Escolar Documentos

Profissional Documentos

Cultura Documentos

Element Warren A2LA 0038 01 Mechanical PDF

Enviado por

Andre CasteloTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Element Warren A2LA 0038 01 Mechanical PDF

Enviado por

Andre CasteloDireitos autorais:

Formatos disponíveis

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2005

ELEMENT WARREN1

27485 George Merrelli Drive

Warren, MI 48092

Scott Gates Phone: 248 560 4021

Email: scott.gates@element.com

MECHANICAL

Valid To: December 31, 2016 Certificate Number: 0038.01

In recognition of the successful completion of the A2LA evaluation process, accreditation is granted to

this laboratory at the location above as well as the two satellite laboratory locations listed below to

perform the following tests:

Mechanical Tests: Tensile/Elongation; Hardness (Durometer, Rockwell, and Wallace);

Compression; Impact (Izod, Charpy, & GM9300P); Strength at Room and High Temperatures;

Shear Strength; Physical Properties Following Fluid Exposure; Burst Strength of Paper, Hoses and

Tubing; Tear Strength Using Tongue, Elmendorf, and Trapezoid Methods; Filler, Glass, Carbon

Black Content; Volume Change; Specific Gravity and Density; Cleanability; Dimensional

Stability; Water Absorption; Melt Flow/Index; Migration and Contact Staining; Flammability;

Compression Set; Low-Temperature Brittleness; Deflection Temperature; Permeability, Vapor

Transmission; On Plastics, Rubber, Elastomer, Composite, Paper/Paperboard, Construction

Elements, and Textile Products.

Enviromental Simulation Tests: Weatherometer (xenon & carbon arc); Sunlamp & QUV Exposure;

Fadometer; Ozone Resistance; Fogging; Salt Spray; CASS; Humidity; Condensing; Crocking;

Water Immersion; Taber Abrasion; Gravelometer; Specular Gloss; Luminous Transmittance;

Chromaticity; Color Reading; Corrodokote; Oil/Gas Immersion Solvent and Detergent Resistance;

Thermal Shock; Paint Adhesion; Spot Test Acid/Water & Soap; Cleanability; Coating Thickness;

Flexibility; Perspiration; Scrub Resistance; Dime Scrape; Cure Test; Thumbnail Hardness; Oven

Aging; Scab Corrosion; Environmental Cycling; Accelerated Corrosion; Filiform Corrosion

Environmental Chambers Testing: Temperature, Dust and Humidity Exposures are Performed

during Durability Cycling Simulating Actual Environment; Microprocessors Control Chambers

allowing Automatic Cycling and Tracking of Desired Time, Temperature and Humidity; Sizes up

to 4m x 10m x 5m; Flow Measurement (Liquid and/or Gas): Hydraulic Pump Performance; Fan

and Blower Delivery Capabilities, Radiator Heat Exchange Capacity, Heater Output;

Dynamometer Measurements: 3/4 to 50 Horsepower; Stress Measurements; Pressure Testing;

Durability Testing Mechanical/Electrical Cycling; Marine Products (Pumps/Motors/Electronics);

Hydrostatic Leak Testing (up to 40,000 psi); Electrodynamic Vibration Systems: Generate

Controlled Sine or Random Vibration, Sine-on Random Vibration Control, Transient Vibration

Control, Mechanical Shock in Sawtooth, Half-sine & Squared Wave Forms, Field Data

Replication, Operating or Non-Operating Mode Environments, High or Low Temperature &

Humidity Conditions Can be Applied; Servohydraulic Test Systems: Control of Displacement,

Force or Acceleration; Thermal Shock, Liquid and Air; Light Intensity; Sound; MAST,

HALT/HAST.

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 1 of 20

Component Durability; Pressure Cycling; Pressure-Vacuum Cycling; Fuel Recirculation;

Temperature Cycling; Component Performance Testing; Fuel Exposure and Fuel Compatibility;

Fuel Dispensing and Capacity Testing; Performance Testing including Fuel Flow and Electrical

Evaluation; Hydrostatic Burst Testing; ECE Burn Testing on Plastic Fuel Tanks, CARB Diurnal

Testing, Permeation Testing (including: Guideline 24), Injector & Manifold Testing on Fuel Lines

and Connectors; Fuel Tanks; Fuel Pumps and Modules; Fuel Injectors; Fuel Filters; Fuel Pressure

Regulators; Fuel Level Senders; Fuel Rails; Fuel Filler Necks, Plastic & Metal Fuel Tanks; Intake

Manifolds; Spark Arrestors; Carbon Canisters; Gas Caps.

Using the following capabilities:

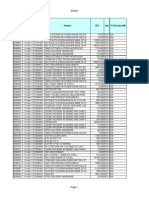

Test Technology Range Reference Standard

Force (0.01 to 100,000) lbf AAR Cargo System

Development

Static Load Test Procedure

Pressure (0.008 to 50,000) psi ESDS7H-19B591-AA

Pulse Pressure Up to 5,000 PSIG, Up to 20 Hz GMW14139

Torque 1 in·oz to 100,000 ft·lbf GMW15607

Temperature (-100 to 650) °C WSS-M2D496-A1

Humidity (5 to 98) % RH MIL-STD-810

Vacuum (0.008 to 29.98) in Hg DVM-0001-AS

Airflow 10 cc/min to 5,000 cfm GMW 15448

Air Velocity (25 to 3,000) ft/min GMW 15448

Sound 20 Hz to 20 kHz, (30 to 100) dB USCAR-15

Liquid Flow 0.01 cc/min to 225 gpm GM10004C

Dimensional (0.00015 to 36.000) in WSS-M15P4

Light Intensity (0.01 to 3,300) lux SDS-17

Vibration:

Vibration Load Capacity Up to 24,000 lbf MIL-STD-810, Method 514

Procedure I

Vibration Frequencies (3 to 2,700) Hz MIL-STD-810, Method 514

Displacement 3 in PK to PK Procedure I

Vibration Acceleration Up to 200 g MIL-STD-810, Method 514

Procedure I

Load/Impact Velocity 1/2 SINE < 1 ms to 35 m/s at MIL-STD-810, Method 514

Terminal Peak Procedure I

Mechanical Shock Capacity Up to 3 500 g MIL-STD-810, Method 514

Combined Environments: (-77 to 177) °C; Procedure I

20 % RH to 95 % RH

Servohydraulic Stroke Up to 50 inches MIL-STD-810, Method 514

Procedure I

Servohydraulic Load Capacity Up to 100,000 lbf MIL-STD-810, Method 514

Procedure I

Servohydraulic Frequencies Up to 50 Hz MIL-STD-810, Method 514

Procedure I

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 2 of 20

Also using customer specific test methods utilizing any combination of test equipment parameters listed

above as well as the following tests and standards:

Test Method Test Technology

AATCC 104 Spot Test Water

AATCC 6 Spot Test Acid

AATCC TM 8 Crocking, Dry & Wet

AATCC TM 15 Perspiration

ABNT NBR 15754 (except Electrical Fuel Pump for Otto-cycles Engines

EMC 4.5.1)

ASTM B117 Operating Salt Spray (Fog) Apparatus

ASTM B368 Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing

(CASS Test)

ASTM B380 Corrosion Testing of Decorative Electrodeposited Coatings by

the Corrodkote Procedure

ASTM B571, Section 3.8, 13 Qualitative Adhesion Testing of Metallic Coatings

ASTM C501 Relative Resistance to Wear of Unglazed Ceramic Tile by the

Taber Abraser

ASTM D1000 Unwind Pull

ASTM D1003 Haze and Luminous Transmittance

ASTM D1004 Initial Tear Resistance of Plastic Film & Sheeting

ASTM D1044 Abrasion-Taber

ASTM D1056 Compression Force

ASTM D1117 Evaluating Nonwoven Fabrics

ASTM D1149 Rubber Deterioration Surface Ozone Cracking in a Chamber

ASTM D1171 Rubber Deterioration Surface Ozone Cracking Outdoors or

Chamber (Triangular)

ASTM D1229 Compression Set at Low Temperatures

ASTM D1238 Melt Index (Flow Rate)

ASTM D1415 Rubber Property - International Hardness

ASTM D1499 Filtered Open-Flame Carbon-Arc Exposures for Plastics

ASTM D1525 Vicat Softening Temperature of Plastic

ASTM D1621 Compressive Properties of Rigid Cellular Plastics

ASTM D1622 Apparent Density of Rigid Cellular Plastics

ASTM D1667 Flexible Cellular Materials-Vinyl Chloride Polymers &

Copolymers

ASTM D1693 Environmental Stress Cracking

ASTM D1708 Tensile Properties of Plastics

ASTM D1735 Standard Practice for Testing Water Resistance of Coatings

Using Water Fog Apparatus

ASTM D1777 Thickness of Textile Materials

ASTM D1793 Spot Test Water & Soap

ASTM D1822 Tensile Impact

ASTM D1894 Static & Kinetic Coefficients of Friction of Plastic Film &

Sheeting

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 3 of 20

Test Method Test Technology

ASTM D1895 Apparent Density, Bulk Factor, and Pourability of Plastic

ASTM D1922 Standard Test Method for Propagation Tear Resistance of Plastic

Film and Thin Sheeting by Pendulum Method

ASTM D1938 Tear-Propagation Resistance of Plastic Film and Thin Sheeting

by a Single-Tear

ASTM D2097 Newark Flex Test

ASTM D2137 Brittleness Point of Flexible Polymers & Coated Fabrics

ASTM D2240, Shore A & D Durometer Hardness

ASTM D2244 Calculation of Color Differences from Instrumentally Measured

Color Coordinates

ASTM D2261 Tongue Tear

ASTM D2344 Short-Beam Strength of Polymer Matrix Composite Materials

ASTM D256 Izod Pendulum Impact Resistance of Plastics

ASTM D2565 Xenon-Arc Exposure of Plastics Intended for Outdoor

Applications

ASTM D2584 Ignition Loss of Cured Reinforced Resins

ASTM D2859 Ignition Characteristics of Finished Textile Floor Covering

Materials

ASTM D3012 Thermal-Oxidative Stability of Propylene Plastics Using a

Specimen Rotator Within an Oven

ASTM D3039 Tensile Properties (Including Poisson’s Ratio)

ASTM D3163 Strength of Adhesive Bonded Rigid Lap Shear Joints

ASTM D3330 Peel Adhesion of Pressure Sensitive Tape

ASTM D3359 Adhesion Tape Test

ASTM D3363 Film Hardness by Pencil Test

ASTM D3389 Coated Fabrics Abrasion Resistance (Rotary Platform, Double-

Head Abrader)

ASTM D3574 Test Methods for Flexible Cellular Materials (except Test G, I4,

Airflow, Test I2 Dynamic Fatigue Test by the Roller Shear at

Constant Force, Test I4 Dynamic Fatigue Test for Carpet

Cushion)

ASTM D3575 Test Methods for Flexible Cellular Materials Made From Olefin

(Except Sections 34-35, 45-46, 49-50, 66-67)

ASTM D3763 Standard Test Method for High Speed Puncture Properties of

Plastics Using Load and Displacement Sensors

ASTM D3769 Heat Sag

ASTM D3776 Mass Per Unit Area (Weight) of Fabric

ASTM D380 Method for Rubber Hose (Except Sections 12-13)

ASTM D3846 In-Plane Shear Strength of Reinforced Plastics

ASTM D3882 Bow and Skew

ASTM D3884 Abrasion Resistance of Textiles, Taber

ASTM D395 Rubber Property-Compression Set (Method B)

ASTM D4060 Taber Abrasion, Organic Coatings

ASTM D412 Tensile Properties, Vulcanized Rubber & Thermoplastics

Elastomers

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 4 of 20

Test Method Test Technology

ASTM D413 Rubber Property-Adhesion to Flexible Substrate

ASTM D4138 Test Methods for Measurement of Dry Film Thickness of

Protective Coating Systems by Destructive Means

ASTM D4157 Abrasion Resistance of Textiles, Wyzenbeek

ASTM D471 Rubber Property-Effect of Liquids

ASTM D4812 Unnotched Cantilever Beam Impact Strength of Plastics

ASTM D4966 Abrasion Resistance of Textile Fabrics

ASTM D4970 Pilling Resistance and Other Related Surface Changes of Textile

Fabrics: Martindale Tester

ASTM D5034 Tensile Strength

ASTM D5035 Breaking Strength, Textile Fabrics, Strip Method

ASTM D518 Rubber Deterioration-Surface Cracking

ASTM D523 Specular Gloss

ASTM D5420 Gardner Impact

ASTM D543 Resistance of Plastics to Chemical Reagents

ASTM D5587 Tearing Strength of Fabrics by the Trapezoid Procedure

ASTM D5628 Standard Test Method for Impact Resistance of Flat, Rigid

Plastic Specimens by Means of a Falling Dart (Tup or Falling

Mass)

ASTM D5630, Method B Ash Content of Thermoplastics

ASTM D570 Water Absorption of Plastic

ASTM D5729 Standard Test Method for Thickness of Nonwoven Fabrics

ASTM D573 Rubber-Deterioration in an Air Oven

ASTM D5733 Tearing Strength of Nonwoven Fabrics by the Trapezoid

Procedure

ASTM D575 Rubber Properties in Compression

ASTM D6110 Impact Resistance of Notched Specimens of Plastics

ASTM D6182 Flexibility and Adhesion of Finish on Leather

ASTM D624 Tear Strength of Conventional Vulcanized Rubber and

Thermoplastic Elastomer

ASTM D635 Flammability, Rigid Plastics

ASTM D638 Tensile Properties of Plastics (Including Poisson’s Ratio)

ASTM D644 Moisture Content of Paper & Paperboard

ASTM D648 Deflection Temperature of Plastics Under Flexural Load in the

Edgewise Position

ASTM D689 Standard Test Method for Internal Tearing Resistance of Paper

ASTM D695 Compressive Properties of Rigid Plastics

ASTM D696 Coefficient of Linear Thermal Expansion of Plastics Between

(-30 & 30 C)

ASTM D7091 Standard Practice for Nondestructive Measurement of Dry Film

Thickness of Nonmagnetic Coatings Applied to Ferrous Metals

and Nonmagnetic, Nonconductive Coatings Applied to Non-

Ferrous Metals

ASTM D732 Shear Strength of Plastics by Punch Tool

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 5 of 20

Test Method Test Technology

ASTM D737 Air Permeability of Fabrics, Fraiser Method

ASTM D746 Brittleness Temperature of Plastics Elastomers by Impact

ASTM D747 Apparent Bending Modulus of Plastics by Means of a Cantilever

Beam

ASTM D750 Deterioration in Carbon-Arc Weathering Apparatus

ASTM D751 Coated Fabrics (Pp 41-49)

ASTM D774 Bursting Strength of Paper

ASTM D785, B, L, M, R Rockwell Hardness of Plastics and Electrical Insulating Materials

ASTM D790 Flexural Properties of Unreinforced and Reinforced Plastics &

Electrical

ASTM D792 Density

ASTM D828 Tensile Breaking Strength of Paper & Paperboard

ASTM D865 Rubber-Deterioration by Heat in Air (Test Tube Enclosure)

ASTM D870 Testing Water Resistance of Coatings Using Water Immersion

ASTM D882 Tensile Properties Thin Plastic Sheeting

ASTM D903 Peel or Stripping Strength of Adhesive Bonds

ASTM D925 Method A Staining of Surfaces (Contact/Migration/Diffusion)

ASTM D952 Bond of Cohesive Strength of Sheet Plastics & Electrical

Insulation

ASTM E132 Poisson’s Ratio

ASTM E96 Water Vapor Transmissions

ASTM F146 Fluid Resistance of Gasket Materials

ASTM F147 Flexibility of Non-Metallic Gasket Materials

ASTM F152 Tension Testing of Nonmetallic Gasket Materials

ASTM F36 Compressibility & Recovery of Gasket Materials

ASTM G152 Carbon Arc Weatherometer, Open Flame (ASTM G23- Expired)

ASTM G153 Carbon Arc Weatherometer, Enclosed (ASTM G23- Expired)

ASTM G154 Fluorescent Light Apparatus for UV Exposure, QUV (ASTM

G53- Expired)

ASTM G155 Standard Practice for Operating Xenon Arc Light Apparatus for

Exposure of Non-Metallic Materials (ASTM G26 – Expired)

ASTM G85 Corrosion Testing

Chrysler LP-463DB-03-01 Plastic Hydrolytic Stability

Chrysler LP-463KB-38-01 Fabric Lint Pickup and Lint Loss

Chrysler LP-463KB-37-01 Resistance to Pilling and Minking of Textile Fabrics

DIN 40050-9 (Withdrawn Protection Against Foreign Objects; Water and Contact;

1993)2 Electrical Equipment

DIN 50017 (Withdrawn Humidity Exposure

10/82)2

DIN 50021 (Withdrawn Salt Spray

06/88)2

DIN 75220 Aging Automobile Components in Solar Simulation Units

DIN 75201 Determination of Windscreen Fogging Characteristics of Trim

Materials in Motor Vehicles

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 6 of 20

Test Method Test Technology

DOE/NE-ID-11173 FreedomCAR Ultracapacitor Test Manual

ECE Reg. 43(Annex 3, Falling Ball-Impact Testing

section2)

FLTM BI 106-01 Paint Adhesion Test

FLTM BI 107-05 Thermal Shock Test for Paint Adhesion

FLTM BI 110-01 Specular Gloss

FLTM BI 113-01 Spot Test Water & Soap

FLTM BI 113-02 Spot Test Acid

FLTM BI 117-01 Coating Thickness

FLTM BI 123-01 Painted Sheet Metal Corrosion, Apg

FLTM BI 124-01 Filiform Corrosion Test

FLTM BN 107-01 Crocking, Dry & Wet

FLTM BN 108-02 Abrasion-Taber

FLTM BN 108-03 Resistance to Pilling

FLTM BN 108-04 Scuffing

FLTM BN 108-13 Scratch Test

FLTM BN 024-02 Automotive Materials, Flammability

FLTM BN 102-02 W Flex

FLTM BN 106-02 Seam Fatigue Testing

FLTM BN 108-03 Resistance to Pilling

FLTM BN 108-14 Resistance to Pilling Wear of Leather

FLTM BN 113-01 Bond Strength of Trim Assemblies

FLTM BN 157-01 Determination of Leather Softness

FLTM BO 101-01 Resistance to Artificial Weather (Xenon Arc)

FLTM BO 112-06 Stain Resistance

FLTM BQ 105-01 Corrosion Testing, CASS

SH-0117 Floor Mat Retention Clip Button Style Performance Specification

FMVSS 571.206, Except Door Locks and Door Retention Components

5.1.1.4

FMVSS 571.209, S5.1 & S5.2 Seat Belt Assemblies

only

FMVSS 571.213, S5.4.1 only Child Restraint Systems

FMVSS 571.223 Rear Impact Guards

FMVSS 571.302 Flammability of Interior Materials

Ford CETP 01.03-L-309 Mini Key Life Test – Side Door Durability

Ford IP-0105 Instrument Panel Sunload Resistance

Ford MA-0128 Simulated Sunload Resistance – Exterior

Ford MA-0130 Humidity Aging

Ford MA-0131 Heat Age

Ford OR-0329 Sunload Resistance – Exterior Ornamentation

Ford/GM 6F-6T70/75 Joint Supplier Sediment Procedure

GM10004C (Inactive 4/09)2 Transmission and Engine Oil Cooler Plumbing System

GM10005C (Inactive 4/08)2 Radiators – Durability and Performance

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 7 of 20

Test Method Test Technology

GM4298P (Inactive 12/10)2 Salt Spray Test

GM4465P (Inactive 1/11)2 Humidity Test

GM4476P (Inactive 12/10)2 CASS Test Copper-Accelerated Acetic Acid Salt Spray Test

(Fog)

GM4486P (Inactive 12/12)2 Test of Ozone Resistance of Elastomer Compounds

GM9032P (Inactive 12/10)2 Impact Strength of Plastics

GM9033P (Inactive 7/13)2 Colorfastness to Crocking (Rubbing)

GM9058P (Inactive 8/10)2 Procedure for Qualifying Hose Coupling Assemblies

GM9059P (Inactive 9/12)2 Thermal-Oxidative Stability Characteristics of Plastics

GM9060P Qualifying Quick-Connector Fittings for Nylon Fuel Line Usage

GM9067P (Inactive 5/14)2 Gasoline Estractables In Hose

GM9070P (Inactive 9/11)2 Testing Flammability of Materials

GM9071P (Inactive 9/12)2 Tape Adhesion Test for Paint Finishes

GM9077P (Inactive 3/13)2 Glass Content of Glass Reinforced Plastic

GM9082P (Inactive 10/12)2 Abrasion Resistance of Textiles, Wyzenbeek

GM9125P (Inactive 5/13)2 Accelerated Exposure of Automotive Materials (Xenon Arc)

GM9126P (Inactive 4/12)2 Cleanability

GM9128P (Inactive 4/11)2 Mildew

GM9130P Resistance to Odor

GM9133P Water Spotting

GM9141P Compatability of Plastic Rolled Goods and Leather to White

Vinyl and to White Leather – Revision C

GM9146P Wicking and Blistering of Convertible Top End Roof Trim

Materials

GM9193P (Inactive 10/14)2 Bond Strength of Fiberglass

GM9200P Accelerated Aging and Steaming

GM9201P (Inactive 12/12)2 Crease Resistance

GM9302P (Inactive 7/11)2 Stress Mark Susceptibility of Plastic Materials

GM9214P (Inactive 12/7)2 Staining of Trim Material

GM9305P (Inactive 9/12)2 Fogging Characteristics of Automotive Interior Trm Materials

GM9306P (Inactive 3/11)2 Ash Determination

GM9310P (Inactive 1/11)2 Variable Surface Temperature Heat Exposure Test (Sept 1988)

GM9327P (Inactive 1/11)2 Accelerated Weathering, Xenon

GM9329P (Inactive 10/12)2 High Temperature Humidity Aging

GM9500P (Inactive 10/08)2 Gasoline Puddle Test for Gasoline Fill Areas

GM9501P (Inactive 8/10)2 Gasoline Dip Test for Painted Parts

GM9502P (Inactive 8/12)2 Knife Cross-Hatch Adhesion Test Procedure for Painted

Elastomeric Plastic Substrates

GM9503P (Inactive 6/12)2 Evaluating Brittleness of Painted Plastics

GM9505P (Inactive 10/12)2 Automotive Environmental Cycles

GM9506P (Inactive 6/13)2 Dime Scrape Test to Determine Paint Adhesion and Brittleness

GM9507P (Inactive 6/11)2 Thumbnail Hardness Test for Painted Parts

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 8 of 20

Test Method Test Technology

GM9508P (Inactive 8/10)2 Chip Resistance of Coating

GM9509P (Inactive 10/12)2 Solvent Rub Method for Determining Cure of Painted Metal Or

Plastic Substrates

GM9515P Abrasion-Taber

GM9517P (Inactive 12/12)2 Perspiration

GM9525P (Inactive 11/7)2 Thermal Shock Test for Paint Adhesion

GM9531P (Inactive 6/12)2 Water Jet Test

GM9540P (Inactive 3/10)2 Accelerated Corrosion Test

GM9600P (Inactive 8/12)2 Car Wash Simulation Test

GM9635P Dust-Out From Fiber Sound Absorber Pad

GM9652P Resistance to Pilling of Automotive Upholstery

GM9676P Procedure for Qualifying Quick – Connector Fittings for Vapor

Fuel Line

GM9684P (Inactive 10/12)2 Parting Lines

GM9736P (Inactive 3/11)2 Sulfur Dioxide Spot Test

GM9900P (Inactive 3/10)2 Cleanability

GM9902P Noncontact Staining Measurement of Elastomers

GMN8020TP, except Lamps – Development and Validation Test Procedures

photometrics, section

4.3.1.2.2.4

GMN6752 (Inactive 4/10)2 Quantify Foreign Material on Engine and Transmission

Components/Assemblies

GMNA9518P (Inactive 8/10)2 Paint Thickness of Painted Flexible Plastic Parts

GMW3172, sections 8 and 9 Specification for Electrical/Electronic Component Analytical

only /Development/Validation (A/D/V) Procedures for Conformance

to Vehicle Environmental, Reliability, and Performance

Requirements

GMW3191 Connector Test and Validation Specification

GMW3211 Resistance to Stretch and Set

GMW3232 Flammability

GMW3235 Fogging

GMW3414 Colorfastness to Artificial Light

GMW3431, except section General Procedures for Testing Switches

4.4.7

GMW8287 Highly Accelerated Life Testing Halt/Hast

GMW14093 Determination of Impact Resistance of Plastic Components

GMW14102 Determination of Water Spotting Test

GMW14124 Automotive Environmental Cycles

GMW14130 Scuff and Mar Resistance

GMW14141 Die Migration

GMW14162 Colorfastness to Artificial Weathering

GMW14334 Chemical Resistance to Fluids

GMW14444, Sections 3.3.7, Material Related Interior Part Performance

3.4.11, 3.4.12, 3.4.13, 3.4.15,

3.4.16, 3.4.19 only

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 9 of 20

Test Method Test Technology

GMW14445 Sunscreen and Insect Repellent Resistance

GMW14688 Resistance to Scratching

GMW14698 Scratch Resistance of Organic Coatings and Self-Adhesive Foils

GMW14829 Tape Adhesion Test for Paint Finishes

GMW14872 Cyclic Corrosion Laboratory Tests

GMW14892, Section 3.1.5 Adhesion

GMW14906 Lamp Development and Validation Test Procedures

GMW15201 Double-Coated Foam Tape for Exterior Attachments

GMW15282 Corrosion/Undercutting Scribe Creepback

GMW15288 Scab Corrosion Creepback of Paint Systems for Metal Substrates

GMW15487 Resistance to Abrasion of Organic Coating

GMW15651 Hook Fastener Resistance

GMW16037 Quantify Cleanliness of Powertrain Components

GMW16190 Determination of Cantilever Sag Resistance

GMW3182 Determination of Mass per Area

GMW3205 Test Method for Determining the Resistance to Odor Propagation

of Interior Materials

GMW3259 Determination of Resistance to Mildew Growth

GMW3326 Tearing Strength of Textile Materials by Trapezoid Method

GMW3387 Fiber Degradation of Automotive Textiles

GMW3402 Soil and Cleaner Resistance of Automotive Materials

GMW3405 Seam Fatigue for Automobile Textiles

GMW4090 Weave and Yarn Count

HES C206 Flammability

HES D6508 Fogging of Interior Materials for Automobiles

IBM CH6-0430-102 Flammability

IEC 60068-2-68 Dust and Sand

(Except LA1 and LC1)

IEC 60068-2-78 Test Cab: Damp Heat, Steady State

IEC 61215, 10.3, 10.8, 10.11- Crystalline Silicon Terrestrial PV Modules

10.16, 10.18

IEC 61646, 10.3, 10.8, 10.11- Thin Film Terrestrial PV Modules

10.16, 10.18

ISO 1133 Plastics – Determination of the Melt Mass-Flow Rate (MFR) and

the Melt Volume-Flow Rate (MVR)

ISO 1183-1 Determining the Density of Non-Cellular Plastics Using

Immersion Method

ISO 12945-2 Determination of Fabric Propensity to Surface Fuzzing and to

Pilling, Modified Martindale Method

ISO 12947-1 Abrasion Resistance of Fabrics by the Martindale Method

ISO 12947-2 Abrasion Resistance of Fabrics by the Martindale Method –

Specimen Breakdown

ISO 12947-3 Abrasion Resistance of Fabrics by the Martindale Method – Mass

Loss

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 10 of 20

Test Method Test Technology

ISO 12947-4 Abrasion Resistance of Fabrics by the Martindale Method –

Assessment of Appearance Change

ISO 13937-2 Tear Properties of Fabrics

ISO 16750 Road Vehicles – Environmental Conditions and Testing for

Electrical and Electronic Equipment

ISO 176 Determination of Loss of Plasticizers – Active Charcoal Method

ISO 178 Determination of Flexural Properties

ISO 179-1 Determination of Charpy Impact Properties, Non-Instrumented

Impact Test

ISO 1798 Flexible Cellular Polymeric Materials- Determination of Tensile

Strength and Elongation at Break

ISO 17235 Leather Softness

ISO 180 Plastics – Determination of Izod Impact Strength

ISO 188 Rubber, Vulcanized Thermoplastic-Accelerated Aging & Heat

Resistance Test

ISO 20653 Road Vehicles – Degress of Protection (IP-Code) – Protection

Against Foreign Objects, Water and Access – Electrical

Equipment

ISO 22088-3 Determination of Resistance to Environmental Stress Cracking

(ESC)

ISO 2808, Mtd 5B/6A Paints and Varnishes – Determination of Film Thickness

ISO 291 Std. Atmosphere, Conditioning

ISO 306 Determination of Vicat Softening Temperature (VST) of

Thermoplastic Materials

ISO 3386-2 Flexible Cellular Polymeric Materials – Determination of Stress-

Strain Characteristics in Compression

ISO 34-1 Determination of Tear Strength of Thermoplastic/Vulcanized

Rubber Using Trouser, Angle and Crescent Pieces

ISO 3451-1 Determination of Ash

ISO 37 Determination of Tensile Stress/Strain Properties of

Thermoplastic/Vulcanized Rubber

ISO 3795 Flammability

ISO 4892-2 Xenon Exposure Testing

ISO 4892-3 Fluorescent Light Apparatus for UV Exposure, QUV

ISO 4892-4 Carbon Arc Weatherometer, Open Flame

ISO 5084 Determination of Thickness of Textiles and Textile Products

ISO 527-1 Tensile Properties Part 1 General Principles

ISO 527-2 Tensile Properties Part 2 Test Conditions for Molding and

Extrusion Plastic

ISO 527-3 Tensile Properties Part 3 Film, Sheets

ISO 527-4 Tensile Properties Part 4 Isoropic and Orthotropic Fiber-

Reinforced Plastics

ISO 527-5 Tensile Properties Part 5 Test Conditions for Unidirectional

Fiber-Reinforced Plastics

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 11 of 20

Test Method Test Technology

ISO 62 Plastics-Determination of Water Absorption

ISO 6722 Road Vehicle 60 V to 600 V Single Core Cable Methods

ISO 75-1 Plastics-Determination Temperature of Deflection Under Load

Part 1 General Test Method

ISO 75-2 Plastics – Determination of Temperature of Deflection Under

Load Part 2 Plastics and Ebonite

ISO 75-3 Plastics – Determination of Temperature of Deflection Under

Load Part 3 High Strength Thermosetting

ISO 815 Determination of Compression Set of Thermoplastic/Vulcanized

Rubber at Ambient, Elevated, or Low Level Temperatures

ISO 8295 Coefficient of Friction

ISO 845 Cellular Plastics and Rubbers – Determination in Apparent

Density (Bulk)

ISO 868 Plastic and Ebonite – Determination of Indentation Hardness by

Means of a Durometer (Shore Hardness)

ISO 9227 Corrosion Testing, Salt Spray

JIS D 0203 (R2, S1, S2) Moisture, Rain & Spray Test for Automobile Parts

JIS D 0207 Dust Test for Automobile Parts (F-Type Only)

JIS D 1601 Vibration Testing Methods for Automobile Parts

JIS D 205 Weatherability for Automotive Parts

JIS Z 87451 Specular Glossiness Methods of Measurement

John Deere JDQ 53.3 Environmental Testing of Electrical/Electronic

Components/Assemblies

MES CF 050 Flammability

MIL-STD-810 (C, D, E, F, G), Environmental Test Methods & Engineering Guidelines

Sections 500, 501, 502, 503,

507, 512, 513, 514, 516, 520,

524, 528 only

MS JP 9-4 Flammability

NES M0131 Methods of High Temperature Test for Passenger Compartment

Synthetic Resin Parts

NES M0132 Thermal Cycle Test Methods for Plastic Parts

NES M0133 Chemical Resistance Test Methods

NES M0134 Falling Ball Impact

NES M0135 Weatherability and Light Resistance, Carbon Arc

NES M0136 Abrasion Resistance

NES M0153 Moisture Resistance Test Method

Nissan 96030 NDS00 Air Spoiler Testing

Nissan 26010NDS00 Front Lamp Testing

(Except Photometrics)

PF 10174 (expired)2 Transmission and Engine Cooler Lines – Severe Service

PF 10523 Coupled Hose – Transmission Cooler Lines

PF 11051 Coupled Hose – Transmission Oil Cooler Plumbing Assy

PF 4088 Exterior Automotive Lighting Devices

PF 4091 Liftgate and Decklid Latches

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 12 of 20

Test Method Test Technology

PF 4614 Suspension – Shock Absorbers – Mounting Attachment Strength

PF 8406 Air Conditioning Condenser Assembly

PF 8728 Door Handle – Exterior

PSTC 1 Non-ASTM Peel

RTCA DO-160 Environmental Conditions/Test Procedures for Airborne

Equipment:

Section 4.0 Temperature & Altitude

Section 5.0 Temperature Variation

Section 6.0 Humidity

Section 7.0 Operation Shocks & Crash Safety

Section 8.0 Vibration

Section 10.0 Waterproofness

Section 11.0 Fluids Susceptibilty

Section 12.0 Sand & Dust

Section 14.0 Salt Spray

SAEJ 1153 Hydraulic Master Cylinders for Motor Vehicle Brakes Test

Procedure

SAEJ 1351 Hot Odor Test for Insulation Materials

SAEJ 1389 Corrosion Test for Insulation Materials

SAEJ 1530 Resistance to Abrasion, Bearding, and Fiber Loss of Carpet,

Taber

SAEJ 1545 Delta-E Value (Color Measurement)

SAEJ 1756 Determination of Fogging Characteristics of Interior Automotive

Materials

SAEJ 1847 Taber Abrasion

SAEJ 1885 (Inactive 2008)2 Accelerated Exposure of Automotive Interior Trim Components

Using a Controlled Irradiance Water Cool

SAEJ 1960 (Inactive 2008)2 Xenon Arc Accelerated Exposure (External)

SAEJ 2044 Quick Connector Specification for Liquid Fuel and

Vapor/Emissions Systems

SAEJ 2334 Cosmetic Corrosion

SAEJ 2464 Shock (Mid-1 and Mid-2 only), Drop, Penetration, Roll-Over,

Immersion, Crush, High Temperature Hazard, Thermal Stability,

Cycling without Thermal Management, Thermal Shock Cycling

SAEJ 2527 Performance Based Standard for Accelerated Exposure of

Automotive Exterior Materials Using a Controlled Irradiance

Xenon-Arc Apparatus

SAEJ 315 Mullen Burst Test

SAEJ 323 Cold Cracking of Flexible Plastic Materials

SAEJ 365 Scuffing Resistance, Taber

SAEJ 369 Automotive Materials, Flammability

SAEJ 400 Chip Resistance of Surface Coatings

SAEJ 575 Lighting Devices and Components for Use on Vehicles Less

Than 2032mm

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 13 of 20

Test Method Test Technology

SAEJ 578 Color Specification

SAEJ 684 Trailer Couplings, Hitches & Safety Chains Automotive Type

SAEJ 855 Stretch and Set

SAEJ 861 Crocking

SAEJ 903 Passenger Car Windshield Wiper Systems

SAEJ 913 Wicking

SAEJ 948 Resistance to Abrasion

SAEJ 1355 Test Method for Measuring Thickness of Resilient Insulating

Paddings

SAEJ 2412 Accelerated Exposure of Automotive Interior Trim Components

using a Controlled Irradiance Xenon-Arc

SAEJ 2527 Accelerated Exposure of Automotive Exterior Materials using a

Controlled Irradiance Xenon-Arc

SAEJ 882 Thickness of Textile Materials

SAEJ 883 Dimensional Stability of Automotive Textiles

SAEJ 912 Blocking Resistance

SAEJ 949 Stiffness (Modulus of Bending)

Toyota TSM0503G Fogging Test Method for Non-Metallic Materials

Toyota TSM0505G Smell Quality of Non-Metallic Materials

Toyota TSM0500G Flammability

UL 1642 (15, 19) Safety for Lithium Batteries

UL 2054 (18-21) Safety for Household and Commercial Batteries

UL 94 HB Flammability of Plastic Parts, Horizontal

UL 94 VO Flammability of Plastic Parts, Vertical

UL Subject 2271 Outline of Investigation for Batteries for use in Light Electric

Vehicle (LEV) Applications

UL Subject 2580 Outline of Investigation for Batteries for use in Electric Vehicles

UN ST/SG/AC.10 Transport of Dangerous Goods Lithium Batteries

USCAR 20 Field Correlated Life Test Supplement to SAE/USCAR-2

USCAR 15 Specification for Testing Automotive Miniature Bulb

Socket/Circuit Plate Assemblies

USCAR 2 Performance Specification for Automotive Electrical Connector

Systems

USCAR 21 Performance Specification for Cable-to-Terminal Electrical

Crimps

USCAR 3 Standard for Testing Automotive Miniature Bulbs

VDA AK 1.4.2 Qualification Test for E-Fan With EC/DC Drive Motor

VW PV1200 Resistance to Environmental Cycle Test (+80/-40) °C

VW PV1303 Exposure Test of Passenger Compartment Components

VW PV2005 Resistance to Environmental Cycle Test

VW PV3015, G Determining Condensable Constituents

VW PV3305 Test of Ozone Resistance and Permanent Deformation

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 14 of 20

Test Method Test Technology

VW PV3316 Reference Photographs after Exposure to Ozone

VW PV3357 Insulating Material Behavior during Flame Exposure

VW PV3900 Odor Test

VW TL1010 Materials for Vehicle Interiors, Burning Behavior

Chemical:

Technology Test Method Test Standard

IR ASTM E1252 FTIR, Qualitative Analysis

ASTM D3677 Rubber – Identification by Infrared Spectrophotometry

Thermo- ASTM D3418 Transition Temperature of Polymers by DSC

Mechanical ASTM D3895 Oxidative Induction Time of Polyolefins by Thermal

Analysis Analysis

ASTM D4591 Heats of Transitions of Flouropolymers by DSC

ASTM E831 Linear Thermal Expansion by Thermomechanical Analysis,

TMA

ASTM E1131 Compositional Analysis by Thermogravimetry, TGA

ASTM E1356 Glass Transition Temperature by DSC

GM 9094P Melting Point by Differential Scanning Calorimeter

(Inactive

2011)2

ISO 11357-1 Differential Scanning Calorimetry, DSC General Principles

ISO 11357-2 Glass Transition Temperature by DSC

ISO 11357-3 Transition Temperature of Polymers by DSC

ISO 11358 Thermogravimetric Analysis, TGA, General Principles

ISO 11359-1 Thermomechanical Analysis, TMA, General Principles

ISO 11359-2 Glass Transition Temp. and Coefficient of Thermal

Expansion by TMA

Ash ISO 3451-1 Ash Content, General Method

(Method A)

ISO 3451-2 Ash Content, Polyalkylene Tera

(Method A)

ISO 3451-3 Ash Content, Cellulose Acetate

(Method A)

ISO 3451-4 Ash Content, Polymides

(Method A)

ISO 3451-5 Ash Content, PVC

(Method A)

Dynamic ASTM D4065 Dynamic Mechanical Properties of Plastics

Mechanical ASTM D4440 Rheological Measurements of Polymer Melts Using

Properties Dynamic Mechanical Procedures

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 15 of 20

ASTM D5279 Dynamic Mechanical Properties of Plastics Using Torsion

ISO 6721-1 Dynamic Mechanical Properties General Principles

ISO 6721-7 Dynamic Mechanical Properties Torsional, Non-Resonance

ISO 6721-10 Dynamic Mechanical Properties Viscosity, Non-Resonance

The laboratory is accredited for the test methods listed above. The accredited test methods are used in

determining compliance with any material specifications included on this Scope below; however, the

inclusion of these material specifications on this Scope does not confer laboratory accreditation to the

material specifications. Inclusion of these material specifications on this Scope also does not confer

accreditation for every method embedded within the specification. Only the methods listed above on this

Scope are accredited.

Mechanical:

Chrysler:

Test Method Test Technology

MS-DC 40 Co-Extruded Polyethylene Film

MS JF-1000 Bodycloth Performance

MS JP 1-3 Color Durability of Interior Materials

PF-10952 Floor Console Assembly System Requirements

PF-11084 Door Trim Panel Assembly and Components

PF-11203 Material Durability Requirements for Interior Plastic Trim

Components

PF-11356 Instrument Panel Module System Requirements

PF-6494 Locator Clips/Wiring Harness Testing

PF-9688 Electrical/Electronic Device Environmental and Durability Test

Specifications

DCX-DC-10611 Electrical/Electronic Component Environmental Testing

Specifications

Ford:

ES-3U5A-9002-AA Steel Fuel Tank Pressure/Vacuum Testing

ES-5L2P-7W092-AA Contamination, Engine Components

ES-7T4E-6B616-AA Contamination, Transmission Components

WSS-M8P18 Fabric Performance

WSS-M1F27 Luxury Leather

WSS-M1F28 Leather

WSS-M15P27-D Headlining

WSS-M15P32-C Trim Assembly, Enclosed Luggage Compartment Covering

WSS-M15P45-A, except Performance, Instrument Panel Assembly, Flexible Cover Skin

section 3.12 Material

WSS-M15P4-E Interior Trim, Assembly Performance

WSS-M15P4-F Assembly Performance, Hard Mold-in-Color Interior

Components

WSS-M2P181-B Paint Performance, Flexible Substrates, Exterior

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 16 of 20

FMVSS:

Test Method Test Technology

FMVSS 571.106 Brake Hoses

GM:

GM1131M Sealing Compounds for Use With Fasteners and Attaching Clips

GM1502M Windshield Washer Tubing

GM2152M Disposable Protective Film

GM2215M Glass Fiber Insulation Material

GM2617M, except 3.4.2.1 Interior Trim Parts Performance

GM2727M Spun Bonded Nylon

GM2751M Automotive Upholstery Fabric

GM2755M Composite Floor Mat Testing

GM2763M Elastic Braid Cord

GM3107M Adhesion Requirements for Closed Cell Foam Tape (Dec 1997)

GM3602M Adhesion Requirements of Bond Interior Assemblies

GM3626M Polyethylene Film

GM3802M Mounting Tape-Exterior Tape

GM3803M Weather-Strips

GM4350M Oil Resistance

GM4351M, except 2.1.2.4 Decorative Second Surface Finishes

GM4372M Decorative Chromium Plating – Copper, Nickel, Chromium Type

GM4373M Decorative Second Surface Finishes

GM4374M Decorative Second Surface Finishes

GM4435M Protective Finishes – Phosphote Type

GM6083M Polyurethane Foam for Headline Applications

GM6086M Flexible Expanded Rubber Materials

GM6090M Automotive Materials, Flammability

GM6121M Performance Requirements of Labels

GM6140M Coolant Hose Striation Resistance

GM6174M Corrosion Protective Coating Phosphate

GM6197M Transmission Oil Cooler Hose

GM6210M Power Steering Return Hose

GM6211M Power Steering Remote Reservoir Hose

GM6264M Plastic Fuel and Vapor Lines, Plastic Fuel Filters, Plastic Clips

GM6273M Performance Requirements for Air Induction Elastomeric Ducts

GM6291M Polyurethane Foam for Trim Pads

GM6406M Low Permeation Vapor Lines-Multilayered Construction

GM7001M Plastic Molding Compounds

GM7400M Plastic Parts

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 17 of 20

Test Method Test Technology

GM (Continued)

GM7451M, except 3.2.3 Finish Durability Requirements for Decorative Interior Plastic

Parts

GM7452M Exterior Plastic Parts

GM7469M Applied Graphics on Plastic Parts

GMW14444 Material Related Interior Part Performance

GMW14231 Automotive Fabrics

GMW14650 Performance Requirements for Exterior Plastic Parts

GMW16443 Peel Test Pressure Sensitive Adhesive

JIS:

JIS L 1096 Woven Fabrics

Hyundai:

MS 300-32 Woven, Knit

MS 320-05 Fabrics for Seats

Nissan:

NES M0094 Flammability of Automotive Materials

SAE:

SAE J 1128 Wire Testing

SAE J 1639 Test Methods for Nylon Materials

SAE J 17 Latex Foam Rubbers

SAE J 30 Fuel and Oil Hoses

Toyota:

Toyota TSH3130G Paint Quality for Interior Parts

VW:

VW PV3366 Elastomer Seals

VW TL496 Door and Side Trim Panel ASSY Material Requirements

Satellite Location: 25440 Sherwood, Center Line, MI 48015

Battery Testing1:

UL1542, Sections 13-14, 20 Safety for Lithium Batteries

UL Subject 2580, Sections 26-31 Outline of Investigation for Batteries for use in Electric Vehicles

UL 2054, Sections 14-17, 22 Safety for Household and Commercial Batteries

UL Subject 2271, Section 32 Outline of Investigation for Batteries for use in Light Electric

Vehicle (LEV) Applications

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 18 of 20

Fuel Testing1:

ES-CU5A-9H307-AA Sender & Pump Assembly – fuel Tank (with & without Integral

Reservoir)

GMW16494 Global Carbon Canister Component Technical Specification

GMW14081 Fuel Pump Module Specification

ES-3U5A-9002-AA Steel Fuel Tank Pressure/Vacuum Testing

GMW14638 3.22 Fuel Resistance – Thermoplastic Fuel Tubing

Recirculation; 3.23 Auto-oxidized

Fuel resistance

SAE2260 7.6 Fuel Exposure pre- Nonmetallic fuel system tubing with one or more layers

conditioning;

7.7 Methanol Resistance

SAE2045 7.8 Resistance to Performance requirements for fuel system tubing asemblies

Auto-oxidized fuel; 4.5 Internal

Fuel Resistance

GM9676 6.5 Fuel Compatibility Procedure for qualifying quick-connector fittings for vapor fuel

line

Satellite Location: 14610 Jib Street, Plymouth, MI 48170

Ford IP-0105 Instrument Panel Sunload Resistance

Ford MA-0128 Simulated Sunload Resistance – Exterior

Ford MA-0130 Humidity Aging

Ford MA-0131 Heat Age

Ford OR-0329 Sunload Resistance – Exterior Ornamentation

GMW3191 Connector Test and Validation Specification

GMW3431, except section 4.4.7 General Procedures for Testing Switches

GMW8287 Highly Accelerated Life Testing Halt/Hast

GMW14124 Automotive Environmental Cycles

GMW14906 Lamp Development and Validation Test Procedures

NES M0132 Thermal Cycle Test Methods for Plastic Parts

Nissan 96030 NDS00 Air Spoiler Testing

PSTC 101 Non-ASTM Peel

PF-11084 Door Trim Panel Assembly and Components

WSS-M15P27-D Headlining

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 19 of 20

WSS-M15P32-C Trim Assembly, Enclosed Luggage Compartment Covering

WSS-M15P45-A, except section 3.12 Performance, Instrument Panel Assembly, Flexible Cover Skin

Material

WSS-M15P4-E Interior Trim, Assembly Performance

WSS-M15P4-F Paint Performance, Flexible Substrates, Exterior

2

This laboratory’s scope contains withdrawn or superseded methods. As a clarifier, this indicates that the

applicable method itself has been withdrawn or is now considered “historical” and not that the

laboratory’s accreditation for the method has been withdrawn.

(A2LA Cert. No. 0038.01) Revised 10/05/2015 Page 20 of 20

Accredited Laboratory

A2LA has accredited

ELEMENT WARREN

Warren, MI

for technical competence in the field of

Mechanical Testing

This laboratory is accredited in accordance with the recognized International Standard ISO/IEC 17025:2005

General requirements for the competence of testing and calibration laboratories. This accreditation demonstrates

technical competence for a defined scope and the operation of a laboratory quality management system

(refer to joint ISO-ILAC-IAF Communiqué dated 8 January 2009).

Presented this 13th day of May 2015.

_______________________

President & CEO

For the Accreditation Council

Certificate Number 0038.01

Valid to December 31, 2016

For the types of tests to which this accreditation applies, please refer to the laboratory’s Mechanical Scope of Accreditation.

Você também pode gostar

- Element Warren A2LA 0038 01 MechanicalDocumento21 páginasElement Warren A2LA 0038 01 MechanicalBau2NineAinda não há avaliações

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedDocumento2 páginasPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsAinda não há avaliações

- Fluteck P7500 CA v01.19Documento2 páginasFluteck P7500 CA v01.19fprovitaliAinda não há avaliações

- Sanalite Hdpe Hoja TecnicaDocumento1 páginaSanalite Hdpe Hoja TecnicaFreddy VeraAinda não há avaliações

- 2015EHCNDocumento3 páginas2015EHCNsvvsnrajuAinda não há avaliações

- Weather Proof LouvreDocumento6 páginasWeather Proof Louvrentt_121987Ainda não há avaliações

- Nitoring Methane Slip: Why em ?Documento2 páginasNitoring Methane Slip: Why em ?Arunkumar MuthukrishnanAinda não há avaliações

- HOSTAPHAN® Polyester films..PETDocumento10 páginasHOSTAPHAN® Polyester films..PETsreeeragAinda não há avaliações

- Iso-Iec 1116-01 2010Documento4 páginasIso-Iec 1116-01 2010Rakhsh KhorvashAinda não há avaliações

- Coatings Deposited Using A Valve-Less Detonation SystemDocumento5 páginasCoatings Deposited Using A Valve-Less Detonation SystemycwbycwbAinda não há avaliações

- Powder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialDocumento1 páginaPowder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialLuiskar MedinaAinda não há avaliações

- Nukote Har: DescriptionDocumento4 páginasNukote Har: DescriptionMarco Dos Santos NevesAinda não há avaliações

- Weather Proof Louvre MDocumento6 páginasWeather Proof Louvre Mntt_121987Ainda não há avaliações

- API Engine Oil Classifications Infineum 2017Documento12 páginasAPI Engine Oil Classifications Infineum 2017iosalcido100% (1)

- Flexible, Low Permeance Vapor Retarders For Thermal InsulationDocumento4 páginasFlexible, Low Permeance Vapor Retarders For Thermal InsulationWUMINGAinda não há avaliações

- Crack Repair Using Chemical GroutDocumento9 páginasCrack Repair Using Chemical GroutSachin SharmaAinda não há avaliações

- A5e78 SDocumento3 páginasA5e78 SAlexVillafuerteAinda não há avaliações

- School of Civil Engineering Engineering CampusDocumento4 páginasSchool of Civil Engineering Engineering Campusekia_myAinda não há avaliações

- MAK Hydrol CEDocumento2 páginasMAK Hydrol CEannamalailubesAinda não há avaliações

- (PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsDocumento2 páginas(PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsMakhdum Muhardiana PutraAinda não há avaliações

- PTFE DatasheetDocumento2 páginasPTFE DatasheetthodatisampathAinda não há avaliações

- Physical Testing of Clinker & CementDocumento61 páginasPhysical Testing of Clinker & CementDineshAinda não há avaliações

- Ultraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Documento2 páginasUltraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Phuoc Thinh TruongAinda não há avaliações

- Nylon MC901Documento2 páginasNylon MC901V ShankarAinda não há avaliações

- Viton Compound Properties for High Temperature ResistanceDocumento1 páginaViton Compound Properties for High Temperature ResistanceiswantmachooAinda não há avaliações

- Air/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDocumento4 páginasAir/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDale XiaoAinda não há avaliações

- L4Tdm-Psa: Product ClassificationDocumento4 páginasL4Tdm-Psa: Product Classificationhassan329Ainda não há avaliações

- Strip Seal Expansion JointDocumento13 páginasStrip Seal Expansion JointsmithAinda não há avaliações

- RHODIA Technyl A218 V30Documento3 páginasRHODIA Technyl A218 V30paquienAinda não há avaliações

- Mobil DTE 10 Excel SeriesDocumento3 páginasMobil DTE 10 Excel SeriesSuprastowo Bin SarinoAinda não há avaliações

- Wimpey - Wacg-22-222-5Documento6 páginasWimpey - Wacg-22-222-5jaas jawadAinda não há avaliações

- ArmaGelDT - TDS - EN-Dual TempDocumento4 páginasArmaGelDT - TDS - EN-Dual TempLee Kok RoyAinda não há avaliações

- Xceltherm EIO Type I RADCODocumento3 páginasXceltherm EIO Type I RADCOlinconxxxAinda não há avaliações

- NM14 SFDocumento2 páginasNM14 SFmicroqualAinda não há avaliações

- Optigear 1100 RangeDocumento3 páginasOptigear 1100 RangeResistenciaDisidenteAinda não há avaliações

- PORON 4701-50 Firm - Supported MaterialsDocumento2 páginasPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedAinda não há avaliações

- Document 1Documento2 páginasDocument 1renebbAinda não há avaliações

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Documento6 páginasTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroAinda não há avaliações

- Nylacast Moly Cast Nylon 6, MoS2 FilledDocumento3 páginasNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmAinda não há avaliações

- HIGH STRENGTH SILICONE SEALANTDocumento1 páginaHIGH STRENGTH SILICONE SEALANTEstevan huertasAinda não há avaliações

- Fryquel EHC PlusDocumento4 páginasFryquel EHC PlusZuli Nur CahyoAinda não há avaliações

- A2LA Accredited Laboratory for Mechanical TestingDocumento6 páginasA2LA Accredited Laboratory for Mechanical TestingWaqar YounasAinda não há avaliações

- Sur Tec 650Documento17 páginasSur Tec 650donhan91Ainda não há avaliações

- Quadrant EPP PVC - Polyvinyl Chloride, Type I, Grade 1: Physical Properties Metric English CommentsDocumento1 páginaQuadrant EPP PVC - Polyvinyl Chloride, Type I, Grade 1: Physical Properties Metric English CommentsArif OthmanAinda não há avaliações

- ElectraGuard Specifications - 2Documento5 páginasElectraGuard Specifications - 2Yavuz SolmazAinda não há avaliações

- Envirolastic AR 425 Data PageDocumento4 páginasEnvirolastic AR 425 Data PageYsmael Steel TeklaAinda não há avaliações

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocumento2 páginasPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaAinda não há avaliações

- CAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaDocumento2 páginasCAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaAngererAinda não há avaliações

- Daelim Industrial HDPE Product Technical Data SheetDocumento2 páginasDaelim Industrial HDPE Product Technical Data SheetAkoyoAinda não há avaliações

- UHMW-PE Tivar 1000Documento2 páginasUHMW-PE Tivar 1000centurion2988Ainda não há avaliações

- Abs (Basf Terluran Gp22)Documento1 páginaAbs (Basf Terluran Gp22)hakangokceAinda não há avaliações

- L4Tnm-Psa: Product ClassificationDocumento4 páginasL4Tnm-Psa: Product Classificationhassan329Ainda não há avaliações

- A PDFDocumento4 páginasA PDFVerenice CentenoAinda não há avaliações

- Product Texts: P:Partial BreakDocumento8 páginasProduct Texts: P:Partial BreakDridi BadredineAinda não há avaliações

- TDS Infinam ST 6100 LDocumento5 páginasTDS Infinam ST 6100 LKacperAinda não há avaliações

- 1430 - Golden Altos Nepp 2017 JuneDocumento19 páginas1430 - Golden Altos Nepp 2017 JuneAylia RizviAinda não há avaliações

- Stator Elastomer Evaluation ProcedureDocumento7 páginasStator Elastomer Evaluation ProcedureSanjenbam SumitAinda não há avaliações

- Coatings Testing - ASTM StandardsDocumento3 páginasCoatings Testing - ASTM StandardsthuronAinda não há avaliações

- PBT GF17% DR48-7001Documento2 páginasPBT GF17% DR48-7001pava16230.meAinda não há avaliações

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingNo EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingAinda não há avaliações

- ASTM D1018-1999 Standard Specification For PVC Plastic Pipe Schedule 40,80 & 120Documento11 páginasASTM D1018-1999 Standard Specification For PVC Plastic Pipe Schedule 40,80 & 120pbp2956Ainda não há avaliações

- D 2104 - 01 - Rdixmdqtmde - PDFDocumento7 páginasD 2104 - 01 - Rdixmdqtmde - PDFAndre CasteloAinda não há avaliações

- D 2290 - 00 - Rdiyotatmda - PDFDocumento5 páginasD 2290 - 00 - Rdiyotatmda - PDFAndre CasteloAinda não há avaliações

- D 2282 - 99 - Rdiyodi - PDFDocumento7 páginasD 2282 - 99 - Rdiyodi - PDFAndre CasteloAinda não há avaliações

- D 2447 - 99 - Rdi0ndctotk - PDFDocumento9 páginasD 2447 - 99 - Rdi0ndctotk - PDFAndre CasteloAinda não há avaliações

- D 2321 - 89 R95 - Rdizmjetukve PDFDocumento11 páginasD 2321 - 89 R95 - Rdizmjetukve PDFAndre CasteloAinda não há avaliações

- D 2241 - 04 - Rdiynde - PDFDocumento9 páginasD 2241 - 04 - Rdiynde - PDFAndre CasteloAinda não há avaliações

- D 2239 - 03 - Rdiymzk - PDFDocumento7 páginasD 2239 - 03 - Rdiymzk - PDFAndre CasteloAinda não há avaliações

- D 2105 - 01 - RdixmduDocumento6 páginasD 2105 - 01 - RdixmduSwapnil CallaAinda não há avaliações

- D 2241 - 04 - Rdiyndetmdq - PDFDocumento9 páginasD 2241 - 04 - Rdiyndetmdq - PDFAndre CasteloAinda não há avaliações

- D 2241 - 00 - Rdiyndetmda - PDFDocumento9 páginasD 2241 - 00 - Rdiyndetmda - PDFAndre CasteloAinda não há avaliações

- Astm D 2290 - 00 PDFDocumento5 páginasAstm D 2290 - 00 PDFral75100% (1)

- D 2105 - 97 - RdixmdutukveDocumento7 páginasD 2105 - 97 - RdixmdutukveSwapnil CallaAinda não há avaliações

- D 2683 - 98 - Rdi2odm - PDFDocumento5 páginasD 2683 - 98 - Rdi2odm - PDFAndre CasteloAinda não há avaliações

- D 2239 - 01 RdiymzktmdeDocumento7 páginasD 2239 - 01 RdiymzktmdeToapanta FredyAinda não há avaliações

- C582Documento7 páginasC582Stephen100% (1)

- D 2104 - 03 - Rdixmdq - PDFDocumento7 páginasD 2104 - 03 - Rdixmdq - PDFAndre CasteloAinda não há avaliações

- D 2564 - 02 - Rdi1njq - PDFDocumento5 páginasD 2564 - 02 - Rdi1njq - PDFAndre CasteloAinda não há avaliações

- D 2729 - 96 - Rdi3mjktotzb PDFDocumento5 páginasD 2729 - 96 - Rdi3mjktotzb PDFAndre CasteloAinda não há avaliações

- D 2609 - 00 - Rdi2mdktukve PDFDocumento5 páginasD 2609 - 00 - Rdi2mdktukve PDFAndre CasteloAinda não há avaliações

- D 2282 - 99 - RdiyoditotkDocumento7 páginasD 2282 - 99 - Rdiyoditotkjohn tanAinda não há avaliações

- D 2517 - 00 - Rdi1mtc - PDFDocumento6 páginasD 2517 - 00 - Rdi1mtc - PDFAndre CasteloAinda não há avaliações

- D 2447 - 01 - Rdi0ndctukve PDFDocumento9 páginasD 2447 - 01 - Rdi0ndctukve PDFAndre CasteloAinda não há avaliações

- ASTM D2412 External Loading of Plastic PipeDocumento6 páginasASTM D2412 External Loading of Plastic PipeHussein BeqaiAinda não há avaliações

- D 2466 - 99 - Rdi0njytotk - PDFDocumento5 páginasD 2466 - 99 - Rdi0njytotk - PDFAndre CasteloAinda não há avaliações

- D 2672 - 96 - Rdi2nzitotzb PDFDocumento4 páginasD 2672 - 96 - Rdi2nzitotzb PDFAndre CasteloAinda não há avaliações

- D 2749 - 02 - Rdi3ndk - PDFDocumento5 páginasD 2749 - 02 - Rdi3ndk - PDFAndre CasteloAinda não há avaliações

- D 2672 - 96a R03 - RDI2NZI - PDFDocumento4 páginasD 2672 - 96a R03 - RDI2NZI - PDFAndre CasteloAinda não há avaliações

- D 2564 - 96 - Rdi1njqtotzb PDFDocumento5 páginasD 2564 - 96 - Rdi1njqtotzb PDFAndre CasteloAinda não há avaliações

- D 2737 - 03 - Rdi3mzc - PDFDocumento7 páginasD 2737 - 03 - Rdi3mzc - PDFAndre CasteloAinda não há avaliações

- Unstiffened Cylinders en 13445-3 - 8.5.2Documento4 páginasUnstiffened Cylinders en 13445-3 - 8.5.2met-calcAinda não há avaliações

- TenCate Polyfelt PGM Brochure en 502023Documento8 páginasTenCate Polyfelt PGM Brochure en 502023ganmosesAinda não há avaliações

- P&LLayout - PPT 1111111111Documento64 páginasP&LLayout - PPT 1111111111amuAinda não há avaliações

- Trail No 198 - M50 BHARATHI + CHRYSO: Concrete Mix Proportioning Details A. Stipulations For ProportioningDocumento4 páginasTrail No 198 - M50 BHARATHI + CHRYSO: Concrete Mix Proportioning Details A. Stipulations For ProportioningMohammad Arif RasheedAinda não há avaliações

- Transmaterial 2 PDFDocumento18 páginasTransmaterial 2 PDFSulman KhalidAinda não há avaliações

- Is 2645 (2003) - Integral Waterproofing Compounds For Cement Mortar and Concrete - SpecificationDocumento16 páginasIs 2645 (2003) - Integral Waterproofing Compounds For Cement Mortar and Concrete - SpecificationMeet ChokshiAinda não há avaliações

- PT I Girder Design 20mDocumento18 páginasPT I Girder Design 20msamirbendre1Ainda não há avaliações

- The Easily Mounted Floor System For Large Spans: Hoesch Additive Floor Technical InformationDocumento16 páginasThe Easily Mounted Floor System For Large Spans: Hoesch Additive Floor Technical InformationIvan ŠpacAinda não há avaliações

- CME355 - Material Handling and Solid Processing Equipment SyllabusDocumento1 páginaCME355 - Material Handling and Solid Processing Equipment SyllabusSCT HOD - MechanicalAinda não há avaliações

- Titanium and Titanium Alloy Seamless Pipe: Standard Specification ForDocumento8 páginasTitanium and Titanium Alloy Seamless Pipe: Standard Specification Forhernan vizaAinda não há avaliações

- Hyundai-Cat 6521891Documento12 páginasHyundai-Cat 6521891Quang Pham DuyAinda não há avaliações

- Dow Foam ProductsDocumento8 páginasDow Foam ProductsJohn E. BeAinda não há avaliações

- NHB 700 - The Practice of Heat TreatmentDocumento75 páginasNHB 700 - The Practice of Heat TreatmentConrad Hendrik De KockAinda não há avaliações

- Concrete Compressive StrengthDocumento4 páginasConcrete Compressive StrengthklynchelleAinda não há avaliações

- Chapter 1 - TompkinsDocumento27 páginasChapter 1 - TompkinsAlex Santito KoK'sAinda não há avaliações

- 1 BravermanDocumento105 páginas1 Bravermanridho ma'rufAinda não há avaliações

- 85 CT McqsDocumento91 páginas85 CT McqsDishantsingh RajputAinda não há avaliações

- Module 8 SAHITA ConcreteDocumento11 páginasModule 8 SAHITA ConcreteHarrybfnAinda não há avaliações

- Analysis of Flexible Pavements Using IIT Pave: Harish G RDocumento4 páginasAnalysis of Flexible Pavements Using IIT Pave: Harish G RAyush KumarAinda não há avaliações

- Second File WipDocumento46 páginasSecond File WipDilip PrajapatiAinda não há avaliações

- Analysis and Design of RC Columns (Based On 2010NSCP)Documento34 páginasAnalysis and Design of RC Columns (Based On 2010NSCP)Angel Lisette LaoAinda não há avaliações

- FusingDocumento6 páginasFusingsift_50100% (1)

- Aerospace Stds SpecifDocumento100 páginasAerospace Stds SpecifJesse Krebs100% (1)

- Raymond Lift Trucks Features BrochureDocumento20 páginasRaymond Lift Trucks Features BrochureJunior HerreraAinda não há avaliações

- Stress, Strain and Relation ExerciseDocumento7 páginasStress, Strain and Relation ExerciseHazeq AzaharAinda não há avaliações

- Glass Embedding: Safe and Fast Glass Embedding Solution For Glass BalustradesDocumento4 páginasGlass Embedding: Safe and Fast Glass Embedding Solution For Glass BalustradesGiri DharanAinda não há avaliações

- DSC TrainingDocumento57 páginasDSC TrainingNabihah AbdullahAinda não há avaliações

- Rebound HammerDocumento18 páginasRebound HammerAmranullah Hassan ZadaAinda não há avaliações

- Sky Marina: Vinayak BuildtechDocumento41 páginasSky Marina: Vinayak BuildtechNitin Chhaperwal0% (1)

- PPG73APR11EXPDocumento469 páginasPPG73APR11EXPAmritAinda não há avaliações