Escolar Documentos

Profissional Documentos

Cultura Documentos

Fundamentals of Process Plant Layout and Piping de - 59c80f3c1723dd10f8a86ce8 PDF

Enviado por

Sadhna RajputDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Fundamentals of Process Plant Layout and Piping de - 59c80f3c1723dd10f8a86ce8 PDF

Enviado por

Sadhna RajputDireitos autorais:

Formatos disponíveis

live, interaCtive classes over the internet

professional certificate of competency in

fundamentals of

Process plant layout

and piping design

12 Modules over 3 months

For upcoming start dates, please view our program schedule at:

http://www.eit.edu.au/schedule

Keep you and your company one step ahead with this

comprehensive overview of Process Plant Layout and Piping Design

Bring yourself up to speed in the latest trends and technologies

what you will learn

• Plant layout fundamentals and work flow procedures

• Terminology and symbols used in plant layout

• Plot plans, elevations and 3-D models

• Fundamental principles of chemical process technology

• Process Flow Diagrams (PFDs)

• Equipment used in process plants

• Instrument symbols and abbreviations Presented by

• Piping and Instrumentation Diagrams (P&IDs)

• Piping design and engineering principles Dr Srinivas

• Terminology, symbols and abbreviations used in

piping design Shastri

B.E., M .S., PhD, M BA

• Piping materials

• Piping specifications and piping codes

• Components of piping systems - fittings, flanges and valves

• Piping isometrics and bill of materials

Secure your place now!

Contact enquiries@eit.edu.au for an application form or more information.

V0003 RTO provider 51971 • ACN 135 762 426

BENEFITS OF presented by

LIVE E-LEARNING Dr Srinivas Shastri

B.E., M .S., PhD, M BA

• Attend lessons in an online classroom with

your lecturer and fellow students

Srinivas has worked in a variety of roles ranging from process

• Upgrade your skills and refresh your engineering to academia and has gained experience in a number of

knowledge without having to take valuable areas. He has worked across cultures in India, Singapore, New Zealand

time away from work (as a student) and now Australia. He completed my first degree in

• Receive information and materials in small, 1989 and then worked on a project for API as part of his M asters.

easy to digest sections

Srinivas started off as a process engineer and then moved to industrial

• Learn while you travel - all you need is an research culminating in the development of a model of the complex hydrometallurgical process of

Internet connection hydrogen reduction of nickel. As a Research Engineer, Srinivas worked on an optimisation solution for a

• Have constant support from your program refinery in Singapore before embarking on research into Alarm Management. The software was

lecturer and coordinator for the duration of the successfully implemented in a large refinery, and the research group has spun off into a company. In a

program faculty role, he had the pleasure of mentoring and developing young engineers while continuing to build

strong links with industry. Entering the alternative energy industry, he led the modelling effort of the

• Interact and network with participants from Shale to Liquid process and significantly contributed to the design of a 115,000 bpd commercial facility.

around the globe and gain valuable insight

into international practice Srinivas is currently developing, in addition to traditional process engineering support, areas of

• Learn from international industry experts, alternative energy technologies, scoping studies, and is actively involved in Business Development.

based around the globe Please note: Lecturers are subject to change.

• Live interactive webinars, not just a ‘book on

the web’

• Receive a certificate of completion for

CPD purposes

12 modules over 3 months

Presentation format

The certificate program features real-world

applications and uses a multi-pronged approach

Program Objectives:

involving self-study, interactive online webinars Process plants, such as refineries and petrochemical plants, are complex facilities consisting of equipment,

and homework assignments with a mentor on call. piping systems, instruments, electrical systems, electronics, computers, and control systems.

The program consists of 12 modules, over a period

The design, engineering and construction of process plants involves a multidisciplinary team effort. Plant

of 3 months.

layout and design of piping systems constitutes a major part of the design and engineering effort. The goal is

Some modules may involve a practical component to design safe and dependable processing facilities in a cost effective manner. The fact is that there are very

or group activity. For each module there will be an few formal training programs that focus on design and engineering of process plants and piping systems.

initial reading assignment along with coursework Therefore, most of the required skills are acquired while on the job, reducing productivity and efficiency.

or problems to be handed in and in some cases

The objective of this program is to provide students the basic knowledge and skills in this discipline to

practical exercises. Participants will have ongoing

facilitate faster learning curves while on the job. This program will cover the fundamental principles and

support from their lecturer and program

concepts used in process plant layout and piping design. Upon completion of this program students will have

coordinator.

a clear understanding of the design and engineering principles used in plant layout and piping design.

Program reading material will be delivered in

electronic (PDF) format in advance of online

presentations. Presentations and group

discussions will be conducted using a live

interactive software system. Assignments will be

submitted electronically and wherever possible,

practical exercises will be conducted using Includes 4 free

simulation software and remote labs.

Reference Manuals Over 1400 pages of tables,

charts, figures and handy hints

valued at over US$400

live webinars You will receive 4 of our up-to-date

technical e-Books to add to your library.

During the program you will participate in 6 live

interactive sessions with the lecturer and other • Fundamentals of Process Plant Layout and

participants from around the world. Each webinar Piping Design

will last approximately 90 minutes, and we take • Practical Pumps: Design, Operation and Maintenance

student availability into consideration wherever for Centrifugal and Positive Displacement Pumps

possible before scheduling webinar times. • Practical Process Compressors

Contact us for details of webinar session

• Practical Mechanical Seals: Selection, Maintenance

scheduling. All you need to participate is an and Troubleshooting

adequate Internet connection, speakers and a

microphone. The software package and setup Received upon completion.

details will be sent to you prior to the program. All materials required for the program will be provided electronically, in smaller, easy-to-read sections.

Please note: Webinars may last up to 2 hours Please Note: e-Books are available in hard copy at 50% of the recommended retail price. Contact us for pricing details.

depending on student interaction and level of content.

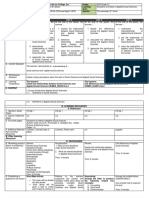

program outline HARDWARE

module 1: Introduction to Process Plant module 7: Piping and Instrumentation and SOFTWARE

Layout and Piping Design

• Plant layout fundamentals

Diagrams (P&IDs) - I

• P&ID basics

REQUIREMENTS

All you need to participate is an adequate Internet

• Procedures and workflow • Use of P&IDs by different disciplines connection, PC, speakers and a microphone. The

• Physical quantities and units • Information contained in P&IDs software package and setup details will be sent to

on the program start date.

• Instruments and instrument symbols

module 2: Introduction to Chemical

Processing Methods module 8: Piping and Instrumentation

• Unit operations and unit processes Diagrams (P&IDs) - II

• Process flow diagrams (PFDs) • Local control, DCS and PLC

Entrance

• Heating and cooling utilities used in process • Discussion of a sample P&ID Requirements

plants • Control valve manifolds Some practical work experience in some of these

• Typical equipment specifications • Meter runs topics would obviously be advantageous.

module 3: Equipment Used in module 9: Plant Layout and Piping

Process Plants - I Design Documentation and Tools - I

• Process equipment

- Reactors

• Piping codes PRACTICAL EXERCISES

• Piping specifications

Throughout the program you will participate in

- Towers • Equipment lists hands-on exercises using simulation software,

- Exchangers • Piping line lists which will help you put theory to practice

- Furnaces immediately!

- Vessels module 10: Plant Layout and Piping

• Mechanical equipment Design Documentation and Tools - II

- Pumps • Stress isometrics

- Compressors

- Turbines

• Piping isometrics and Bill of Materials

• PFDs, plot plans, and P&IDs

certification

• Equipment foundations and supports • 3D models Participants completing and achieving at

least 50% or more in each assignment,

module 11: Fundamentals of Pipe and as well as attending 65% of the live

module 4: Equipment Used in webinars, will receive the Engineering

Pipe Fittings

Process Plants - II (Documents) Institute of Technology Professional

• Pipe dimensions and pipe representation Certificate of Competency in

• Equipment data sheets

• Use of pipe data tables Fundamentals of Process Plant Layout

• Equipment sketches and Piping Design.

• Pipe joining methods

• Equipment drawings

• Pipe fittings

• Equipment nozzle specifications

- Elbows

• Equipment foundation drawings

- Tees

module 5: Plant Layout and Plot Plans - Reducers

and piping design

ocess plant layout

• Plant layout specifications - End caps fundamentals of pr

• Codes and safety considerations • Fitting dimensions and tables

• Development of plot plans

module 12: Piping System Components

• Plot plan use by disciplines

• Basics of flanges

• Sample plot plans and equipment

arrangement drawings - Flange ratings and flange types

• Layout case studies • Flange data tables and their use

• Different types of valves and their

module 6: Piping Materials and

applications ON-site training

Material Specifications • Valve data tables We can provide our training at the venue of your

choice. On-site training can be customised and

• Material properties • Piping restraints

by bringing the trainer to site the dates can be

• Classification of materials - Supports, anchors and guides set to suit you!

• Material specifications (ASTM) “The Customer is Always Right” – so tell us what

you need and we will design a training solution

• Common piping materials at your own site.

• Piping specifications

For a FREE detailed proposal please

• Material selection contact Kevin Baker via e-mail:

• Material testing, inspection and QA training@idc-online.com

Você também pode gostar

- Case Analysis - Kent ChemicalsDocumento10 páginasCase Analysis - Kent Chemicalssampleassignment.com100% (2)

- Preply Tutoring Methodology - July, 2018 PDFDocumento14 páginasPreply Tutoring Methodology - July, 2018 PDFErica SouzaAinda não há avaliações

- EIT IP Brochure EgyptDocumento4 páginasEIT IP Brochure Egyptheka2006Ainda não há avaliações

- Fundamentals of Process Plant Layout and Piping Design: 12 Modules Over 3 MonthsDocumento3 páginasFundamentals of Process Plant Layout and Piping Design: 12 Modules Over 3 MonthsAnkitaSharmaAinda não há avaliações

- EIT Course Process Electrical Instrumentation Drawings Docs CDR BrochureDocumento3 páginasEIT Course Process Electrical Instrumentation Drawings Docs CDR BrochureSaleem AdamAinda não há avaliações

- EIT Instrumentation Automation Process Control BrochureDocumento3 páginasEIT Instrumentation Automation Process Control BrochureMuhammad ImranAinda não há avaliações

- Chemical Engineering and Plant Design: 12 Modules Over 3 MonthsDocumento3 páginasChemical Engineering and Plant Design: 12 Modules Over 3 MonthschandravadiyaketanAinda não há avaliações

- Project Management: 12 Modules Over 3 MonthsDocumento3 páginasProject Management: 12 Modules Over 3 MonthsbariAinda não há avaliações

- EIT Course Onshore Offshore Pipeline Systems COO BrochureDocumento3 páginasEIT Course Onshore Offshore Pipeline Systems COO BrochureDoni RandanuAinda não há avaliações

- ABB Handbook Protection and Control DevicesDocumento3 páginasABB Handbook Protection and Control DevicesFaicel TabitAinda não há avaliações

- Inudustrial Data Communication PDFDocumento3 páginasInudustrial Data Communication PDFAnonymous Uqrw8OwFWuAinda não há avaliações

- EIT Course Electrical and Instrumentation Engineering Oil and Gas Facilities COG BrochureDocumento3 páginasEIT Course Electrical and Instrumentation Engineering Oil and Gas Facilities COG BrochureKatamba RogersAinda não há avaliações

- Process Plant Layout and Piping Design: Fundamentals ofDocumento4 páginasProcess Plant Layout and Piping Design: Fundamentals ofSolakhudin Al Ayubi100% (1)

- EIT Course Gas Turbine Engineering CGT Brochure Rev3Documento3 páginasEIT Course Gas Turbine Engineering CGT Brochure Rev3gochi best100% (1)

- EIT Course Gas Turbine Engineering CGT BrochureDocumento3 páginasEIT Course Gas Turbine Engineering CGT BrochureMuhammad ImranAinda não há avaliações

- Machine Learning and Artificial Intelligence: 12 Modules Over 3 MonthsDocumento3 páginasMachine Learning and Artificial Intelligence: 12 Modules Over 3 MonthsgivepleaseAinda não há avaliações

- EIT Course Power Distribution CPD BrochureDocumento3 páginasEIT Course Power Distribution CPD BrochureKatamba RogersAinda não há avaliações

- Advanced Tcp/Ip-Based Industrial Networking: 12 Modules Over 3 MonthsDocumento3 páginasAdvanced Tcp/Ip-Based Industrial Networking: 12 Modules Over 3 MonthsbariAinda não há avaliações

- EIT - Control Valve SizingDocumento3 páginasEIT - Control Valve SizingbariAinda não há avaliações

- Siemens S7 1200/tia Portal: 12 Modules Over 3 MonthsDocumento3 páginasSiemens S7 1200/tia Portal: 12 Modules Over 3 MonthsbariAinda não há avaliações

- Hazardous Areas and Intrinsic Safety: 12 Modules Over 3 MonthsDocumento3 páginasHazardous Areas and Intrinsic Safety: 12 Modules Over 3 MonthsSreekanthMylavarapuAinda não há avaliações

- Troubleshooting, Designing, and Installing Digital and Analog Closed Circuit TV SystemsDocumento3 páginasTroubleshooting, Designing, and Installing Digital and Analog Closed Circuit TV SystemsgivepleaseAinda não há avaliações

- EIT Course Mechanical Design Concepts For Non Engineers CMW BrochureDocumento3 páginasEIT Course Mechanical Design Concepts For Non Engineers CMW BrochurepratAinda não há avaliações

- Heating, Ventilation and Air-Conditioning (Hvac) : 12 Modules Over 3 MonthsDocumento3 páginasHeating, Ventilation and Air-Conditioning (Hvac) : 12 Modules Over 3 MonthsTathego GomolemoAinda não há avaliações

- EIT Course Diesel Power Plants CDG BrochureDocumento3 páginasEIT Course Diesel Power Plants CDG BrochureKatamba RogersAinda não há avaliações

- EIT Course IEC 61850 Substation Automation CSZ BrochureDocumento3 páginasEIT Course IEC 61850 Substation Automation CSZ BrochureKatamba RogersAinda não há avaliações

- Dept. of Computer Science Faculty of Science and TechnologyDocumento28 páginasDept. of Computer Science Faculty of Science and TechnologySormila HossainAinda não há avaliações

- Industrial Data Communications: 12 Modules Over 3 MonthsDocumento3 páginasIndustrial Data Communications: 12 Modules Over 3 Monthsbilal7617465Ainda não há avaliações

- Cad Cam Lab ManualDocumento79 páginasCad Cam Lab ManualJaff FdoAinda não há avaliações

- PM Au Darwin 2014 Ea OdDocumento4 páginasPM Au Darwin 2014 Ea OdvextersAinda não há avaliações

- Practical Operation, Maintenance and Testing of Diesel Power Generating PlantsDocumento3 páginasPractical Operation, Maintenance and Testing of Diesel Power Generating PlantsArafat BauntoAinda não há avaliações

- Power Electronics, Switch Mode Power Supplies and Variable Speed DrivesDocumento3 páginasPower Electronics, Switch Mode Power Supplies and Variable Speed DrivesMuhammad ImranAinda não há avaliações

- Product Note PGP in Data ScienceDocumento5 páginasProduct Note PGP in Data ScienceArushi SinghAinda não há avaliações

- Project Sample BietDocumento30 páginasProject Sample BietRatan ShetAinda não há avaliações

- Black Book Documentation On SeoDocumento31 páginasBlack Book Documentation On SeoGufran AnsariAinda não há avaliações

- SPM Unit 2 RelatedDocumento86 páginasSPM Unit 2 RelatedOye it's hubAinda não há avaliações

- Kopal GangradeDocumento4 páginasKopal GangradeSkillytek ServiceAinda não há avaliações

- Institute of Technology, Sligo Job DescriptionDocumento4 páginasInstitute of Technology, Sligo Job DescriptionShahidul HoqueAinda não há avaliações

- Handout For Research Centre 2 12 2010Documento10 páginasHandout For Research Centre 2 12 2010Ganesh SinghAinda não há avaliações

- NI - PresentationDocumento14 páginasNI - PresentationAkash ShettannavarAinda não há avaliações

- Project Dissertation Semester V and Project Implementation Semester VIDocumento30 páginasProject Dissertation Semester V and Project Implementation Semester VIT-SeriesAinda não há avaliações

- EIT Course PLCs SCADA Systems CAU BrochureDocumento3 páginasEIT Course PLCs SCADA Systems CAU Brochuresukhbir24Ainda não há avaliações

- Summer Training in Software DevelopmentDocumento10 páginasSummer Training in Software DevelopmentDevender KhariAinda não há avaliações

- L1 - Project Lifecycles and Agile ApproachesDocumento24 páginasL1 - Project Lifecycles and Agile ApproachesNikku SinghAinda não há avaliações

- Engineering Design Methods and Tools: Sahar IdreesDocumento14 páginasEngineering Design Methods and Tools: Sahar IdreesMian Abdullah YaseenAinda não há avaliações

- Program Electrical EngineeringDocumento3 páginasProgram Electrical Engineeringlex_of_rocknetAinda não há avaliações

- PUCIT - Software Engineering - Course OutlineDocumento7 páginasPUCIT - Software Engineering - Course Outlineibrahim.samad100% (2)

- 6774 Database Connectivity ToolkitDocumento2 páginas6774 Database Connectivity ToolkitHerwin SuprijonoAinda não há avaliações

- NUS SOC Analytics Brochure 28032024Documento18 páginasNUS SOC Analytics Brochure 28032024mukeshAinda não há avaliações

- Industrial Training in Software - 2011Documento9 páginasIndustrial Training in Software - 2011Devender KhariAinda não há avaliações

- Project Implementation Guide (E-Next - In)Documento30 páginasProject Implementation Guide (E-Next - In)Aamash AnsariAinda não há avaliações

- Dbms Draft ReportDocumento28 páginasDbms Draft ReportAditi AAinda não há avaliações

- Industrial Training Report 1Documento48 páginasIndustrial Training Report 1Mia NiveriaAinda não há avaliações

- Intern ReportDocumento14 páginasIntern Reportu creatorAinda não há avaliações

- 2021 Beng Software Engineering 4465Documento10 páginas2021 Beng Software Engineering 4465FrankAinda não há avaliações

- Education For Brighter FuturesDocumento26 páginasEducation For Brighter FuturesJONATHAN ALEXANDER NARVAEZ MONDRAGONAinda não há avaliações

- HR 242 2021 JD - Senior Analyst - IT SystemsDocumento5 páginasHR 242 2021 JD - Senior Analyst - IT SystemsefabriquesiAinda não há avaliações

- Module 1 - SEDocumento10 páginasModule 1 - SEAilene SibayanAinda não há avaliações

- Abhi NewDocumento32 páginasAbhi NewAniket PhapaleAinda não há avaliações

- AWS Certified Cloud Practitioner: Study Guide with Practice Questions and LabsNo EverandAWS Certified Cloud Practitioner: Study Guide with Practice Questions and LabsNota: 5 de 5 estrelas5/5 (1)

- (Applied Clinical Psychology) Robert P. Liberman, Eugenie G. Wheeler, Louis A. J. M. de Visser, Julie Kuehnel, Timothy Kuehnel (auth.) - Handbook of Marital Therapy_ A Positive Approach to Helping Tro.pdfDocumento267 páginas(Applied Clinical Psychology) Robert P. Liberman, Eugenie G. Wheeler, Louis A. J. M. de Visser, Julie Kuehnel, Timothy Kuehnel (auth.) - Handbook of Marital Therapy_ A Positive Approach to Helping Tro.pdfLeonardoGiraldoSanchez100% (1)

- Chemistry Syllabus: Ms. Claire CrouseDocumento4 páginasChemistry Syllabus: Ms. Claire Crouseapi-262741759Ainda não há avaliações

- English 110 Spring 2018 SyllabusDocumento4 páginasEnglish 110 Spring 2018 Syllabusapi-387766454Ainda não há avaliações

- COPYREADING and HEADLINE WRITING (Secondary-English) Directions: Copyread The News Story Below Using The Appropriate Copyreading Marks. The FirstDocumento13 páginasCOPYREADING and HEADLINE WRITING (Secondary-English) Directions: Copyread The News Story Below Using The Appropriate Copyreading Marks. The FirstJoveth TempladoAinda não há avaliações

- Capital Markets & Investments (Lochstoer) SU2014Documento5 páginasCapital Markets & Investments (Lochstoer) SU2014darwin12Ainda não há avaliações

- Homework Data EntryDocumento4 páginasHomework Data Entryafeuswybr100% (1)

- Syllabus-ME 31100 ECE31200Documento3 páginasSyllabus-ME 31100 ECE31200DavidVizcaínoAinda não há avaliações

- Discrete Mathematics 2005Documento4 páginasDiscrete Mathematics 2005gassun2999Ainda não há avaliações

- Effects of School Workload To Quality Family Time of CNSTHS Grade 12 Students PDFDocumento44 páginasEffects of School Workload To Quality Family Time of CNSTHS Grade 12 Students PDFLawlDNoobAinda não há avaliações

- Syllabus 151Documento10 páginasSyllabus 151Michael TooAinda não há avaliações

- English Didactics SyllabusDocumento9 páginasEnglish Didactics SyllabusDanny FergusonAinda não há avaliações

- HD 300 SyllabusDocumento9 páginasHD 300 Syllabusapi-291458163Ainda não há avaliações

- English 101 Syllabus - Spring 2016 LavcDocumento4 páginasEnglish 101 Syllabus - Spring 2016 Lavcapi-278336146Ainda não há avaliações

- Mysql Lab1Documento2 páginasMysql Lab1Motaz IbrahimAinda não há avaliações

- QMI Syllabus Fall 2019Documento1 páginaQMI Syllabus Fall 2019Johnathan SandersonAinda não há avaliações

- Blah BlahDocumento21 páginasBlah BlahKier Nadela LatonioAinda não há avaliações

- Day 1 Day 2 Day 3 Day 4: Daily Lesson LogDocumento5 páginasDay 1 Day 2 Day 3 Day 4: Daily Lesson LogBRIAN INCOGNITOAinda não há avaliações

- Unit: Lesson Title: Grade/Period:: Baker College Teacher Prep Lesson Plan FormDocumento6 páginasUnit: Lesson Title: Grade/Period:: Baker College Teacher Prep Lesson Plan Formapi-318157741Ainda não há avaliações

- Griffin Matsen: Professional SummaryDocumento11 páginasGriffin Matsen: Professional SummaryNavneet VishnoiAinda não há avaliações

- No Homework Fridays: ( This Data Is Based Upon The Theoretical Average Time Usage On A Weekend)Documento1 páginaNo Homework Fridays: ( This Data Is Based Upon The Theoretical Average Time Usage On A Weekend)Edry DinapoAinda não há avaliações

- M427J Syllabus 53290-1Documento3 páginasM427J Syllabus 53290-1billo rydiAinda não há avaliações

- HOMEWORK - A Boon or A Bane?Documento3 páginasHOMEWORK - A Boon or A Bane?Eric FairmanAinda não há avaliações

- Class 4 Holiday Homework 2023Documento10 páginasClass 4 Holiday Homework 2023minalAinda não há avaliações

- Lesson 29 Homework 2.4Documento5 páginasLesson 29 Homework 2.4ffutcfrmg100% (1)

- Holidays Homework Volunteers Organization Management Getting Along Morning Routine Sponge Activities and Much More!Documento22 páginasHolidays Homework Volunteers Organization Management Getting Along Morning Routine Sponge Activities and Much More!alana reneAinda não há avaliações

- Lesson Plan Arthur's ToothDocumento2 páginasLesson Plan Arthur's ToothPersephoni MooreAinda não há avaliações

- PSYCH 610 GUIDE Real EducationDocumento21 páginasPSYCH 610 GUIDE Real Educationveeru31Ainda não há avaliações

- Patterns of Development in WritingDocumento19 páginasPatterns of Development in WritingStephanie Torcatos50% (2)