Escolar Documentos

Profissional Documentos

Cultura Documentos

Rabindra Nayak - Qualification Certificate025

Enviado por

Anonymous AdofXEYAgE0 notas0% acharam este documento útil (0 voto)

25 visualizações6 páginassdas

Título original

Rabindra Nayak_qualification Certificate025

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentosdas

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

25 visualizações6 páginasRabindra Nayak - Qualification Certificate025

Enviado por

Anonymous AdofXEYAgEsdas

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 6

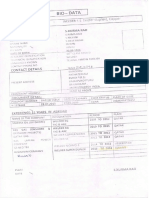

3x60 MW TPS EXPANSION PROJECT-KORADI a

LARSEN & TOUBRO LIMITED Page |

RECORD OF WELDER QUALIFICATION TEST

Welder Name : RABINDRA NAYAK Welder No, Lat / AW-113

Using WPS No. WPS/15 /Rev. 0 Welding Date :29/11/2012

The above welder is qualified forthe following ranges

Variable Actual Values Qualified Range

Welding process GTAW:SMAW. GTAW+SMAW

Welding Type MANUAL MANUAL

Backing NO WITH or Without_BAGRING

Material spec. (P-No) ergy

“Thickness Groove 891m

Fillet Se

Diameter Groove ed

Fillet =

Filler Metal Spec/Class L as7e8 526/55

228/55

FNo, os ALL 6) 1,2.3.4(With backing)

Welding Position aa

Weld Progression ei UPHILL

DOEN/DOEP

Gas type / Backing gas ‘Argon

Welding current type / polarity OCEN/ DOEP 1

‘Mode of metal transfer waa

Direct/Remate visual control (a 7

YWSUAL TESTRESUUTS |

\GRAPHIC TEST RESULTS

Rea RRNATIVE QUALIFICATION OF GROOVE WELDS BY RADIOGRAP ES)

Yogrannc Repor No: LTAVAT/ 2, 4 Date: 28.1.1

Result Ascepted

FILLET WELD TEST RESULTS,

ture Test: NA__

sth and Percent of Defects NA mm___NA, %

0 Test Fusion Report No,

cent ay mm BY mm. Convexily mm. or Concaviy mm

conducted by L & T TPPC Division Laboratory Test No. N/A

SAY Ina the statemont inthis record are correct and thal he test welds were Prepared,

‘and tested in accordance withthe requirements of ASME See ix

L&T TPPC QA/QC LMBPL Qa/QC

z Prva Baran ok tshy

‘ATURE Bovfvsfp

a

z Tn

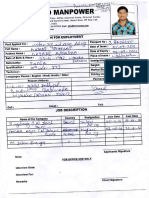

|SECOND TIME QUALIFICATION

[AT Report No

VARIABLES

Welding process

Welding Type

[Backing

Material speo,

P Number

[Thickness

[Diameter

Filler Metal SpeciClass

Date: 22.2,

ACTUAL VALUES

13 [RT Result: Agepca

(QUALIFIED RANGE

GtRw+

om

we

a aw

Welaing Position

IGas type /Backin

Reviewed By

Lat TPPC GwaC

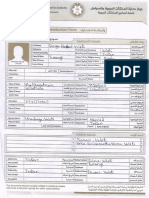

[THIRD TIME QUALIFICATION

RT Report No

Lar wlll

[DATES

ACTUAL VALUES

AT Result:

(QUALIFIED RANGE,

VARIABLES.

Welding process,

[Weiging Type.

[Backing

Material spee,

IP Number

Thickness

Diameter

Filer Metal SpeciClass

Without Backing

Wh Backing:

lWelding Postion

[Gas type / Backin

[Reviewed By

LaT TPPC awac

[FOURTH TIME QUALIFICATION

[RT Report No

‘VARIABLES

Welding process,

Wetding Ty

Backing

Waterial spec.

IP Number

Thickness

Diameter

Filer Metal Spec/Class

L&T MHI QA/ac

DATE:

ACTUAL VALUES

[RT Result:

QUALIFIED RANGE.

jivout Backing:

th Backing

Welding Position,

Gas type / Backin

Reviewed By

a5

LaT TPC Qwac Lact MHI QA/OC

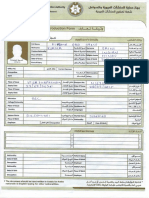

CERT. No, JHAW/.12. 875 V7:

FORM NO. XIII bate. 16/08/2017

Qualified Boiler Welder's Certificate

ISSUED UNDER

THE INDIAN BOILER REGULATIONS, 1950

Name of Welder

Father's Name

Date of birth

t hand thunt:

Identification marks

Weight sce

Lefthand Thumb Impression ray -6

Sealand Signatureof ee Kekgyte eel

Competent Authority, Vist. om ° z

‘ : Address of Welder +jley, ladsanapur,

LG. ieY Jadsanapur,

PERIOD OF VALIDITY

From To

3.2017

This is to certify that Shiri... 77%. son

of Shri... 12 has

been examined and tested in the prescribed maninerin the presence of...»

‘oiler Snax ’hana, Dinanbad,

chie= inspects:

(Representative cf Competent Authority)

and is deemed to have satisfactorily proved his ability to make sound welds as per particulars given

overleaf and is hereby authorised to undertake such welds. He is authorised/netuthiorised to

undertake welding where radiographic examination is necessary under the Regulations.

GRANTED this... 45.22 day of......nazeh 20.42 cone NOE

the seat and authority of... Demi nue, SO GES Thon ene et

Competent Authority

Peseta iat

Você também pode gostar

- Kurma Rao Saini - CVDocumento1 páginaKurma Rao Saini - CVAnonymous AdofXEYAgEAinda não há avaliações

- Kurma Rao Saini - Qualification Certificate044Documento10 páginasKurma Rao Saini - Qualification Certificate044Anonymous AdofXEYAgEAinda não há avaliações

- Kurma Rao Saini - Introduction Form040Documento2 páginasKurma Rao Saini - Introduction Form040Anonymous AdofXEYAgEAinda não há avaliações

- Vantakula Rambabu-Resume PDFDocumento1 páginaVantakula Rambabu-Resume PDFAnonymous AdofXEYAgEAinda não há avaliações

- JD FormDocumento1 páginaJD FormAnonymous AdofXEYAgEAinda não há avaliações

- JD FormDocumento1 páginaJD FormAnonymous AdofXEYAgEAinda não há avaliações

- Kurma Rao Saini - CVDocumento1 páginaKurma Rao Saini - CVAnonymous AdofXEYAgEAinda não há avaliações

- Vantakula Rambabu-Experience CertificatesDocumento10 páginasVantakula Rambabu-Experience CertificatesAnonymous AdofXEYAgEAinda não há avaliações

- Behra Dombo l9997839 CVDocumento28 páginasBehra Dombo l9997839 CVAnonymous AdofXEYAgEAinda não há avaliações

- Receipt Report IE-2485530Documento1 páginaReceipt Report IE-2485530Anonymous AdofXEYAgEAinda não há avaliações

- JD FormDocumento1 páginaJD FormAnonymous AdofXEYAgEAinda não há avaliações

- Pandi Devaraju Reddy p6303778 CVDocumento36 páginasPandi Devaraju Reddy p6303778 CVAnonymous AdofXEYAgEAinda não há avaliações

- 7.interview PersonalDocumento1 página7.interview PersonalAnonymous AdofXEYAgEAinda não há avaliações

- Intro FormDocumento2 páginasIntro FormAnonymous AdofXEYAgEAinda não há avaliações

- Mohammad Mukhtar Ali-CvDocumento15 páginasMohammad Mukhtar Ali-CvAnonymous AdofXEYAgEAinda não há avaliações

- Kommuji Eswar A Rao - Intro FormDocumento2 páginasKommuji Eswar A Rao - Intro FormAnonymous AdofXEYAgEAinda não há avaliações

- Agent Profile SheetDocumento1 páginaAgent Profile SheetAnonymous AdofXEYAgEAinda não há avaliações

- Transcript of Mark List: Harish RDocumento2 páginasTranscript of Mark List: Harish RAnonymous AdofXEYAgEAinda não há avaliações

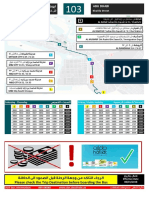

- Bus Service 103Documento2 páginasBus Service 103Anonymous AdofXEYAgEAinda não há avaliações

- Pradhan Bhagirathi - JD Manpower FormDocumento1 páginaPradhan Bhagirathi - JD Manpower FormAnonymous AdofXEYAgEAinda não há avaliações

- BPVC-IX-Interp Stnd-63 2015 Jan PDFDocumento6 páginasBPVC-IX-Interp Stnd-63 2015 Jan PDFAnonymous AdofXEYAgEAinda não há avaliações

- Department of Clinical Biochemistry Liver Function TestDocumento1 páginaDepartment of Clinical Biochemistry Liver Function TestAnonymous AdofXEYAgEAinda não há avaliações

- 1144 TWI Diploma in Welding Engineering July 2012 PDFDocumento1 página1144 TWI Diploma in Welding Engineering July 2012 PDFdaimaheshAinda não há avaliações

- Pyarechand Kumar - Qualification Certificate064Documento1 páginaPyarechand Kumar - Qualification Certificate064Anonymous AdofXEYAgEAinda não há avaliações

- Pradhan Bhagirathi CVDocumento1 páginaPradhan Bhagirathi CVAnonymous AdofXEYAgEAinda não há avaliações

- Agent Application FormDocumento1 páginaAgent Application FormAnonymous AdofXEYAgEAinda não há avaliações

- String Weave and Heat InputDocumento4 páginasString Weave and Heat InputAnonymous AdofXEYAgEAinda não há avaliações

- Curriculum Vitae HariprasadDocumento2 páginasCurriculum Vitae HariprasadAnonymous AdofXEYAgEAinda não há avaliações

- Transcript of Marks: Name: Date of BirthDocumento2 páginasTranscript of Marks: Name: Date of BirthAnonymous AdofXEYAgEAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)