Escolar Documentos

Profissional Documentos

Cultura Documentos

Pyrocrete 241 PDF

Enviado por

malaya tripathy0 notas0% acharam este documento útil (0 voto)

254 visualizações4 páginasTítulo original

Pyrocrete 241.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

254 visualizações4 páginasPyrocrete 241 PDF

Enviado por

malaya tripathyDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

Piperack support protected with Pyrocrete 241, withstands hydrocarbon fire.

Pyrocrete 241 applied offsite and transported to jobsite.

History of Performance Excellence

Over 30 years of successful case histories and more than 100 million square feet of

structural steel protected worldwide.

Since the late 1970’s Pyrocrete 241 has been the industry leader in cementitious fireproofing and continues to be the most specified and

highly regarded cementitious fireproofing material in the world. With over 30 years of unparalleled performance, it is the global benchmark

for high performance cementitious fireproofing in the refining and petrochemical industries.

Pyrocrete 241 is synonymous with high quality. Pyrocrete 241 is manufactured using only the highest quality raw materials with strict QA/

QC protocols all under the UL follow up service to ensure the highest quality product for our customers worldwide.

Pyrocrete 241 Performance Advantages

Pyrocrete 241 is a high density, exterior grade, heavy duty, cementitious fireproofing material ideal for use in industrial and petrochemical

environments. This cement based fireproofing can provide 1 to 4 hour(s) of fire protection for structural steel, vessel skirts, bulkheads, LPG

vessels, LNG terminals or to upgrade the fire resistance of existing concrete.

Pyrocrete 241 is suitable for both field and shop applications. The superior physical properties of Pyrocrete 241 promote high durability

when handling, during construction, and while in service.

Applications Product Feature Performance Benefit

»» Refineries Harder, more durable material.

»» Chemical Plants 55 PCF Density (avg.) Tough surface suitable for harsh

exterior exposures.

»» Gas Plants

»» LPG Vessels High Impact & Compressive Damage resistant during

Strength transportation, construction, and

»» LNG Facilities thoughout service life.

»» Pharmaceutical Facilities Prevents failures from

»» Pulp and Paper Mills High Bond Strength disbondment and cracking which

lowers repair & maintenance

»» Nuclear Power Plants costs.

»» Conventional Power Plants

Industry Leading Ratings Lower installation & material

»» Biomedical Facilities costs.

»» Factories and Warehouses

»» Commercial Buildings Weight savings, reducing overall

1/5 The Weight of Concrete construction costs. Reduced

transportation & installation costs.

Jet Fire Impingement Cryogenic Exposure

Rigorously Tested, Certified, & Proven

Pyrocrete 241 has a proven track record of performance when subjected to the

harshest environmental conditions and the extreme heat of hydrocarbon fire.

Pyrocrete 241 has been tested and certified for a variety of exposures. It has also preformed by protecting steel in actual hydrocarbon fires

in refining and petrochemical facilities around the world.

Certifications & Listings: Physical Properties Test Procedure Typical Results

»» UL (Underwriter’s Laboratories) 55 PCF

UL 1709 Hydrocarbon Ratings Density ASTM E605

(.88 g/cm3)

UL 263 (ASTM E-119) Cellulosic Ratings

4,871 psf

Bond Strength ASTM E736

(233 kPa)

»» Lloyd’s Register of Shipping

Jet Fire Ratings 817 psi

Compressive Strength ASTM E761

(5,633 kPa)

A-30, A-60, H-30, H-60, H-120, Bulkhead Ratings

Impact Resistance ASTM E760 Pass

»» BS-476 Hydrocarbon Ratings

HP/A: 30-305

Deflection ASTM E759 Pass

»» FM Global (Factory Mutual)

Corrosion ASTM E937 0.00 g/mm

LPG Vessel Approvals

Structural Steel Approvals

Flame Spread ASTM E84 0

UL Environmental Testing: Smoke Development ASTM E84 0

Pyrocrete 241 has successfully passed the following

502 psi

exposures simulating 20+ year exterior life cycle: Average Flexural Strength ASTM D790

(3,461 kPa)

»» Accelerated Aging

Insulation “K” Factor 0.87 BTU in/hr ft2 °F

»» High Humidity ASTM C177

@ 75°F (24°C) (0.125 W/m°K )

»» Industrial Atmosphere

»» Salt spray Coverage per 50 lb (22.7 kg) bag -

14.3 ft2

»» Combination Wet / Freeze / Dry Cycling (1.3 m2)

Performance Testing Pyrocrete 241 Pyrocrete 241

Pyrocrete 241 has successfully passed the following Contour Design Box Design

test programs:

»» Jet Fire Impingement

»» Hose Stream Endurance

»» Cryogenic Exposure

»» 3 Bar Overblast

CAR B O LIN E

G l o b a l°FH e ad q u ar ter s

2150 Schuetz Rd.

St. Louis, MO 63146

PHONE +1-314-644-1000

TOLL FREE +1-800-848-4645

FAX +1-314-587-2693

www.carboline.com

Customer Service

1- 8 8 8 -2 27-26 5 4

Technical Service

1- 8 0 0 - 8 4 8 - 4 6 4 5

PROVEN PROTECTION UNDER FIRE™

Você também pode gostar

- Pyrocrete Series Brochure - 0115Documento4 páginasPyrocrete Series Brochure - 0115Fadhana Anggara PutraAinda não há avaliações

- Dpcast 01enhancedphysicalproperties 2019-10-08 2.0Documento2 páginasDpcast 01enhancedphysicalproperties 2019-10-08 2.0giakovidAinda não há avaliações

- FK CO2 Fire Ex Portable (2,5) KGDocumento1 páginaFK CO2 Fire Ex Portable (2,5) KGmohammadAinda não há avaliações

- Emitterline LeverDocumento2 páginasEmitterline LevervictorAinda não há avaliações

- Able UCT S: Wiring ChannelsDocumento8 páginasAble UCT S: Wiring ChannelsberdinsonAinda não há avaliações

- CuClad Laminates Data SheetDocumento4 páginasCuClad Laminates Data SheetDenis CarlosAinda não há avaliações

- Dow Corning AllGuard Silicone Elastomeric CoatingDocumento4 páginasDow Corning AllGuard Silicone Elastomeric Coatinggpax42Ainda não há avaliações

- Product 266: Technical Data SheetDocumento2 páginasProduct 266: Technical Data SheetFabio ParceroAinda não há avaliações

- Factory Mutual # Standard Pg. 261Documento14 páginasFactory Mutual # Standard Pg. 261شركة الطيبىAinda não há avaliações

- RLA Brochure R1Documento2 páginasRLA Brochure R1Dwi Sulistyo BudiAinda não há avaliações

- Primacorelw 81ni1h enDocumento2 páginasPrimacorelw 81ni1h enedwinAinda não há avaliações

- Rti Prorox WM 940 Es ExpDocumento1 páginaRti Prorox WM 940 Es ExpMadiaw NajaAinda não há avaliações

- Pyrocrete 241-ProductFlyer-072314Documento2 páginasPyrocrete 241-ProductFlyer-072314Angel SanjuanAinda não há avaliações

- 20 MN CR 5Documento3 páginas20 MN CR 5abhayuietAinda não há avaliações

- TD Ferrocote 61a UsDocumento2 páginasTD Ferrocote 61a UsJavier RodriguezAinda não há avaliações

- Nailable Insulation Guide: AcfoamDocumento32 páginasNailable Insulation Guide: AcfoamАлександар Але СтојановићAinda não há avaliações

- Protective & Marine Coatings: Polysiloxane 1KDocumento4 páginasProtective & Marine Coatings: Polysiloxane 1KAna CabreraAinda não há avaliações

- The Beast - Beast Super G - TDSDocumento1 páginaThe Beast - Beast Super G - TDSShaara NeyAinda não há avaliações

- Super Shield Nickel Epoxy Conductive Coating 841ER Technical Data SheetDocumento8 páginasSuper Shield Nickel Epoxy Conductive Coating 841ER Technical Data Sheetsrikanth NakkaAinda não há avaliações

- CCX CCDocumento4 páginasCCX CCchudAinda não há avaliações

- Sintetico KeltecDocumento1 páginaSintetico KeltecIngeniería AplicacionesAinda não há avaliações

- Ceilcote 2000 Flakeline+td+engDocumento2 páginasCeilcote 2000 Flakeline+td+engMohamed NouzerAinda não há avaliações

- Wall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019Documento8 páginasWall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019joseocsilvaAinda não há avaliações

- CatalogueDocumento58 páginasCatalogueGanesh DuraisamyAinda não há avaliações

- 10 2118@178431-PaDocumento6 páginas10 2118@178431-Pathlim19078656Ainda não há avaliações

- SA 387 Grade 91 Class 2Documento4 páginasSA 387 Grade 91 Class 2briang-2Ainda não há avaliações

- 20Mncr5: Steel GradeDocumento3 páginas20Mncr5: Steel GradeRajat DubeyAinda não há avaliações

- Proprietary Insulating Castable Material For Furnace LiningsDocumento3 páginasProprietary Insulating Castable Material For Furnace LiningsAleem QureshiAinda não há avaliações

- GN 001 India A4Documento2 páginasGN 001 India A4Shanmukganathan ManickamAinda não há avaliações

- Carboguard: Carboguard 60 Is A High Solids and Corrosion Resistant Epoxy Polyamide CoatingDocumento2 páginasCarboguard: Carboguard 60 Is A High Solids and Corrosion Resistant Epoxy Polyamide CoatingMuhammad Prima JayaAinda não há avaliações

- LR-C-VentureClad Catalogue 01Documento16 páginasLR-C-VentureClad Catalogue 01himanshu desaiAinda não há avaliações

- Fire Shield LFST - 42E: Premium Performance Industry Applications Product AvailabilityDocumento1 páginaFire Shield LFST - 42E: Premium Performance Industry Applications Product Availabilityray9699Ainda não há avaliações

- PBN DatasheetDocumento1 páginaPBN DatasheetLove MishraAinda não há avaliações

- Roxul Comfortboard 80: Insulated SheathingDocumento1 páginaRoxul Comfortboard 80: Insulated SheathingMark RauAinda não há avaliações

- SULZER CastMaterials - E00510Documento5 páginasSULZER CastMaterials - E00510nhirpara1Ainda não há avaliações

- Aceite Sintetico KeltecDocumento1 páginaAceite Sintetico KeltecSAUL OSPINOAinda não há avaliações

- C&D Flooded Batteries-KCR-KARDocumento4 páginasC&D Flooded Batteries-KCR-KARvikasmikkuAinda não há avaliações

- Loctite 567™: Technical Data SheetDocumento3 páginasLoctite 567™: Technical Data SheetManikanta Sai KumarAinda não há avaliações

- 4.10) Arch Shaped Self Supporting Trussless Roof Specifications PDFDocumento11 páginas4.10) Arch Shaped Self Supporting Trussless Roof Specifications PDFGaddam Padmaja ReddyAinda não há avaliações

- Aegis Multifunction RelayEnglish PDFDocumento29 páginasAegis Multifunction RelayEnglish PDFmalad drmAinda não há avaliações

- Self Powered Relay-CGI14SEnglishDocumento16 páginasSelf Powered Relay-CGI14SEnglishjoydip.dgp2152100% (2)

- OC& Earth Fault RelayEnglishDocumento16 páginasOC& Earth Fault RelayEnglishAnish KshitijAinda não há avaliações

- Technical Information ASSET DOC LOC 1541021Documento1 páginaTechnical Information ASSET DOC LOC 1541021Henry PonceAinda não há avaliações

- Power Mar Bus BarDocumento16 páginasPower Mar Bus BarKatty CachagoAinda não há avaliações

- 5kV 6mm Xlpe Cts PVC Cable: Application StandardsDocumento1 página5kV 6mm Xlpe Cts PVC Cable: Application StandardsAHMED YOUSEFAinda não há avaliações

- 4622 Product InfoDocumento4 páginas4622 Product InfoVendy KurniawanAinda não há avaliações

- Exceed S 9243MLDocumento2 páginasExceed S 9243MLzhen liuAinda não há avaliações

- CAFCO 400 Data SheetDocumento4 páginasCAFCO 400 Data Sheetajuhaseen100% (1)

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocumento4 páginasPintura Epoxica Sherwin Willians Hoja Seguridad1Ainda não há avaliações

- Syntho-Glass XT TDS (JK R15 0315) EnglishDocumento2 páginasSyntho-Glass XT TDS (JK R15 0315) EnglishMasood KhanAinda não há avaliações

- Ajedium Films (Solvay)Documento3 páginasAjedium Films (Solvay)hyper meshAinda não há avaliações

- DTM Acrylic Coating: Protective & Marine CoatingsDocumento4 páginasDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraAinda não há avaliações

- Corian Exterior Cladding: Technical BulletinDocumento6 páginasCorian Exterior Cladding: Technical BulletinnaheedahmedAinda não há avaliações

- Marine Lubricants FlyerDocumento4 páginasMarine Lubricants FlyerjjgonzalezquinaAinda não há avaliações

- NG30-02JBK - Next PolymersDocumento4 páginasNG30-02JBK - Next PolymersdigiarkanandAinda não há avaliações

- Exxon LD 100 BWDocumento2 páginasExxon LD 100 BWAli KüçükAinda não há avaliações

- Kooltherm K5 EWB Datasheet ME - 10th Issue - Feb 2021Documento2 páginasKooltherm K5 EWB Datasheet ME - 10th Issue - Feb 2021Sunrise RBAinda não há avaliações

- Tectyl HF 46 PDS ENDocumento1 páginaTectyl HF 46 PDS ENAdham TunggalAinda não há avaliações

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingNo EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingAinda não há avaliações

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantNo EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantNota: 3.5 de 5 estrelas3.5/5 (3)

- Auramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic TechnologyDocumento2 páginasAuramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic Technologymalaya tripathy100% (1)

- SDS Conplast SP600 IndiaDocumento7 páginasSDS Conplast SP600 Indiamalaya tripathyAinda não há avaliações

- Relationships Between Porosity and PermeDocumento6 páginasRelationships Between Porosity and Permemalaya tripathyAinda não há avaliações

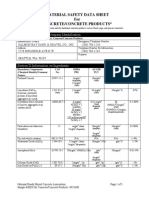

- Material Safety Data Sheet For Concrete/Concrete Products : Section I-Product and Company IdentificationDocumento5 páginasMaterial Safety Data Sheet For Concrete/Concrete Products : Section I-Product and Company Identificationmalaya tripathyAinda não há avaliações

- SUPRA50®: Chemical Composition (Weight %)Documento3 páginasSUPRA50®: Chemical Composition (Weight %)malaya tripathyAinda não há avaliações

- Material Safety Data Sheet: EC-25 MSDS Page 1 of 3Documento3 páginasMaterial Safety Data Sheet: EC-25 MSDS Page 1 of 3malaya tripathyAinda não há avaliações

- Applied Sciences: Dimensional Stability of SBR-Modified Cementitious Mixtures For Use in 3D Additive ConstructionDocumento13 páginasApplied Sciences: Dimensional Stability of SBR-Modified Cementitious Mixtures For Use in 3D Additive Constructionmalaya tripathyAinda não há avaliações

- Material Safety Data Sheet (MSDS) Butane Please Ensure That This MSDS Is Received by An Appropriate PersonDocumento3 páginasMaterial Safety Data Sheet (MSDS) Butane Please Ensure That This MSDS Is Received by An Appropriate Personmalaya tripathyAinda não há avaliações

- Material Safety Data Sheet: November 2012 Page 1 of 7Documento7 páginasMaterial Safety Data Sheet: November 2012 Page 1 of 7malaya tripathyAinda não há avaliações

- Safety Data Sheet: AcetoneDocumento15 páginasSafety Data Sheet: Acetonemalaya tripathyAinda não há avaliações

- List of Indian States Capitals and Chief Ministers PDFDocumento2 páginasList of Indian States Capitals and Chief Ministers PDFmalaya tripathy100% (1)

- Material Safety Data Sheet: Identification of The Substance/mixture and of The Company/undertakingDocumento10 páginasMaterial Safety Data Sheet: Identification of The Substance/mixture and of The Company/undertakingmalaya tripathyAinda não há avaliações

- Admixture MSDSDocumento5 páginasAdmixture MSDSmalaya tripathyAinda não há avaliações

- ICC T20 World Cup 2020 Schedule Venue Group's PDF DownloadDocumento3 páginasICC T20 World Cup 2020 Schedule Venue Group's PDF Downloadmalaya tripathyAinda não há avaliações

- Faunal Extinction in Australia: The Status of Australia's BiodiversityDocumento24 páginasFaunal Extinction in Australia: The Status of Australia's Biodiversitymalaya tripathyAinda não há avaliações

- MOST Volume 1Documento494 páginasMOST Volume 1malaya tripathyAinda não há avaliações

- Rivers of WorldDocumento28 páginasRivers of Worldmalaya tripathyAinda não há avaliações

- Techno Commercial Part IIDocumento9 páginasTechno Commercial Part IImalaya tripathyAinda não há avaliações

- Presidents Usa PDFDocumento3 páginasPresidents Usa PDFmalaya tripathyAinda não há avaliações

- Nlsaw 2nd Complete PDFDocumento84 páginasNlsaw 2nd Complete PDFmalaya tripathyAinda não há avaliações

- List of Presidents of The United States: President Term Began Term EndedDocumento1 páginaList of Presidents of The United States: President Term Began Term Endedmalaya tripathy100% (1)

- Epcot Building Codes 2015 Edition Code Change Submittals Effective 10/01/2015Documento48 páginasEpcot Building Codes 2015 Edition Code Change Submittals Effective 10/01/2015LALA0% (1)

- Monokote Field Application Manual PDFDocumento136 páginasMonokote Field Application Manual PDFJohn Doe100% (2)

- GYPSUM BOARD Guide Specification National Gypsum CompanyDocumento19 páginasGYPSUM BOARD Guide Specification National Gypsum CompanyJerome PalicteAinda não há avaliações

- Prysmian - Product Catalogue - A Guide To BS8519Documento11 páginasPrysmian - Product Catalogue - A Guide To BS8519Amr EidAinda não há avaliações

- Concrete Masonry Fire Resistance June 2016Documento4 páginasConcrete Masonry Fire Resistance June 2016Hendrix TilloAinda não há avaliações

- Petronas Technical Standards: Passive Fire and Cryogenic Protection For Structural SteelDocumento27 páginasPetronas Technical Standards: Passive Fire and Cryogenic Protection For Structural SteelvinothAinda não há avaliações

- Australian Standard: Timber Structures Part 4: Fire Resistance For Structural Adequacy of Timber MembersDocumento21 páginasAustralian Standard: Timber Structures Part 4: Fire Resistance For Structural Adequacy of Timber MembersGaneshalingam Ramprasanna1Ainda não há avaliações

- 2161 - 97 RC and Masonry Fire ResistanceDocumento26 páginas2161 - 97 RC and Masonry Fire Resistanceanon_434029895Ainda não há avaliações

- Coltman Technical SpecificationDocumento10 páginasColtman Technical SpecificationltslloydAinda não há avaliações

- Cdnc85082enc 001 PDFDocumento346 páginasCdnc85082enc 001 PDFindrajit sodhaAinda não há avaliações

- Mobil Standard Fire ProofingDocumento16 páginasMobil Standard Fire ProofingAnonymous yCpjZF1rFAinda não há avaliações

- RC Vs Steel PiperackDocumento4 páginasRC Vs Steel PiperacksinambeladavidAinda não há avaliações

- Chartek 1709 Protecting Lives, Protecting Assets BrochureDocumento2 páginasChartek 1709 Protecting Lives, Protecting Assets BrochureAhmed IbrahimAinda não há avaliações

- VIKING-Water Spray System DesignDocumento16 páginasVIKING-Water Spray System Designbonaccorsokar9802100% (2)

- EP FF 02 PH Philosophy Passive Fire FightingDocumento18 páginasEP FF 02 PH Philosophy Passive Fire FightingagaricusAinda não há avaliações

- Pyroclad X1: Selection & Specification DataDocumento6 páginasPyroclad X1: Selection & Specification DataDuongthithuydungAinda não há avaliações

- Specification For Replacement of Fireproof Coating Over Pentane Bullets, Gail-GandharDocumento12 páginasSpecification For Replacement of Fireproof Coating Over Pentane Bullets, Gail-GandharVikas PatelAinda não há avaliações

- Design of Fire Protection Systems For Tall BuildingsDocumento32 páginasDesign of Fire Protection Systems For Tall BuildingsMridulHasan100% (1)

- Fire Resistance of Masonry AssembliesDocumento6 páginasFire Resistance of Masonry AssembliesRyan KuntzAinda não há avaliações

- SCI 160 - Structural Fire Design IntumescentDocumento74 páginasSCI 160 - Structural Fire Design IntumescentAshwin B S Rao100% (2)

- Nbs Plus k10 Specification DetailsDocumento0 páginaNbs Plus k10 Specification Detailsmajkil1988100% (1)

- UL Design - S729Documento3 páginasUL Design - S729souravrobinAinda não há avaliações

- Saes B 006Documento21 páginasSaes B 006Anonymous a4Jwz14W100% (2)

- Report Insulco EmiratesDocumento13 páginasReport Insulco EmiratesLena MirajAinda não há avaliações

- Katalog Krisbow 4Documento1 páginaKatalog Krisbow 4Dermawan PurbaAinda não há avaliações

- ASFP TGD 16 - Code of Practice For Off-Site Applied Thin Film Intumescent CoatingsDocumento50 páginasASFP TGD 16 - Code of Practice For Off-Site Applied Thin Film Intumescent CoatingsAnselmo Ribeiro100% (4)

- Piping Class SpecificationDocumento6 páginasPiping Class Specificationcitra puspita sariAinda não há avaliações

- Cab. Reg. No. 498 - Latvian Construction Standard LBN 201-10Documento38 páginasCab. Reg. No. 498 - Latvian Construction Standard LBN 201-10GeorgeAinda não há avaliações

- 155 - Supalux Water Resistant Shaftwall PDFDocumento0 página155 - Supalux Water Resistant Shaftwall PDFodemircioglu2Ainda não há avaliações

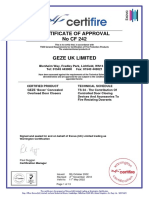

- Certificate of Approval No CF 242Documento13 páginasCertificate of Approval No CF 242Florin RazvanAinda não há avaliações