Escolar Documentos

Profissional Documentos

Cultura Documentos

Atlas MFC Metal Cabinet

Enviado por

6KILLER0 notas0% acharam este documento útil (0 voto)

70 visualizações1 páginaThis document provides details on milling machine attachments and accessories for an Atlas milling machine, including:

1) A floor cabinet (No. 9050) that provides a rigid mounting for the milling machine and includes storage space.

2) Side pans and cutter arbors of various diameters that attach to the milling machine spindle to hold cutting tools.

3) An automatic coolant system (Nos. M1-600A and M1-600B) that reduces tool wear and improves work finish with a centrifugal pump and adjustable nozzle.

4) Additional accessories like a draw-in bar, crank handle, miller lamp, and outboard arbor support.

Descrição original:

Atlas MFC Metal Cabinet

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document provides details on milling machine attachments and accessories for an Atlas milling machine, including:

1) A floor cabinet (No. 9050) that provides a rigid mounting for the milling machine and includes storage space.

2) Side pans and cutter arbors of various diameters that attach to the milling machine spindle to hold cutting tools.

3) An automatic coolant system (Nos. M1-600A and M1-600B) that reduces tool wear and improves work finish with a centrifugal pump and adjustable nozzle.

4) Additional accessories like a draw-in bar, crank handle, miller lamp, and outboard arbor support.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

70 visualizações1 páginaAtlas MFC Metal Cabinet

Enviado por

6KILLERThis document provides details on milling machine attachments and accessories for an Atlas milling machine, including:

1) A floor cabinet (No. 9050) that provides a rigid mounting for the milling machine and includes storage space.

2) Side pans and cutter arbors of various diameters that attach to the milling machine spindle to hold cutting tools.

3) An automatic coolant system (Nos. M1-600A and M1-600B) that reduces tool wear and improves work finish with a centrifugal pump and adjustable nozzle.

4) Additional accessories like a draw-in bar, crank handle, miller lamp, and outboard arbor support.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

MSO-22

MILLING MACHINE ATTACHMENTS

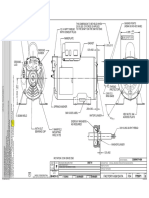

FLOOR CABINET

J'

No. 90S0 MILLING

MACHINE FLOOR

CUTTER ARBORS

CABINET. Provides the Ground stressproof steel with full length keyway and No_ 2

rigid mounting required Morse taper shank. Driver threaded for spindle nose. Collars

for accurate miller 10/8" diameter, precision-ground - rwo 2", one 1", one %",

work. Legs, top and one 1/2" and one 1/4" furnished. Length, shoulder to nut,

shelf are heavy 13 61f4". No. MI-576 draw-in bar is required.

gauge steel, with spot No. Ml-S60 %" diam. CUTTER ARBOR for Atlas milling

welded joints. Sides of machine, complete with nut, six collars and driver. ZETYR,

top are flared to catch 5 Ibs.

oil, top has hole for

coolant system. Shelf is No. M 1-S60L I" diam. CUTTER ARBOR for Atlas milling

handy storage space for machine, compJete with nut, six collars and driver. ZEWAN,

6 lbs.

tools and attachments,

28" long x 18" wide x

32%" high. Less side

pans. ZEPOK. 80 lbs.

No. 90S1 SIDE PANS. DRAW-IN BAR

Attach to each side of No. MI-576 DRAW-IN BAR. Required to hold MI-560 or

No. 9050 stand to catch MI-560L cutter arbors, and MI-577 shank cutter .adapter, in

oil drippings as miller spindle taper. Code ZEV AM, wt. 1'12 Ibs.

table moves from side

to side. Heavy gauge

steel, with flared sides. CRANK HANDLE

Clamp brackets and

bolts furnished. 11" x 8" Required for No. MI-576 draw-in bar and

wide. Z ERA]. 5 lbs. No. Ml·300 vise. Drop forged.

per pair.

No. 57-100 CRANK HANDLE. Code

ZEVYS, wt. [1/2 Ibs.

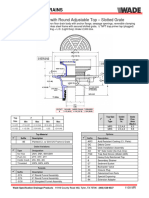

MOTORS - 3-PHASE SWITCH AUTOMATIC

COOLANT SYSTEMS

No. Phase Volt Cycle RPM Wt. Code

These coo Iant systems, de-

2730 One 110/220 60 1725 28 YIDFA signed especially for use

2831 Three 220/440 50/60 1425/1725 26 YIHEK with Atlas milling machines,

All motors listed above are V3 HP, have .v8" single-end sbafc. reduce tool wear, improve

work finish, and meet peak

No. 57-300 Three Phase Switch. 6lbs. ZEBAR. production demands. Their

simple construction assures

No. 2710 Cord and Plug for single-phase motor. 1 lb.

smooth, r r o u b l e- free per-

YIDEG.

formance and long service

life.

The mod ern cen trifugal-

MILLER LAMP type pump - engineered for

continuous service with any cutting fluid - is installed in

3·pint reservoir compartment in base of the Atlas miller.

No. 1238 MILLER LAMP. Im- The coolant stream can be easily directed to any point on

proves vision by throwing cutter with the adjustable outlet nozzle and a sliding arm

plenty of light directly on your that supports the rubber feed line. Control valve regulates

work. Has 15" flexible cable, flow - from slow drip to fast washing action. No priming

necessary. Built-in switch.

un i v e t: s a I mounting bracket.

PUMPING CAPACITY (Gallons per Hour)

Push-through switch. ZODUK.

Soluble Oil Lard Oil

2 lb. (50% Solution) (700 F.)

No. Ml·600A 198 78

No. MI-600B 360 108

No. Ml-600A COOLA T SYSTEM complete as shown. Motor: in.

duction. 3450 RPM for 110/120 volt, 50·60 cycle AC. Code word

ZE]BE, wt , 12 lbs.

OUTBOARD ARBOR SUPPORT No. Ml-6001l COOLA T SYSTEM for Atlas milling machines com.

plete as shown. Motor: universal, 6000 RPM for 110/120 volt

Locks arbor, overarm and knee together AC/DC. Code word ZEKEC, wt. 19Y2 Ibs.

rigidly - improves work finish on heavy cuts

by reducing chatter and vibration to a min.

imum. Fits any Aelas milling machine. COOLANT TANK

Quickly and easily installed or removed-

bolts to overarm support bracket and cross This graviry-flow tank is a simple,

feed screw bearing (furnished). Support bar inexpensive coolant device. Ca-

is heavy iron casnng, slotted and machined

for quick heighr adjustment. pacity approx. 1 qt. Sliding sup-

No. Ml-6S0 OUTBOARD ARBOR SUP· port arm and adjustable nozzle to

PORT for Atlas MF series milling machines. direct coo l a n t s t rea m. Valve

7 Ibs. ZIACY.

regulates flow. Nozzle has ex-

No. Ml-660 OUTBOARD ARBOR SUP· truded plastic tip.

PORT for Atlas MI and MH series milling

machines. 7 Ibs. ZIADZ. No. Ml-SS0 COOLANT TANK.

Series numbers art shown O·'~ nomenclature plate. Code ZETAL, wt. 8 Jbs.

Você também pode gostar

- Opera Ting Manual: HQ400/3A - HQ400/3B - HQ400/3L Multi - Purpose MachineDocumento34 páginasOpera Ting Manual: HQ400/3A - HQ400/3B - HQ400/3L Multi - Purpose MachinerianrureAinda não há avaliações

- Diagnosis A140eDocumento49 páginasDiagnosis A140eTanaka MachanaAinda não há avaliações

- Projects For The Unimat Part 2Documento95 páginasProjects For The Unimat Part 26KILLER100% (2)

- Bell 47D1 Flight ManualDocumento80 páginasBell 47D1 Flight Manual6KILLER100% (2)

- Projects For The Unimat Part 1Documento85 páginasProjects For The Unimat Part 16KILLER83% (6)

- Stag Goods BS II Parts CatalogueDocumento257 páginasStag Goods BS II Parts CatalogueBhawani CopyAinda não há avaliações

- Atlas Lathe Operations ManualDocumento5 páginasAtlas Lathe Operations Manualursind80% (5)

- Section MillingDocumento2 páginasSection MillingCharles DesmazuresAinda não há avaliações

- National Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsDocumento24 páginasNational Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsNitin B maskeAinda não há avaliações

- BMS Submittal SampleDocumento66 páginasBMS Submittal Sampleaads1984Ainda não há avaliações

- Welding Journal 1960 4Documento219 páginasWelding Journal 1960 4AlexeyAinda não há avaliações

- Savage 2020 Product Catalogue PDFDocumento94 páginasSavage 2020 Product Catalogue PDFValdez RulioAinda não há avaliações

- Jaw Crusher Model 2650 Spec Sheet: Base LubricationDocumento2 páginasJaw Crusher Model 2650 Spec Sheet: Base LubricationDilnesa EjiguAinda não há avaliações

- Screw BookDocumento182 páginasScrew BookNeoAinda não há avaliações

- 250cc (LT-Z250 AJ4AA 2004-2006) Suzuki ATV Parts ListDocumento54 páginas250cc (LT-Z250 AJ4AA 2004-2006) Suzuki ATV Parts ListMarkAinda não há avaliações

- Wind Turbine Spares Supply ListDocumento8 páginasWind Turbine Spares Supply ListbalaAinda não há avaliações

- Machine Tools Questions and Answers - Drilling MachineDocumento4 páginasMachine Tools Questions and Answers - Drilling MachineRohit Ghulanavar100% (3)

- Big State Industrial Supply 2022 Line SheetDocumento16 páginasBig State Industrial Supply 2022 Line SheettimBSI100% (1)

- Caveman Chemistry Book 2Documento237 páginasCaveman Chemistry Book 26KILLERAinda não há avaliações

- Manual de Partes RFADocumento140 páginasManual de Partes RFALeonardo Benitez100% (1)

- TG 70Documento1 páginaTG 70Shisir ishaqAinda não há avaliações

- Unigrind SLIM Machine LeafletDocumento2 páginasUnigrind SLIM Machine LeafletDeepak RajanAinda não há avaliações

- Data SheetDocumento2 páginasData SheetProject AnalysisAinda não há avaliações

- Cutting Head Part Numbers Cutting Head Part Numbers: Discontinued in 2014 (Available While Supplies Last)Documento1 páginaCutting Head Part Numbers Cutting Head Part Numbers: Discontinued in 2014 (Available While Supplies Last)Marcelo Luz MatosAinda não há avaliações

- News Room Services Products Sales Network Manufacturing Units Corporate Profile Financial DataDocumento1 páginaNews Room Services Products Sales Network Manufacturing Units Corporate Profile Financial DataVarun PatelAinda não há avaliações

- HMT RM65 Radial DrillDocumento2 páginasHMT RM65 Radial Drillsomnath213Ainda não há avaliações

- G SpecDocumento1 páginaG SpecVishwanathanAinda não há avaliações

- Encoder 7055Documento2 páginasEncoder 7055Stephane RichardAinda não há avaliações

- 800T/H 30.5 MM Push Buttons NEMA Push Button Specifications: Approximate DimensionsDocumento2 páginas800T/H 30.5 MM Push Buttons NEMA Push Button Specifications: Approximate DimensionsAllen BradleyAinda não há avaliações

- Catalog Hand ToolsDocumento14 páginasCatalog Hand ToolsVijay BelekarAinda não há avaliações

- Gear Lathe MachineDocumento44 páginasGear Lathe MachineBurhoneySonAinda não há avaliações

- Sewing 04-Needle Class 118 of Groz-Beckert For Union Special FlatseamersDocumento6 páginasSewing 04-Needle Class 118 of Groz-Beckert For Union Special Flatseamersfriendztoall4351Ainda não há avaliações

- Fichetechnique-White-Metal Anglais Site 2Documento1 páginaFichetechnique-White-Metal Anglais Site 2sourajpatelAinda não há avaliações

- Bomba Myres I2ci-15rDocumento5 páginasBomba Myres I2ci-15rJemka RodriguezAinda não há avaliações

- Brake Lining, Rivetting & De-Rivetting SystemsDocumento2 páginasBrake Lining, Rivetting & De-Rivetting SystemsC S KumarAinda não há avaliações

- 1100 MRDocumento1 página1100 MRAhmed RamzyAinda não há avaliações

- ST-4S-veer IndustriesDocumento2 páginasST-4S-veer IndustriesManish KumarAinda não há avaliações

- Milling CatalogueDocumento12 páginasMilling CatalogueModi NamanAinda não há avaliações

- Zoom Highlightsub 20SM6072Documento1 páginaZoom Highlightsub 20SM6072Vara PrasadAinda não há avaliações

- Cutting ToolsDocumento246 páginasCutting ToolsHuron Industrial SupplyAinda não há avaliações

- B10 ELECTRA 25300 Catalogue Sheet EN 05 21Documento10 páginasB10 ELECTRA 25300 Catalogue Sheet EN 05 21bulentAinda não há avaliações

- Magnum: Rock BitsDocumento1 páginaMagnum: Rock Bitsmohammad teimuriAinda não há avaliações

- Skyjack SJ 61 T, SJ 66 TDocumento1 páginaSkyjack SJ 61 T, SJ 66 TjohnAinda não há avaliações

- Somani Industries: Complete Rock Mining SolutionDocumento8 páginasSomani Industries: Complete Rock Mining SolutionLeonardo Da-vinciAinda não há avaliações

- Mounting AccessoriesDocumento18 páginasMounting AccessoriesJack BaeAinda não há avaliações

- RASO Series en v001Documento12 páginasRASO Series en v001silviolcAinda não há avaliações

- Everett Product CatalogDocumento20 páginasEverett Product CatalogchevronismeAinda não há avaliações

- 12-25 15MFD 445X 2Documento1 página12-25 15MFD 445X 2mohammad teimuriAinda não há avaliações

- 1100 MSDocumento1 página1100 MSAhmed RamzyAinda não há avaliações

- 12-25 15MFD 447X 2Documento1 página12-25 15MFD 447X 2mohammad teimuriAinda não há avaliações

- Self-Drilling Screws: Key BenefitsDocumento8 páginasSelf-Drilling Screws: Key BenefitsGabriel MacedoAinda não há avaliações

- Ador BookletDocumento22 páginasAdor Bookletgssrraju0% (1)

- Tmp-003-A Oxyacetylene CutingDocumento2 páginasTmp-003-A Oxyacetylene CutingAkaalj InspeccionAinda não há avaliações

- E - Linear Slot Diffusers PDFDocumento17 páginasE - Linear Slot Diffusers PDFabdullah khanAinda não há avaliações

- Product Specifications: Specification Sheet 12 1/4" (311 MM)Documento1 páginaProduct Specifications: Specification Sheet 12 1/4" (311 MM)WHWENAinda não há avaliações

- 00 CINCINNATI No 2 Radius Grinding AttachmentDocumento4 páginas00 CINCINNATI No 2 Radius Grinding AttachmentGilberto GarciaAinda não há avaliações

- Magnum: Rock BitsDocumento1 páginaMagnum: Rock Bitsmohammad teimuriAinda não há avaliações

- Leaflet-Thermoforming - webversion سلسة سحب الفومDocumento6 páginasLeaflet-Thermoforming - webversion سلسة سحب الفوممحمد الجمالAinda não há avaliações

- 【Discontinued Model】SCS Series (1MB)Documento38 páginas【Discontinued Model】SCS Series (1MB)phanuekmkwaptAinda não há avaliações

- FT7000 User 9510Documento22 páginasFT7000 User 9510Son TonAinda não há avaliações

- Neiman Machinery Hydracrop SeriesDocumento8 páginasNeiman Machinery Hydracrop SeriesWilliam RoarkAinda não há avaliações

- 2018 Stonage Fittings and Accessories WebDocumento35 páginas2018 Stonage Fittings and Accessories WeblupiAinda não há avaliações

- Vertex Hose ClampDocumento8 páginasVertex Hose ClampRamasamy PAinda não há avaliações

- Threading System: 300 CompleteDocumento1 páginaThreading System: 300 CompleteAmadeo AlejandroAinda não há avaliações

- Diff Carrier RS13 PlusDocumento4 páginasDiff Carrier RS13 PlusPaulo PereiraAinda não há avaliações

- Rice&wheat Combine HarvesterDocumento4 páginasRice&wheat Combine HarvesterHardeep Singh KangAinda não há avaliações

- Ez Cutter 2018Documento2 páginasEz Cutter 2018um erAinda não há avaliações

- E McqaDocumento19 páginasE McqaTháiSơnTrầnAinda não há avaliações

- Makita Die GrinderDocumento2 páginasMakita Die GrinderEngineerAinda não há avaliações

- HCI - 180 & R-220 Notes BDocumento2 páginasHCI - 180 & R-220 Notes B6KILLERAinda não há avaliações

- John Wilding 16th Century Clock CoverDocumento1 páginaJohn Wilding 16th Century Clock Cover6KILLER100% (1)

- John Wilding 16th Century Clock-SmallDocumento72 páginasJohn Wilding 16th Century Clock-Small6KILLER100% (6)

- Instructions For Parts Books: Note About Country CodesDocumento74 páginasInstructions For Parts Books: Note About Country Codes6KILLERAinda não há avaliações

- C-60 Snowblower ManualDocumento6 páginasC-60 Snowblower Manual6KILLERAinda não há avaliações

- A Source For U90 Brush CapsDocumento1 páginaA Source For U90 Brush Caps6KILLERAinda não há avaliações

- Atlas Babbit Spindle BearingsDocumento3 páginasAtlas Babbit Spindle Bearings6KILLER100% (2)

- Zenoah G230PU Petrol Engine PDFDocumento4 páginasZenoah G230PU Petrol Engine PDF6KILLER100% (1)

- Ysp-900 VLTDocumento272 páginasYsp-900 VLTO gaAinda não há avaliações

- Unwithdrawn Local Materials As of June 06, 2019Documento7 páginasUnwithdrawn Local Materials As of June 06, 2019rachelle gonzalesAinda não há avaliações

- 1630CT0701 - Square D NQ Panelboard Class 1640 CatalogDocumento25 páginas1630CT0701 - Square D NQ Panelboard Class 1640 CatalogBrunophb2012Ainda não há avaliações

- Ga 722645 20220205Documento7 páginasGa 722645 20220205R. Laurent SetjodiningratAinda não há avaliações

- Assembly Drawing DetailDocumento2 páginasAssembly Drawing DetailDearRed FrankAinda não há avaliações

- 40QDU - 38LHU - Catalog (DX - Floor Stand-Big)Documento2 páginas40QDU - 38LHU - Catalog (DX - Floor Stand-Big)Kyaw KoAinda não há avaliações

- Lite Pak Training ManualDocumento24 páginasLite Pak Training ManualGeorge MbuguaAinda não há avaliações

- TOTO Sanitary Catalog July 2021Documento40 páginasTOTO Sanitary Catalog July 2021Yansen HardjokoAinda não há avaliações

- Elna 434 Parts ListDocumento40 páginasElna 434 Parts Liststp717Ainda não há avaliações

- Parts List For:: FB40-8771 Item No.Documento1 páginaParts List For:: FB40-8771 Item No.RASOUL KHADIBIAinda não há avaliações

- 1 in 12 52KgDocumento11 páginas1 in 12 52Kgrailway maintenanceAinda não há avaliações

- REFEReNCIA CRZADA Jacobs CumminsDocumento15 páginasREFEReNCIA CRZADA Jacobs CumminsLUIS LAHUASIAinda não há avaliações

- Storepdfnice Apollo HySecurity 3501 Vanguard Residential Swing Gate Operator Installation ManualDocumento26 páginasStorepdfnice Apollo HySecurity 3501 Vanguard Residential Swing Gate Operator Installation Manualjyzjz6sr65Ainda não há avaliações

- Johnson Power - Maina Gear Coupling CatalogDocumento9 páginasJohnson Power - Maina Gear Coupling CatalogDavid MejidoAinda não há avaliações

- Process & Timing Calculation: Rapid ApproachDocumento9 páginasProcess & Timing Calculation: Rapid ApproachPamela GonzalesAinda não há avaliações

- A. Direction. Write TRUE If The Statement Is Correct and FALSE If It Is Wrong. WriteDocumento4 páginasA. Direction. Write TRUE If The Statement Is Correct and FALSE If It Is Wrong. WriteShabby Gay TroganiAinda não há avaliações

- LE40B535P7W User Manual PDFDocumento158 páginasLE40B535P7W User Manual PDFTy3aPaAinda não há avaliações

- Power Supply, Ground & Circuit Elements: SectionDocumento74 páginasPower Supply, Ground & Circuit Elements: SectionederengAinda não há avaliações

- Snack & Drink Vending MachinesDocumento14 páginasSnack & Drink Vending MachinesAbel TeferaAinda não há avaliações

- Caleffi Central HeatingDocumento1 páginaCaleffi Central HeatingSite OfficeAinda não há avaliações

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDocumento16 páginasClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyJoseph RaventhAinda não há avaliações