Escolar Documentos

Profissional Documentos

Cultura Documentos

Article - Corrosion

Enviado por

DGWTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Article - Corrosion

Enviado por

DGWDireitos autorais:

Formatos disponíveis

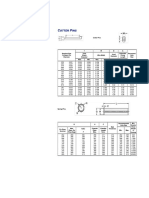

Style 7797

MATERIAL PROPERTIES*:

Color: Black

Composition: Neoprene rubber

Durometer, Shore A, (+/- 5): 80

Temperature1, °F (°C)

Minimum: -20 (-29)

Maximum: +250 (+121)

Pressure1, (psig (bar)

Preferred operating: 150 (10)

Maximum: 250 (17)

P x T (max.)1, psig x °F (bar x °C): 20,000 (600)

Finish Available

Through 1/8” Cloth

Over 1/8” Smooth

Meets Specifications: MIL-R-3065 and MIL-Std. 417 Type S Grade SC815 A1 E3 E5

TYPICAL PHYSICAL PROPERTIES*:

ASTM D412 Tensile Strength, psi (N/mm2): 1500 (10)

ASTM D412 Elongation, %: 125

ASTM D395 B Compression Set, 25% Deflection, Max. %

70 hours at 212°F (100°C): 75

ASTM F586 Design Factors

“m” factor: 1.0

“y” factor, psi (N/mm2): 200 (1.4)

(3)

ASTM D2000 Line Call Out: 4BC815A14EO14EO34G21

IMMERSION PROPERTIES*

ASTM D471 Volume Change in ASTM #1 Oil, Range %

70 hours at 212°F (100°C): -7 to 0

ASTM D471 Volume Change in ASTM #3 Oil, Range %

70 hours at 212°F (100°C): 45 to 60

Notes:

* This is a general guide and should not be the sole means of selecting or rejecting this material. Values do not constitute specification limits.

1

When approaching maximum pressure and/or temperature, minimum temperature or 50% of maximum PxT, consult Garlock Applications Engineering.

Minimum temperature rating is conservative.

2

Indicates the electrical current arced around and not through the gasket. Dielectric strength is higher than what is shown.

3

ASTM D2000 line call out is based on testing performed on slabs made to ASTM D412.

REV: 12/12/16

GARLOCK Tel: 1-877-GARLOCK / 315.597.4811

an EnPro Industries family of companies Fax: 800.543.0598 / 315.597.3216

1666 Division Street www.garlock.com

Palmyra, NY 14522

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Ins200 Assignment Hazardous PlaceDocumento10 páginasIns200 Assignment Hazardous PlaceNur Syafatin Natasya86% (7)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Wood Finishing Basics: Application Techniques & Product SelectionDocumento13 páginasWood Finishing Basics: Application Techniques & Product SelectionDGWAinda não há avaliações

- He130 - Driveway Asphalt Coating: Physical PropertiesDocumento2 páginasHe130 - Driveway Asphalt Coating: Physical PropertiesDGWAinda não há avaliações

- Masonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)Documento2 páginasMasonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)DGWAinda não há avaliações

- What Is Sealcoating - Asphalt Sealcoating - Seal CoatDocumento2 páginasWhat Is Sealcoating - Asphalt Sealcoating - Seal CoatDGWAinda não há avaliações

- Lee Spring CatalogDocumento391 páginasLee Spring CatalogDGWAinda não há avaliações

- Overkote Asphalt Pavement Coating: DescriptionDocumento1 páginaOverkote Asphalt Pavement Coating: DescriptionDGWAinda não há avaliações

- D-01 7041 Flange-ANSI 125,150-RevlDocumento4 páginasD-01 7041 Flange-ANSI 125,150-RevlJohanna RojasAinda não há avaliações

- Flat Washer and FastenersDocumento49 páginasFlat Washer and FastenersDGWAinda não há avaliações

- 01 04tocDocumento428 páginas01 04tocFaltooAinda não há avaliações

- Standard Pipe Sizes ME303-4.1.1Documento5 páginasStandard Pipe Sizes ME303-4.1.1manashbdAinda não há avaliações

- Standard Pipe Sizes ME303-4.1.1Documento5 páginasStandard Pipe Sizes ME303-4.1.1manashbdAinda não há avaliações

- Tap Drill ChartDocumento2 páginasTap Drill ChartDGWAinda não há avaliações

- Nord-Lock Washers: The Original Wedge-Locking SolutionDocumento16 páginasNord-Lock Washers: The Original Wedge-Locking SolutionDGWAinda não há avaliações

- Schedule 80 Pipe Dimensions & Pressure RatingsDocumento1 páginaSchedule 80 Pipe Dimensions & Pressure RatingsDGWAinda não há avaliações

- Thrust Restraint For Expansion JointDocumento2 páginasThrust Restraint For Expansion JointDGWAinda não há avaliações

- Pipe Chart PDFDocumento2 páginasPipe Chart PDFCarlos Rivera0% (1)

- Technical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDocumento2 páginasTechnical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDGWAinda não há avaliações

- The First Hillside Washer That Eliminated Back-Up Plates!Documento1 páginaThe First Hillside Washer That Eliminated Back-Up Plates!DGWAinda não há avaliações

- Rubber Expansion JointsDocumento9 páginasRubber Expansion JointsDGWAinda não há avaliações

- E Pipe Restraint ROMAC 612 CDocumento1 páginaE Pipe Restraint ROMAC 612 CDGWAinda não há avaliações

- Countersinking Drill Bit ReamerDocumento1 páginaCountersinking Drill Bit ReamerDGWAinda não há avaliações

- JLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDocumento2 páginasJLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDGWAinda não há avaliações

- Tap Drill DataDocumento1 páginaTap Drill DataDGWAinda não há avaliações

- PVC Gravity Sewer PipeDocumento1 páginaPVC Gravity Sewer PipeDGWAinda não há avaliações

- Threaded RodDocumento1 páginaThreaded RodDGWAinda não há avaliações

- Steel Rebar SizesDocumento1 páginaSteel Rebar SizesDGWAinda não há avaliações

- Bolt - Astm A449Documento2 páginasBolt - Astm A449DGWAinda não há avaliações

- Screw Threads DesignDocumento1 páginaScrew Threads DesignDGWAinda não há avaliações

- Cotter Pins and Spring PinsDocumento1 páginaCotter Pins and Spring PinsDGWAinda não há avaliações

- Standard Pipe Schedules and Sizes ChartDocumento1 páginaStandard Pipe Schedules and Sizes ChartDGWAinda não há avaliações

- Laser Security System For HomeDocumento19 páginasLaser Security System For HomeSelvakumar SubramaniAinda não há avaliações

- Basics Stats Ti NspireDocumento7 páginasBasics Stats Ti NspirePanagiotis SotiropoulosAinda não há avaliações

- PT Shri Krishna Sejahtera: Jalan Pintu Air Raya No. 56H, Pasar Baru Jakarta Pusat 10710 Jakarta - IndonesiaDocumento16 páginasPT Shri Krishna Sejahtera: Jalan Pintu Air Raya No. 56H, Pasar Baru Jakarta Pusat 10710 Jakarta - IndonesiaihsanlaidiAinda não há avaliações

- Agile Marketing Reference CardDocumento2 páginasAgile Marketing Reference CardDavid BriggsAinda não há avaliações

- CS506 Mid SubjectiveDocumento2 páginasCS506 Mid SubjectiveElma AlamAinda não há avaliações

- 2 Players The One With Steam BaronsDocumento1 página2 Players The One With Steam BaronsBrad RoseAinda não há avaliações

- CV Najim Square Pharma 4 Years ExperienceDocumento2 páginasCV Najim Square Pharma 4 Years ExperienceDelwarAinda não há avaliações

- ANNEX C LIST OF EXCEPTIONS (Non-Disslosure of Information)Documento3 páginasANNEX C LIST OF EXCEPTIONS (Non-Disslosure of Information)ryujinxxcastorAinda não há avaliações

- Enabling Trade Report 2013, World Trade ForumDocumento52 páginasEnabling Trade Report 2013, World Trade ForumNancy Islam100% (1)

- Pa 28 151 161 - mmv1995 PDFDocumento585 páginasPa 28 151 161 - mmv1995 PDFJonatan JonatanBernalAinda não há avaliações

- All About Ignition Coils: Technical InformationDocumento15 páginasAll About Ignition Coils: Technical InformationTrương Ngọc ThắngAinda não há avaliações

- The Financing Cycle Summary, Case Study, AssignmentsDocumento18 páginasThe Financing Cycle Summary, Case Study, AssignmentsbernadetteAinda não há avaliações

- Digest of Ganila Vs CADocumento1 páginaDigest of Ganila Vs CAJohn Lester LantinAinda não há avaliações

- Hardening'-Australian For Transformation: A Monograph by MAJ David J. Wainwright Australian Regular ArmyDocumento89 páginasHardening'-Australian For Transformation: A Monograph by MAJ David J. Wainwright Australian Regular ArmyJet VissanuAinda não há avaliações

- Eudemon8000E XDocumento2 páginasEudemon8000E XGladys Medina100% (1)

- Evaluating The Policy Outcomes For Urban Resiliency in Informal Settlements Since Independence in Dhaka, Bangladesh: A ReviewDocumento14 páginasEvaluating The Policy Outcomes For Urban Resiliency in Informal Settlements Since Independence in Dhaka, Bangladesh: A ReviewJaber AbdullahAinda não há avaliações

- A Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingDocumento22 páginasA Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingPl TorrAinda não há avaliações

- Power Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range EDocumento8 páginasPower Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range Ejrz000Ainda não há avaliações

- Galanz - Galaxy 7-9-12K - SPLIT PDFDocumento42 páginasGalanz - Galaxy 7-9-12K - SPLIT PDFUbaldo BritoAinda não há avaliações

- Kolodin Agreement For Discipline by ConsentDocumento21 páginasKolodin Agreement For Discipline by ConsentJordan ConradsonAinda não há avaliações

- Organization of Brigada Eskwela Steering and Working CommitteesDocumento2 páginasOrganization of Brigada Eskwela Steering and Working CommitteesCherry Lou RiofrirAinda não há avaliações

- Midterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsDocumento3 páginasMidterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsGarp Barroca100% (1)

- San Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintDocumento25 páginasSan Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintFindLawAinda não há avaliações

- On The Backward Problem For Parabolic Equations With MemoryDocumento19 páginasOn The Backward Problem For Parabolic Equations With MemorykamranAinda não há avaliações

- Integrated Recycling Systems: Harris Complete PackageDocumento4 páginasIntegrated Recycling Systems: Harris Complete PackageNicolás Toro ValenzuelaAinda não há avaliações

- Sample Pilots ChecklistDocumento2 páginasSample Pilots ChecklistKin kei MannAinda não há avaliações

- Collection of Solid WasteDocumento38 páginasCollection of Solid WasteMuhammad UsmanAinda não há avaliações

- A88438-23 Critical Procedure 11-01 - Pipeline Cut Outs - A5X9W9Documento7 páginasA88438-23 Critical Procedure 11-01 - Pipeline Cut Outs - A5X9W9mahmoudAinda não há avaliações

- Digitalisasi Alquran-1 PDFDocumento40 páginasDigitalisasi Alquran-1 PDFMohammad Zildan Pasyha MAinda não há avaliações