Escolar Documentos

Profissional Documentos

Cultura Documentos

Overview of Pre-Engineered Buildings: Mr. Aditya P. Mehendale, Prof. Dr. A. K. Gupta & Prof. D. B. Desai

Enviado por

ShubhamTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Overview of Pre-Engineered Buildings: Mr. Aditya P. Mehendale, Prof. Dr. A. K. Gupta & Prof. D. B. Desai

Enviado por

ShubhamDireitos autorais:

Formatos disponíveis

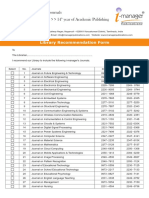

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-2, Issue-6, 2016

ISSN: 2454-1362, http://www.onlinejournal.in

Overview of Pre-Engineered Buildings

Mr. Aditya P. Mehendale1, Prof. Dr. A. K. Gupta2 & Prof. D. B. Desai3

1

PG Student, Civil Engineering Department, Dr.J.J.Magdum College of Engineering,

Jaysingpur, Maharashtra, India.

2,3

Professor, Civil Engineering Department, Dr.J.J.Magdum College of Engineering,

Jaysingpur, Maharashtra, India.

Abstract: Buildings & houses are the basic could be restricted to standard designs, the buildings

requirements of any human being. There are several could be properly called pre-engineered. Once the

changes in construction technology since the industry started to offer custom-designed metal

beginning. The basic requirements of construction buildings to fill the particular needs of each client,

nowadays are best aesthetic look, fast, economical & the name pre-engineered building became somewhat

high quality. Pre- engineered building is best option of a misnomer. In addition, this term was

for these all requirements. Pre-engineered buildings uncomfortably close to, and easily confused with, the

are cost effective, time consuming as compared to unsophisticated prefabricated buildings, with which

other conventional buildings. Generally pre- the new industry did not want to be associated.

engineered buildings are faster than conventional Despite the fact that the term pre-engineered

buildings, 25 % less time consuming & 30% lighter buildings is still widely used, and will be often found

than conventional buildings. The plan & load on the even in this book, the industry now prefers to call its

building are calculated at the beginning, & the product metal building systems.

members are manufactured in factory & they are just Steel industry is growing rapidly in almost all

assembled on actual site at time of construction. the parts of the world. The use of steel structures is

not only economical but also Eco-friendly at the time

1. Introduction when there is a threat of global warming. Here,

“economical” word is stated considering time and

The scientific-sounding term pre-engineered cost. Time being the most important aspect, steel

buildings came into being in the 1960s.The buildings structures (Pre-fabricated) is built in very short

were pre-engineered because, like their ancestors, period and one such example is Pre Engineered

they relied upon standard engineering designs for a Buildings (PEB). Pre-engineered buildings are

limited number of off-the-shelf configurations. nothing but steel buildings in which excess steel is

Several factors made this period significant for the avoided by tapering the sections as per the bending

history of metal buildings. First, the improving moment’s requirement. One may think about its

technology was constantly expanding the maximum possibility, but it’s a fact many people are not aware

clear-span capabilities of metal buildings. The first about Pre Engineered Buildings. If we go for regular

rigid-frame buildings introduced in the late 1940s steel structures, time frame will be more, and also

could span only 40 ft. In a few years, 50-, 60-, and cost will be more, and both together i.e. time and

70-ft buildings became possible. By the late 1950s, cost, makes it uneconomical. Thus in pre-engineered

rigid frames with 100-ft spans were made ribbed buildings, the total design is done in the factory, and

metal panels became available, allowing the as per the design, members are pre-fabricated and

buildings to look different from the old tired then transported to the site where they are erected in

corrugated appearance. Third, collared panels were a time less than 6 to 8 weeks.

introduced by Strand-Steel Corp. in the early 1960s, The structural performance of these buildings is

permitting some design individuality. At about the well understood and, for the most part, adequate code

same time, continuous span cold-formed Z purlins provisions are currently in place to ensure

were invented, the first factory-insulated panels were satisfactory behavior in high winds. Steel structures

developed by Butler, and the first UL-approved also have much better strength-to-weight ratios than

metal roof appeared on the market.1st And last, but RCC and they also can be easily dismantled. Pre

not least, the first computer-designed metal buildings Engineered Buildings have bolted connections and

also made their debut in the early 1960s. With the hence can also be reused after dismantling. Thus,

advent of computerization, the design possibilities pre-engineered buildings can be shifted and/or

became almost limitless. All these factors combined expanded as per the requirements in future. In this

to produce a new metal-building boom in the late paper we will discuss the various advantages of pre-

1950s and early 1960s. As long as the purchaser engineered buildings and also, with the help of three

Imperial Journal of Interdisciplinary Research (IJIR) Page 1421

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-2, Issue-6, 2016

ISSN: 2454-1362, http://www.onlinejournal.in

examples, a comparison will be made between pre-

engineered buildings and conventional steel

structures.

Presently, large column free area is the utmost

requirement for any type of industry and with the

advent of computer software’s it is now easily

possible. With the improvement in technology,

computer software’s have contributed immensely to

the enhancement of quality of life through new

researches. Pre-engineered building (PEB) is one of Figure 1: Typical rafter & column

such revolution. "Pre-engineered buildings" are fully

fabricated in the factory after designing, then

transported to the site in completely knocked down

(CKD) condition and all components are assembled

and erected with nut-bolts, thereby reducing the time

of completion.

2. Advantages of Pre-Engineered

Buildings

a) Construction Time: Buildings are generally Figure 2: Typical frame of PEB

constructed in just 6 to 8 weeks after approval of 3.2 Secondary System

drawings. PEB will thus reduce total construction Secondary structural system consists of Purlins

time of the project by at least 40%. This allows faster (roof), Girts (side cladding) and Eave struts (at

occupancy and earlier realization of revenue. This is eaves) stiffened with sag rods. This also includes the

one of the main advantages of using Pre-engineered flange stiffeners which connects the untied flanges of

building. the PEB primary structure to secondary system.

b) Lower Cost: Because of systems approach, Some of the commonly used secondary system are

considerable saving is achieved in design, Lipped C or Lipped Z purlins, MS rods and Lipped

manufacturing and erection cost. Angles. These are generally cold formed sections

c) Flexibility of Expansion: These can be easily conforming to IS:801

expanded in length by adding additional bays. Also

expansion in width and height is possible by pre

designing for future expansion.

d) Large Clear Spans: Buildings can be supplied to

around 90m clear spans. This is one of the most

important advantages of PEB giving column free

space.

e) Quality Control: Buildings are manufactured

completely in the factory under controlled Figure 3: Z & C purlins

conditions, and hence the quality can be assured.

f) Low Maintenance: PEB Buildings have high

quality paint systems for cladding and steel to suit

ambient conditions at the site, which in turn gives

long durability and low maintenance coats.

g) Energy Efficient Roofing: Buildings are supplied

with polyurethane insulated panels or fiberglass

blankets insulation to achieve required “U” values

(overall heat transfer coefficient). Figure 4: Eaves strut

3. Various systems in PEB

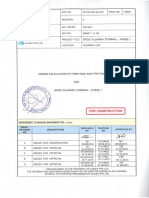

3.1 Primary System

Primary system consists of tapered or parallel

columns and tapered beams which are called as

rafters. The base of the columns can be either pinned

or fixed based on the load requirements. Lengths of

these members are generally restricted to 12m for

ease of transports. Joints are connected with high

Figure 5: girts

tensile bolts.

Imperial Journal of Interdisciplinary Research (IJIR) Page 1422

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-2, Issue-6, 2016

ISSN: 2454-1362, http://www.onlinejournal.in

3.3 Wind Bracing System The design is done on span length given by

There are two types of wind bracing systems. customer. The basic span length starts from 10 to150

The first one is Rod bracing system and the second meters or above with intermediate columns. Aircraft

one is portal system. Each type of system is chosen hangars, manufacturing industries, Stadiums posses

based on the design and functional requirement of major span width. No modifications or extending

the structure. span be done.

2. Length of Building

The length of PEB is the total length extending

from one frontend to the rear end of the building.

The length of PEB can be extendable in future.

3. Building Height

Building height is the eave height which usually

is the distance from the bottom of the main frame

Figure 6: typical wind bracing across rafters column base plate to the top outer point of the eave

3.4 Roofing & Cladding System strut. When columns are recessed or elevated from

Roofing and cladding system can be with single finished floor, eave height is the distance from

skin zinc and aluminum coated steel sheets, GI finished floor level to top of eave strut.

sheets, both of which could be bare or color coated; 4. Roof Slope

It could with double skin sheets with or without This is the angle of the roof with respect to the

insulation material in between; It could be sandwich horizontal. The most common roof slopes are 1/10

panels with steel sheets outside and and 1/20 for tropical countries like India. The roof

PUF/PIR/Mineral Wool/Glass wool core inside. slope in snowfall locations can go up to 1/30 to 1/60.

Roofing and cladding could have skylights with Poly Any practical roof slope is possible as per customers’

Carbonate/ PVC or FRP sheets. requirement.

3.5 Accessories 5. Design Loads

Accessories include, Turbo Ventilators, Ridge Unless otherwise specified per-engineered

vents, Flashings, trims, Gutters, Down pipes, ladders, buildings are designed for the following minimum

Louvers etc. loads. The designed loads play a crucial role in case

of PEB. The failure of the structures occurs if not

properly designed for loads. The determination of the

loads acting on a structure is a complex problem. The

nature of the loads varies essentially with the

architectural design, the materials, and the location

of the structure. Loading conditions on the same

structure may change from time to time, or may

Figure 8: turbo ventilator, gutter with down pipe change rapidly with time. Loads are usually

3.6 Finishing classified into two broad groups as dead loads and

Primary structural members are generally live loads. Dead loads (DL) are essentially constant

finished with shot peening, Sand blasting, two coats during the life of the structure and normally consist

of anti corrosive primers, followed by two coats of of the weight of the structural elements. On the other

paints to specifications. Secondary members or either hand, live loads (LL) usually vary greatly. The

painted after sand blasting or Galvanized to 275 gsm weight of occupants, snow and vehicles, and the

or above based on the requirement. forces induced by wind or earthquakes are examples

of live loads. The magnitudes of these loads are not

known with great accuracy and the design values

4. Technical Parameters of PEB must depend on the intended use of the structure.

Pre Engineered Buildings are custom designed 5.1 Dead Load

to meet clients requirements. PEBs are defined for The structure first of all carries the dead

definite measurements. The produced members fit to load, which includes its own weight, the weight of

the designed dimensions. Measurements are taken any permanent non-structural partitions, built-in

accurately for the requirements. The basic cupboards, floor surfacing materials and other

parameters that can define a PEB are finishes. It can be worked out precisely from the

1. Width or Span of Building known weights of the materials and the dimensions

The centre to centre length from one end wall on the working drawings.

column to the other end wall column of a frame is 5.2 Live Load

considered breadth or span of the building. The All the movable objects in a building such

width between two columns can be measured as as people, desks, cupboards and filing cabinets

span. The span length for different buildings varies. produce an imposed load on the structure. This

Imperial Journal of Interdisciplinary Research (IJIR) Page 1423

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-2, Issue-6, 2016

ISSN: 2454-1362, http://www.onlinejournal.in

loading may come and go with the result that its ridge line at the peak or centre of the building. The

intensity will vary considerably. At one moment a maximum practical width or span is up to 90 meters,

room may be empty, yet at another packed with but it can also be extended up to 150 meters in case

people. Imagine the `extra' live load at a lively party. of Aircraft Hangars.

5.3 Wind Loads 7.2 Arched Clear Span

Wind has become a very important load in The column is an RF column while the

recent years due to the extensive use of lighter Rafter is curved. It has no ridge line and peak. The

materials and more efficient building techniques. A curved roof rafter is used in for aesthetic look. The

building built with heavy masonry, timber tiled roof maximum practical is up to 90meters, but can be

may not be affected by the wind load, but on the extended to 120 meters.

other hand the structural design of a modern light 7.3 Multi Span (Ms1)

gauge steel framed building is dominated by the The Multi spans (MS1) are those which

wind load, which will affect its strength, stability and have more than 1 span. The intermediate column is

serviceability. The wind acts both on the main used for the clear span in which width of each span is

structure and on the individual cladding units. The called width module.

structure has to be braced to resist the horizontal load 7.3.1 Arched Multi Span (Ams1)

and anchored to the ground to prevent the whole Arched multi span has RF column and a

building from being blown away, if the dead weight curved Rafter with one intermediate column. It has

of the building is not sufficient to hold it down. The width module for the entire span. The multi spans

cladding has to be securely fixed to prevent the wind can be extended up to AMS1, AMS2 and AMS3 etc.

from ripping it away from the structure. 7.3.2 Multi Span 2 (Ms2)

The Multi Span (MS2) has more than one

5.4 Roof Load intermediate span. It has three width modules with

Live loads produced by maintenance one ridge line.

activities, rain, erection activities, and other movable 7.4 Single Slope

or moving loads by not including wind, snow, It has two columns with different heights

seismic, crane, or dead loads. having Roof sloping on both the column.

5.5 Roof Snow Load 7.5 Multi Gable

Gravity load induced by the forces of wind Multi gable has two or more spans where no

blowing from any horizontal direction. intermediate columns are used. The columns are

5.6 Auxiliary Loads added to the extended width and columns are not

Dynamic loads induced by cranes, placed at the ridge lines.

conveyers, or other material handling systems. 7.6 Roof Systems

5.7 Seismic Loads It has straight columns with Roof having

They are the Horizontal loads acting in any supports are not by TPCA.

direction structural systems due to action of an 7.7 Lean To

earthquake. Lean to slopes is used extremely for an

5.8 Floor Live Loads extending to a building on either side with short

Loads induced on a floor system by span. The rafters rest on column designed for lean to

occupants of a building and their furniture, on one side and rests on the main column of the

equipment, etc building.

6 Bay Spacing 7.8 Canopy

The distance between the two adjacent Canopies are used in case of open ends where

frames of a building is called as a Bay spacing. The there is an easy access. There are columns in straight

spacing between two frames is a bay. End Bay length path having roof extended to a large length.

is the distance from outside of the outer flange of end 5. Applications of PEB

wall columns of centre line of the first interior frame warehouses

columns. Interior bay length is the distance between factories

the centre lines of two adjacent interior main frames workshops

Columns. The most economical bay spacing is 7.5m

offices

to 8.0m. However bay length up to 10m is possible.

gas stations

7 Types of Frame

vehicle parking sheds

A frame is a combination of Columns and

inclined beams (rafters). There are various type of showrooms

frames. aircraft hangars

7.1 Clear Span (Cs) metro stations

It’s the span length between two columns schools

without any obstruction. It has split Beams with recreational

indoor stadium roofs

Imperial Journal of Interdisciplinary Research (IJIR) Page 1424

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-2, Issue-6, 2016

ISSN: 2454-1362, http://www.onlinejournal.in

outdoor stadium canopies

bridges

railway platform shelters

6. Conclusion

This paper effectively conveys that PEB

structures can be easily designed by simple

design procedure.PEB structures are more

advantageous than conventional structures in

economy, speed of construction & simple

erection. Hence it is concluded that PEB has

wide scope in India but they are still not

preferred.

7. References

[1]Milind Bhojkar & Milind Darade,“Comparison of

Pre Engineering Building and Steel Building with

Cost and Time Effectiveness”; International Journal

of Innovative Science, Engineering & Technology,

Vol. 1 Issue 10, December 2014.

[2]Saurabh A. Shah, Madhav B. Kumthekar, “An

overview of Pre- Engineered Building Systems in

India”;Proceedings of 27th IRF International

Conference, 24th May 2015, Pune, India.

[3] C.M.Meera,“Pre-Engineered Building Design of

An Industrial Warehouse”;International Journal of

Engineering Sciences & Emerging Technologies,

June 2013 Volume 5, Issue 2, pp: 75-82 ©IJESET.

[4] J.Jayavelmurugan J.R.Thirumal, Padmanabhan

haridas, “A study of Pre-Engineered Building

structures”, International Journal of Innovative

Research in Science, Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 1, January 2015.

[5]G. SaiKiran, A. KailasaRao, R. Pradeep Kumar

“Comparison of Design Procedures for Pre

Engineering Buildings (PEB): A Case Study”; World

Academy of Science, Engineering and Technology

International Journal of Civil, Environmental,

Structural, Construction and Architectural

Engineering Vol:8, No:4, 2014.

[6]D V Swathi“Design And Analysis of Pre-

Engineered Steel Frame”; D V Swathi , et al ,

International Journal of Research Sciences and

Advanced Engineering [IJRSAE] Volume 2 , Issue 8,

PP: 250 - 255 , OCT -DEC -2014.

Imperial Journal of Interdisciplinary Research (IJIR) Page 1425

Você também pode gostar

- ContohDocumento6 páginasContohTheoAinda não há avaliações

- Indian PEB Industry:: Economic and Environmental Sustainability Factors Ensure Continued Rapid GrowthDocumento4 páginasIndian PEB Industry:: Economic and Environmental Sustainability Factors Ensure Continued Rapid GrowthShubhamAinda não há avaliações

- Elli Fritt 1993Documento12 páginasElli Fritt 1993ShubhamAinda não há avaliações

- 2831 Pre Engineered BuildingDocumento13 páginas2831 Pre Engineered BuildingdilipAinda não há avaliações

- Conference Paper TemplateDocumento3 páginasConference Paper TemplateDeden MSAinda não há avaliações

- The Effect of Multi Parameter Changes of Arch Bridge On Buckling Analysis of Arch BridgeDocumento6 páginasThe Effect of Multi Parameter Changes of Arch Bridge On Buckling Analysis of Arch BridgeShubhamAinda não há avaliações

- Peb B D0513243Documento16 páginasPeb B D0513243Daniyal AhmedAinda não há avaliações

- Analysis and Design of PEB Using IS800 and International StandardDocumento5 páginasAnalysis and Design of PEB Using IS800 and International StandardPratik R. AtwalAinda não há avaliações

- Industrial Building Design Study Using STAAD ProDocumento6 páginasIndustrial Building Design Study Using STAAD ProShubhamAinda não há avaliações

- SSC Junior Engineer exam notice postponed to Feb 1Documento1 páginaSSC Junior Engineer exam notice postponed to Feb 1SURADA SATISHAinda não há avaliações

- Design & Analysis of Pre-Engieered Building StructureDocumento3 páginasDesign & Analysis of Pre-Engieered Building StructureShubhamAinda não há avaliações

- RCC 1 PDFDocumento8 páginasRCC 1 PDFNgọc TuyênAinda não há avaliações

- Cole 1992Documento2 páginasCole 1992ShubhamAinda não há avaliações

- Cole1992 PDFDocumento10 páginasCole1992 PDFShubhamAinda não há avaliações

- BMC Sub Engineer SyllabusDocumento7 páginasBMC Sub Engineer SyllabusRupesh JadhavAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- 00.blending Unit - Roof - LayoutDocumento1 página00.blending Unit - Roof - LayoutMartens HategeAinda não há avaliações

- Layout of Steel TrussDocumento27 páginasLayout of Steel TrussCivilEngClub100% (10)

- EASYSPAN Truss Manual FinalDocumento36 páginasEASYSPAN Truss Manual FinalHoa PhamAinda não há avaliações

- Steel Portal Frames 4 PDFDocumento37 páginasSteel Portal Frames 4 PDFPn EkanayakaAinda não há avaliações

- Specification Complete Assembly 17.02.2020Documento45 páginasSpecification Complete Assembly 17.02.2020AnithaAinda não há avaliações

- Celdon Garage - Sheet - S101 - STRUCTURAL PLANSDocumento1 páginaCeldon Garage - Sheet - S101 - STRUCTURAL PLANSRodAinda não há avaliações

- Pre Engineered BuildingsDocumento4 páginasPre Engineered BuildingsniroshniroshAinda não há avaliações

- Garages Stubbie InstallDocumento16 páginasGarages Stubbie InstallMattAinda não há avaliações

- ErectionDocumento55 páginasErectionAjay Sastry100% (7)

- Pre Engineered BuildingsDocumento20 páginasPre Engineered BuildingsGyandeep Jaiswal100% (3)

- Main Workshop A2b - Assembly - List - Rev A #05.11.2021Documento3 páginasMain Workshop A2b - Assembly - List - Rev A #05.11.2021Ma'arif Nuzul AddibAinda não há avaliações

- Zamil Steel BroDocumento36 páginasZamil Steel BroBùi Văn HợpAinda não há avaliações

- AGB Purlin BrochureDocumento50 páginasAGB Purlin BrochureMelissa GrahamAinda não há avaliações

- Presentation by Gursharan SinghDocumento46 páginasPresentation by Gursharan SinghNishanth SoansAinda não há avaliações

- UltraZED Roof, Side and Floor BEAM Section PropertiesDocumento52 páginasUltraZED Roof, Side and Floor BEAM Section Propertiesnelutu12345100% (1)

- Productivity Rates 9Documento84 páginasProductivity Rates 9Freedom Love Nabal100% (1)

- Structural Design Basis ReportDocumento31 páginasStructural Design Basis ReportRajaram100% (1)

- Proposed Gate House Bill of QuantitiesDocumento9 páginasProposed Gate House Bill of Quantitiesoseni momoduAinda não há avaliações

- Over 1000 buildings across 20 statesDocumento8 páginasOver 1000 buildings across 20 statesAzhar IqbalAinda não há avaliações

- Kalzip ConstructiondetailsDocumento87 páginasKalzip ConstructiondetailsIrina PlopeanuAinda não há avaliações

- Onduline Installation Guide - 3Documento8 páginasOnduline Installation Guide - 3appanagAinda não há avaliações

- Demolition and excavation worksDocumento30 páginasDemolition and excavation worksHafizan Hanafiah100% (3)

- Teklabook Lesson7 SteelDetailingDocumento28 páginasTeklabook Lesson7 SteelDetailingMrsonsoAinda não há avaliações

- Sattar Metal. Steel & Civil CostDocumento4 páginasSattar Metal. Steel & Civil Costrahul.sopanengineersAinda não há avaliações

- Blue Ladder Epc Solutions Pvt. LTD.: Job No. Project ClientDocumento10 páginasBlue Ladder Epc Solutions Pvt. LTD.: Job No. Project ClientJitendra PAinda não há avaliações

- Bend Angle in Hopper PDFDocumento61 páginasBend Angle in Hopper PDFrajasekar23081981Ainda não há avaliações

- Pre Engineered Steel STRTDocumento21 páginasPre Engineered Steel STRTPooja JabadeAinda não há avaliações

- Design Calculations for Foam Tank and Fire Pump Shed FoundationDocumento187 páginasDesign Calculations for Foam Tank and Fire Pump Shed FoundationSaravan KumarAinda não há avaliações

- Example Calculations For Purlins (Ver 1.1 1098)Documento5 páginasExample Calculations For Purlins (Ver 1.1 1098)Ear Choungchhay100% (1)

- Standard Material Specifications IndexDocumento6 páginasStandard Material Specifications IndexvgvpplAinda não há avaliações