Escolar Documentos

Profissional Documentos

Cultura Documentos

Board Problems - StemEZ

Enviado por

Rey Danielle Taray NaveaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Board Problems - StemEZ

Enviado por

Rey Danielle Taray NaveaDireitos autorais:

Formatos disponíveis

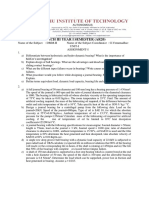

a. The load on a 10-cm full bearing is 9 kN, n = 320 rpm; D/L = 1; c d/D = 0.

0011; operating oil viscosity is 234 centipoises. Determine the frictional

power loss, bearing pressure and coefficient of friction in the bearing.

b. A band brake has 60 cm drum and fitted with a steel band 5/2 cm thick lined with a brake lining having a coefficient of friction of 0.25. The angle

of contact is 2500. The drum is attached to a hoisting drum and rotates at 180 rpm. Determine the force on the slack and tight side if the frictional

horsepower is 65

c. A flywheel for a shearing machine is to be designed. It will be used to punch a 2 cm diameter and 1 cm thick hole. The shearing ultimate strength

of the plate to be punch is 795 MPa. The flywheel to be used will have a mean diameter of 95 cm with a width of 26 cm. The estimated average

speed is 170 rpm during the shearing process. The rim is to be made of steel which has a density of 7210 kg/m 3. Assuming that the arms and hub

account 15% of the rim weight, which concentrated at the mean diameter, determine the thickness of the rim. The coefficient of fluctuation of a

shearing machine is 0.075.

d. Two 6-in diameter and 10-in long bearings support a load of 8000 lb. The coefficient of friction in bearings is 0.01 and the shaft rotates at 500

rpm. The bearing radial clearance is 0.006 in. The lubricating oil has a specific heat of 0.4 Btu/lb- oF, density of 0.03 lb/in.3 and viscosity of 6.5

microreyn. Determine the volume flow rate of the lubricating oil if the oil temperature rises 16 oF.

e. For a single-block brake, as shown, drum contact width is 3.5 in. The molded asbestos lining subtends θ = 60 o, symmetrical about the vertical axis;

D = 15 in.; force W = 400 lb; and n = 600 rpm. Coefficient of friction between the drum and the block is 0.35. Compute the frictional horsepower

loss if the drum rotates (a) clockwise and (b) counter-clockwise.

f. A multi-disc clutch composed of three plates with inside diameter of 150 mm and outside diameter of 200 mm is designed to transmit 100 kW at

3000 rpm at a coefficient of friction of 0.5. A spring with 766 N/mm spring scale is used to engage the clutch. Determine the deflection of the

spring.

g. An exhaust fan in a wood shop is driven by a belt from a 20-kW squirrel-cage motor that runs at 880 rpm, compensator started. A medium double leather

belt, with a specific mass of 970 kg/m 3, 25 cm wide is used; C = 138 cm; D 1 = 36 cm (motor), D2 = 138 cm both iron. The coefficient of friction of leather on

iron is 0.3. If the allowable stress of the belt is 1.38 MPa, determine the minimum thickness of the belt. Compute the belt length.

h. A worm-gear speed reducer receives 60 hp at a speed ratio of 8. The worm has a pitch diameter and axial pitch of 3.7 in. and 1.2812 in. The gear has 40

teeth. The gear casing has an approximate surface area of 15 ft 2. During operation, the temperature of the lubricating oil, with a coefficient of heat transfer

of 0.45 ft-lb/min.-in2-OF, rises to 120 oF. Compute the efficiency and the helix angle of gear.

i. A conveyor is driven by an electric motor through a flexible coupling to a worm-gear speed reducer, whose m w ≈ 35, and then via a roller chain to the

conveyor shaft that is to turn about 12 rpm; motor rpm is 1750. RC 60 is used which has ¾-in. pitch, 0.234-in. pin diameter, ½-in. roller length and 0.094-in

link-plate thickness. The conveyor shaft sprocket has 50 teeth. Center to center distance is 18 in. What is the maximum horsepower that can be transmitted

of the roller chain if the allowable bearing stress is 5 ksi? How many links are required?

j. A parallel helical gear 10 in. in diameter having 20 O involute stub teeth and a helix angle of 30 O carries 10 hp at 200 rpm. Determine the angle of obliquity

in a plane normal to the pitch element of a tooth and the resultant load on the teeth.

k. For a mine hoist, the cage weighs 5900 lb., the cars 2100 lb., and the load of coal in the car 2800 lb.; one car loaded loaded at a time on the hoist. The

drum diameter is 5 ft., the wire diameter of the rope is 0.084 in., the metallic area of the rope is 0.625 in. 2 and the maximum depth is 1500 ft. It takes 6 sec.

to accelerate the loaded cage to 3285 fpm. The wire rope has an ultimate load of 120 kips and a modulus of elasticity of 30x10 6 psi. What is the factor of

safety? Neglect the weight of the rope.

Você também pode gostar

- Demag DF 125 enDocumento234 páginasDemag DF 125 enBaciu Nicolae50% (2)

- Reinforced Concrete Design of A 5 Storey Seminary Main BuildingDocumento117 páginasReinforced Concrete Design of A 5 Storey Seminary Main Buildingjedsclement100% (1)

- Optimized Skid Design For Compressor PackagesDocumento9 páginasOptimized Skid Design For Compressor Packagesmario_gAinda não há avaliações

- Ta300 T4 0pli 11001Documento374 páginasTa300 T4 0pli 11001Ravinder Singh100% (3)

- Machine Design VipDocumento55 páginasMachine Design VipGeorgiaAinda não há avaliações

- Virtual Buce 3Documento92 páginasVirtual Buce 3Ralph Edward Santiago Moran100% (1)

- Helical Gears ProblemsDocumento29 páginasHelical Gears Problemsa17e100% (1)

- Local Checks 1Documento85 páginasLocal Checks 1Alphyl BalasabasAinda não há avaliações

- TMP - 30490-ME PREBOARD - MDSP1535486914Documento11 páginasTMP - 30490-ME PREBOARD - MDSP1535486914rex tanongAinda não há avaliações

- Problem Set MD Day 3Documento5 páginasProblem Set MD Day 3DE GUZMAN, MELVIN CARLO A.Ainda não há avaliações

- Nissan RB Engine - WikipediaDocumento60 páginasNissan RB Engine - WikipediaZedrick Nell100% (2)

- MDDocumento51 páginasMDRaymartAinda não há avaliações

- Machine DesignDocumento12 páginasMachine DesignJohn Robert GonzalesAinda não há avaliações

- Machine Design, Materials and Shop Practice Multiple ChoiceDocumento7 páginasMachine Design, Materials and Shop Practice Multiple ChoiceNeil SequioAinda não há avaliações

- Machine Design CouchingDocumento403 páginasMachine Design CouchingJomari DichosoAinda não há avaliações

- Fabrication Erection and Installation Procedure For PipingDocumento36 páginasFabrication Erection and Installation Procedure For Pipinggst ajah100% (2)

- v1903 2203tvengineDocumento46 páginasv1903 2203tvenginehuo sun100% (1)

- MDSP Diag 2 Set BDocumento3 páginasMDSP Diag 2 Set BTyron RebellonAinda não há avaliações

- Machine Design Exam PDFDocumento6 páginasMachine Design Exam PDFLanz Cruzat100% (1)

- FinallDocumento175 páginasFinallremeceldo dagamac100% (1)

- MDSP - February 2022Documento7 páginasMDSP - February 2022Joshua Gagate100% (1)

- Jollibee Supermeal BDocumento20 páginasJollibee Supermeal BAaron Somera SolisAinda não há avaliações

- 2022 MDSP With AnswersDocumento101 páginas2022 MDSP With AnswersMarc Citcian Gatinao67% (3)

- Mechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Documento4 páginasMechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Harpinder GotraaAinda não há avaliações

- BRAKESDocumento4 páginasBRAKESAjayBravo0% (1)

- Plate No RaDocumento5 páginasPlate No RaEdelleAinda não há avaliações

- Nu Day 3Documento2 páginasNu Day 3Jan Tiangco100% (1)

- Pointers For ReviewDocumento3 páginasPointers For ReviewAdriel JohnAinda não há avaliações

- Homework No.6Documento3 páginasHomework No.6terrence miguel balitaAinda não há avaliações

- COMPRE EXAM Machine Design No ChoicesDocumento6 páginasCOMPRE EXAM Machine Design No ChoicesJunalin FabroAinda não há avaliações

- Possible Exercise On Machine Element Two Flat BeltDocumento4 páginasPossible Exercise On Machine Element Two Flat BeltAbebaw AyeleAinda não há avaliações

- MD 2 Midterm Exam FS 4 9 22Documento1 páginaMD 2 Midterm Exam FS 4 9 22Juvannie CuevaAinda não há avaliações

- MDSP Platinum Problem Part 1Documento81 páginasMDSP Platinum Problem Part 1aljay balingitAinda não há avaliações

- Iii Me Ii Sem Q.bank 2016-17Documento32 páginasIii Me Ii Sem Q.bank 2016-17Abhishek SakatAinda não há avaliações

- ME 5 Computational Laboratory Activity No. 1Documento2 páginasME 5 Computational Laboratory Activity No. 1jmmaderazo08Ainda não há avaliações

- Chapter Wise Questions Bank MD-iiDocumento6 páginasChapter Wise Questions Bank MD-iiinderpreet singhAinda não há avaliações

- DMM-2 3 1 Q&aDocumento6 páginasDMM-2 3 1 Q&aAnand vinayAinda não há avaliações

- Machine Theory NumericalsDocumento5 páginasMachine Theory NumericalsSaad FarooqAinda não há avaliações

- Requirements For Transferees FinalDocumento29 páginasRequirements For Transferees FinalKaren GedalangaAinda não há avaliações

- Design Problems CoachingDocumento31 páginasDesign Problems CoachingsedexxAinda não há avaliações

- Machine Design Trial 1Documento13 páginasMachine Design Trial 1JerdAinda não há avaliações

- PRIME Diagnostic Test 4 MDSP Problem SolvingDocumento5 páginasPRIME Diagnostic Test 4 MDSP Problem SolvingFrankie NovelaAinda não há avaliações

- Machine Design ProblemsDocumento2 páginasMachine Design Problemskyla.marasigan01Ainda não há avaliações

- Assignment QuestionsDocumento12 páginasAssignment QuestionsPallavi CholkhaneAinda não há avaliações

- MDSP Problem Coaching Part 2Documento403 páginasMDSP Problem Coaching Part 2Sadam August Dulom100% (1)

- MD2 Model QuestionsDocumento2 páginasMD2 Model Questionsmanish sharmaAinda não há avaliações

- Macine DesignDocumento40 páginasMacine DesignKarl Angelo R. Dela CruzAinda não há avaliações

- At 6602 ACCD Imp Qns 2by2resultsDocumento3 páginasAt 6602 ACCD Imp Qns 2by2resultsKarthickAinda não há avaliações

- gupta PG - No:176) Exercise 9Documento3 páginasgupta PG - No:176) Exercise 9mahendra babu mekalaAinda não há avaliações

- MDlab FinalsDocumento18 páginasMDlab FinalsNarry StrummerAinda não há avaliações

- MD-II Question BankDocumento3 páginasMD-II Question BankAnonymous Pfi1bgrYAinda não há avaliações

- Machine Design Trial 1Documento7 páginasMachine Design Trial 1JerdAinda não há avaliações

- Unit 3 BIGDocumento3 páginasUnit 3 BIGVasanth KumarAinda não há avaliações

- Previous Questions DomDocumento5 páginasPrevious Questions DomSafeer MAinda não há avaliações

- MD Coaching 1Documento31 páginasMD Coaching 1Jom BautistaAinda não há avaliações

- ME4001D Assign 1Documento3 páginasME4001D Assign 1vivek geddamAinda não há avaliações

- MD Practice Exam 2Documento9 páginasMD Practice Exam 2diegs diegsAinda não há avaliações

- Dom Assignment - PDFDocumento2 páginasDom Assignment - PDFMohan KosuruAinda não há avaliações

- rr320304 Dynamics of MachinesDocumento8 páginasrr320304 Dynamics of MachinesSRINIVASA RAO GANTAAinda não há avaliações

- Machine Design REVIEWERDocumento13 páginasMachine Design REVIEWERryan bhinogAinda não há avaliações

- Imp Qoestions MDDocumento3 páginasImp Qoestions MDvenuedAinda não há avaliações

- Machine Design I TutorialDocumento3 páginasMachine Design I TutorialbngelotrAinda não há avaliações

- Vance - Antonio LACAYANGA - ASSESSMENT TESTDocumento7 páginasVance - Antonio LACAYANGA - ASSESSMENT TESTAyuguAinda não há avaliações

- Dme-2 2013Documento3 páginasDme-2 2013Mohammed YunusAinda não há avaliações

- Scientific American Supplement, No. 384, May 12, 1883No EverandScientific American Supplement, No. 384, May 12, 1883Ainda não há avaliações

- Scientific American Supplement, No. 384, May 12, 1883No EverandScientific American Supplement, No. 384, May 12, 1883Ainda não há avaliações

- Scientific American Supplement, No. 441, June 14, 1884.No EverandScientific American Supplement, No. 441, June 14, 1884.Ainda não há avaliações

- Scientific American Supplement, No. 633, February 18, 1888No EverandScientific American Supplement, No. 633, February 18, 1888Ainda não há avaliações

- How Beer Is Made in Industrial Brewing ProcessDocumento7 páginasHow Beer Is Made in Industrial Brewing ProcessRey Danielle Taray NaveaAinda não há avaliações

- Distribution For Ground Floor (AutoRecovered)Documento11 páginasDistribution For Ground Floor (AutoRecovered)Rey Danielle Taray NaveaAinda não há avaliações

- Competition GuidelinesDocumento7 páginasCompetition GuidelinesRey Danielle Taray NaveaAinda não há avaliações

- Competition GuidelinesDocumento7 páginasCompetition GuidelinesRey Danielle Taray NaveaAinda não há avaliações

- CodesDocumento2 páginasCodesRey Danielle Taray NaveaAinda não há avaliações

- Low Cost CSPDocumento94 páginasLow Cost CSPWaqar SiddiquiAinda não há avaliações

- Introduction To Industrial Safety and HealthDocumento3 páginasIntroduction To Industrial Safety and HealthRey Danielle Taray NaveaAinda não há avaliações

- Campus ManagementDocumento20 páginasCampus ManagementRey Danielle Taray NaveaAinda não há avaliações

- Selectrode: Non-Machinable Cast IronDocumento2 páginasSelectrode: Non-Machinable Cast IronAlvaro Fernando Reyes CastañedaAinda não há avaliações

- FD100 分Documento17 páginasFD100 分Hadi FaisalAinda não há avaliações

- Centrifugal Pumps PresentationDocumento28 páginasCentrifugal Pumps Presentationprasoon_eilAinda não há avaliações

- 3D Static and Dynamic AnalysisDocumento32 páginas3D Static and Dynamic AnalysisvanmurthyAinda não há avaliações

- 1-2 Introduction To Control PDFDocumento10 páginas1-2 Introduction To Control PDFyapacagınız sıteyı s..100% (1)

- To Download List of A Books Available in Library I - 59d42dbc1723dd1de323c9b4 PDFDocumento188 páginasTo Download List of A Books Available in Library I - 59d42dbc1723dd1de323c9b4 PDFRISHIKESH KUMARAinda não há avaliações

- Staad Input FileDocumento18 páginasStaad Input FileKP SahuAinda não há avaliações

- Hydraulics - Civil Engineering Questions and Answers Page 3Documento6 páginasHydraulics - Civil Engineering Questions and Answers Page 3umairAinda não há avaliações

- 654 Guess Paper Physics 10th ClassDocumento9 páginas654 Guess Paper Physics 10th ClassMuhammad MujtabaAinda não há avaliações

- Refresher No.4 (Pipe)Documento5 páginasRefresher No.4 (Pipe)chyno.kang08Ainda não há avaliações

- Industrial Valve Cross Ref - Vickers VS Rexroth For Primary Metal Applications0309Documento60 páginasIndustrial Valve Cross Ref - Vickers VS Rexroth For Primary Metal Applications0309Abelio TavaresAinda não há avaliações

- BR Cat VF-W STD Eng r07 1Documento268 páginasBR Cat VF-W STD Eng r07 1Brian LeslieAinda não há avaliações

- Suspension A8Documento5 páginasSuspension A8Bonny SidhuAinda não há avaliações

- Faculty of Engineering and Technology: Sessional Test 1-February 2020Documento2 páginasFaculty of Engineering and Technology: Sessional Test 1-February 2020Sunny BhatiaAinda não há avaliações

- C Chains APIDocumento1 páginaC Chains APILuisSilvaAinda não há avaliações

- PET 332 E Production Engineering & Surface FacilitiesDocumento13 páginasPET 332 E Production Engineering & Surface Facilities000Ainda não há avaliações

- Modification and Development in Air CoolerDocumento6 páginasModification and Development in Air CoolerSONUAinda não há avaliações

- 5 Gas Exchange Processes - UpdatedDocumento24 páginas5 Gas Exchange Processes - UpdatedShahzaib Anwar OffAinda não há avaliações

- Hipps: High Integrity Pressure Protection SystemsDocumento9 páginasHipps: High Integrity Pressure Protection SystemsAndrew XuguomingAinda não há avaliações

- N A GockcenDocumento12 páginasN A GockcendolkeenAinda não há avaliações

- Exploded View of WEBER 32-36 DGV 5A GBPDocumento3 páginasExploded View of WEBER 32-36 DGV 5A GBPJannie CoetzeeAinda não há avaliações