Escolar Documentos

Profissional Documentos

Cultura Documentos

General: Model ICB 100-800 HP Boilers

Enviado por

sebaversaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

General: Model ICB 100-800 HP Boilers

Enviado por

sebaversaDireitos autorais:

Formatos disponíveis

Model ICB 100-800 HP Boilers

The following sample specification is provided by Cleaver-Brooks to assist you in meeting

your customer’s specific needs and application.

The Sample Specifications are typically utilized as the base template for the complete

boiler specification. Contact your local Cleaver-Brooks Authorized Representative for

information on special insurance requirements, special code requirements, optional

equipment, or general assistance in completing the specification.

PART 1 GENERAL

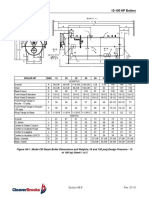

Model ICB Steam Boiler (100 – 800 hp, 15 – 300 psig)

1.1 Boiler Characteristics (Steam)

A. The Steam Boiler shall be Cleaver-Brooks Model ICB, Fuel Series _____ (100, 200,

700), _____ hp designed for _____ psig (15, 150, 200, 250, 300 psig steam). The

maximum operating pressure shall be _____ psig.

B. The boiler shall have a maximum output of _____ Btu/hr, or _____ horsepower when

fired with CS 12-48 No. 2 oil and/or natural gas, _____ Btu/cu-ft. Electrical power

available will be _____ Volt _____ Phase _____ Cycle and 115/1/60 for the control

circuit.

PART 2 PRODUCTS

2.1 General Boiler Design

A. Number of Passes — Select one of the following:

• (Four-Pass) The boiler shall be a four-pass intercooled horizontal firetube updraft

boiler. It shall be mounted on a heavy steel frame with forced draft burner and

burner controls.

• (Three-Pass) The boiler shall be a three-pass intercooled horizontal firetube

updraft boiler. It shall be mounted on a heavy steel frame with forced draft burner

and burner controls.

1. Approvals: The complete burner/boiler package shall be approved as a unit by

Underwriters Laboratories Inc. and bear the UL/cUL label.

2. The boiler shall be completely preassembled and fire tested at the factory. The

unit shall be ready for immediate mounting on floor or simple foundation and

ready for attachment of water, steam, fuel, electrical, vent and blowdown

connections.

B. Boiler Shell (Steam)

1. The boiler shell must be constructed in accordance with ASME Boiler Code and

must receive authorized boiler inspection prior to shipment. A copy of the

inspection report shall be furnished to the purchaser.

2. Two lifting eyes shall be located on top of the boiler.

3. Front and rear doors on the boiler shall be davited.

Section A4-30 Rev. 02-08

Model ICB 100-800 HP Boilers

4. The rear door shall be insulated with a blanket material and a steel covering to

give the surface a hard durable finish.

5. The boiler tubes shall not include turbulators, swirlers or other add-on

appurtenances.

6. The boiler shall be furnished with a manhole and handholes to facilitate boiler

inspection and cleaning.

7. Exhaust Vent — Select one of the following:

• (Four-Pass) The exhaust gas vent shall be located near the front of the

boiler on the top center line and shall be capable of supporting 2000 lbs.

• (Three-Pass) The exhaust gas vent shall be located at the rear of the

boiler on the top center line and shall be capable of supporting 2000 lbs.

8. Observation ports for the inspection of flame conditions shall be provided at each

end of the boiler.

9. The boiler insulation shall consist of a 2 inch blanket under a sectional preformed

sheet metal lagging. This insulation must be readily removable and capable of

being reinstalled, if required.

10. The entire boiler based frame and other components shall be factory painted

before shipment using a hard finish enamel coating.

11. An inner rear turnaround access opening shall swing on a davit, to allow full

accessibility to the 2nd pass tubes and furnace.

12. Tubes shall be removable from either the front or rear of the boiler.

2.2 Steam Boiler Trim

A. 3.1 Water Column

A water column shall be located on the right hand side of the boiler complete with

gauge glass set and water column blowdown valves.

1. Feedwater Pump Control

The boiler feedwater pump control shall be included as an integral part of the

water column to automatically actuate a motor driven feedwater pump

maintaining the boiler water level within normal limits.

2. Low Water Cutoff

The low water cutoff shall be included as an integral part of the boiler feedwater

control wired into the burner control circuit to prevent burner operation if the

boiler water level falls below a safe level.

B. Auxiliary Low Water Cutoff

The auxiliary low water cutoff shall be included, piped to the vessel, and wired to the

burner control circuit. A manual reset device shall be used for this control.

C. Steam Pressure Gauge

The steam pressure gauge shall be located at the front of the boiler and include cock

and test connection.

D. Safety Relief Valves

Safety valves of a type and size to comply with ASME Code requirements shall be

shipped loose.

E. Steam Pressure Controls

The steam pressure controls to regulate burner operation shall be mounted near the

water column.

Section A4-31 Rev. 02-08

Model ICB 100-800 HP Boilers

2.3 Burner and Controls

A. Mode of Operation

Burner operation shall be the full modulation principle. The burner shall always return

to low fire position for ignition.

B. Blower

1. All air for combustion shall be supplied by a forced draft blower mounted on the

burner, to eliminate vibration and reduce noise level.

2. Maximum sound level of the boiler/burner package shall not exceed _____ dBA

(when measured in accordance with ABMA Sound Test Standards).

3. The impeller shall be fabricated aluminum with radial blade, carefully balanced,

and directly connected to the blower motor shaft.

C. Combustion Air Control — Select one of the following:

• (Four-Pass) Combustion air damper and fuel control valve (100 – 250 hp) or

cam operated fuel metering valve (300 – 800 hp) shall be operated by a

single damper control motor that regulates the flame according to load

demand. Potentiometer type position controls shall be provided to regulate

operation of the damper control motor.

• (Three-Pass) Combustion air damper and fuel control valve (100 – 350 hp) or

cam operated fuel metering valve (400 – 800 hp) shall be operated by a

single damper control motor that regulates the flame according to load

demand. Potentiometer type position controls shall be provided to regulate

operation of the damper control motor.

D. Fuel Specification and Piping

Select one of the following fuel types:

• Fuel series 700 — Gas fired (para 4.4.1).

• Fuel series 100 — Light oil (No. 2) fired (para 4.4.2).

• Fuel series 200 — Light oil or gas fired (para 4.4.3).

1. FUEL SERIES 700 — GAS FIRED

a. Burner Type — The burner shall be mounted at the front of the boiler and be

of high radiant multi-port type for gas. The burner shall be approved for

operation on natural gas fuel.

b. Gas Pilot — The gas pilot shall be a premix type with automatic electric

ignition. An electronic detector shall monitor the pilot so that the primary gas

valve cannot open until pilot flame has been established. The pilot train shall

include one (1) shut-off valve, solenoid valve, pressure regulator, and one (1)

plugged leakage test connection (Canada only).

c. Gas Burner Piping — Select one of the following:

1) 100 hp. Gas burner piping on all units shall include two (2) manual shut-

off valves, gas pressure regulator, one (1) motorized gas valve with proof

of closure switch, two (2) plugged leakage test connections, and high

and low gas pressure switches. The gas valves shall be wired to close

automatically in the event of power failure, flame failure, low water, or

any abnormal shutdown condition.

2) 125 – 250 hp. Gas burner piping on all units shall include two (2) manual

shut-off valves, gas pressure regulator, two (2) motorized gas valves,

one (1) valve with proof of closure switch, two (2) plugged leakage test

Section A4-32 Rev. 02-08

Model ICB 100-800 HP Boilers

connections, and high and low gas pressure switches. The gas valves

shall be wired to close automatically in the event of power failure, flame

failure, low water, or any abnormal shutdown condition.

3) 300 – 350 hp. Gas burner piping on all units shall include two (2) manual

shut-off valves, gas pressure regulator, two (2) motorized gas valves,

one (1) valve with proof of closure switch, main gas vent valve, two (2)

plugged leakage test connections, and high and low gas pressure

switches. The gas valves shall be wired to close automatically in the

event of power failure, flame failure, low water, or any abnormal

shutdown condition.

4) 400 – 800 hp. Gas burner piping on all units shall include two (2) manual

shut-off valves, gas pressure regulator, two (2) motorized gas valves,

one (1) valve with proof of closure switch, main gas vent valve, two (2)

plugged leakage test connections, and high and low gas pressure

switches. The gas valves shall be wired to close automatically in the

event of power failure, flame failure, low water, or any abnormal

shutdown condition.

2. FUEL SERIES 100 — LIGHT OIL FIRED

a. Burner Type — The burner shall be mounted at the front of the boiler, and

shall be approved for operation with CS12-48, Commercial No. 2 oil.

b. Gas Pilot — The gas pilot shall be a premix type with automatic electric

ignition. An electronic detector shall monitor the pilot so that the primary gas

valve cannot open until pilot flame has been established. The pilot train shall

include one (1) shut-off valve, solenoid valve, pressure regulator, and one (1)

plugged leakage test connection (Canada only).

c. Oil Pump — An oil pump with a capacity of approximately twice the

maximum burning rate shall be included. Pump shall be motor driven and

shipped loose to be field installed near the oil storage tank. Oil pump motor

starter shall also be provided.

d. Oil Burner Piping

1) Four-Pass — Select one of the following:

• 100 – 150 hp. Fuel oil piping on the unit shall include oil pressure

regulating device, oil metering controls, two (2) solenoid oil shut-off

valves, and pressure gauge all integrally mounted on the unit.

• 200 – 250 hp. Fuel oil piping on the unit shall include oil pressure

regulating device, oil metering controls, two (2) solenoid oil shut-off

valves, atomizing air proving switch, low oil pressure switch, and

pressure gauge all integrally mounted on the unit.

• 300 – 800 hp. Fuel oil piping on the unit shall include oil metering

system, one (1) solenoid oil shut-off valve, one (1) motorized oil

valve with proof of closure switch, pressure relief valve, atomizing air

proving switch, and low oil pressure switch all integrally mounted on

the unit.

2) Three-Pass — Select one of the following:

• 100 – 150 hp. Fuel oil piping on the unit shall include oil pressure

regulating device, oil metering controls, two (2) solenoid oil shut-off

valves, and pressure gauge all integrally mounted on the unit.

• 200 – 350 hp. Fuel oil piping on the unit shall include oil pressure

regulating device, oil metering controls, two (2) solenoid oil shut-off

Section A4-33 Rev. 02-08

Você também pode gostar

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNo Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNota: 4 de 5 estrelas4/5 (1)

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Documento5 páginasModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaAinda não há avaliações

- Section A5: Model CBL 900-1800 HP BoilersDocumento5 páginasSection A5: Model CBL 900-1800 HP BoilerssebaversaAinda não há avaliações

- Section A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)Documento4 páginasSection A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)sebaversaAinda não há avaliações

- Spec Modelcble Steam Mar4Documento12 páginasSpec Modelcble Steam Mar4Jason PoloAinda não há avaliações

- SPEC Model CB Steam Jan11Documento12 páginasSPEC Model CB Steam Jan11Stanford BrownAinda não há avaliações

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocumento5 páginasModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaAinda não há avaliações

- Model 4WI 100 - 800 HP Boilers: WarrantyDocumento4 páginasModel 4WI 100 - 800 HP Boilers: WarrantysebaversaAinda não há avaliações

- CB CBLE HW SpecsDocumento11 páginasCB CBLE HW SpecsDiogenes Rafael TorresAinda não há avaliações

- Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Documento12 páginasModel Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Diogenes Rafael TorresAinda não há avaliações

- Section A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Documento4 páginasSection A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)sebaversa100% (1)

- SPEC ModelCBR Steam Mar4Documento10 páginasSPEC ModelCBR Steam Mar4Jason PoloAinda não há avaliações

- Boiler SpecificationsDocumento25 páginasBoiler Specificationspaul kioiAinda não há avaliações

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocumento5 páginasModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaAinda não há avaliações

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocumento4 páginasModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaAinda não há avaliações

- AIA Boiler Specification CM2 v1.2 Master Spec PDFDocumento11 páginasAIA Boiler Specification CM2 v1.2 Master Spec PDFbotosionAinda não há avaliações

- CSI Spec EXN-SGO-07Documento5 páginasCSI Spec EXN-SGO-07davidvranaAinda não há avaliações

- Hurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDocumento5 páginasHurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDaniel GonzalezAinda não há avaliações

- Hurst Boiler & Welding Company, IncDocumento7 páginasHurst Boiler & Welding Company, IncChristian Veliz CamargoAinda não há avaliações

- 88 Series 2 Boiler: Suggested SpecificationsDocumento4 páginas88 Series 2 Boiler: Suggested SpecificationsAdam Bin Abu BakarAinda não há avaliações

- Bfit Model BFIT Condensing Hot Water Boiler SpecificationDocumento8 páginasBfit Model BFIT Condensing Hot Water Boiler SpecificationjoeAinda não há avaliações

- Series 500 Water SpecDocumento5 páginasSeries 500 Water SpecChristhofer Arroyo ChacónAinda não há avaliações

- Boiler SpecificationsDocumento19 páginasBoiler Specificationspaul kioiAinda não há avaliações

- Series 4vt Steam SpecificationsDocumento5 páginasSeries 4vt Steam Specificationsagusti24Ainda não há avaliações

- Sample Chiller SpecificationDocumento5 páginasSample Chiller Specificationjlcheefei9258Ainda não há avaliações

- HVAC Guide Specifications Commercial Air-Cooled Condensing UnitsDocumento4 páginasHVAC Guide Specifications Commercial Air-Cooled Condensing UnitsHazemAinda não há avaliações

- SECTION 15550 Hot Water Boilers Part 1 - General 1.1 Related DocumentsDocumento13 páginasSECTION 15550 Hot Water Boilers Part 1 - General 1.1 Related DocumentsMunir RasheedAinda não há avaliações

- Hurst Boiler & Welding Co., IncDocumento4 páginasHurst Boiler & Welding Co., IncChristian Veliz CamargoAinda não há avaliações

- Hurst Boiler & Welding Company, Inc.: Sample SpecificationsDocumento3 páginasHurst Boiler & Welding Company, Inc.: Sample Specificationskikokiko KarimAinda não há avaliações

- Mohawk Steam Sample SpecificationsDocumento7 páginasMohawk Steam Sample SpecificationsXamir Suarez AlejandroAinda não há avaliações

- HVAC Guide Specifications Commercial Air-Cooled Condensing Units 63 To 87 KW (18 To 25 Tons), Nominal 38AH Part 1 GeneralDocumento4 páginasHVAC Guide Specifications Commercial Air-Cooled Condensing Units 63 To 87 KW (18 To 25 Tons), Nominal 38AH Part 1 GeneralcarlosorizabaAinda não há avaliações

- Turn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsDocumento18 páginasTurn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsKarim Galal IsmailAinda não há avaliações

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Documento5 páginasPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffAinda não há avaliações

- ASB Boiler CatalogueDocumento12 páginasASB Boiler CatalogueJivaAliAinda não há avaliações

- Flash Tank Heat Recovery SpecificationDocumento3 páginasFlash Tank Heat Recovery SpecificationMerisaAinda não há avaliações

- Model CBL 900-1800 HP BoilersDocumento5 páginasModel CBL 900-1800 HP BoilerssebaversaAinda não há avaliações

- Model 4WG 100 - 800 HP Boilers: Figure A3-9. Boiler Room Length (Typical Layouts) - Model 4WGDocumento4 páginasModel 4WG 100 - 800 HP Boilers: Figure A3-9. Boiler Room Length (Typical Layouts) - Model 4WGsebaversaAinda não há avaliações

- Model ICB 100-800 HP BoilersDocumento4 páginasModel ICB 100-800 HP BoilerssebaversaAinda não há avaliações

- 8 Series Steam or Hot Water Boiler-Burner Unit Installation & Operating InstructionsDocumento24 páginas8 Series Steam or Hot Water Boiler-Burner Unit Installation & Operating Instructionsmanuals1121Ainda não há avaliações

- Model CBLE 100-800 HP BoilersDocumento4 páginasModel CBLE 100-800 HP BoilerssebaversaAinda não há avaliações

- Boiler Manual - EnglishDocumento20 páginasBoiler Manual - Englishengrasadullah000Ainda não há avaliações

- Dartmouth College Design November 15, 2007 & Construction GuidelinesDocumento4 páginasDartmouth College Design November 15, 2007 & Construction GuidelinesIndira SharanAinda não há avaliações

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocumento5 páginasModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaAinda não há avaliações

- Section 35 - Air Conditioning and Mechanic Ventilation SystemDocumento32 páginasSection 35 - Air Conditioning and Mechanic Ventilation SystemMAYMODERN SITEINFOAinda não há avaliações

- Chiller & FahuDocumento12 páginasChiller & FahuHafnazSabeerAinda não há avaliações

- Model CBR 125-800 HP BoilersDocumento5 páginasModel CBR 125-800 HP BoilerssebaversaAinda não há avaliações

- Steam Boiler Spec.Documento17 páginasSteam Boiler Spec.bandithaguru6338100% (1)

- HVAC Guide Specifications Indoor Self-Contained Air-Cooled Unit Constant Volume ApplicationDocumento3 páginasHVAC Guide Specifications Indoor Self-Contained Air-Cooled Unit Constant Volume ApplicationasdthuAinda não há avaliações

- Engineering Data: Model CBEX Elite 1300-2200HP BoilersDocumento4 páginasEngineering Data: Model CBEX Elite 1300-2200HP BoilerssebaversaAinda não há avaliações

- Guide Specifications: Commercial Air-Cooled Condensing Units HVAC Guide SpecificationsDocumento4 páginasGuide Specifications: Commercial Air-Cooled Condensing Units HVAC Guide SpecificationshtanhAinda não há avaliações

- Eca Day Tank SpecDocumento3 páginasEca Day Tank Specenlightened1718Ainda não há avaliações

- Domestic Pump: Series CM Boiler Feed UnitsDocumento4 páginasDomestic Pump: Series CM Boiler Feed UnitsAnonymous 7xHNgoKE6eAinda não há avaliações

- LES VI Boiler SpecDocumento3 páginasLES VI Boiler SpecliamcsAinda não há avaliações

- Model CBL 900-1800 HP Boilers: Engineering DataDocumento5 páginasModel CBL 900-1800 HP Boilers: Engineering DatasebaversaAinda não há avaliações

- 2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)Documento22 páginas2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)sabrila wandaAinda não há avaliações

- 11/29/19 Design No. - SECTION 15580 Feedwater EquipmentDocumento20 páginas11/29/19 Design No. - SECTION 15580 Feedwater EquipmentJhoAinda não há avaliações

- Feed Water UnitDocumento2 páginasFeed Water UnitEslam ElsayedAinda não há avaliações

- SEC 226200 Laboratory Vacuum SystemDocumento8 páginasSEC 226200 Laboratory Vacuum SystemAkilaJosephAinda não há avaliações

- 213113P - Fire Pumps and Controllers 09 09 2022Documento11 páginas213113P - Fire Pumps and Controllers 09 09 2022albfaragAinda não há avaliações

- ATC-E Unit SpecificationsDocumento3 páginasATC-E Unit SpecificationsgamunozdAinda não há avaliações

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocumento5 páginasModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaAinda não há avaliações

- Model CB 15-100 HP Boilers: Sound LevelDocumento5 páginasModel CB 15-100 HP Boilers: Sound LevelsebaversaAinda não há avaliações

- Model CB 15-100 HP Boilers: LightsDocumento5 páginasModel CB 15-100 HP Boilers: LightssebaversaAinda não há avaliações

- Model CB 15-100 HP BoilersDocumento5 páginasModel CB 15-100 HP BoilerssebaversaAinda não há avaliações

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocumento5 páginasModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaAinda não há avaliações

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocumento5 páginasModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaAinda não há avaliações

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocumento5 páginasModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaAinda não há avaliações

- Model CB 15-100 HP BoilersDocumento5 páginasModel CB 15-100 HP BoilerssebaversaAinda não há avaliações

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocumento5 páginasModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaAinda não há avaliações

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocumento5 páginasModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaAinda não há avaliações

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocumento5 páginasModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaAinda não há avaliações

- Model CBL 900-1800 HP Boilers: Engineering DataDocumento5 páginasModel CBL 900-1800 HP Boilers: Engineering DatasebaversaAinda não há avaliações

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocumento5 páginasModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaAinda não há avaliações

- Model CBL 900-1800 HP BoilersDocumento5 páginasModel CBL 900-1800 HP BoilerssebaversaAinda não há avaliações

- Features and Benefits: Model CB 15-100 HP BoilersDocumento5 páginasFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaAinda não há avaliações

- Model CBR 125-800 HP BoilersDocumento5 páginasModel CBR 125-800 HP BoilerssebaversaAinda não há avaliações

- Model CBL 900-1800 HP BoilersDocumento5 páginasModel CBL 900-1800 HP BoilerssebaversaAinda não há avaliações

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocumento5 páginasModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaAinda não há avaliações

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocumento5 páginasModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaAinda não há avaliações

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocumento5 páginasModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaAinda não há avaliações

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocumento4 páginasModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaAinda não há avaliações

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Documento6 páginasModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaAinda não há avaliações

- Model ICB 100-800 HP BoilersDocumento4 páginasModel ICB 100-800 HP BoilerssebaversaAinda não há avaliações

- Model ICB 100-800 HP BoilersDocumento4 páginasModel ICB 100-800 HP BoilerssebaversaAinda não há avaliações

- Model ICB 100-800 HP Boilers: Performance DataDocumento4 páginasModel ICB 100-800 HP Boilers: Performance DatasebaversaAinda não há avaliações

- Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizeDocumento4 páginasModel ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizesebaversaAinda não há avaliações

- Research ArticleDocumento9 páginasResearch ArticlesebaversaAinda não há avaliações

- Model ICB 100-800 HP BoilersDocumento4 páginasModel ICB 100-800 HP BoilerssebaversaAinda não há avaliações

- Sample Monologues PDFDocumento5 páginasSample Monologues PDFChristina Cannilla100% (1)

- Canoe Matlab 001Documento58 páginasCanoe Matlab 001Coolboy RoadsterAinda não há avaliações

- A Survey On Security and Privacy Issues of Bitcoin-1Documento39 páginasA Survey On Security and Privacy Issues of Bitcoin-1Ramineni HarshaAinda não há avaliações

- Tutorial 5 SolvedDocumento3 páginasTutorial 5 SolvedAshutoshKumarAinda não há avaliações

- My Mother at 66Documento6 páginasMy Mother at 66AnjanaAinda não há avaliações

- QSP 04bDocumento35 páginasQSP 04bakrastogi94843Ainda não há avaliações

- Illustrating An Experiment, Outcome, Sample Space and EventDocumento9 páginasIllustrating An Experiment, Outcome, Sample Space and EventMarielle MunarAinda não há avaliações

- 1 in 8.5 60KG PSC Sleepers TurnoutDocumento9 páginas1 in 8.5 60KG PSC Sleepers Turnoutrailway maintenanceAinda não há avaliações

- Recitation Math 001 - Term 221 (26166)Documento36 páginasRecitation Math 001 - Term 221 (26166)Ma NaAinda não há avaliações

- AMULDocumento11 páginasAMULkeshav956Ainda não há avaliações

- 2016 Closing The Gap ReportDocumento64 páginas2016 Closing The Gap ReportAllan ClarkeAinda não há avaliações

- 2022 WR Extended VersionDocumento71 páginas2022 WR Extended Versionpavankawade63Ainda não há avaliações

- Unsuccessful MT-SM DeliveryDocumento2 páginasUnsuccessful MT-SM DeliveryPitam MaitiAinda não há avaliações

- Bom Details FormatDocumento6 páginasBom Details FormatPrince MittalAinda não há avaliações

- Bullshit System v0.5Documento40 páginasBullshit System v0.5ZolaniusAinda não há avaliações

- LP For EarthquakeDocumento6 páginasLP For Earthquakejelena jorgeoAinda não há avaliações

- 40 People vs. Rafanan, Jr.Documento10 páginas40 People vs. Rafanan, Jr.Simeon TutaanAinda não há avaliações

- Anatomy of the pulp cavity กย 2562-1Documento84 páginasAnatomy of the pulp cavity กย 2562-1IlincaVasilescuAinda não há avaliações

- Promotion-Mix (: Tools For IMC)Documento11 páginasPromotion-Mix (: Tools For IMC)Mehul RasadiyaAinda não há avaliações

- BrochureDocumento3 páginasBrochureapi-400730798Ainda não há avaliações

- Micro Lab Midterm Study GuideDocumento15 páginasMicro Lab Midterm Study GuideYvette Salomé NievesAinda não há avaliações

- Apple Change ManagementDocumento31 páginasApple Change ManagementimuffysAinda não há avaliações

- Triaxial Shear TestDocumento10 páginasTriaxial Shear TestAfiqah Nu'aimiAinda não há avaliações

- Delusion in SocietyDocumento2 páginasDelusion in SocietyGasimovskyAinda não há avaliações

- Z-Purlins: Technical DocumentationDocumento11 páginasZ-Purlins: Technical Documentationardit bedhiaAinda não há avaliações

- Standard Answers For The MSC ProgrammeDocumento17 páginasStandard Answers For The MSC ProgrammeTiwiAinda não há avaliações

- Miguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Documento22 páginasMiguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Immigrant & Refugee Appellate Center, LLCAinda não há avaliações

- Rajiv Gandhi University of Health Sciences, Bengaluru, KarnatakaDocumento9 páginasRajiv Gandhi University of Health Sciences, Bengaluru, KarnatakaNavin ChandarAinda não há avaliações

- The Covenant Taken From The Sons of Adam Is The FitrahDocumento10 páginasThe Covenant Taken From The Sons of Adam Is The FitrahTyler FranklinAinda não há avaliações

- Mechanical Production Engineer Samphhhhhle ResumeDocumento2 páginasMechanical Production Engineer Samphhhhhle ResumeAnirban MazumdarAinda não há avaliações

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesNo EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesNota: 4 de 5 estrelas4/5 (2)

- Advanced Production Decline Analysis and ApplicationNo EverandAdvanced Production Decline Analysis and ApplicationNota: 3.5 de 5 estrelas3.5/5 (4)

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsAinda não há avaliações

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingNo EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingAinda não há avaliações

- Abrasive Water Jet Perforation and Multi-Stage FracturingNo EverandAbrasive Water Jet Perforation and Multi-Stage FracturingAinda não há avaliações

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesNo EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesAinda não há avaliações

- Casing and Liners for Drilling and Completion: Design and ApplicationNo EverandCasing and Liners for Drilling and Completion: Design and ApplicationNota: 5 de 5 estrelas5/5 (3)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNo EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsAinda não há avaliações

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsNo EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsNota: 4 de 5 estrelas4/5 (4)

- Fundamentals and Applications of Bionic Drilling FluidsNo EverandFundamentals and Applications of Bionic Drilling FluidsAinda não há avaliações

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityNo EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityNota: 3 de 5 estrelas3/5 (2)

- The Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsNo EverandThe Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsNota: 3.5 de 5 estrelas3.5/5 (5)

- Well Testing Project Management: Onshore and Offshore OperationsNo EverandWell Testing Project Management: Onshore and Offshore OperationsAinda não há avaliações

- Oil and Gas Artificial Fluid Lifting TechniquesNo EverandOil and Gas Artificial Fluid Lifting TechniquesNota: 5 de 5 estrelas5/5 (1)