Escolar Documentos

Profissional Documentos

Cultura Documentos

Induced Roll Magnetic Separator: Data Sheet - IRM

Enviado por

MIzan NursiadiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Induced Roll Magnetic Separator: Data Sheet - IRM

Enviado por

MIzan NursiadiDireitos autorais:

Formatos disponíveis

Data Sheet - IRM

MT-DS-002

Rev: 1

Induced Roll Magnetic Separator

Overview

The Reading Induced Roll Magnetic Separator (IRM) is one of a series of high intensity electromagnetic machines

designed for the separation of granular materials having very weak magnetic susceptibility. The unit consists of a

number of specially designed laminated rollers rotating between the poles of powerful electromagnets. Mineral

Technologies specialise in custom designed IRM units to suit specific client requirements

Features

Designed for continuous, heavy duty applications

Optional low intensity drum for removal of particles with high

magnetic susceptibility

Laminated roller profiles selected to suit mineral feed particle

size

Magnet pole (nose iron) profiles selected to suit application

Adjustable magnet poles (air gap) for intensity optimisation

Coil rated for continuous use giving up to 2 Tesla adjustable to

suit application

Magnetic circuit design for minimal flux leakage

Single feed point for 2 start separator

Trash screen to protect against tramp oversize

Single fibre separation roller wiping brush on each separation

stage

Adjustable splitter position with provision for a middlings

fraction on the lower rollers

Control panel incorporating magnetic field control, motor starter and interlocks

Design Data

Size Range: >45micron to 3.0mm

Feed Temperature: 80°C Standard (with option upto 120°C on Custom order)

Moisture Content: Dry, free-flowing

Applications

Removal of any magnetic contaminants from non-magnetic products to meet grade targets

Production of glass / silica sand and other industrial minerals

Cleaning of zircon or rutile products

Separation of high temperature feedstocks

www.mineraltechnologies.com Page 1 of 5 Leaders in Mineral Separation

Data Sheet - IRM

MT-DS-002

Rev: 1

Configurations Available

Configuration Capacity (t/h)

2 x 2 x 760mm x 133 dia. 2-5

2 x 2 x 1000mm x 160 dia. 5-12

Equipment can be fitted with special features as required to suit specific applications:

Scalper drum magnets can be fitted to remove highly susceptible magnetic contaminants when required

Option to retreat magnetics, middlings or non-magnetics on lower rollers

New feed presented to all rolls for 4 x single pass separation

Knifegates on feed and dust ports to allow isolation

Optional VSD on feed roll to give remote control of feed rate

Optional Drive Arrangements :

a) Belt and pulley driven - standard

b) Feed rollers only – direct drive with VSD control

c) Feed and separation rollers – direct drive with VSD control

www.mineraltechnologies.com Page 2 of 5 Leaders in Mineral Separation

Data Sheet - IRM

MT-DS-002

Rev: 1

General Specifications

760mm x 133dia. Configuration 1000mm x 160dia. Configuration

2x2 2x2+Scalper 2x2 2x2+Scalper

Equipment No. Separator RR9011 RR9001 RR9101 RR9111

Separator Nett Weight (kg) 4800 5300 6250 6500

Throughput Capacity (t/h) 2-5 5-12

“A” height (mm) 2700 2975 2880 3280

Dimension

“B” Width (mm) 1630 1630

“C” Depth (mm) Note 1 1370 1610

Feed Connection 1 x 80NB Table D Flanges 1 x 80NB Table D Flanges

Dust Extraction Connection 2 x 80NB Table D Flanges 2 x 80NB Table D Flanges

Dust Extraction Requirement 750m³/hr 750m³/hr

Power Consumption (kW) 5.6 (a) / 6.5 (b) / 7.5 (c) 6.3 (a) / 6.8 (b) / 9.8 (c)

Control Panel Equipment No. RR9031-3 (Option A) RR9031-1 ( Option B) RR9031-2 ( Option C) RR9031-4 ( Option D)

Suitable for 2x2

Suitable for 2x2 Suitable for 2x2

Suitable for 2x2 and Direct Drive

Belt & Pulley Drive Belt & Pulley Drive

Control Panel Description 2x2+Scalper c/w 3 x VSD for

c/w 1 x VSD for Feed c/w 2 x VSD for Feed

Belt & Pulley Drive 1 x Feed and

OR Separation and Separation

2 x Separation

Size (wide x depth x height) : 800 x 400 x1300 800 x 400 x1900 800 x 400 x1900 800 x 400 x1900

Weight (kg) : 160 230 230 230

Protection Rating : IP.55

General Note:

Mineral Technologies reserves the right to alter specifications without prior notice.

For Certified Drawings suitable for Engineering Design purposes please refer to Mineral Technologies

Note 1:

Depth based on Option A – Drive Arrangement

www.mineraltechnologies.com Page 3 of 5 Leaders in Mineral Separation

Data Sheet - IRM

MT-DS-002

Rev: 1

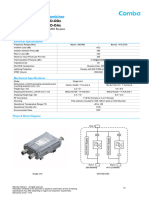

Pilot Induced Roll Magnetic Separator

Overview

The “Reading” Pilot Induced Roll Magnetic Separator is specifically designed for the highly selective dry magnetic

separation of samples of dry granular materials. As the machine represents a full-scale cross-section of a full-scale

production model, direct performance comparisons and machine settings are possible.

Features

The separation of weakly magnetic materials requiring a field

strength up to 20,000 Gauss (Dependent on Magnet Pole Air

Gap Setting)

The separation of weakly magnetic materials requiring a field

strength up to 2.4 Tesla (dependent on magnet pole air gap

setting)

Adjustable nose iron (magnet pole air gap)

Vibrating feeder for precise feed control, standard on all

models

Optional supplementary feed hopper for larger feed samples.

Single fibre separation roller wiping brush

Double adjustable product splitters with a “drain free” product chutes to minimise contamination risk of

Integral controls incorporated on front panel of the separator

Dual intensity switch giving (low and high range amp indication)

Design Data

Size Range: >45micron to 3.0mm

Feed Temperature: 80°C Standard (with option upto 120°C on Custom order)

Moisture Content: Dry, free-flowing

Applications

Removal

Grade control testing on plant processes.

Separation for assaying purposes

Assessment of plant equipment performance

Research into new separation techniques and prior to plant flowsheet changes

Analysis of prospecting samples

Preparation of batches of material for further research and testing

www.mineraltechnologies.com Page 4 of 5 Leaders in Mineral Separation

Data Sheet - IRM

MT-DS-002

Rev: 1

Options Avaliable

1x1x100x133dia. (Refer Figure previous page)

1x1x100x133dia. Semi-Lift Vibratory Feeder design for analytical separations and high purity magnetic fractions.

1x1x100x160dia.

General Specifications

Equipment Description 133dia. Standard 133dia. Semi-Lift 160dia. Standard

Equipment No. RL9011 RL9021 RL9101

Separator Nett Weight (kg) 345 345 345

Throughput Capacity (t/h) 0.25 (nominal) 0.25 (nominal) 0.3 (nominal)

“A” height (mm) 1770 1770 1770

Dimension

“B” Width (mm) 915 915 915

“C” Depth (mm) 675 675 675

240V / 50hZ / 15 Amps /

Power Requirements / Consumption

1.5kW incl. Geared Motor and Magnet Coils

www.mineraltechnologies.com Page 5 of 5 Leaders in Mineral Separation

Você também pode gostar

- StarLAN Technology ReportNo EverandStarLAN Technology ReportNota: 3 de 5 estrelas3/5 (1)

- MT-DS-008 ESP Electrostatic Plate SeparatorDocumento5 páginasMT-DS-008 ESP Electrostatic Plate SeparatorCarlos Hurtado GarcíaAinda não há avaliações

- MT Electrostatoc High Tension Roll HTR400 MT-DS-009Documento4 páginasMT Electrostatoc High Tension Roll HTR400 MT-DS-009Carlos Hurtado GarcíaAinda não há avaliações

- RMX-JZVMB DatabookDocumento35 páginasRMX-JZVMB DatabookUbaldo BritoAinda não há avaliações

- PlatformDocumento4 páginasPlatformma1102Ainda não há avaliações

- Terms of UseDocumento56 páginasTerms of UsekicsispermaAinda não há avaliações

- DRV5053-Q1 Automotive Analog-Bipolar Hall Effect Sensor: 1 Features 2 ApplicationsDocumento31 páginasDRV5053-Q1 Automotive Analog-Bipolar Hall Effect Sensor: 1 Features 2 ApplicationsSobanAinda não há avaliações

- Prose Mb-G64o9x65v-00Documento3 páginasProse Mb-G64o9x65v-00hasib_muhammedAinda não há avaliações

- Dynadet-C3-25ms TDS 2019-04-04 en UKDocumento2 páginasDynadet-C3-25ms TDS 2019-04-04 en UKpepeAinda não há avaliações

- MCR 370NDocumento2 páginasMCR 370NMilo SorriAinda não há avaliações

- Durolon HFR 1910Documento2 páginasDurolon HFR 1910elrolo3000Ainda não há avaliações

- CM-FM2-Oxx-CM-FM2D-Oxx-DS-3-0-0Documento2 páginasCM-FM2-Oxx-CM-FM2D-Oxx-DS-3-0-0Witto PereAinda não há avaliações

- Modules-Stada 2022Documento36 páginasModules-Stada 2022akbar raizoAinda não há avaliações

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocumento1 páginaData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACAinda não há avaliações

- OneBase DiplexerDocumento2 páginasOneBase DiplexerJŕ MaiaAinda não há avaliações

- DCP02 Series, 2-W, 1000-V Isolated, Unregulated DC/DC Converter Modules 1 Features 3 DescriptionDocumento33 páginasDCP02 Series, 2-W, 1000-V Isolated, Unregulated DC/DC Converter Modules 1 Features 3 DescriptionAvs ElectronAinda não há avaliações

- Direct Drive Servomotor Turrets: SeriesDocumento18 páginasDirect Drive Servomotor Turrets: SeriesSHG AUTMEC MANUTENÇÃO E AUTOMAÇÃO MÁQ. INDUSTRIAISAinda não há avaliações

- Magnectic Drill Pro 36 Auto FeedDocumento1 páginaMagnectic Drill Pro 36 Auto FeedopulitheAinda não há avaliações

- TX 392013Documento3 páginasTX 392013minhAinda não há avaliações

- TTVA Fender Data SheetDocumento3 páginasTTVA Fender Data SheetNestor Fernando LagraNaAinda não há avaliações

- M1832 1932 1942 Sme-ADocumento96 páginasM1832 1932 1942 Sme-Azied nasriAinda não há avaliações

- Sandvik DT1130-C Data: Application Main SpecificationsDocumento4 páginasSandvik DT1130-C Data: Application Main SpecificationsLuis JaimesAinda não há avaliações

- Cat-Mi58 Mi58s MC58 MC59 Mc60-EDocumento3 páginasCat-Mi58 Mi58s MC58 MC59 Mc60-Eرضا محمود ريحانAinda não há avaliações

- Lapp Pro247enDocumento3 páginasLapp Pro247enTrung Trinh BaoAinda não há avaliações

- DRV5011 Low-Voltage, Digital-Latch Hall Effect Sensor: 1 Features 3 DescriptionDocumento34 páginasDRV5011 Low-Voltage, Digital-Latch Hall Effect Sensor: 1 Features 3 DescriptionGustavo GarciaAinda não há avaliações

- Makita - Product Details - DTW1002Z 18V LXT Brushless Impact WrenchDocumento1 páginaMakita - Product Details - DTW1002Z 18V LXT Brushless Impact Wrenchwrya hussainAinda não há avaliações

- Smart™ Sensor: Thru-Hull Triducer MultisensorDocumento2 páginasSmart™ Sensor: Thru-Hull Triducer Multisensormumus123Ainda não há avaliações

- Roland EGX-300 - SpecificationsDocumento2 páginasRoland EGX-300 - SpecificationsHAinda não há avaliações

- En NTN 6208ZZC3 5KDocumento3 páginasEn NTN 6208ZZC3 5Krozzaq dhmgroupAinda não há avaliações

- mdc22002500bb eDocumento2 páginasmdc22002500bb e周政毅Ainda não há avaliações

- Hydraulic Side Acting GripsDocumento4 páginasHydraulic Side Acting Gripsmohamed ahmedAinda não há avaliações

- Tri-Band Clover AntennaDocumento5 páginasTri-Band Clover Antenna'Theodora Georgiana100% (1)

- Technical Manual Air BreatherDocumento8 páginasTechnical Manual Air BreatherMuhammad RyanAinda não há avaliações

- VibraDocumento14 páginasVibraMohammedIrfanAinda não há avaliações

- Manual RadarRight 400Documento48 páginasManual RadarRight 400Jims Poma VilcahuamanAinda não há avaliações

- Fuente DC-DCDocumento28 páginasFuente DC-DCantonio mayaAinda não há avaliações

- Hall Sensor DRV5053Documento30 páginasHall Sensor DRV5053jpAinda não há avaliações

- Hydraulic WinchDocumento4 páginasHydraulic WinchFrancisco MochoAinda não há avaliações

- Cable - Datasheet - (En) NSSHCÖU, Prysmian - 2013-06-10 - Screened-Power-CableDocumento4 páginasCable - Datasheet - (En) NSSHCÖU, Prysmian - 2013-06-10 - Screened-Power-CableA. Muhsin PamungkasAinda não há avaliações

- Water Jet PortfoliaDocumento7 páginasWater Jet PortfoliaSagar KumarAinda não há avaliações

- Acl 079 ProvisoryDocumento8 páginasAcl 079 ProvisoryRuben KammingaAinda não há avaliações

- Encoderld PDFDocumento13 páginasEncoderld PDFLaura PrietoAinda não há avaliações

- Technical Data: Single Row or Matched Pairs of Angular Contact Ball BearingsDocumento3 páginasTechnical Data: Single Row or Matched Pairs of Angular Contact Ball BearingsDjamel Eddine LAZZOUNIAinda não há avaliações

- LM324Documento6 páginasLM324TRICKS TIPSTECHNOLOGYAinda não há avaliações

- 1SVR730774R1300 CM Pas 31sDocumento4 páginas1SVR730774R1300 CM Pas 31sCanh NguyenAinda não há avaliações

- ts3204 00aDocumento2 páginasts3204 00aziksonAinda não há avaliações

- Dn65 Devicenet I/O Module: DescriptionDocumento8 páginasDn65 Devicenet I/O Module: DescriptionwilfredoAinda não há avaliações

- 446 - Diamond Coring Tool, DD 200Documento1 página446 - Diamond Coring Tool, DD 200Amirul Ariff ShaharudinAinda não há avaliações

- CR600 Sizer Brochure PDFDocumento8 páginasCR600 Sizer Brochure PDFAdil DouziAinda não há avaliações

- Duct Grade Unitube Eca 103097Documento3 páginasDuct Grade Unitube Eca 103097JESUS ALEXANDER GUTIERREZ GOMEZAinda não há avaliações

- CM-MPN.72S: CM-MPN.72S Three-Phase Monitoring Relay 2c/o, 0,0.1-30s, L1-L2-L3 3x530-820VACDocumento4 páginasCM-MPN.72S: CM-MPN.72S Three-Phase Monitoring Relay 2c/o, 0,0.1-30s, L1-L2-L3 3x530-820VACSSE ACCAinda não há avaliações

- Solido 500 enDocumento3 páginasSolido 500 enFariyad AnsariAinda não há avaliações

- SD314D-HF2P4LDF (D00S) - Dual Port, 4 Dipole, 7.5 DBD, HD, Low PIM, 406-470 MHZDocumento2 páginasSD314D-HF2P4LDF (D00S) - Dual Port, 4 Dipole, 7.5 DBD, HD, Low PIM, 406-470 MHZpsalazar23Ainda não há avaliações

- Dyadic Systems RSADocumento3 páginasDyadic Systems RSAServo2GoAinda não há avaliações

- Solmax - HDPE REFLECTIVE IMPERIALDocumento6 páginasSolmax - HDPE REFLECTIVE IMPERIALchipnowAinda não há avaliações

- Category 6 PVC Cable: Catalogue Number: 6 327 24/26Documento2 páginasCategory 6 PVC Cable: Catalogue Number: 6 327 24/26sam7sAinda não há avaliações

- Centron C1SR R300 IdmDocumento4 páginasCentron C1SR R300 IdmYaciro CabezasAinda não há avaliações

- DD212Documento8 páginasDD212Raul Reynaldo Ccorpuna LeonAinda não há avaliações

- Ingecon Sun Storage 1play TL M: List of Approved Power MetersDocumento6 páginasIngecon Sun Storage 1play TL M: List of Approved Power MetersalarmaAinda não há avaliações

- Annex to the certificate concerning the examination of conformityDocumento21 páginasAnnex to the certificate concerning the examination of conformityCyril YomiAinda não há avaliações

- Ellingham DiagramsDocumento4 páginasEllingham DiagramsSumit KumarAinda não há avaliações

- Electrochemical Methods TinDocumento9 páginasElectrochemical Methods TinMIzan NursiadiAinda não há avaliações

- 070305ar07 77291aDocumento4 páginas070305ar07 77291aMIzan NursiadiAinda não há avaliações

- Velocities VDocumento6 páginasVelocities VMIzan NursiadiAinda não há avaliações

- SheuiDocumento6 páginasSheuiMIzan NursiadiAinda não há avaliações

- The Effects of Blends of Enugu Coal and Anthracite On Tin Smelting Using Nigerian Dogo Na Hauwa CassiteriteDocumento4 páginasThe Effects of Blends of Enugu Coal and Anthracite On Tin Smelting Using Nigerian Dogo Na Hauwa CassiteriteMIzan NursiadiAinda não há avaliações

- Effect of Na Co On The Preparation of Metallic Tin From Cassiterite Roasted Under Strong Reductive AtmosphereDocumento7 páginasEffect of Na Co On The Preparation of Metallic Tin From Cassiterite Roasted Under Strong Reductive AtmosphereMIzan NursiadiAinda não há avaliações

- Chapt5 Theory of Sedimentation PDFDocumento18 páginasChapt5 Theory of Sedimentation PDFMIzan NursiadiAinda não há avaliações

- 12 - Chapter 3 PDFDocumento20 páginas12 - Chapter 3 PDFDr.Rekha SinghAinda não há avaliações

- Methodology of Calculation The Terminal Settling Velocity Distribution of Spherical Particles For High Values of The Reynolds NumberDocumento14 páginasMethodology of Calculation The Terminal Settling Velocity Distribution of Spherical Particles For High Values of The Reynolds NumberMIzan NursiadiAinda não há avaliações

- SheuiDocumento6 páginasSheuiMIzan NursiadiAinda não há avaliações

- Methodology of Calculation The Terminal Settling Velocity Distribution of Spherical Particles For High Values of The Reynolds NumberDocumento14 páginasMethodology of Calculation The Terminal Settling Velocity Distribution of Spherical Particles For High Values of The Reynolds NumberMIzan NursiadiAinda não há avaliações

- Effect of Na Co On The Preparation of Metallic Tin From Cassiterite Roasted Under Strong Reductive AtmosphereDocumento7 páginasEffect of Na Co On The Preparation of Metallic Tin From Cassiterite Roasted Under Strong Reductive AtmosphereMIzan NursiadiAinda não há avaliações

- Preparation and Measurement of Cassiterite For SN Isotope AnalysisDocumento7 páginasPreparation and Measurement of Cassiterite For SN Isotope AnalysisMIzan NursiadiAinda não há avaliações

- Terminal Velocity Lab: ObjectivesDocumento4 páginasTerminal Velocity Lab: ObjectivesMIzan NursiadiAinda não há avaliações

- International Journal of Mineral Processing: Senol Cetinkaya, Serafettin ErogluDocumento3 páginasInternational Journal of Mineral Processing: Senol Cetinkaya, Serafettin ErogluMIzan NursiadiAinda não há avaliações

- Lecture21 PDFDocumento4 páginasLecture21 PDFMIzan NursiadiAinda não há avaliações

- Mass Balance Calculations in Flash SmeltingDocumento5 páginasMass Balance Calculations in Flash SmeltingMIzan NursiadiAinda não há avaliações

- Imagej Grain Size Analysis Mizan NursiadiDocumento3 páginasImagej Grain Size Analysis Mizan NursiadiMIzan NursiadiAinda não há avaliações

- Imagej Grain Size AnalysisDocumento3 páginasImagej Grain Size AnalysisMIzan NursiadiAinda não há avaliações

- Chang 2016Documento15 páginasChang 2016MIzan NursiadiAinda não há avaliações

- Raw Material (Galvanized Steel Coil) : StartDocumento1 páginaRaw Material (Galvanized Steel Coil) : StartMIzan NursiadiAinda não há avaliações

- ImageJ Grain Size AnalysisDocumento3 páginasImageJ Grain Size AnalysisMIzan NursiadiAinda não há avaliações

- Imagej Grain Size AnalysisDocumento3 páginasImagej Grain Size AnalysisMIzan NursiadiAinda não há avaliações

- I J Tra 150110129212Documento6 páginasI J Tra 150110129212MIzan NursiadiAinda não há avaliações

- Metal Serbuk Sesi 1Documento10 páginasMetal Serbuk Sesi 1MIzan NursiadiAinda não há avaliações

- Imagej Grain Size AnalysisDocumento3 páginasImagej Grain Size AnalysisMIzan NursiadiAinda não há avaliações

- The Volume Deficit of Iron-Carbon Alloys234Documento6 páginasThe Volume Deficit of Iron-Carbon Alloys234MIzan NursiadiAinda não há avaliações

- Checklist PBL 2Documento3 páginasChecklist PBL 2Hazrina AwangAinda não há avaliações

- Syllabus - Mech 3rd YearDocumento130 páginasSyllabus - Mech 3rd YearAbhishek AmarAinda não há avaliações

- SABIC Ethanolamines RDS Global enDocumento10 páginasSABIC Ethanolamines RDS Global enmohamedmaher4ever2Ainda não há avaliações

- Discount & Percentage Word Problems SolutionsDocumento4 páginasDiscount & Percentage Word Problems SolutionsrheAinda não há avaliações

- Harry Styles: The Rise of a Pop StarDocumento9 páginasHarry Styles: The Rise of a Pop StarBilqis LaudyaAinda não há avaliações

- ThesisDocumento18 páginasThesisapi-29776055293% (15)

- Factors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawatDocumento26 páginasFactors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawathumeragillAinda não há avaliações

- Pike River Case StudyDocumento7 páginasPike River Case StudyGale HawthorneAinda não há avaliações

- Libros de ConcretoDocumento11 páginasLibros de ConcretoOSCAR GABRIEL MOSCOL JIBAJAAinda não há avaliações

- Draft of The English Literature ProjectDocumento9 páginasDraft of The English Literature ProjectHarshika Verma100% (1)

- How To Open and Convert An .SCM FileDocumento5 páginasHow To Open and Convert An .SCM FilejackAinda não há avaliações

- Congress Policy Brief - CoCoLevyFundsDocumento10 páginasCongress Policy Brief - CoCoLevyFundsKat DinglasanAinda não há avaliações

- Cycles in Nature: Understanding Biogeochemical CyclesDocumento17 páginasCycles in Nature: Understanding Biogeochemical CyclesRatay EvelynAinda não há avaliações

- Diagram of Thermal RunawayDocumento9 páginasDiagram of Thermal RunawayVeera ManiAinda não há avaliações

- Concept, Types, Characteristics and ClassificationsDocumento6 páginasConcept, Types, Characteristics and ClassificationsCJ FaAinda não há avaliações

- FOMRHI Quarterly: Ekna Dal CortivoDocumento52 páginasFOMRHI Quarterly: Ekna Dal CortivoGaetano PreviteraAinda não há avaliações

- Racial and Ethnic Challenges in the UAE vs UKDocumento16 páginasRacial and Ethnic Challenges in the UAE vs UKATUL KORIAinda não há avaliações

- 16 BPI V FernandezDocumento1 página16 BPI V FernandezAngelica Joyce BelenAinda não há avaliações

- Parasim CADENCEDocumento166 páginasParasim CADENCEvpsampathAinda não há avaliações

- Lab 2 ReportDocumento9 páginasLab 2 Reportsherub wangdiAinda não há avaliações

- Personal InsuranceDocumento11 páginasPersonal InsuranceSumit Kumar SharmaAinda não há avaliações

- Market Participants in Securities MarketDocumento11 páginasMarket Participants in Securities MarketSandra PhilipAinda não há avaliações

- Keynes Presentation - FINALDocumento62 páginasKeynes Presentation - FINALFaith LuberasAinda não há avaliações

- High Frequency Voltage Probe Non-Availability on GeMDocumento2 páginasHigh Frequency Voltage Probe Non-Availability on GeMjudeAinda não há avaliações

- Tps65070X Power Management Ic (Pmic) With Battery Charger, 3 Step-Down Converters, and 2 LdosDocumento98 páginasTps65070X Power Management Ic (Pmic) With Battery Charger, 3 Step-Down Converters, and 2 Ldosmok waneAinda não há avaliações

- Library Management System (Final)Documento88 páginasLibrary Management System (Final)Ariunbat Togtohjargal90% (30)

- Iqvia PDFDocumento1 páginaIqvia PDFSaksham DabasAinda não há avaliações

- A K A G .: RUN Umar Shok UptaDocumento2 páginasA K A G .: RUN Umar Shok UptaArun GuptaAinda não há avaliações

- Broadband BillDocumento1 páginaBroadband BillKushi GowdaAinda não há avaliações

- Guardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicDocumento110 páginasGuardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicTarun BharadwajAinda não há avaliações