Escolar Documentos

Profissional Documentos

Cultura Documentos

Design of Solar Water Pumping System With FCMA Soft Starter

Enviado por

Riad TifaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Design of Solar Water Pumping System With FCMA Soft Starter

Enviado por

Riad TifaDireitos autorais:

Formatos disponíveis

Proceedings of the IEEE 2017 International Conference on Computing Methodologies and Communication

(ICCMC)

Design Of Solar Water Pumping System With

FCMA Soft Starter.

Ms.Marathe Bhagyashree S. Prof. Khule S. S.

Department of Electrical Engineering Department of Electrical Engineering

Matoshri College of Engineering & Research Matoshri College of Engineering & Research

Centre, Nashik, India Centre, Nashik, India

Bhagyashreemarathe24@gmail.com Khule_ss@rediffmail.com

Abstract—This paper presents a novel stand-alone solar disadvantages of PV array powered, induction motor drive

powered water pumping system, especially suited for usage in system is the efficiency of the induction motor is not as high

rural or remote areas. In this scheme, inverter drives the as that of the dc motor. Output requires a variable speed

induction motor, which drives the water pump. Moreover, the control since the motor required a soft start & the sun

starting ability of an induction motor becomes quite poor due to constantly changes its position so power generated by

the drop in the system voltage when the motor starts. For these

stationary PV cells varies accordingly, due to different voltge

reason, overall efficiency of an induction motor based drive

systems supplied by a PV array is lower. To obtain maximum situation, motor don’t produce maximum torque. Therefore,

output power of the solar panel, the inverter is operated at soft by using FCMA technology supply voltage and speed should

start to minimize starting current of motor by using FCMA be changed.

technology. The use of FCMA helps in variable speed controls, In typical PV panel the voltage range is about 20 to 50V.

increasing the life of components and reducing the capital cost & Such small level of voltage cannot run any equipment hence

maintenance. It also assists in enhancing motor efficiency. needs to be step up up to usable range. So by using inverter and

Keywords—FCMA, Induction Motor, Photovoltaic, Solar transformer, voltage is step up to constant 415 V AC. If output

Pump, Soft Start. voltage has to increase several PV modules are connected in

parallel. For utility ac supply is generated by using inverter &

I. INTRODUCTION transformer.

As the non renewable sources are rapidly decreasing and the

demand is increasing continuously. Solar photovoltaic energy

is one of the solutions for this problem. Photovoltaic powered Solar Panel Inverter Transfor FCMA Mot

mer

systems are becoming increasingly popular due to- i) The

absence of the power line near the water pumping sites in

Pum

remote areas, frequent shortage of electrical power. ii)

Environmental degradation caused by fossil fuel. iii) High cost Fig:1 Block diagram of solar water pump with FCMA

of fossil fuel based electricity. iv) Low cost of fossil fuel

based electricity. Now-a-days more focus is done on The V-I characteristics and the MPP i.e. maximum power

point tacking are affected by many factors like solar radiation

renewable energy sources. Growth has been experienced over

and temperature. Considering the domestic use, the output from

few past decades because of exhaustion of fossil fuels, energy

PV system changes due to partial shadow and unequal

security is another aspect need to be paid attention. Many electrical parameter.

International Agency for Energy has reported that in near

future more over 60% of generation will be through renewable

energy source. There are many forms of renewable energy II. SYSTEM DESIGN & ANALYSIS

source available, in which Photovoltaic generation is much

flexible and easy to use either for domestic or industrial i) An design a PV water pumped system to determine the

application or in commercial application. amount of water to be pumped i.e. 48meter cube/day ii)

Hydraulic power/ Pump power = Q*TDH* density *g. Q is the

PV array receives energy from the sunlight & generates flow rate in meter cube per day, TDH is the total dynamic head

electric power, which is fed to 3 phase induction motor via in meter, density of water in Kg per meter cube, & g is

inverter & FCMA unit. 3 phase induction motor is considered acceleration in meter per sec-square. So, Q=48 /day,

TDH=18 m, density=1000 kg/ , g=9.8m/ , power =

because of its reliability, dependability, low value & low

48*18*1000*9.8 (multiply by 1/3600 to convert in second in

maintenance cost. However, the use of squirrel cage induction

hours) = 2354.4 watt-hour/day. iii) Solar radiation data=6

motor is receiving increasing attention because of their

hours/day (peak of 1000 W/ ) iv) Solar radiation data=6

reliability and maintenance free operation. Induction motors hours/day (peak of 1000 W/ ) panel=total hydraulic energy

do not have the commutators and brushes that are blamed for /No. of hours of peak sunshine /day = 2354.4/6 = 392.4 watt.

most of the problems that occur in dc motors. The main System losses = Total PV panel wattage /pump efficiency *

978-1-5090-4890-8/17/$31.00 ©2017 IEEE 951

Proceedings of the IEEE 2017 International Conference on Computing Methodologies and Communication

(ICCMC)

mismatch factor =392.4/ (.6*.85) = 769.4, considering magneto motive force (mmf) created by the main and

operating factor = Total PV panel wattage after compensating windings. As both the fluxes are sinusoidal in

losses/operating factor=769.4/.75 = 1026 watt i.e. also PV nature, the net flux in the core is sinusoidal. As the motor

panel capacity so number of PV panel required = 1026/200 ~= speed increases the compensating flux increases, thus reducing

6. Power rating of motor= 1026/746 ~= 2 HP motor the net flux in the core. The impedance of the main winding

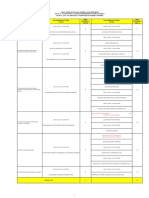

TABLE I hence decreases with motor speed, to keep the motor current

constant and increment the motor voltage. The voltage

Specification of Induction Motor increment is obtained by correcting the natural drop in the

Parameter Values motor current with speed. Thus the effective motor voltage

increases from a low value (typically 50 percent) at start, to

Number of poles 4 near full value (typically 95 percent) when the motor reaches

Phase 3 full speed. As the FCMA impedance varies in a step less

manner the voltage increment is also step less. The voltage

Rated power 1.5 kW increment feature is very advantageous for acceleration of

Rated voltage 415 V centrifugal drives such as load, because the load torque

demand also increases with speed, in a near parabolic fashion.

Rated current 3.2 A The FCMA core is always subjected to alternating fluxes and

Supply frequency 50 Hz works in the linear zone, thus ensuring that the voltage and

current waveforms are purely sinusoidal in nature and totally

Rated speed 1470 rpm harmonic free. When the drive accelerates to full speed the run

Power factor 0.81 mode contactor bypass the FCMA with closed transition.

FCMA soft starters control the amplitude of motor current

without distorting the current waveform. This leads to zero

III. FCMA TECHNOLOGY harmonics and substantially low starting current.

FCMA (flux compensation magnetic amplifier) benefit the

pumping scheme as follows: i) reduced starting current &

limits voltage drop. ii) Harmonic free starting and running. iii)

Transformer can be sized for running power and need not be

Feedback Main

larger only for starting consideration. iv) Smooth starting can

increase component life. v)It is possible to improve design Winding winding

efficiency of the motor by relaxing the direct online starting

current limit. vi) By using tap of FCMA, we can adjust the

voltage supply to motor.

The fundamental function of the soft starter is to accelerate Fig: Flux compensation principle

the motor combination smoothly with the least possible α

starting current value and in the optimum time. The pump = SinѲ ---- Main flux

represents the load, which is defined by its torque speed = Sin(Ѳ − 180) ---- Compensating flux

characteristics during starting and rotating inertia. The = + ---- Net flux

relationship between the load torque demand and speed is = SinѲ - Sin(Ѳ − 180) ---- Net flux

parabolic nature governed by the following equation:

Tα As the motor speed increases, the compensating flux

Where T represents the torque demand and N represents the increases, thus reducing the net flux and hence reducing the

load speed. It is ensured through FCMA that the motor torque impedance of the FCMA.

is always larger than the load torque demand by 0.1 per unit

ensuring gradual and continuous acceleration.

IV. RESULT

The FCMA soft starter work on the principle of impedance

control. FCMA consists of two windings wound on a common Case I: Starting curve of motor driven pump (i.e. current vs.

magnetic core. The first winding is called the main winding speed curve and torque vs. speed curve) with FCMA soft

and is connected in series with the motor winding as shown in starter at 40% voltage. Starting current is 2.4 p.u.

fig. and carries the main motor current. The second winding is

called the feedback winding or compensating winding and is

wound with a polarity opposite to the main winding. This

winding is excited with the counter electromotive force (emf)

generated by the motor. The core is subjected to two

simultaneous sinusoidal fluxes opposing each other due to the

978-1-5090-4890-8/17/$31.00 ©2017 IEEE 952

Proceedings of the IEEE 2017 International Conference on Computing Methodologies and Communication

(ICCMC)

Table 2: FCMA Soft Starter Results

4.0 6.0

3.5 5.0 % Voltage Voltage Starting Impedance

3.0 voltage to motor across current

4.0 to motor (V) FCMA(V) (amp) (Ohm)

2.5

2.0 3.0

40 166 249 8 18.72

1.5 2.0

1.0 50 208 208 10 12.48

0.5 1.0

60 249 166 12 8.32

0.0 0.0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Table 3: Transformer Selection

Fig: Starting curve for motor driven pump with FCMA soft Description Transformer Sizing

starter at 40% voltage.

Transformer selection with DOL 9200 VA

Case II: Starting curve of motor driven pump (i.e. current vs.

speed curve and torque vs. speed curve) with FCMA soft Transformer selection with FCMA soft 3700 VA

starter at 50% voltage. Starting current is 3 p.u. starter

4.0 6.0

3.5 5.0 From above table leads to modify transformer sizing with

3.0 FCMA soft starter reduced by 60%.

2.5 4.0

2.0 3.0

1.5 2.0 V. CONCLUSION

1.0

0.5 1.0 FCMA soft starter approach to improve the efficiency and

0.0 0.0

operating performance of induction motor based drive systems

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 supplied by PV arrays. This paper proposed solar photovoltaic

array fed water pumping system is operated at different voltage

condition. The use of FCMA helps in optimization systems,

Fig: Starting curve for motor driven pump with FCMA soft increase the life of components, and increase the motor

starter at 50% voltage. efficiency. To obtain maximum output power of the solar

Case II: Starting curve of motor driven pump (i.e. current vs. panel, the inverter is operated at FCMA soft start to minimize

speed curve and torque vs. speed curve) with FCMA soft stall current of motor. Transformer and inverter can be sized

starter at 60% voltage. Starting current is 3.6 p.u. for running power and need not be larger only for starting

consideration. Starting current of motor driven pump with

FCMA soft starter is found to be comfort and at 40% of

4.0 6.0

voltage. This leads to modify transformer sizing by 60%

3.5 5.0 reduced size.

3.0

2.5 4.0 REFERENCE

2.0 3.0 [1] P Sadasivam, M Kumaravel, Krishna Vasudevan and Ashok

1.5 2.0 Jhunjhunwala, “Analysis of Subsystems Behaviour and Performance

1.0 Evaluation of Solar Photovoltaic Powered Water Pumping System,”

0.5 1.0 IEEE transaction paper – 2013

0.0 0.0 [2] Rayyan Azam Khan, Liaquat Ali Khan, Syed Zahid Hussain, “Design

and Simulation of 0.75hp Soft Start AC Water Pump Powered by PV

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Solar System,” Universal Journal of Mechanical Engineering 3(4): 113-

121, 2015

Fig: Starting curve for motor driven pump with FCMA soft [3] Geet Jain, Arun Shankar V.K., Umashankar S, “Modelling and

starter at 60% voltage. Simulation of Solar Photovoltaic fed Induction Motor for Water

Pumping Application using Perturb and Observer MPPT Algorithm,”

IEEE transaction paper – 2016.

[4] Mikhail Tsypkin, “Vibration of Induction Motors Operating with

Variable Frequency Drives - a Practical Experience,” IEEE 28-th

Convention of Electrical and Electronics Engineers in Israel-2014.

[5] Flavio Palmiro, Joao Onofre Pereira Pinto, Lucio Henrique Pereira,

Ruben Barros Godoy, “Cost Effective Photovoltaic Water Pumping

System for Remote Regions Communities,” IEEE Transactions-2016.

[6] A.Betka, A.Moussi, “Optimized Solar Water Pumping System Based On

Induction Motor Driving Centrifugal Pump,” IEEE Transactions On

Industry Applications, Nov-2001.

978-1-5090-4890-8/17/$31.00 ©2017 IEEE 953

Proceedings of the IEEE 2017 International Conference on Computing Methodologies and Communication

(ICCMC)

[7] Y.Yao, P.Bustamante, R.S.Ramshaw, “Improvement of Induction Motor [12] John A. Kay, “Methods for the Control of Large Medium-Voltage

Drive Systems Supplied By Photovoltaic Arrays With Frequency Motors: Application Considerations and Guidelines,” IEEE Trans. Ind.

Control,” IEEE Transactions Energy Conversion, Vol.9, No. 2, June- Applicat., vol. 36, pp. 1688-1694, Nov./Dec. 2000

1994. [13] Renu, Birinchi Bora, Kamlesh Yadav, Manander Bangar, Arun Kumar

[8] S.R.Bhat, Andre Pittet, B.S.Sonde, “Performance Optimization of and O.S. Sastry, “Analysis of Temperature Effect on Optimum Sizing of

Induction Motor Pump System Using Photovoltaic Energy Source,” Solar Photovoltaic Water Pumping System,” IEEE transaction paper –

IEEE Transactions On Industry Applications, Vol. IA-23, Nov-1987. 2015

[9] Eduard Muljadi, Roger Taylor, “PV Water Pumping With Peak Power [14] Mohammed Ali Elgendy, Bashar Zahawi, Senior Member, IEEE, and

Tracker Using Simple Six Step Square Wave Inverter,” IEEE David John Atkinson, “Comparison of Directly Connected and Constant

Transactions Energy Conversion, Nov-1996 Voltage Controlled Photovoltaic Pumping Systems,” IEEE transactions

[10] Fernando J. T. E. Ferreira, Mihail V. Cistelecan, Anibal T. de Almeida, on sustainable energy, Vol. 1, No. 3, Oct-2010

“Comparison of Different Tapped Windings for Flux Adjustment in [15] Sobhy. S. Dessouky, Adel A. Elbaset, Ali H. Kasem Alaboudy, Hamed

Induction Motors,” IEEE transaction on energy conversion – 2013 A. Ibrahim, Saad A. Mohamed Abdelwahab “Performance Improvement

[11] Athira Chandran, Arun Shaji, Athul Pillai, Jonin Thankachen, “Solar of A PV-Powered Induction-Motor-Driven Water Pumping System,”

Water Pumping System with Improved Efficiency and Less IEEE transaction paper – 2016

Maintenance,” IJIREEICE, Vol. 4, Issue 4, Apr. 2016

978-1-5090-4890-8/17/$31.00 ©2017 IEEE 954

Você também pode gostar

- Performance Analysis of Stand-Alone PV System Using Single Voltage Sensor Based MPPT MethodDocumento7 páginasPerformance Analysis of Stand-Alone PV System Using Single Voltage Sensor Based MPPT MethodIJRASETPublicationsAinda não há avaliações

- Photovoltaic System 1Documento62 páginasPhotovoltaic System 1Ankit SinghAinda não há avaliações

- Research To Study Variable Frequency Drive and Its Energy SavingsDocumento4 páginasResearch To Study Variable Frequency Drive and Its Energy SavingsIjsrnet EditorialAinda não há avaliações

- 1 s2.0 S0038092X17303377 MainDocumento15 páginas1 s2.0 S0038092X17303377 MainCaroline TedescoAinda não há avaliações

- Sun Tracking System For Productivity Enhancement o PDFDocumento9 páginasSun Tracking System For Productivity Enhancement o PDFRameswaran BalasubramaniamAinda não há avaliações

- EE6511-Control and Instrumentation Laboratory - 2013 - RegulationDocumento98 páginasEE6511-Control and Instrumentation Laboratory - 2013 - Regulationmokshagna saitejaAinda não há avaliações

- FL Sim p4-6Documento369 páginasFL Sim p4-6pauloghunterAinda não há avaliações

- Microcontrollers 4 Sem ECE NotesDocumento19 páginasMicrocontrollers 4 Sem ECE NotesVigneshwar DhamodharanAinda não há avaliações

- Assignment Report1Documento20 páginasAssignment Report1Keshav GopaulAinda não há avaliações

- Project Report of Laser Security Alarm SystemDocumento25 páginasProject Report of Laser Security Alarm SystemB LIKHITH KUMARAinda não há avaliações

- Electro-Hydraulic and Electro-Pneumatic LaboratoryDocumento18 páginasElectro-Hydraulic and Electro-Pneumatic LaboratoryengrodeAinda não há avaliações

- Introduction To Operational Amplifiers: 0 in OutDocumento3 páginasIntroduction To Operational Amplifiers: 0 in Outjaya1816Ainda não há avaliações

- MEM 341 - Chapter 13 Pneumati CircuitDocumento14 páginasMEM 341 - Chapter 13 Pneumati CircuitMuhammad AbdullahAinda não há avaliações

- University of Mauritius: (10 Mins Reading Time)Documento3 páginasUniversity of Mauritius: (10 Mins Reading Time)Keshav GopaulAinda não há avaliações

- OP AMP NotesDocumento31 páginasOP AMP NotesEbonguko ClintonAinda não há avaliações

- WS11Documento5 páginasWS11Thưởng Văn LêAinda não há avaliações

- Assignment 2Documento4 páginasAssignment 2Muhammad Hamza Bin ShujaAinda não há avaliações

- 2009B (D09) C1 Question PaperDocumento17 páginas2009B (D09) C1 Question PaperLila LilakAinda não há avaliações

- MATLAB PV module simulationDocumento20 páginasMATLAB PV module simulationluysf548067% (3)

- 06 Programmable Logic Controller PracticalDocumento3 páginas06 Programmable Logic Controller PracticalAnkitAinda não há avaliações

- PID Controller Back UpDocumento114 páginasPID Controller Back Upluli_pedrosaAinda não há avaliações

- CorrigéDocumento7 páginasCorrigéIbrahima GueyeAinda não há avaliações

- User Manual: Couple Tank ExperimentDocumento22 páginasUser Manual: Couple Tank ExperimentRUBEN DARIO TAMAYO BALLIVIANAinda não há avaliações

- Nguyenngochieu CVDocumento5 páginasNguyenngochieu CVTran Hong TaiAinda não há avaliações

- CRPE Flowchart June 2012Documento1 páginaCRPE Flowchart June 2012jaya1816Ainda não há avaliações

- Amta6 7 Using Hydraulic SystemsDocumento26 páginasAmta6 7 Using Hydraulic SystemsMohammed Al-OdatAinda não há avaliações

- Manualfluidsimeng PDFDocumento277 páginasManualfluidsimeng PDFRevilo OrtegaAinda não há avaliações

- Sensor para Fuerza y PresionDocumento32 páginasSensor para Fuerza y PresionJosé ÁlvarezAinda não há avaliações

- Control System PrototypeDocumento4 páginasControl System Prototypevan hangAinda não há avaliações

- Single-Phase Power Transformers - Course Sample - 579439-591956 PDFDocumento43 páginasSingle-Phase Power Transformers - Course Sample - 579439-591956 PDFjhonxd05Ainda não há avaliações

- Design of Solar Panel As Wind Turbine BladesDocumento12 páginasDesign of Solar Panel As Wind Turbine BladesIJRASETPublicationsAinda não há avaliações

- Simulation With SimulinkDocumento6 páginasSimulation With SimulinkNaresh GajAinda não há avaliações

- Evaluating The Benefits of An Electrical Energy Storage System in A Future Smart Grid PDFDocumento9 páginasEvaluating The Benefits of An Electrical Energy Storage System in A Future Smart Grid PDFnpfhAinda não há avaliações

- Malawi Smart Hydro Power V2 - Sin PreciosDocumento21 páginasMalawi Smart Hydro Power V2 - Sin PreciosRodolfo CastroAinda não há avaliações

- Power Electronics and Power Systems 05 61xxDocumento55 páginasPower Electronics and Power Systems 05 61xxwhiteelephant93Ainda não há avaliações

- Practical: 15 To Study Counters: Sohil Vohra (Lecturer - Shri K.J. Polytechnic College, Bharuch (C.E. Deptt) )Documento11 páginasPractical: 15 To Study Counters: Sohil Vohra (Lecturer - Shri K.J. Polytechnic College, Bharuch (C.E. Deptt) )Sohil VohraAinda não há avaliações

- Smart - Grid Assignment 1Documento9 páginasSmart - Grid Assignment 1Tanzil MahmoodAinda não há avaliações

- Traffic Lights Beginner Arduino ProjectDocumento10 páginasTraffic Lights Beginner Arduino ProjectPrasad PawaskarAinda não há avaliações

- Electric Energy Generation, Conservation and Utilization NotesDocumento62 páginasElectric Energy Generation, Conservation and Utilization NotesKarthikeyan KrishnanAinda não há avaliações

- Sensors For Handling and Processing Technology - Sensors For Force and PressureDocumento180 páginasSensors For Handling and Processing Technology - Sensors For Force and PressureJose Niño TabiAinda não há avaliações

- Assignment Brief and Feedback - Assignment3 - Unit22 (LO3 Oscillators) RevA - V1.2Documento5 páginasAssignment Brief and Feedback - Assignment3 - Unit22 (LO3 Oscillators) RevA - V1.2Davide JonesAinda não há avaliações

- PV Hybrid Project Case Study - 161102135436Documento25 páginasPV Hybrid Project Case Study - 161102135436ReynanteAinda não há avaliações

- 5 InductiveReactanceDocumento4 páginas5 InductiveReactanceSyed Noman AhmedAinda não há avaliações

- Wireless Electric Vehicle Battery Charging System Using PV ArrayDocumento9 páginasWireless Electric Vehicle Battery Charging System Using PV ArrayIJRASETPublicationsAinda não há avaliações

- Electrical Machines Curriculum GuideDocumento76 páginasElectrical Machines Curriculum GuidesirageldeenAinda não há avaliações

- Modeling of PVDocumento25 páginasModeling of PVSatyakarVeeramalluAinda não há avaliações

- Applied Physics Notes For Computer, Electrical, Electronics Branch by Prof. Atul Waghmare 9657824223Documento48 páginasApplied Physics Notes For Computer, Electrical, Electronics Branch by Prof. Atul Waghmare 9657824223AtulWaghmareAinda não há avaliações

- Power Electronics Lab Manual Safety GuideDocumento68 páginasPower Electronics Lab Manual Safety GuideJonathan727Ainda não há avaliações

- MiniatureCircuitBreakers Primer EN 201601250852395217 PDFDocumento60 páginasMiniatureCircuitBreakers Primer EN 201601250852395217 PDF3238NDAinda não há avaliações

- Power Electronics Lab ManualDocumento51 páginasPower Electronics Lab ManualAnand ShankarAinda não há avaliações

- Hang Hy Van - 19ED10130Documento85 páginasHang Hy Van - 19ED10130van hangAinda não há avaliações

- Thesis ProposalDocumento11 páginasThesis ProposalMerawi WubishetAinda não há avaliações

- Control Techniques - Fan & Pump Motor Energy Savings Guide PDFDocumento14 páginasControl Techniques - Fan & Pump Motor Energy Savings Guide PDFLuis Eduardo Ribeiro100% (1)

- Simulation of Automatic Water Level Control System by Using Programmable Logic ControllerDocumento8 páginasSimulation of Automatic Water Level Control System by Using Programmable Logic ControllerEditor IJTSRDAinda não há avaliações

- Efficiency Trends in Electric Machines and DrivesDocumento6 páginasEfficiency Trends in Electric Machines and Drivessadeq03Ainda não há avaliações

- Optimization of Auxiliary Power at Thermal Power Plant Using Variable Frequency DriveDocumento28 páginasOptimization of Auxiliary Power at Thermal Power Plant Using Variable Frequency DriveZakariyaAinda não há avaliações

- Solar Cell Materials: Developing TechnologiesNo EverandSolar Cell Materials: Developing TechnologiesGavin J. ConibeerAinda não há avaliações

- Analysis of Self Excited Induction Generator For Standalone Micro-Hydro SchemeDocumento10 páginasAnalysis of Self Excited Induction Generator For Standalone Micro-Hydro SchemeMaisAinda não há avaliações

- .0 .0 Tensors - Fluid - Dynamics - CreteDocumento8 páginas.0 .0 Tensors - Fluid - Dynamics - CreteRabei RomulusAinda não há avaliações

- Final Paper R-2022Documento11 páginasFinal Paper R-2022Hafedh AbidAinda não há avaliações

- Tertiary and Secondary Control Levels For Efficiency Optimization and System Damping in Droop Controlled DC-DC ConvertersDocumento12 páginasTertiary and Secondary Control Levels For Efficiency Optimization and System Damping in Droop Controlled DC-DC ConvertersRiad TifaAinda não há avaliações

- An Enhanced Droop Control Method For Accurate Load Sharing and Voltage Improvement of Isolated and Interconnected DC MicrogridsDocumento11 páginasAn Enhanced Droop Control Method For Accurate Load Sharing and Voltage Improvement of Isolated and Interconnected DC MicrogridsRiad TifaAinda não há avaliações

- Homer PaperDocumento13 páginasHomer PaperRiad TifaAinda não há avaliações

- WSN 672 2017 126 148 2Documento24 páginasWSN 672 2017 126 148 2Amit DostAinda não há avaliações

- 10 1109@tie 2017 2698425 PDFDocumento12 páginas10 1109@tie 2017 2698425 PDFRiad TifaAinda não há avaliações

- Economic Comparison of Solar PV and Diesel Water Pumping SystemDocumento6 páginasEconomic Comparison of Solar PV and Diesel Water Pumping SystemRiad TifaAinda não há avaliações

- Control Engineering Practice: Youssef Krim, Dhaker Abbes, Saber Krim, Mohamed Faouzi MimouniDocumento16 páginasControl Engineering Practice: Youssef Krim, Dhaker Abbes, Saber Krim, Mohamed Faouzi MimouniRiad TifaAinda não há avaliações

- 10 1109@tie 2017 2698425 PDFDocumento12 páginas10 1109@tie 2017 2698425 PDFRiad TifaAinda não há avaliações

- 74 Adaptive Decentralized Droop ControllerDocumento11 páginas74 Adaptive Decentralized Droop ControllerRiad TifaAinda não há avaliações

- Control Engineering Practice: Youssef Krim, Dhaker Abbes, Saber Krim, Mohamed Faouzi MimouniDocumento16 páginasControl Engineering Practice: Youssef Krim, Dhaker Abbes, Saber Krim, Mohamed Faouzi MimouniRiad TifaAinda não há avaliações

- ICREEC'2019: International Conference on Renewable Energy and Energy ConversionDocumento2 páginasICREEC'2019: International Conference on Renewable Energy and Energy ConversionRiad TifaAinda não há avaliações

- 3 Maison PDFDocumento6 páginas3 Maison PDFRiad TifaAinda não há avaliações

- Solar PV Array Fed Water Pumping Using BLDC Motor Drive With Boost-Buck ConverterDocumento8 páginasSolar PV Array Fed Water Pumping Using BLDC Motor Drive With Boost-Buck ConverterRiad TifaAinda não há avaliações

- Solar PV-Battery Based Hybrid Water Pumping System Using BLDC Motor DriveDocumento6 páginasSolar PV-Battery Based Hybrid Water Pumping System Using BLDC Motor DriveRiad TifaAinda não há avaliações

- 07041977Documento6 páginas07041977Riad TifaAinda não há avaliações

- 07038525Documento6 páginas07038525Riad TifaAinda não há avaliações

- Optoacoplador Integrado 4N25Documento7 páginasOptoacoplador Integrado 4N25aureliocsAinda não há avaliações

- 07418710Documento4 páginas07418710Riad TifaAinda não há avaliações

- High and Low Side Driver: Features Product SummaryDocumento14 páginasHigh and Low Side Driver: Features Product SummaryMiguel GalvánAinda não há avaliações

- High and Low Side Driver: Features Product SummaryDocumento14 páginasHigh and Low Side Driver: Features Product SummaryMiguel GalvánAinda não há avaliações

- Modeling of A Number of Heat Pump Water Heaters As Control Equipment For Load Frequency Control in Power SystemsDocumento7 páginasModeling of A Number of Heat Pump Water Heaters As Control Equipment For Load Frequency Control in Power SystemsRiad TifaAinda não há avaliações

- IRFP460Documento9 páginasIRFP460yusufwpAinda não há avaliações

- Air Source Heat Pump A Key Role in The Development of Smart Buildings in Future Energy SystemsDocumento6 páginasAir Source Heat Pump A Key Role in The Development of Smart Buildings in Future Energy SystemsRiad TifaAinda não há avaliações

- PDFDocumento4 páginasPDFRiad TifaAinda não há avaliações

- Design and Simulation of A Photovoltaic Induction Motor Coupled Water Pumping SystemDocumento8 páginasDesign and Simulation of A Photovoltaic Induction Motor Coupled Water Pumping SystemRiad TifaAinda não há avaliações

- Performance Analysis of A Directly Coupled Photovoltaic Water-Pumping SystemDocumento6 páginasPerformance Analysis of A Directly Coupled Photovoltaic Water-Pumping SystemRiad TifaAinda não há avaliações

- Supplementary Load Frequency Control by Use of A Number of Both Electric Vehicles and Heat Pump Water HeatersDocumento10 páginasSupplementary Load Frequency Control by Use of A Number of Both Electric Vehicles and Heat Pump Water HeatersRiad TifaAinda não há avaliações

- Supplementary Load Frequency Control by Use of A Number of Both Electric Vehicles and Heat Pump Water HeatersDocumento10 páginasSupplementary Load Frequency Control by Use of A Number of Both Electric Vehicles and Heat Pump Water HeatersRiad TifaAinda não há avaliações

- Design and Simulation of A Photovoltaic Induction Motor Coupled Water Pumping SystemDocumento8 páginasDesign and Simulation of A Photovoltaic Induction Motor Coupled Water Pumping SystemRiad TifaAinda não há avaliações

- Fixed Gas Detector Instruction Manual SI-1000Documento21 páginasFixed Gas Detector Instruction Manual SI-1000Vũ Thiên ÂnAinda não há avaliações

- Pi 081 Mge G, Mle GDocumento188 páginasPi 081 Mge G, Mle GAdriano Moyses OutlookAinda não há avaliações

- DS1103Documento6 páginasDS1103studysmAinda não há avaliações

- SRP-6MA (-HV) : Key FeaturesDocumento2 páginasSRP-6MA (-HV) : Key FeaturesNanangDatadikJatimAinda não há avaliações

- AC Circuits Knowledge Bank ExplainedDocumento34 páginasAC Circuits Knowledge Bank ExplainedMalak SamirAinda não há avaliações

- ST3PA, ST3PC Time Relay ManualDocumento2 páginasST3PA, ST3PC Time Relay ManualMohamedAinda não há avaliações

- EMC quiz questionsDocumento1 páginaEMC quiz questionsSree MurthyAinda não há avaliações

- WEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRDocumento50 páginasWEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRJuan I. Meza Lozano100% (1)

- An3095 Stevalisv002v1 Stevalisv002v2 3 KW Gridconnected PV System Based On The Stm32f103xx StmicroelectronicsDocumento55 páginasAn3095 Stevalisv002v1 Stevalisv002v2 3 KW Gridconnected PV System Based On The Stm32f103xx StmicroelectronicsAhmar Hayat KhanAinda não há avaliações

- 11 PurchaseOrder FormDocumento2 páginas11 PurchaseOrder FormJocelyn Nacion OrogoAinda não há avaliações

- Quint-Ps1ac 40 Eng TdsDocumento13 páginasQuint-Ps1ac 40 Eng TdsirkhajuAinda não há avaliações

- 1 2 7 Ak Understandingdigitaldesign RNGDocumento5 páginas1 2 7 Ak Understandingdigitaldesign RNGapi-290804719Ainda não há avaliações

- Transformer FundamentalsDocumento6 páginasTransformer FundamentalsAditya TiwariAinda não há avaliações

- Tcad Quick Start GuideDocumento25 páginasTcad Quick Start GuideThi NguyenAinda não há avaliações

- What Is A Tandem IsolatorDocumento3 páginasWhat Is A Tandem Isolatordebasis_cpp123100% (2)

- New Core Loss Measurement Methods: Mingkai Mu, Fred C. LeeDocumento35 páginasNew Core Loss Measurement Methods: Mingkai Mu, Fred C. LeeMichaelEdwardWrightAinda não há avaliações

- Memory HierarchyDocumento20 páginasMemory HierarchySailash RanaAinda não há avaliações

- E256.1-230 Latching relay technical specsDocumento2 páginasE256.1-230 Latching relay technical specssaqib ghouriAinda não há avaliações

- 2 Hardware enDocumento676 páginas2 Hardware enNoor Cano100% (1)

- Bersemuka LDocumento7 páginasBersemuka LPK K0% (1)

- Reply Daly BattrixxDocumento40 páginasReply Daly Battrixxyogesh kumar jaiswalAinda não há avaliações

- Spinner Air Traffic Control: Superior Rotary Joints For ATCDocumento60 páginasSpinner Air Traffic Control: Superior Rotary Joints For ATChennrynsAinda não há avaliações

- Design of High Speed Multiplier Using Modified Booth Algorithm With Hybrid Carry Look-Ahead AdderDocumento7 páginasDesign of High Speed Multiplier Using Modified Booth Algorithm With Hybrid Carry Look-Ahead Adderspkrishna4u7369Ainda não há avaliações

- Atomic Structure - DPP-02 II NEET Ultimate CC 2023Documento4 páginasAtomic Structure - DPP-02 II NEET Ultimate CC 2023vijaylakshmi0727Ainda não há avaliações

- Uygulama 211130 160308Documento5 páginasUygulama 211130 160308Joao Nogueira ClementeAinda não há avaliações

- MOELLER DF4-341-55k PDFDocumento173 páginasMOELLER DF4-341-55k PDFWilliam SanabriaAinda não há avaliações

- s66698 138URecPrtrDocumento36 páginass66698 138URecPrtrPeter SamuelAinda não há avaliações

- PJ2500M-C / PJ2000M-C: User ManualDocumento40 páginasPJ2500M-C / PJ2000M-C: User ManualQuive CarlosAinda não há avaliações

- VLT Micro DriveDocumento11 páginasVLT Micro DriveMiguel E RosasAinda não há avaliações

- Philips+Chassis+TPM18 6LDocumento90 páginasPhilips+Chassis+TPM18 6LJackson FerreiraAinda não há avaliações