Escolar Documentos

Profissional Documentos

Cultura Documentos

TR Differential Ret670

Enviado por

Sebastián SolisTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

TR Differential Ret670

Enviado por

Sebastián SolisDireitos autorais:

Formatos disponíveis

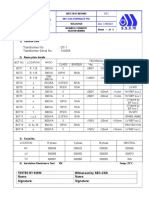

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 1 of 19

Contractor: Contract no.: Substation No :

Note:

The approved updated final settings should be applied and printed out from

the relay by using the software of the relay.

The approved final setting and the printout final setting should be attached

with this test format.

The print out final setting should be signed by SEC AND Contractor.

The following test format contains minimum required tests and some of

settings are mentioned as an example and not as limitation.

1. GENERAL DATA & INFORMATION

Panel No. CT Ratio of HV Side

Relay Type TR DIFF + REF CT Ratio of LV Side

Manufacturer Draw. & Sh No.

Serial No Dc. Auxiliary. Voltage 125VDC

Order - No. 1MRK004816-DC Frequency Fn 60 Hz

Software Version 1.2.3 Opto-Coupler Supply: 125 V

2. MECHANICAL CHECKS AND VISUAL INSPECTION

As per TCS –P–105 Rev -1, Item no 4.1& 4.12.1.1

ITEM DESCRIPTION REMARKS

1. Inspect for any physical damage or defects. Yes N/A

2. Verify connections and ferrules as per approved drawings Yes N/A

3. Check tightness of all the connections. Yes N/A

4. Check Apparatus List Yes N/A

Check relay version and switching elements on printed circuit

5. Yes N/A

board

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 2 of 19

Contractor: Contract no.: Substation No :

3. ELECTRICAL TESTS

As per TCS –P–105 Rev -1, Item no 4.2& 4.12.1.2

3.1. Function Test

ITEM DESCRIPTION REMARKS

1. Human Machine Interface (HMI) Checked. Yes N/A

2. Case Earthing checked. Yes N/A

3. LED’s Function Checked. Yes N/A

4. Trip Contacts Checked. Yes N/A

5. Reset Function Checked Yes N/A

6. Group active Functions Checked Yes N/A

7. Binary inputs checked. Yes N/A

8. Output Relays Checked Yes N/A

9. Event Display on HMI Screen Checked Yes N/A

10. Test switch / plug checked for correct function. Yes N/A

11. Watchdog contacts checked Yes N/A

12. Current shorting facility. Yes N/A

3.2. OPERATING DC SUPPLY CURRENT

DC current w/o DC current with

DC voltage (V) Max. calculated watt (W)

fault (mA) fault(mA)

125

Limit: DC burden 50 watts. (Refer to the reference technical manual page 391).

3.3. WATCH DOG CHECK

SUPPLY OFF

TERMINALS (CLOSED) - (X11:2, X11:3) :

TERMINALS (OPEN) - (X11:2, X11:1) :

SUPPLY ON

TERMINALS (CLOSED) - (X11:1, X11:2) :

TERMINALS (OPEN) - (X11:3, X11:2) :

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 3 of 19

Contractor: Contract no.: Substation No :

3.4. TIME AND DATE CHECK:-

To check time &date go to main menu on the display for RET670 then system

time and adjust time &date.

To test this, remove the auxiliary supply from the relay for approximately 30

seconds, then restoring the auxiliary supply, the time and date should be

correct.

Result: ____________

3.5. SETTING ADOPTED:

Transformer Data: (All Values as an example)

Winding 1 ( HV ) Winding 2 ( LV ) Winding 3 (Tertiary.)

Connection Type Y0 y0 d1

Capacity ( MVA ) 100 100

Rated Voltage ( KV ) 132 33

Rated Current ( A ) 437 1750

CT Data:

CT 1 ( HV ) CT 2 ( LV ) CT 3 (Tertiary.)

Connection Type Y y

Primary Current ( A ) 800 2000

Secondary Current (A ) 1 1

Calculated Amplitude Matching Factor (K):

KX = CTX / Rated Current of Ref. Wdg

Where Ref. Wdg is First Wdg with Y connection. If no Y connection then HV

side selected automatically

KHV = 1.830

KLV = 1.143

KTerit. =

General Differential Equation:

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 4 of 19

Contractor: Contract no.: Substation No :

Where

1. is Differential Current

2. is Differential Current Contribution from W1 side

3. is Differential Current Contribution from W2 side

4. is Differential Current Contribution from W3 side

A, B, C is a coefficients depended on vector group; refer to Manual to get

exact value.

3.6. SECONDARY INJECTION TESTS: (ALL VALUES AS AN EXAMPLE)

3.6.1. MEASUREMENTS (HV side):

TRM P40 - 9I+3U

Injected Measured Values

Channel DUTY CTR REMARKS

Values Primary Sec

CH 1-I W1 CT IL1

CH 2-I W1 CT IL2

CH 3-I W1 CT IL3

CH 4-I W1 CT IN

CH 5-I W2 CT IN

CH 6-I W2 CT IL1

CH 7-I W2 CT IL2

CH 8-I W2 CT IL3

CH 9-I Spare

CH 10-U W1 VT Ph-R

CH 11-U W1 VT PhY

CH 12-U W1 VT Ph-B

Limits: Amplitude Accuracy; ± 0.5 % Ir

According to the Catalogue for Technical Data Page: 32

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 5 of 19

Contractor: Contract no.: Substation No :

3.6.2. PICK- UP & DROP- OFF TEST FOR DIFFERENTIAL CURRENT (ID):

This is single phase injection test.

Disable SOTF facility.

Disable any Negative Sequence facility.

Disable zero Sequence removing facility.

Apply equation at page 3 the Diff. Eq. for single phase injection, 2

winding will be:

IDLx = A. KHV. Iw1Lx + B. (U2/U1). KLV. Iw2L

Where x represents the concerted phase

HV Winding

Measured Value Drop Out Operating Time @

Id min.

Calculated (A) Pick Up 2X

Phase Set Value

value (A) Ratio I pick up (ms)

Pick up Drop out

0.1

R 0.3

0.5

0.1

Y 0.3

0.5

0.1

B 0.3

0.5

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 6 of 19

Contractor: Contract no.: Substation No :

LV Winding

Measured Value Drop Out Operating Time @

Id min.

Calculated (A) Pickup 2X

Phase Set Value

value ( A ) Pick up Drop out Ratio I pickup (ms)

0.1

R 0.3

0.5

0.1

Y 0.3

0.5

0.1

B 0.3

0.5

Limits: Pick up & Drop Out ±2% of Ir for I < Ir or ±2% of I for I > Ir,

Reset Ratio > 95%,

Timing tolerance Typically 25 ms for 2 Id, and 12 ms for 5 Id for

unrestrained function ,

According to the Catalogue for Technical Data Page: 143

3.6.3. PICK-UP & DROP-OFF TEST FOR UNRESTRAINED DIFFERENTIAL

CURRENT (ID):

H.V Winding

Measured Value

Drop Out Operating Time

(A)

Phase Set Value Calculated Pickup @ 5X

value ( A ) Pick Ratio I pickup (ms)

Drop out

up

2.00

R 3.00

5.00

2.00

Y 3.00

5.00

2.00

B 3.00

5.00

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 7 of 19

Contractor: Contract no.: Substation No :

L.V Winding

Measured Value Drop Out Operating Time @

Calculated (A)

Phase Set Value Pickup 5X

value ( A )

Ratio I pickup (ms)

Pick up Drop out

2.00

R 3.00

5.00

2.00

Y 3.00

5.00

2.00

B 3.00

5.00

3.6.4. BIAS CHARACTERISTIC TESTING

Inject H.V and L.V phase with equal current on each, and angle 0 for

H.V and 180 for L.V, then decrease L.V Phase until trip, while leave

H.V with fixed current which will be the bias current, and record

values and check that corresponds to following equation.

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 8 of 19

Contractor: Contract no.: Substation No :

a. Section 1 (All Values as an example)

Where bias current is between:

0 ≤ Ibias ≤ Endsection1

Idmin = 0.3 ,

Set End section1 = 1.25

Slope I bias IH.V Expected Id Measured IL.V (A) Errors %

section1 (A) (A) IL.V (A) calculated R Y B R Y B

0.3 0.3

Idmin 0.4 0.3

1.00 0.3

Limits; ± 2 %Ir According to the Technical Reference Catalogue

– Page24

b. SLOPE Section 2 (All Values as an example)

When bias current is between:

Endsection1 ≤ Ibias ≤ Endsection2

Trip Id = (Idmin + slope section2/100 *(Ibias - End section1) A

Where; Idmin ; The Basic Diff Current Setting.

To check more than one point at the same slope, Change the bias

current value and the equation above can be used, and also for

other differential settings '' Different slopes, Is1 ''.

Apply the above procedure for each phase.

Set Idmin = 0.3

End section1 = 1.25

End section2 =3.0

Slope section 2 = 40%

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 9 of 19

Contractor: Contract no.: Substation No :

Ibias IH.V = Ibias / Expected Id Measured IL.V (A) Errors %

A kHV A IL.V = (Ibias calculated R Y B R Y B

– Id) / kLV

(A)

1.25 0.300

1.50 0.400

1.75 0.500

2.00 0.600

2.25 0.700

2.50 0.800

Limits; ± 2 %Ir According to the Technical Reference Catalogue – Page24

c. SLOPE Secton3 (All Values as an example)

Repeat the test and check the result with the following

equation;

When bias current is more than:

Ibias ≥ End section2

Trip Id = (Idmin + slope section2/100*(End section2 - End section1)) +

(Slope section3/100 * (Ibias- End section2)) A

Set End section1 = 1.25

End section2 =3.0

Slope section1 = 40%

Slope section2 = 80%

Idmin = 0.3

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 10 of 19

Contractor: Contract no.: Substation No :

I bias IH.V = Ibias Expected IL.V = Id Measured IL.V Errors %

A / kHV A (Ibias – Id) / kLV calculated (A)

(A) R Y B R Y B

3.0 1.000

3.5 1.400

4.0 1.800

4.5 2.200

Limits; ± 2 %Ir According to the Technical Reference Catalogue

– Page24

3.6.5. Test of 2nd Harmonics (All Values as an example)

Idmin = 0.3 Ib

I1 ( F =60 Hz ) I2 ( F = 120 Hz )

Phase I2 / I1 ratio %

(Pickup Value) Expected Blocking Measured

R 10 1.0 0.100

Y 50 1.0 0.500

B 100 1.0 1.00

3.6.6. Test of 5th Harmonics

I5 ( F = 300 Hz )

Phase I5 / I1 ratio % I1 ( F =60 Hz )

Expected Blocking Measured

R 15 1.0 0.150

Y 30 1.0 0.300

B 50 1.0 0.500

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 11 of 19

Contractor: Contract no.: Substation No :

3.6.7. CROSS BLOCK TEST

Cross Cross

Winding IR IY IB

Block on Block Off

I > pickup

I > pickup with

without 2nd

2nd harmonic

harmonic

I > pickup

I > pickup with

HV without 2nd

2nd harmonic

harmonic

I > pickup

I > pickup with

without 2nd

2nd harmonic

harmonic

I > pickup

I > pickup with

without 2nd

2nd harmonic

harmonic

I > pickup

I > pickup with

l.V without 2nd

2nd harmonic

harmonic

I > pickup

I > pickup with

without 2nd

2nd harmonic

harmonic

Test done at I2/I1= 15%, I5/I1 = 25 %

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 12 of 19

Contractor: Contract no.: Substation No :

3.6.8. NEGATIVE SEQUENCE TEST:

IminNegSeq test :

INegSeq. =1/3 { IR + a2 IY + a IB } , where a = 1120

Irelay = Iinject * K

And we at test inject single phase then :

Irelaynegseq = 1/3 Iinject * K

IH.V ( > IMinNegSeq setting )

IMinNegSeq setting Expected IL..V (A) Measured IL..V (A)

(A)

0.04 0.11 0.100

0.08 0.22 0.201

0.09 0.24 0.226

Negative sequence Relay Operating Angle (NegSeqROA ) test :

Inject H.V & L.V > IMinNegSeq

Inject H.V with angle zero degree and change the L.V to get the operating zone.

Expected IL..V angle for Measured IL..V angle for

NegSeqROA setting

operating zone (Deg) operating zone (Deg)

30 330 – 30

40 320 – 40

80 280 – 80

Sensitive negative sequence ( turn-to-turn fault ) test:

This function based on Negative sequence discriminator . where if there is no start signal ( independent on

existence or not for start signal ) and the fault is classified as internal fault and at same time for H.V and L.V

sides the negative sequence current is greater than IminNegSeq .. then trip transformer

To test it , inject single phase from 2 winding in phase and increase them at same time until trip , ( must

happen by ssneg only not restrain function ) .

Status ____________________

3.7.HV REF:

PICK/UP AND DROP/OFF TEST

Idiff = IN + 3I0

Ibias = the highest current at 3 Phases or Neutral

Inj. Curr. to Setting value P/Up (A) D/Off (A)

IN 10% IB

IN 20% IB

Limits : ± 2.0% of Ir at I £ Ir

± 2.0% of I at I > Ir Reset ratio > 95%

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 13 of 19

Contractor: Contract no.: Substation No :

3.7.1. TIMING TEST:

Inj. Curr. to Setting value Inj current (A) Meas time (ms)

IN 10% IB

Limits : 20 ms typically at 0 to 10 x Id

HV REF (REFPDIF) DIRECTIONALITY CHECK

Injected Current

Phase Id Min Setting ROA Meas. ROA

3I0 IN

3I0

0.1 x IB 600 0.1 A ∟00 0.1 A ∟00

IN

Limits : ± 2.0 degree

3.7.2. SLOPE TEST:

As per technical reference manual page 147, 148:

End zone 1=125% IB

End zone 2=2.536 (calculated from the graph at our setting Idmin=10%).

First Slope =70%.

Second Slope=100%.

Current Injected

I 1st 2nd

Slope1 Slope1 Slope1 Slope1 I diff Remarks

Injection bias Slope Slope

IN 3I0 IN 3I0

1.25 A

HV 3I0 1.50 A

& 2.536 A

HV IN 3.00 A

5.00 A

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 14 of 19

Contractor: Contract no.: Substation No :

3.8. LV REF:

3.8.1. PICK/UP AND DROP/OFF TEST

Idiff = IN + 3I0

Ibias = the highest current at 3 Phases or Neutral

Inj. Current to Setting value P/Up (A) D/Off (A)

IN 10% IB

IN 20% IB

Limits : ± 2.0% of Ir at I £ Ir

± 2.0% of I at I > Ir Reset ratio > 95%

3.8.2. TIMING TEST:

Inj. Curr. to Setting value Inj current (A) Meas time (ms) Remarks

IN 10% IB

Limits : 20 ms typically at 0 to 10 x Id

3.8.3. LV REF (REFPDIF) DIRECTIONALITY CHECK:

Injected Current

Phase Id Min Setting ROA Meas. ROA

3I0 IN

3I0

0.1 x IB 600 0.1 A ∟00 0.1 A ∟00

IN

Limits : ± 2.0 degre

3.8.4. SLOPE TEST:

As per technical reference manual page 147, 148:

End zone 1=1.25*IB

End zone 2=2.536*IB (calculated from the graph at our setting Idmin=10%).

First Slope =70%. Second Slope =100%.

Current Injected

2nd

Slope1 Slope1 Slope1 Slope1 I diff I bias 1st Slope Remarks

Injection Slope

IN 3I0 IN 3I0

1.25 A

HV 3I0 1.50 A

&

HV IN 2.536 A

3.00 A

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 15 of 19

Contractor: Contract no.: Substation No :

3.9. WINDING-1 OVERCURRENT & EARTH FAULT PROTECTION TEST

3.9.1. PICK/UP AND DROP/OFF TEST

Current OC4TOC: 1 Current EF4TOC: 1 [IO>]

Setting R Y B Setting N

Amps Amps

Pick Up Drop Off Pick Up Drop Off Pick Up Drop Off Pick Up Drop Off

I> Io>

1xIn = 1 0.1xIn = 0.1

1.5xIn = 1.5 0.3xIn = 0.3

Limits : ± 1.0% of Ir at I £ Ir

± 1.0% of I at I > Ir Reset ratio > 95%

3.9.2. TIMING TEST

INJECT EXPECTED OPERATING TIME (SEC), TMS = 1.0

RANGE

FUNCTION CURRENT TIME

SEC

AMPS SEC R Y B N

IEC 2 x Isetting 10.03 10.52 – 9.519

NORMAL

INVERSE 10 x Isetting 2.97 3.188 – 2.82

IEC 2 x Isetting 13.5 14.175 – 12.825

NORMAL

INVERSE 10 x Isetting 1.5 1.57 – 1.42

IEC 2 x Isetting 26.67 28.00 – 25.336

NORMAL

INVERSE 10 x Isetting 0.808 0.848 – 0.767

IEC 2 x Isetting 120 126 – 114

NORMAL

INVERSE 10 x Isetting 13.333 13.999 – 12.666

Limits: IEC 60255-3, class 5 + 40 ms

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 16 of 19

Contractor: Contract no.: Substation No :

3.10. WINDING 2 OVERCURRENT& EARTH FAULT PROTECTION TEST

3.10.1. PICK/UP AND DROP/OFF TEST

Current OC4TOC: 2 Current EF4TOC: 2 [IO>]

Setting R Y B Setting N

Amps Amps

Pick Up Drop Off Pick Up Drop Off Pick Up Drop Off Pick Up Drop Off

I> Io>

1xIn = 1 0.1xIn = 0.1

1.5xIn = 1.5 0.3xIn = 0.3

Limits : ± 1.0% of Ir at I £ Ir

± 1.0% of I at I > Ir

3.10.2. TIMING TEST

INJECT EXPECTED OPERATING TIME (SEC), TMS = 1.0

RANGE

FUNCTION CURRENT TIME

SEC

AMPS SEC R Y B N

IEC 2 x Isetting 10.03 10.52 – 9.519

NORMAL

INVERSE 10 x Isetting 2.97 3.188 – 2.82

IEC 2 x Isetting 13.5 14.175 – 12.825

NORMAL

INVERSE 10 x Isetting 1.5 1.57 – 1.42

IEC 2 x Isetting 26.67 28.00 – 25.336

NORMAL

INVERSE 10 x Isetting 0.808 0.848 – 0.767

IEC 2 x Isetting 120 126 – 114

NORMAL

INVERSE 10 x Isetting 13.333 13.999 – 12.666

Limits : IEC 60255-3, class 5 + 40 ms

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 17 of 19

Contractor: Contract no.: Substation No :

3.11. RESIDUAL OVER CURRENT (EF4PTOC:3) STEP 1 NEUTRAL ALARM

3.11.1. PICK UP AND DROP-OFF TEST:

Current EF4TOC: 3 [IO>]

Setting N

Amps

Pick Up Drop Off

Io>

0.03xIn = 0.03

0.05xIn = 0.05

3.11.2. TIMING TEST

INJECTED TIME OPERATING TIME

CURRENT SETTING

Amps sec N

0.05

0.1

Limits: ± 0.5% of set time ± 10 ms

3.12. RESIDUAL OVER CURRENT (EF4PTOC:3)

STEP 2 SENSITIVE EARTH FAULT

3.12.1. PICK UP AND DROP-OFF TEST:

Current EF4TOC: 3 [IO>>]

Setting N

Amps

Pick Up Drop Off

Io>>

0.05xIn = 0.05

0.1xIn = 0.1

Limits: ± 1.0% of Ir at I £ Ir

± 1.0% of I at I > Ir

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 18 of 19

Contractor: Contract no.: Substation No :

3.12.2. TIMING TEST

Ion=1A, Is (Io>>) =0.3 x Ion =0.3A,

OPERATING TIME (SEC),

INJECT EXPECTED TMS = 1.0 RANGE

FUNCTION CURRENT TIME

SEC

AMPS SEC N

IEC 2 x Isetting 10.03 10.52 – 9.519

NORMAL

INVERSE 10 x Isetting 2.97 3.188 – 2.82

IEC 2 x Isetting 13.5 14.175 – 12.825

NORMAL

INVERSE 10 x Isetting 1.5 1.57 – 1.42

IEC 2 x Isetting 26.67 28.00 – 25.336

NORMAL

INVERSE 10 x Isetting 0.808 0.848 – 0.767

IEC 2 x Isetting 120 126 – 114

NORMAL

INVERSE 10 x Isetting 13.333 13.999 – 12.666

Limits : IEC 60255-3, class 5 + 40 ms

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: RET670 TRANSFORMER DIFFERENTIAL

Equip. No. Drawing ref.: Page 19 of 19

Contractor: Contract no.: Substation No :

15 : BREAKER FAILURE (CCRBRF:2)

15.1: PICK UP TEST:

OC4PTOC: 2

CURRENT

R Y B

SETTING

Amps I> P/U P/U P/U

A A A

0.1 X In=0.1

0.2X In=0.2

0.3 X In=0.3

Limits : ± 1.0% of Ir at I £ Ir

± 1.0% of I at I > Ir

15:2 TIMING TEST

TIME operating time in sec

SETTING

SEC R Y B

0.1

0.2

0.3

Limits : ± 0.5% of set time ± 10 ms

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Você também pode gostar

- T 60 Diff SimulatorDocumento4 páginasT 60 Diff SimulatorNeelakandan MasilamaniAinda não há avaliações

- Sel421 Relay Setting CalculationDocumento58 páginasSel421 Relay Setting Calculation1453h100% (1)

- 7ut85 Relay Test ReportDocumento5 páginas7ut85 Relay Test ReportAbhishek Rajput100% (1)

- 7ss - Busbar Low Imp Relay Test-1Documento17 páginas7ss - Busbar Low Imp Relay Test-1Ravi100% (3)

- 7UT612 ProcedureDocumento10 páginas7UT612 Procedurem khAinda não há avaliações

- Project Name: Dcu Test Report For Motor Protection RelayDocumento4 páginasProject Name: Dcu Test Report For Motor Protection RelayArul Kumar100% (1)

- Site Acceptance Test Report For 33Kv Cable: Project: Construction of 306 Villas - Al SaadDocumento3 páginasSite Acceptance Test Report For 33Kv Cable: Project: Construction of 306 Villas - Al SaadJayaprakash M PAinda não há avaliações

- Distance RELAY TEST REPORTDocumento2 páginasDistance RELAY TEST REPORTFareh Khan100% (1)

- Substation DesignDocumento764 páginasSubstation Designprashious100% (2)

- Substation DesignDocumento764 páginasSubstation Designprashious100% (2)

- Robin Ex13 Parts ManualDocumento42 páginasRobin Ex13 Parts ManualkatilicousAinda não há avaliações

- LV Distribution Fuse Board (Feeder Pillar) Kahramaa SpecificationDocumento29 páginasLV Distribution Fuse Board (Feeder Pillar) Kahramaa SpecificationRaison Mukkath100% (5)

- Red670 Distance Line DifferentialDocumento23 páginasRed670 Distance Line DifferentialRatheesh KumarAinda não há avaliações

- 7sd Line Differentrial Relay TestDocumento28 páginas7sd Line Differentrial Relay TestAnoss Olier100% (1)

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDocumento2 páginasTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun AhsanAinda não há avaliações

- Sel-487v Relay Test For CapacitorDocumento21 páginasSel-487v Relay Test For CapacitorSentaAinda não há avaliações

- 7sa Line Distance Relay TestDocumento34 páginas7sa Line Distance Relay Testsubhasish sarkarAinda não há avaliações

- Commissioning Service Department Commissioning Standard Test Formats Description: Line Distance & Directional Ef Protection-7Sa522Documento34 páginasCommissioning Service Department Commissioning Standard Test Formats Description: Line Distance & Directional Ef Protection-7Sa522subhasish sarkar100% (1)

- Ref615 - Oc Ef Relay TestDocumento8 páginasRef615 - Oc Ef Relay TestMeghavahinaAinda não há avaliações

- TR Differential Ret670Documento19 páginasTR Differential Ret670Mahdi AlamriAinda não há avaliações

- 7SR1587 Voltage and Frequency RelayDocumento4 páginas7SR1587 Voltage and Frequency RelayAnonymous dH3DIEtzAinda não há avaliações

- Non Dir. O/C Relay ARGUS - 7SR1102: 1. General Data & InformationDocumento6 páginasNon Dir. O/C Relay ARGUS - 7SR1102: 1. General Data & InformationAnonymous dH3DIEtzAinda não há avaliações

- Site Test Report For OVER CURRENT Relay (7SJ60XX) : Customer Contract # Project Job # Location Equipment TagDocumento4 páginasSite Test Report For OVER CURRENT Relay (7SJ60XX) : Customer Contract # Project Job # Location Equipment TagAdetunji TaiwoAinda não há avaliações

- Rel670 - Line DistanceDocumento17 páginasRel670 - Line DistanceRatheesh KumarAinda não há avaliações

- p443 - Line DistanceDocumento31 páginasp443 - Line Distancem khAinda não há avaliações

- Abb Rec670 Cap Bank ProtnDocumento11 páginasAbb Rec670 Cap Bank ProtnRatheesh KumarAinda não há avaliações

- Testing of Relays and Detailed ProcedureDocumento30 páginasTesting of Relays and Detailed Proceduresetyo nugrohoAinda não há avaliações

- Line Distance Protection Relay Rcs 902aDocumento36 páginasLine Distance Protection Relay Rcs 902aEng-Abdallh GremanAinda não há avaliações

- Final END To END Test MAIN 1 FormatDocumento69 páginasFinal END To END Test MAIN 1 FormatVAJIRAVEL NAGALINGAM50% (2)

- O/C E/F Relay Test ReportDocumento2 páginasO/C E/F Relay Test ReportMd. zahidul IslamAinda não há avaliações

- 2.u#1 11KV Switchgear Testing Book-2 PDFDocumento219 páginas2.u#1 11KV Switchgear Testing Book-2 PDFSabyasachi PatraAinda não há avaliações

- GT - 1 Bushing Current Transformer Ir Test ReportDocumento5 páginasGT - 1 Bushing Current Transformer Ir Test ReportPrathap KumarAinda não há avaliações

- Dist Relay Test ProcedureDocumento7 páginasDist Relay Test ProcedureTamilventhan S100% (1)

- Transformer Stability Test: Differential Relay As Well As REF Relay StabilityDocumento4 páginasTransformer Stability Test: Differential Relay As Well As REF Relay StabilityHosam JabrallahAinda não há avaliações

- T60TDocumento39 páginasT60TMourad BenderradjiAinda não há avaliações

- P 220 Testing ProcedureDocumento8 páginasP 220 Testing ProcedureRanjit Rjt100% (3)

- 25ref RelayDocumento8 páginas25ref Relaysikander843562Ainda não há avaliações

- Rel670 Relay Graphs: Parameters System Details Range ValueDocumento3 páginasRel670 Relay Graphs: Parameters System Details Range ValueMuhammad Imran Sharif100% (1)

- VT Secondary Injection FormatDocumento3 páginasVT Secondary Injection FormatDanish AfzalAinda não há avaliações

- 546 MicomDocumento37 páginas546 MicomNambiAinda não há avaliações

- Protective Relay Requirements and ApprovalsDocumento8 páginasProtective Relay Requirements and ApprovalsJorge DuranAinda não há avaliações

- SOTFDocumento13 páginasSOTFK Vijay Bhaskar ReddyAinda não há avaliações

- P343 Test FormatDocumento8 páginasP343 Test Formatrohitctpp0% (1)

- Over Current and Earth Fault Protection Relay CommissioningDocumento7 páginasOver Current and Earth Fault Protection Relay Commissioningkemu sindiAinda não há avaliações

- Ict-1 Test ReportDocumento41 páginasIct-1 Test ReportSuresh Chandra PadhyAinda não há avaliações

- Testing of Micom P546 - Dist - Def - LinediffDocumento37 páginasTesting of Micom P546 - Dist - Def - Linediffsamlash100% (2)

- Distance Relay Calculation Format For 220KV LineDocumento10 páginasDistance Relay Calculation Format For 220KV LineNishanth KumarAinda não há avaliações

- ISA Introduction To The Test of Protection RelaysDocumento23 páginasISA Introduction To The Test of Protection RelaysCata CatalinAinda não há avaliações

- TAN DELTA Testing ProcedureDocumento6 páginasTAN DELTA Testing ProcedureKamlesh MhatreAinda não há avaliações

- Line 1 (4) - 403 (401) - 400KV Guindy # (Reviised)Documento15 páginasLine 1 (4) - 403 (401) - 400KV Guindy # (Reviised)1453hAinda não há avaliações

- 7SA611 SettingDocumento10 páginas7SA611 SettingcuamiAinda não há avaliações

- Trafo. Diff Slope Calc Micom p643Documento4 páginasTrafo. Diff Slope Calc Micom p643Anoss OlierAinda não há avaliações

- Directional Earth Fault ProtectionDocumento1 páginaDirectional Earth Fault ProtectionSenthilkumaran VenkatasamyAinda não há avaliações

- RET 670 3windingDocumento4 páginasRET 670 3windingm khAinda não há avaliações

- Current Transformer (TPU 50.23) - FAT ReportsDocumento45 páginasCurrent Transformer (TPU 50.23) - FAT Reportsmad_sam282729Ainda não há avaliações

- K15 - 11kV BS-1 - F25 PDFDocumento7 páginasK15 - 11kV BS-1 - F25 PDFmadhavanAinda não há avaliações

- Testing of BushingDocumento8 páginasTesting of BushingAmir Ali khanAinda não há avaliações

- Commissioning Test Report For Differential Relay: 7SR242 Page 1/5Documento5 páginasCommissioning Test Report For Differential Relay: 7SR242 Page 1/5apsAinda não há avaliações

- Line Differential Red670Documento12 páginasLine Differential Red670Ashish ChughAinda não há avaliações

- 7ut - Transformer Diff Relay TestDocumento25 páginas7ut - Transformer Diff Relay TestAnoss Olier100% (2)

- Transformer Diff - p643Documento20 páginasTransformer Diff - p643rajeshAinda não há avaliações

- Commissioning Service Department Commissioning Standard Test Formats Description: HIGH IMP. DIFF PROT. - MFAC34Documento5 páginasCommissioning Service Department Commissioning Standard Test Formats Description: HIGH IMP. DIFF PROT. - MFAC34saiAinda não há avaliações

- Line Diff - p546Documento9 páginasLine Diff - p546shanthikumaravel100% (1)

- Commissioning Service Department Commissioning Standard Test Formats Description: Low Impedance Busbar Protection Relay Type - 7Ss522Documento17 páginasCommissioning Service Department Commissioning Standard Test Formats Description: Low Impedance Busbar Protection Relay Type - 7Ss522Arun KumarAinda não há avaliações

- Auto-Reclosure Synchro-Check & Voltage CheckDocumento31 páginasAuto-Reclosure Synchro-Check & Voltage CheckMouhemed MouhaAinda não há avaliações

- 66kV Outdoor Surge ArresterDocumento6 páginas66kV Outdoor Surge Arresterm khAinda não há avaliações

- BasicsDocumento30 páginasBasicsm khAinda não há avaliações

- Rollarc CompleteDocumento30 páginasRollarc Completem khAinda não há avaliações

- Current Transformers: CT BasicsDocumento22 páginasCurrent Transformers: CT BasicsThankyou ThankyouAinda não há avaliações

- Electrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 3Documento8 páginasElectrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 3m khAinda não há avaliações

- كتالوج لخلايا الضغط المتوسط وقواطع الدوره لشركةDocumento109 páginasكتالوج لخلايا الضغط المتوسط وقواطع الدوره لشركةm khAinda não há avaliações

- Analysis of Unbalanced FaultsDocumento22 páginasAnalysis of Unbalanced FaultsMiguel CbAinda não há avaliações

- Electrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 1Documento10 páginasElectrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 1m khAinda não há avaliações

- 1MRK000066 DaDocumento7 páginas1MRK000066 Dabuzka000Ainda não há avaliações

- Prediccion Baterias Por Resistencia Interna PDFDocumento8 páginasPrediccion Baterias Por Resistencia Interna PDFandres guerreroAinda não há avaliações

- Bus Protection FundamentalsDocumento66 páginasBus Protection Fundamentalshugopacoluis1Ainda não há avaliações

- Electrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 4Documento11 páginasElectrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 4m khAinda não há avaliações

- Electrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 4Documento11 páginasElectrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 4m khAinda não há avaliações

- Electrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 2Documento8 páginasElectrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 2m khAinda não há avaliações

- 32A.Power System Protection Notes Vol-1-BnewDocumento286 páginas32A.Power System Protection Notes Vol-1-Bnewm khAinda não há avaliações

- Neutral Earthing Resistors or Reactors Application GuideDocumento98 páginasNeutral Earthing Resistors or Reactors Application Guideecordero78100% (1)

- Commissioning Services Department Commissioning Manual Factory Type and Routine TestsDocumento19 páginasCommissioning Services Department Commissioning Manual Factory Type and Routine Testsm khAinda não há avaliações

- EHV - Grounding TransformerDocumento23 páginasEHV - Grounding Transformerm kh100% (1)

- Siemens 8djh EngDocumento80 páginasSiemens 8djh EngAris HabbilAinda não há avaliações

- Prediccion Baterias Por Resistencia Interna PDFDocumento8 páginasPrediccion Baterias Por Resistencia Interna PDFandres guerreroAinda não há avaliações

- 1-Calculator For OC Tripping Time.Documento7 páginas1-Calculator For OC Tripping Time.m khAinda não há avaliações

- GK PresentationDocumento256 páginasGK Presentationgkpalepu100% (18)

- Basics of Distance Protectionjg1Documento71 páginasBasics of Distance Protectionjg1m khAinda não há avaliações

- DC Ground 2 PDFDocumento5 páginasDC Ground 2 PDFm khAinda não há avaliações

- Installation Guide: Protection and Control IED Manager PCM600 1MRS756450Documento2 páginasInstallation Guide: Protection and Control IED Manager PCM600 1MRS756450m khAinda não há avaliações

- Testing Considerations For Distance Protection LatestDocumento46 páginasTesting Considerations For Distance Protection Latestm kh50% (2)

- Sip5 Apn 030Documento48 páginasSip5 Apn 030sajjad ramezanzadehAinda não há avaliações

- 2015 F150 SpecsDocumento2 páginas2015 F150 SpecsSufian MahadinAinda não há avaliações

- SIEMENS - 1500 based - ET200SP PLC CPU 型錄Documento10 páginasSIEMENS - 1500 based - ET200SP PLC CPU 型錄CHIENMAO WUAinda não há avaliações

- Service Manual: Xga Color Monitor Model: 531XDocumento26 páginasService Manual: Xga Color Monitor Model: 531XStefanAinda não há avaliações

- DXR75 1000 June 1996Documento2 páginasDXR75 1000 June 1996SergiSerranoAinda não há avaliações

- DM4000 Accessories Fact SheetDocumento4 páginasDM4000 Accessories Fact SheetSydney Sam S PhiriAinda não há avaliações

- Standard Deep Groove Ball Bearings by JESADocumento3 páginasStandard Deep Groove Ball Bearings by JESAAjanta BearingAinda não há avaliações

- LO550Documento40 páginasLO550alejandro inocenteAinda não há avaliações

- Otm API Ring GrooversDocumento4 páginasOtm API Ring GrooverssandipjawalkarAinda não há avaliações

- Microprocessors and Microcontroller System-Prelim Lab Quiz 2-20-20Documento6 páginasMicroprocessors and Microcontroller System-Prelim Lab Quiz 2-20-20Dr.DokieAinda não há avaliações

- Automation: PLC S7 1200 Training PanelDocumento1 páginaAutomation: PLC S7 1200 Training PanelLulzim MulliqiAinda não há avaliações

- Jazz GK5 Charging System Circuit Diagram Build-In Type MICUDocumento1 páginaJazz GK5 Charging System Circuit Diagram Build-In Type MICUTomyAinda não há avaliações

- Fluid-Manual Transmission 48-25859 A: ScopeDocumento1 páginaFluid-Manual Transmission 48-25859 A: ScopeJOSE MIGUELAinda não há avaliações

- L. A. Bryan E. A. Bryan - Programmable Controllers - Theory and Implementation-Industrial Text Co (1997) - 229-237Documento9 páginasL. A. Bryan E. A. Bryan - Programmable Controllers - Theory and Implementation-Industrial Text Co (1997) - 229-237Obada Ar-ruzziAinda não há avaliações

- Television HistoryDocumento5 páginasTelevision HistoryJaider Mercado López100% (1)

- Trolleys C7Documento4 páginasTrolleys C7mahmoudglobaltechAinda não há avaliações

- Instruction Sheet 735 3101: Industrial Frequency Converter 400 V (735 3101)Documento4 páginasInstruction Sheet 735 3101: Industrial Frequency Converter 400 V (735 3101)John Philip Rosario SabayleAinda não há avaliações

- IDC 800HP Self-Prop Drilling Rig S&P CD S1 IntroDocumento24 páginasIDC 800HP Self-Prop Drilling Rig S&P CD S1 IntroIDC-47Ainda não há avaliações

- Volume: Iih Section-Iii Operation and Control Philosophy: (PCA - CD-003.491798982Documento13 páginasVolume: Iih Section-Iii Operation and Control Philosophy: (PCA - CD-003.491798982Anonymous 5XvUbWynnAinda não há avaliações

- 11 - 7-Series Architecture OverviewDocumento56 páginas11 - 7-Series Architecture OverviewbaluAinda não há avaliações

- Experiment #3: Validating Kirchhoff's Laws Using A BreadboardDocumento17 páginasExperiment #3: Validating Kirchhoff's Laws Using A BreadboardIP GAMINGAinda não há avaliações

- Technical Specification: Minicas Ii, 24 V Ac/Dc and 120 V Ac Supervision RelayDocumento4 páginasTechnical Specification: Minicas Ii, 24 V Ac/Dc and 120 V Ac Supervision RelaySEA ROCK TECHNICALAinda não há avaliações

- I I I I: Operating Manual Double Relay Switch FGS-222-EN-A-v1.1Documento2 páginasI I I I: Operating Manual Double Relay Switch FGS-222-EN-A-v1.1Ioan BogdanAinda não há avaliações

- Fire Protection and Detection For Aircraft and Engines-1 PDFDocumento2 páginasFire Protection and Detection For Aircraft and Engines-1 PDFParvesh kambojAinda não há avaliações

- Programe Structure List PLCDocumento7 páginasPrograme Structure List PLCalfianAinda não há avaliações

- From Jim Marshall: Valvestate 2000 AVT AmplifiersDocumento9 páginasFrom Jim Marshall: Valvestate 2000 AVT AmplifiersRogerio MathiasAinda não há avaliações

- Categorisation of DefectsDocumento231 páginasCategorisation of DefectsSimon CooperAinda não há avaliações

- Light Emiting Polymers Seminar ReportDocumento23 páginasLight Emiting Polymers Seminar ReportitsmemonuAinda não há avaliações

- Baja SAE Tech Inspection Sheet 2014-2015Documento12 páginasBaja SAE Tech Inspection Sheet 2014-2015FoureyeddjAinda não há avaliações