Escolar Documentos

Profissional Documentos

Cultura Documentos

1SXU200075B0201 PMPandLEAPBrochureLongVersion

Enviado por

baguspermana7Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1SXU200075B0201 PMPandLEAPBrochureLongVersion

Enviado por

baguspermana7Direitos autorais:

Formatos disponíveis

Brochure Low Voltage Products Service

Preventive Maintenance (PMP) and

Predictive Maintenance (LEAP)

for Emax Air Circuit Breakers

ABB Low Voltage Breaker (LVB) Service

Every solution at your disposal

ABB Low Voltage Breaker Service offers a complete range of ABB Low Voltage Breaker Service offers every kind of

services to support customers in all stages of the product's maintenance solution for customers in order to maximize

life: repair, substitutions, spare parts, retrofitting solutions and circuit breaker efficiency, safety, performance and life

any type of maintenance activities. extension:

• On-site repairs performed by our field engineers who are

By integrating information with our customers, we can collect highly specialized and equipped with the proper tools.

all requests for assistance and maintenance. In this way, our • Preventive and Predictive maintenance in order to maximize

services are always immediate and of the highest level. circuit breaker performance; increasing the reliability, safety and

the lifetime of switchgear, switchboards and electrical power

systems and reducing the total costs.

Technical support

Spare Parts

Training

Installation &

commissioning

Retrofit & Maintenance

replacement

ABB LVB

Service

2 | ABB Low Voltage | LEAP Brochure

Maintenance with ABB Low Voltage Breaker

Circuit breakers are protection devices and require regular Maintenance definitions

maintenance for a high level of performance and to avoid • Preventive maintenance

costly repairs. • Predictive maintenance

Maintenance is mandatory for work safety standards set by • Scheduled maintenance

OSHA and NFPA 70E, Standard for Electrical Safety in the • Condition based maintenance

Workplace. • Corrective maintenance

• Predetermined maintenance

MAINTENANCE

Preventive Corrective

Predetermined Conditioned-based Urgent Deferred

Scheduled Predictive

LEAP Brochure | ABB Low Voltage | 3

Why maintain your breaker?

Necessary circuit breaker maintenance implies inspection and Environmental Conditions Consequences

checking of the integrity of the mechanical and electrical High level – corrosion and oxidation of the

components. Replacing the parts that have ended their life of moisture metal components:

cycle will keep performance level high. • arc chambers

• main contacts

Which components to maintain? • contacts

The life expectancy of any circuit breaker involves the wear • auxiliary contacts/shunt releases

and tear of the most sensitive components: – reduction of the dielectric

• Frame and plastic components proprieties of the plastics

– reduction of performance level of

• Main contacts the electric components

• Jaw Type contacts – loss of insulation

High

• Auxiliary contacts temperatures – aging of the lubricant inside the

• Operating mechanism operating mechanism

• Electrical and mechanical accessories – Changing of the mechanical

• Trip unit and dielectrical proprieties of the

plastics

• Lubricating products.

– Early aging of the electronic

components

Environmental and utilization conditions High – loss of continuity in the contacts

The ordinary aging process begins with the commissioning of vibrations – early aging of the operating

the circuit breaker. However, the service age of the circuit mechanism due to mechanical

wear

breaker is not the only parameter to define the aging of the

– reduction of the tightening

device. Environment and use are other important factors which strength of the screws

can speed up the aging of the device. – breaking of the plastic parts and

Maintenance is particularly recommended where the electrical components

Dusty or polluted – reduction of the operating

environmental and utilization conditions cause both mechanical mechanism’s lifetime

environmental

and electrical overstressing of the circuit breaker. Below is a list – reduction of insulation

of the basic signs which could indicate a concern about – increasing of the resistance in the

increasing wear: contacts points

Salinity – premature corrosion on the

metal components

Consequences

– faults associated with secondary

Utilization – early wear of the operating accessories

High number of

conditions mechanism and its mechanical

operations – reduction of insulation

components

– early wear on the plates of the main

Breaking current (if

contacts and arcing chambers

short circuit)

– insulation leakage

High load – early aging of plastic components,

percentage lubricant, and electrical components

Unused circuit breaker – lubricant hardness which implies the

(always open or mechanical compromising of the

always closed) operating mechanism

4 | ABB Low Voltage | LEAP Brochure

ABB Low Voltage Breaker Service Maintenance

Packages

Extend the circuit-breaker life up to 100% in demanding

environments

Investing in prevention of failure, rather than living with its Professionalism and Safety

consequences, such as loss of production and possible • ABB guarantees the highest level of safety at work

violation of health and safety legislation, is a primary concern • All ABB field service engineers are authorized and certified

for many businesses. Successful prevention of failure can by means of a regular verification process to maintain a

make the difference as to whether or not a company manages high level of competence.

to retain its long-term competitiveness.

Thanks to our technical knowledge of the circuit breakers, ABB

Technical assistance in the form of ABB Low Voltage Breaker Low Voltage Breaker Service has maintenance plans tailored

Service is effective and has a widespread network of numerous for any customer that will reduce the risk of failure and the

production facilities and certified service centers throughout aging of the circuit breaker.

the world. In addition to the maintenance of a unit, which includes any

ABB Field Service Engineers have extensive experience and type of emergency intervention, there are also complete

product knowledge due to: preventive (PMP) and predictive (LEAP) maintenance service

packages available. These tools ensure that those who

Continuous education manage the plant can gain considerable knowledge in terms

• On new products during regular training classes of reliability, safety and reduction of costs.

• On any single component upgrade by direct contact with An on-site audit carried out by our Field Service specialized

R&D and the production line. Engineers is very important and will result in a proposal of

short or long term maintenance actions.

Manufacturer dedicated service tools

• Factory authorized spare parts only

• Dedicated and state-of-the-art tooling

• Elaboration of the measurements found during the

maintenance activity by ABB field Service Engineers:

Monitoring and diagnosing the circuit breaker can help in

identifying the correct information about circuit-breaker

conditions in order to reduce the costs with specific

maintenance interventions.

LEAP Brochure | ABB Low Voltage | 5

Preventive Maintenance Program – PMP

ABB Low Voltage Breaker Service offers a Preventive

Maintenance Program – PMP – for new installtions as well Ordinary 1° activity

Maintenance

as existing equipment, to reduce the risk of failure and

deterioration.

Ordinary 2° activity

The program consists of a cycle of 3 maintenance activities: Maintenance

1st - 2nd activities: Ordinary Maintenance on the circuit-

breaker to make all needed checks and ensure correct

function. Extraordinary

3° activity

Maintenance

3rd activity: Extraordinary Maintenance on the circuit breaker,

carried out only by highly qualified ABB personnel, to extend

the life of the circuit breaker and increase its reliability and

original efficiency.

For Circuit breakers older than 3 years, the first intervention is

Extraordinary Maintenance.

6 | ABB Low Voltage | LEAP Brochure

Predictive Maintenance Program LEAP

By integrating LEAP (Life Expectancy Analysis Program), and Maintenance

analyzing the specific environment and application, the The manual data is completed with the list of the

preventative maintenance plan is now a predictive diagnostic maintenance activities performed by the ABB Field Service

tool that optimizes the efficiency of the Emax circuit breakers. Engineer.

The aim of LEAP is to give the customer a complete report,

which shows the device’s health before and after the Field Analysis

Service Engineer’s intervention, with very important All the data is transmitted to the ABB Server via the Web and

suggestions about future maintenance activities. analyzed to understand the circuit-breaker use and age.

The complete analysis is generated by ABB’s sophisticated

and patented software.

Three phases are followed:

Inspection with the collection of all the

Phase 1

information about each circuit-breaker

Inspection

On site monitoring and acquisition of the parameters of the Maintenance activity carried out by

Phase 2

ABB Field Service Engineers

circuit breaker in standard condition:

Manual data (1):

• Environmental data (temperature, moisture, salinity, etc…), Analysis with LEAP algorithm

Phase 3

• Application data (application, Load, etc…). and ABB Server

Automatic data:

Phase 4 Report

• Stored inside the electronic trip unit (trip history, contact

wear, alarms, etc…).

(1)

Information about the environmental conditions to be supplied

by customer

LEAP Brochure | ABB Low Voltage | 7

Predictive Maintenance Program LEAP

Report Each color represents the risk probability for circuit breaker

The report is generated based on the information acquired failure:

in the field and includes: Red: High

• Characteristics of the circuit-breaker and of the

Orange: Moderate

switchboard in which it is contained, application,

Yellow: Medium

environmental conditions and working conditions

• Description of the main circuit-breaker components Green: Low

subjected to maintenance

• List of maintenance actions performed on each sensitive There are 2 curves:

component, including replaced parts • Green → circuit-breaker aging curve from the production

• Suggested maintenance actions for the future date to the commissioning date

• Recommendations about the frequency of maintenance • Blue → circuit-breaker aging curve from the commissioning

interventions date.

• 2 curves representing respectively the load and mechanical

life at the moment of the maintenance activity

Aging

• A graph showing the risk of fault of the circuit-breaker

as it relates to real working conditions. Circuit breaker’s

aging

The four colored areas have different sizes according to the

Circuit breaker’s

applications, the environment and the conditions of use. aging after

ABB Service

maintenance activity

yr 1

yr 2

yr 3

yr 4

yr 5

yr 0

-

Service age

Commissioning date

Manufacturing date

*See Appendix for full sample LEAP report

8 | ABB Low Voltage | LEAP Brochure

LEAP Offers

LEAP EASY AUDIT LEAP AUDIT

The customer, after an online registration (LEAP EASY AUDIT), After an easy online registration (LEAP AUDIT), an ABB

receives a user ID and a password to access a special online Service Sales representative will visit the customer’s site to

section of LEAP tool. perform surveys and obtain a more accurate LEAP analysis.

By using the data from the trip unit (with Ekip Connect SW)

The customer inserts a few pieces of information about the and a few pieces of manually acquired data about the

circuit-breaker (i.e. number of operations, its application and application and the circuit-breaker operating and

the environmental conditions, etc…). environmental conditions, it is possible provide a detailed

The result is an emailed health analysis of the circuit-breaker. Report with the LEAP Software.

The Report is developed on a purely theoretical and statistical The customer receives the Report via email with the real time

basis in order to have an estimation of the circuit-breaker’s circuit-breaker’s health and the list of the recommended next

health and to highlight the LEAP tool’s potential. maintenance activities to be performed.

Aging

Aging

2007

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

Service age Service age

LEAP STAND ALONE LEAP + PMP

ABB Field Service Engineer performs a maintenance activity LEAP, integrated into the preventive maintenance program

at the customer’s site. The customer receives a complete (PMP), is the best solution for the customer:

Report with all the information about the installation Targeted and scheduled maintenance provides the customer

conditions and the list of maintenance activities performed. with immediate evidence of the added value of ABB based

The aging curve, which is included in all LEAP reports, shows service.

the status of the circuit-breaker pre and post intervention. The graphic representation shows how each maintenance

The report also contains a list of recommended future activity has improved the life of the circuit-breaker throughout

maintenance actions. the course of time.

Customers can minimize costs by extending the device’s life

cycle and thereby reducing the risk of unscheduled outages

and unwanted shutdowns.

Aging

Aging

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

2000

2001

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2019

2020

Service age Service age

LEAP Brochure | ABB Low Voltage | 9

Benefits

Customer benefits with PMP Added benefits by utilizing LEAP

– E nsure a high level of safety – LEAP is unique and certified software created by ABB that

– Increase production reliability is able to give a detailed and objective diagnostic in terms

– Reduce overall costs: of:

• direct costs of emergency maintenance • status of the circuit-breaker health

• indirect costs due to loss of production (increasing the • recommended time between maintenance activities

meantime before failure value) according to the device’s specific needs

– Support during all the phases of the product lifecycle – The report is detailed, transparent and complete

– ABB professional competence guaranteed. – Extend the product’s life in demanding applications.

10 | ABB Low Voltage | LEAP Brochure

Appendix

LEAP Brochure | ABB Low Voltage | 11

Appendix

12 | ABB Low Voltage | LEAP Brochure

Appendix

LEAP Brochure | ABB Low Voltage | 13

Appendix

14 | ABB Low Voltage | LEAP Brochure

Appendix

15 | ABB Low Voltage | LEAP Brochure

Appendix

16 | ABB Low Voltage | LEAP Brochure

Contact us

1SXU200075B0201

ABB Inc.

Low Voltage Service

1425 Discovery Parkway

Wauwatosa, WI 53226

www.abb.com

www.abb.com/service

Você também pode gostar

- 1CAKok For Fun Only PDFDocumento8 páginas1CAKok For Fun Only PDFbaguspermana7Ainda não há avaliações

- Current Transformers How To Specify Them PDFDocumento36 páginasCurrent Transformers How To Specify Them PDFargari19Ainda não há avaliações

- FDocumento2 páginasFbaguspermana7Ainda não há avaliações

- FDocumento8 páginasFsergio gonzalezAinda não há avaliações

- PAS Understanding ISA 18.2 PDFDocumento9 páginasPAS Understanding ISA 18.2 PDFtriminhdang_phar6701Ainda não há avaliações

- FDocumento2 páginasFbaguspermana7Ainda não há avaliações

- 7 Specification Sheet NGR PDFDocumento5 páginas7 Specification Sheet NGR PDFbaguspermana7Ainda não há avaliações

- Thermal 49 CalculatorDocumento2 páginasThermal 49 CalculatorRiansyah Kurnia WibowoAinda não há avaliações

- Control iCT contactors remote guideDocumento5 páginasControl iCT contactors remote guidebaguspermana7Ainda não há avaliações

- Un 2017 SD MTK PDFDocumento16 páginasUn 2017 SD MTK PDFbaguspermana7Ainda não há avaliações

- FDocumento8 páginasFsergio gonzalezAinda não há avaliações

- FDocumento8 páginasFsergio gonzalezAinda não há avaliações

- FDocumento8 páginasFsergio gonzalezAinda não há avaliações

- FDocumento8 páginasFsergio gonzalezAinda não há avaliações

- Dse Gencomm enDocumento38 páginasDse Gencomm enbaguspermana7Ainda não há avaliações

- FDocumento2 páginasFbaguspermana7Ainda não há avaliações

- 3782k - en Leroy SomerDocumento12 páginas3782k - en Leroy Somerbaguspermana7Ainda não há avaliações

- FDocumento8 páginasFsergio gonzalezAinda não há avaliações

- Set Module Access PIN CodesDocumento2 páginasSet Module Access PIN CodesJoaquin Chavez ArquiñigoAinda não há avaliações

- Kabel 185 Dan 300Documento1 páginaKabel 185 Dan 300baguspermana7Ainda não há avaliações

- 0.24 KV 0.24 KV: One-Line Diagram - OLV1 (Short-Circuit Analysis)Documento1 página0.24 KV 0.24 KV: One-Line Diagram - OLV1 (Short-Circuit Analysis)baguspermana7Ainda não há avaliações

- Stamford DM110 Voltage RegulatorDocumento71 páginasStamford DM110 Voltage RegulatorThomas Pendergrass100% (2)

- Penawaran HargaDocumento2 páginasPenawaran Hargabaguspermana7Ainda não há avaliações

- Basic Barrier Maintenance Guide: Tasks Hydraulic ElectricDocumento2 páginasBasic Barrier Maintenance Guide: Tasks Hydraulic Electricbaguspermana7Ainda não há avaliações

- Mechanical and Electronic Recorders PDFDocumento3 páginasMechanical and Electronic Recorders PDFbaguspermana7Ainda não há avaliações

- (DATASHEET) - Proximity Schneider PDFDocumento174 páginas(DATASHEET) - Proximity Schneider PDFPhreakerAinda não há avaliações

- How Electric Bonding WorksDocumento10 páginasHow Electric Bonding WorksAMIYA SHANKAR PANDAAinda não há avaliações

- A5 Data Network Cables For Low-Frequency Analoguedigital Signal TransmissionDocumento1 páginaA5 Data Network Cables For Low-Frequency Analoguedigital Signal Transmissionbaguspermana7Ainda não há avaliações

- Sentinel: Circular Chart Recorder ControllerDocumento7 páginasSentinel: Circular Chart Recorder Controllerbaguspermana70% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Protection, Control and Instrumentation Ver4Documento97 páginasProtection, Control and Instrumentation Ver4g.HtrughtreAinda não há avaliações

- Substation Protection Devices ExplainedDocumento24 páginasSubstation Protection Devices ExplainedAshish AgarwalAinda não há avaliações

- Elec Wiring Regs 2007 Rev 01Documento240 páginasElec Wiring Regs 2007 Rev 01Akhtar Abbas Syed100% (2)

- BB Series User Manual V0 (2) .0Documento28 páginasBB Series User Manual V0 (2) .0a.elwahabAinda não há avaliações

- SF6 GCB 72.5-245kVDocumento8 páginasSF6 GCB 72.5-245kVMichael Parohinog GregasAinda não há avaliações

- Micom P145: Feeder Management RelayDocumento8 páginasMicom P145: Feeder Management RelayLa Picarona del PeruAinda não há avaliações

- Aramco Switch Gear Hvac CalculationsDocumento15 páginasAramco Switch Gear Hvac Calculationspsn_kylmAinda não há avaliações

- 220 KV GSS Heerapura ReportDocumento43 páginas220 KV GSS Heerapura ReportNitin Bhardwaj100% (2)

- 3.2 Powercommand 3.3 Spec Sheet S-1570Documento11 páginas3.2 Powercommand 3.3 Spec Sheet S-1570akheel201Ainda não há avaliações

- Auto Chlor ManualDocumento16 páginasAuto Chlor ManualBob LubenAinda não há avaliações

- Alarm Codes Lav Girbau HS LS SeriesDocumento6 páginasAlarm Codes Lav Girbau HS LS SeriesArcadio Gonzales77% (13)

- Havells ConsumerSwitchgearDocumento28 páginasHavells ConsumerSwitchgeardppl.mepAinda não há avaliações

- Overcurrent Coordination Setting Guidelines ConductorsDocumento5 páginasOvercurrent Coordination Setting Guidelines ConductorsMrAinda não há avaliações

- GE Evolution Series E9000 Motor Control Center Renewal Parts BulletinDocumento16 páginasGE Evolution Series E9000 Motor Control Center Renewal Parts BulletinAnonymous Aj7PenAinda não há avaliações

- Electrical Distribution: Submitted To:-Manager EDDocumento9 páginasElectrical Distribution: Submitted To:-Manager EDawais jadoon100% (1)

- X3 For PR222DS/P/PD T4..T6F Ala - Sign.-LDocumento2 páginasX3 For PR222DS/P/PD T4..T6F Ala - Sign.-LVictor CAinda não há avaliações

- Operation and Maintenance of Sub - Stations Revised 030909Documento96 páginasOperation and Maintenance of Sub - Stations Revised 030909Vikas RazdanAinda não há avaliações

- System Protection Coordination Study For Electrical Distribution SystemDocumento6 páginasSystem Protection Coordination Study For Electrical Distribution SystemCarlos CamayoAinda não há avaliações

- TPDDL Report PDFDocumento60 páginasTPDDL Report PDFAbhishek PAinda não há avaliações

- C WI C200-C1000 Gaseous Fuel Injector ReplacementDocumento19 páginasC WI C200-C1000 Gaseous Fuel Injector ReplacementJefferson Mosquera PerezAinda não há avaliações

- ARNA-BE-EGS-49-0002 - 6kV SWGR Rev.1 PDFDocumento248 páginasARNA-BE-EGS-49-0002 - 6kV SWGR Rev.1 PDFpra2_49250Ainda não há avaliações

- Circuit Breakers Classified by Interrupting MediumDocumento4 páginasCircuit Breakers Classified by Interrupting MediumVasudev AgrawalAinda não há avaliações

- Thermal Power Plant IntroductionDocumento51 páginasThermal Power Plant IntroductiondheerumgiAinda não há avaliações

- Air conditioner installation manualDocumento66 páginasAir conditioner installation manualelpolanicoAinda não há avaliações

- Automation ManualDocumento51 páginasAutomation ManualDimitrije MacicAinda não há avaliações

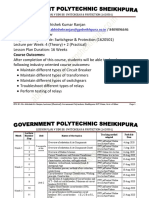

- Abhishekranjan@gpsheikhpura - Co.in: Course OutcomesDocumento5 páginasAbhishekranjan@gpsheikhpura - Co.in: Course OutcomesRajeev KrishnaAinda não há avaliações

- ULTRA-700 0 - 1040 0-1400 0-EN-New DC Recombiner PDFDocumento4 páginasULTRA-700 0 - 1040 0-1400 0-EN-New DC Recombiner PDFAdrian Ioan POPAinda não há avaliações

- SIPROTEC 4 7SD61 Differential Protection Relay For Two Line EndsDocumento26 páginasSIPROTEC 4 7SD61 Differential Protection Relay For Two Line EndsBogdan VicolAinda não há avaliações

- 1SQC900001C0201 - ReliaGear neXT CT - DGTDocumento68 páginas1SQC900001C0201 - ReliaGear neXT CT - DGTAdamAinda não há avaliações

- Commissioning Atlas Copco ZR900 VSD Air CompressorDocumento9 páginasCommissioning Atlas Copco ZR900 VSD Air CompressorLeonardo SilvaAinda não há avaliações