required to serve three basic functions:

• Transmit and support axial loads; Slim hole 2 7/8 4 4 1/2

• Transmit and support torsional loads;

• Transmit hydraulics. With the exception of specialty tools, probably no other part

of the drill stem is subjected to the complex stresses which

The design parameters and a step-by-step procedure of drill string must withstand. For this reason, the combined

designing a string are given in API RP 7G, 16th ed, Section 7. skills of steel-industry engineers, with full cooperation from

oil companies and drilling contractors and in conjunction with

Another recommended source document is G. K. McK- API and IADC, have been used in the development of this vi-

own, Drill String Optimization for High-Angle Wells, 1989 tal tool. The same skill was utilized in formulating suggested

SPE/IADC Drilling Conference, SPE/IADC 18650. practices in the care and handling of pipe on the surface, while

making trips in and out of the hole and while drilling. With this

Seamless drillpipe is offered in the grades listed below under information, contractors and operators can extend drill-string

“Mechanical Properties API Steel Drill Pipe”. The drill string life and realize inprove project economics.

is used to transmit power by rotary motion from surface to

a drill bit at the bottom of the hole, to convey flushing media Drill string is an important and expensive part of the rig,

to the cutting face of the tool, and to carry cuttings out of the but suffers from a relatively short life. The cost of the drill

hole. Thus, it plays a vital part in the successful drilling of oil string places it in the category of a capital investment. It is

and gas wells. not strictly expendable. A recommended practice, followed

by many contractors, is to identify each joint upon purchase

Here are commonly used abbreviations for drill-pipe upsets: with an alpha-numeric serial. This serial number, along with

• IU: Internal upset; the length of the joint, should be recorded when it is placed

• EU: External upset;

• IEU: Internal-external upset.

Table DS-4: Mechanical properties of API steel drill pipe.

Grade E-75 X-95 G-105 S-135

Yield Strength (minimum psi) 75,000 95,000 105,000 135,000

Yield Strength (maximum psi) 105,000 125,000 135,000 165,000

Tensile Strength (minimum psi) 100,000 105,000 115,000 145,000

IADC Drilling Manual Copyright © 2015

DRILL STRING DS–3

in the string. This practice, along with field support and of- Markings at base of pin: ZZ 6 07 YY E 1 NC50

fice accounting, will facilitate: Tool joint mfctr: ZZ (ZZ Co.)

• Determining the useful life of the joint; Month welded: 6 (June)

Year welded: 07 (2007)

• Recording types of service and stresses the joint might

Pipe upsetter/processor YY

be exposed to;

Pipe grade: E

• Switching within the string to optimize use;

Pipe weight code 1

• Determining causes of failures more accurately; Tool-joint type: NC50

• Preventing or minimizing downhole failures.

Drill pipe grades

Grade Symbol

Grades and lengths of steel drillpipe E-75 E

As discussed in API/ISO Specifications above, drillpipe ZZ 6 07 YY E 1 NC50

X-95 X

tubes are furnished in the following API length ranges: G-105 G

• Range 1: 18-22 ft; S-135 S

• Range 2: 27-30 ft; V-150 V

• Range 3: 38-45 ft.

Figure DS-2: Tool joint markings for component identification.

Marking Note: Pin base marks should be clear and legible and not

Drillpipe identification is marked at the base of the pin by the struck over with manufacturing data.

tool joint manufacturer after the pin is affixed. The marking

will be in accordance with Figure DS-2. It is further recom- Pipe Grade

Code

Pipe Weight

Code

Groove

mended that drillpipe other than standard weight Grade

E-75, be marked according to Figures DS-3 through DS-5.

This is to give the crew rapid identification of high strength

Milled

drillpipe on the racks and on the floor during trips when it is Slot

in a combination string with Grade E-75. With little trouble, 1/4 in.

if necessary cleaning out the milled slot, the specific grade

and weight can be determined from the stenciled figures. L PB

joint OD surfaces should be performed, with an emphasis

L PB

on detection of longitudinal cracks. 2

See note B

• In highly stressed drilling environments or if

evidence of fatigue damage is noted, magnetic

particle inspection should be made of the entire box

threaded area, especially the last engaged thread

area, to determine if transverse cracks are present.

• The wet fluorescent magnetic particle method is Figure DS-3: Identification of standard weight high

strength drill pipe. (Refer to notes on p DS-4.) .

preferred.

Pipe Grade Pipe Weight

Weld-on tool joint description/basic theory Code Code

The flash welded tool joint was the first weld-on type tool

joint introduced to the industry in 1938. Inertia welding was

Milled

offered in 1974 and continuous-drive friction welding in Slot

1978. Figure DS-1 illustrates weld-on tool joint. 1/4 in.

Both inertia and continuous-drive friction welders use fric- L PB

L PB

tional heat for achieving welding temperatures. However, 2

1”

1/16R min.

the inertia welder uses a flywheel and momentum principle, 45°

See

Note B

whereas the continuous drive-friction welder maintains a

constant rpm motor and brake system.

Tool-joint selection

For many years tool joints have had a minimum yield strength

of 120,000 psi. The old IF, XH, FH, etc., have been replaced Figure DS-4: Identification of heavier-than-standard weight

with Numbered Connection series - NC plus a number in- Grade E-75 drill pipe. (Refer to notes on p DS-4.)

IADC Drilling Manual Copyright © 2015

DS–4 DRILL STRING

dicating pitch diameter in inches and tenths. NC46 replac- Pipe Grade

Code

Pipe Weight

Code

es the old 4 1/2-in. Extra Hole (XH). The NC series have the

same “V” threads, but with a 0.038-in.rounded root radius.

This offers a slightly better fatigue life and a slightly smaller Milled

cross section. Groove Slot

1/4 in.

Table DS-3 shows the interchangeability between NC con-

L PB

nections and the old style designations.

L PB

2

Torsional strength 1”

1/16” R min.

1-1/4”

The torsional strength of a tool joint is a function of several 45° See

Note B

variables. These include the strength of the steel, connec-

tion size, thread form, lead, taper, and coefficient of friction

on the mating surfaces of threads and shoulders. The torque

required to yield a rotary-shouldered connection may be ob-

tained from the equation in Appendix A, API RP7G. Figure DS-5: Identification of heavier-than-standard weight

high-strength drill pipe. (Refer to notes below.)

The pin or box area, whichever controls, is the largest factor

and is subject to the widest variation. The tool-joint outside Note A: Standard weight Grade E-75 drill pipe designated

diameter (OD) and inside diameter (ID) largely determine the by an asterisk (*) in the drill pipe weight code will have no

strength of the joint in torsion. The OD affects the box area and groove or milled slot for identification. Grade E-75 heavier

the ID affects the pin area. Choice of OD and ID determines than standard weight drill pipe will have a milled slot only in

the areas of the pin and box and establishes the theoretical the center of the tong space.

torsional strength, assuming all other factors are constant.

Note B: Groove radius approximately 3/8-in. Groove and milled

slot to be ¼-in. deep on 5 ¼-in. OD and larger tool joints, 3/16

OD wear causes the greatest reduction in theoretical tor- in. deep on 5-in. OD and smaller tool joints.

sional strength of a tool joint. At whatever point the tool-

joint box area becomes the smaller or controlling area, any Note C: Stencil the grade code symbol and weight code num-

further reduction in OD causes a direct reduction in torsion- ber corresponding to grade and weight of pipe in milled slot

al strength. If the box area controls when the tool joint is of pin. Stencil with ¼-in. high characters so marking may be

new, initial OD wear reduces torsional strength. It is possi- read with drill pipe hanging in elevators.

ble to increase torsional strength by making joints with over-

sized OD and reduced ID.

Elevator shoulder design

Tool joint box elevator shoulders are manufactured in both

the square and 18° taper. Most weld-on type tool joints are

furnished with tapered shoulders.

Tool joint pins are generally furnished with 35° tapered shoul-

ders, but can be made available with an 18° tapered shoulder.

Elevators are available to work with either 18° tapered or

square-shouldered joints. Those for use with the 18° tapered

shoulders are generally heavier due to the higher radial loading

that results from the wedging action. API Specification 8C spec-

ifies elevator bores to correspond to dimensions of the box

elevator upset.

On some tool joint assemblies, such as slim hole, lifting

plugs are used to provide the elevator shoulder necessary to

handle the drill string. Figure DS-6: Plastic coating in the pin bore acts as a stress

coat and serves as an early indicator of pin stretch.

IADC Drilling Manual Copyright © 2015

DRILL STRING DS–5

Tool-joint markings

It is recommended that weld on tool joints be stenciled on the

base of the pin with the information shown in Figure DS-2. In

addition, it is further recommended that drillpipe weight and

grade identification as shown in Figure DS-3, -4 and -5 be

used.

Drillpipe upsets for weld-on tool joints

Drillpipe must have upsets for installation of weld-on type

tool joints. This allows an adequate safety factor in the weld

area for mechanical strength and metallurgical consider-

ations. The tool joint is made with a welding neck or tang to

facilitate welding API upsets for various sizes, grades and

weights of drillpipe listed in API 5DP.

Figure DS-7: Thread protectors will prevent most tool-joint

damage that can occur during moving or racking.

High-strength drillpipe

Because of deeper drilling and higher stress levels, grades

of drillpipe stronger than Grade E-75 have been developed.

High-strength drillpipe requires heavier and longer upsets

Stress, pounds per sq in. (psi)

50,000 than those used on Grade E-75. Tool joints on high-strength

drillpipe are designed to fit the same elevators as those used

45,000

for the Grade E-75 assemblies.

Cleaning and inspection

40,000

35,000 Pin and box thread and shoulders should be thoroughly

cleaned to prepare them for adding to the string. Cleaning

30,000 pays off in three ways. Cleaning:

• Removes foreign material and permits proper

25,000

make-up, thereby reducing danger of galling and

wobbles;

20,000

• Permits better inspection;

15,000

• Increases the life of connections by eliminating abrasive

10,000 100,0000 1,000,000 10,000,000 100,000,000

materials.

Number of Cycles of Stress

Figure DS-8: S-N curve of mild steel shows number Connections should be thoroughly dried after cleaning so that

of cycles under stress to produce failure. the thread compound will properly adhere to the surface. An

approved way to clean tool joint threads and shoulders is to

wet the connection with kerosene or diesel; then brush with

ordinary gel. Catch the old dope and gel and dispose of prop-

erly. This will leave connections clean and dry for visual in-

spection and for applying fresh thread compound.

After cleaning, inspect thread and shoulders carefully. Dam-

aged connections should never be run in the hole. Even slight

damage will likely cause wobbling or leaking. Slight damage

may be repaired at the rig with a shoulder dressing tool or file.

Test each box and pin shoulder with a shoulder dressing tool

test ring. Use the benchmark to make sure that no tool joint

shoulder has been dressed beyond recommended limits. Check

the plastic coating in the pin bore under the last engaged thread

as a first check on pin stretch (Figure DS-6). After inspection,

protect all boxes and pins with clean, dry thread protectors.

Figure DS-9: Example of pure fatigue in a drill string box.

IADC Drilling Manual Copyright © 2015

Você também pode gostar

- Catalog Rulmenti INADocumento732 páginasCatalog Rulmenti INAadysan73100% (2)

- Drill String DesignDocumento117 páginasDrill String DesignMuhammad Imran100% (2)

- Pressure Vessel DesignDocumento21 páginasPressure Vessel DesignAbdullah AlgwhriAinda não há avaliações

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Drill String Design & BHA DesignDocumento115 páginasDrill String Design & BHA DesignUsama Bin Sabir97% (79)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- DPT1 - 02 - Drill String DesignDocumento109 páginasDPT1 - 02 - Drill String DesignBrahim Letaief100% (1)

- Grant Prideco Rotary Shoulder HandbookDocumento112 páginasGrant Prideco Rotary Shoulder Handbookrlk2806Ainda não há avaliações

- An Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberNo EverandAn Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberNota: 5 de 5 estrelas5/5 (1)

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDocumento19 páginasSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13Ainda não há avaliações

- تقی زادهDocumento216 páginasتقی زادهHamed NazariAinda não há avaliações

- Radio Frequency Transistors: Principles and practical applicationsNo EverandRadio Frequency Transistors: Principles and practical applicationsNota: 4 de 5 estrelas4/5 (3)

- Tubulars and Tubular Services Catalog: DrilcoDocumento29 páginasTubulars and Tubular Services Catalog: DrilcoDoni KurniawanAinda não há avaliações

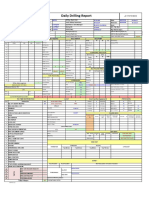

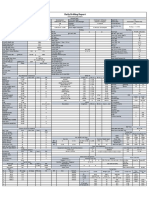

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocumento25 páginasDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariAinda não há avaliações

- DIN 3760 - RetentoresDocumento13 páginasDIN 3760 - RetentoresJosé100% (1)

- Drill PipeDocumento14 páginasDrill PipeNigin Parambath100% (2)

- Is Iso 7425 1 1988Documento10 páginasIs Iso 7425 1 1988Claudio De Sa OliveiraAinda não há avaliações

- Drill StringDocumento27 páginasDrill StringAboZaidAinda não há avaliações

- Wedge Thread Tool Joints Applications and EconomicsDocumento9 páginasWedge Thread Tool Joints Applications and EconomicsalexintelAinda não há avaliações

- Drill String Design BHA DesignDocumento97 páginasDrill String Design BHA DesignAhmed SallamAinda não há avaliações

- ASME Code News (Questions and Answers)Documento4 páginasASME Code News (Questions and Answers)dj22500Ainda não há avaliações

- HMH KFDJ Diverters r1Documento9 páginasHMH KFDJ Diverters r1budygmoodAinda não há avaliações

- Drill String Design Group 3Documento15 páginasDrill String Design Group 3Anusha AnuAinda não há avaliações

- Weld Metal Selector Guide: Effective March, 2000Documento28 páginasWeld Metal Selector Guide: Effective March, 2000saghirhassan61Ainda não há avaliações

- Tubulars Tubular Services Catalog PDFDocumento29 páginasTubulars Tubular Services Catalog PDFHERNANDO CASTILLO100% (1)

- A545-736-11-42-DS-0034 - A - Flow TeeDocumento2 páginasA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranAinda não há avaliações

- 3 Party Certification Requirements Per Issuance of October 14, 2010 Code of Federal RegulationsDocumento29 páginas3 Party Certification Requirements Per Issuance of October 14, 2010 Code of Federal RegulationsJosé Luis Párraga QuispeAinda não há avaliações

- Hydraulic Fluid Power - CylindersDocumento6 páginasHydraulic Fluid Power - CylindersRenuAinda não há avaliações

- IS 10605 (Steel Globe Valves (Flanged and Butt Welded Ends) For Petroleum, Petrochemical and AlliDocumento17 páginasIS 10605 (Steel Globe Valves (Flanged and Butt Welded Ends) For Petroleum, Petrochemical and AlliRajan SteeveAinda não há avaliações

- BB4-Catalogue 2015Documento11 páginasBB4-Catalogue 2015nima hasanzadehAinda não há avaliações

- 2Documento345 páginas2Brijesh MishraAinda não há avaliações

- JDS-G173 3Documento8 páginasJDS-G173 3FCP PUNEKARAinda não há avaliações

- Cement OsDocumento28 páginasCement OsLuis Romer Soliz AndiaAinda não há avaliações

- Titan Worldwide FlextralDocumento266 páginasTitan Worldwide FlextralKali Tapia LunaAinda não há avaliações

- General Product Specification For Swiv e L Ring Flan G e (SRF)Documento10 páginasGeneral Product Specification For Swiv e L Ring Flan G e (SRF)Juan Roberto López BetanzosAinda não há avaliações

- Catalogue Seal Oil CoolerDocumento28 páginasCatalogue Seal Oil CoolerSharad KokateAinda não há avaliações

- Provincial Electricity Authority Technical Specification for Hotline ClampsDocumento19 páginasProvincial Electricity Authority Technical Specification for Hotline ClampsTAEWARAT RAKRUANGAinda não há avaliações

- Comparación Mangueras Hidráulicas SAE e ISODocumento5 páginasComparación Mangueras Hidráulicas SAE e ISOJuan David Barrera FlorezAinda não há avaliações

- Nut and Bolt Compatibility ChartDocumento1 páginaNut and Bolt Compatibility Chartreach_arindomAinda não há avaliações

- TFP725 08 2016Documento8 páginasTFP725 08 2016Jun AntonioAinda não há avaliações

- TS of HardwareDocumento9 páginasTS of HardwareabhishekAinda não há avaliações

- Mil PRF 13789eDocumento9 páginasMil PRF 13789eOm Parkash SharmaAinda não há avaliações

- Sect 04 - DrillstringDocumento34 páginasSect 04 - Drillstringmin thantAinda não há avaliações

- Flanges Fittings PDFDocumento24 páginasFlanges Fittings PDFSalman KhanAinda não há avaliações

- Conduit PVCDocumento5 páginasConduit PVCefmartin21Ainda não há avaliações

- Tyco Grinnell Grooved CouplingDocumento4 páginasTyco Grinnell Grooved Couplingprvns0074377Ainda não há avaliações

- GRINNEL Figure 577 Acoplamiento Rig RanDocumento4 páginasGRINNEL Figure 577 Acoplamiento Rig RanFIRE RL SYSTEMSAinda não há avaliações

- Disconnect Switches and Fuse Blocks: Technical DataDocumento62 páginasDisconnect Switches and Fuse Blocks: Technical DataVicente CastruitaAinda não há avaliações

- Iso 2341-1986Documento8 páginasIso 2341-1986Azadeh AliabadiAinda não há avaliações

- ISO-228-1-1994 Metric Pipe Thread DimensionDocumento8 páginasISO-228-1-1994 Metric Pipe Thread DimensionMijatovic BoskoAinda não há avaliações

- Cylindrical Compression Helix Springs For Suspension SystemsNo EverandCylindrical Compression Helix Springs For Suspension SystemsAinda não há avaliações

- DDR1402 02 09Documento26 páginasDDR1402 02 09Hamed Nazari100% (1)

- غزالDocumento1 páginaغزالHamed NazariAinda não há avaliações

- Mehdi Soltani: Curriculum VitaeDocumento3 páginasMehdi Soltani: Curriculum VitaeHamed NazariAinda não há avaliações

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 páginasDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariAinda não há avaliações

- MD-1 NPT-Farvardin 1400: DescriptionDocumento5 páginasMD-1 NPT-Farvardin 1400: DescriptionHamed NazariAinda não há avaliações

- Mehrdad Mohammadpour MD Resume: OphthalmologyDocumento15 páginasMehrdad Mohammadpour MD Resume: OphthalmologyHamed NazariAinda não há avaliações

- Daily Drilling ReportDocumento3 páginasDaily Drilling ReportHamed NazariAinda não há avaliações

- 4 5963071420547203453Documento85 páginas4 5963071420547203453Hamed NazariAinda não há avaliações

- Daily Drilling ReportDocumento25 páginasDaily Drilling ReportHamed NazariAinda não há avaliações

- اقای غمامی تهران کیش 9 تیرDocumento1 páginaاقای غمامی تهران کیش 9 تیرHamed NazariAinda não há avaliações

- Da13 DDR N1 14000305 254 0Documento3 páginasDa13 DDR N1 14000305 254 0Hamed NazariAinda não há avaliações

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud PumpDocumento26 páginasDaily Drilling Report: Bha Tally Bit Record Mud Report Mud PumpHamed NazariAinda não há avaliações

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 páginasDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariAinda não há avaliações

- Da DDR N1 1Documento3 páginasDa DDR N1 1Hamed NazariAinda não há avaliações

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 páginasDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariAinda não há avaliações

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 páginasDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariAinda não há avaliações

- Full Field Study & MDP Preparation For Asmari Reservoir of Parsi FieldDocumento60 páginasFull Field Study & MDP Preparation For Asmari Reservoir of Parsi FieldHamed NazariAinda não há avaliações

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 páginasDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariAinda não há avaliações

- Daily Drilling Report for Danan Oilfield Development Well DA-14Documento3 páginasDaily Drilling Report for Danan Oilfield Development Well DA-14Hamed NazariAinda não há avaliações

- Da13 DDR N1 14000229 247 0Documento3 páginasDa13 DDR N1 14000229 247 0Hamed NazariAinda não há avaliações

- Daily Drilling Report for Danan Oilfield Development Well DANAN-DA-13Documento3 páginasDaily Drilling Report for Danan Oilfield Development Well DANAN-DA-13Hamed NazariAinda não há avaliações

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 páginasDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariAinda não há avaliações

- Da14 DDR N2 14000103 175 0Documento3 páginasDa14 DDR N2 14000103 175 0Hamed NazariAinda não há avaliações

- Daily Drilling ReportDocumento3 páginasDaily Drilling ReportHamed NazariAinda não há avaliações

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocumento25 páginasDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariAinda não há avaliações

- Da14 DDR N2 14000103 175 0Documento3 páginasDa14 DDR N2 14000103 175 0Hamed NazariAinda não há avaliações

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 páginasDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariAinda não há avaliações

- Daily Drilling Report for Danan Oilfield Development Well DA-13Documento3 páginasDaily Drilling Report for Danan Oilfield Development Well DA-13Hamed NazariAinda não há avaliações