Escolar Documentos

Profissional Documentos

Cultura Documentos

"Lifting - Lug" - Lifting Lug Analysis: Program Description

Enviado por

Nicoleta cristianTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

"Lifting - Lug" - Lifting Lug Analysis: Program Description

Enviado por

Nicoleta cristianDireitos autorais:

Formatos disponíveis

"LIFTING_LUG" --- LIFTING LUG ANALYSIS

Program Description:

"LIFTING_LUG" is a spreadsheet program written in MS-Excel for the purpose of analysis of lifting lugs, used in

rigging operations. The user can enter a desired factor of safety (most applications, F.S. = 5.0). The program will

determine the ultimate strength of the lifting lug based on several checks and will apply the desired factor of safety

to the strengths to attain allowable loads for the lifting lug.

This program is a workbook consisting of two (2) worksheets, described as follows:

Worksheet Name Description

Doc This documentation sheet

Lifting Lug Analysis of lifting lugs per 13th Ed. AISC Manual (ASD) and Reference #1a & b

Program Assumptions and Limitations:

1. The following references were used in the development of this program:

a. "Design and Construction of Lifting Beams" - David T. Ricker, originally published in American Institute of

Steel Construction (AISC) - Design Journal, 4th Quarter 1991.

b. "Design of Below-the-Hook Lifting Devices" - ASME BTH-1-2008, American Society of Mechanical Engineers.

c. American Institute of Steel Construction (AISC) 13th Edition Allowable Stress Design (ASD) Manual (2005)

2. This program contains “comment boxes” which contain a wide variety of information including explanations of

input or output items, equations used, data tables, etc. (Note: presence of a “comment box” is denoted by a

“red triangle” in the upper right-hand corner of a cell. Merely move the mouse pointer to the desired cell to view

"LIFTING_LUG.xls" Program

Version 1.4

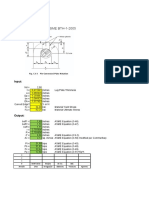

LIFTING LUG ANALYSIS

Per AISC 13th Edition ASD Manual, ASME BTH-1-2008, and

"Design and Construction of Lifting Beams" by David T. Ricker

Project Name: Client:

Project No.: Prep. By: Date:

Input:

Design Parameters:

Lug Yield Strength, Fy = 36 ksi

Lug Ult. Strength, Fu = 58 ksi

Edge Dist., a = 2.500 in.

Edge Dist., e = 1.000 in.

Lug Width, b = 6.000 in.

Rounded Edge? = No

Will Pin Rotate Under Load? = No

Hole Diameter, dh = 1.000 in.

Pin Diameter, dpin = 0.750 in.

Lug Thickness, t = 0.750 in.

AISC Factor of Safety, F.S.1 = 5.0

AISC Factor of Safety, F.S.2 = 3.1 F.S.2 = max{3, Fy/(Fu/F.S.1)} ASME Notation

ASME Factor of Safety, F.S.3 = 3.0 Assuming Category B lifters

AISC Preferred Geometry AISC Alternate Geometry

Results:

Check Geometry:

Check 1: O.K. dh - dpin > 0, Pin fits in hole, O.K.

Check 2: O.K. a >= max(0.5*dh,2*t), Plate Proportions are O.K.

Check 3: O.K. e >= 0.67*dh, Plate Proportions are O.K.

Check 4: N.G. e < 1.33*a, Use a,eff = min(a, 3*e/4, 4*t, dh*1.25) in design

a,eff = 0.75 in. 3*e/4 controls

a,max = 2.13 in. a,max = 2*t+.625

a,use = 0.75 in. Use a,eff in design

(continued)

02/25/2019 file:///conversion/tmp/scratch/410284276.xls Page 2

14:23:20 410284276.xls of 3

"LIFTING_LUG.xls" Program

Version 1.4

Tensile Strength of Lifting Lug (AISC Eqn. D5-1):

P1 = 13.05 kips P1 = (2*a,use*t*Fu) / F.S.1

Bearing Capacity of Lifting Lug (AISC Eqn. J7-1):

P2 = N/A kips P2 = (1.8*Fy*t*dpin) / F.S.2

Per Ricker, only check bearing capacity if pin is "snug" in hole

Tearing Tension Capacity of Lifting Lug (Ricker pg 152):

P3 = 14.53 kips P3 = {(1.67*Fy*t*e^2)/dh} / F.S.2

Per Ricker pg. 152, Fb is used instead of Fy, but Fb = Fy/F.S.2

Shear Capacity (Shear Rupture) of Lifting Lug (AISC Eqn D5-2):

P4 = 10.44 kips P4 = (0.6*Fu*2*t*e) / F.S.1

Per AISC Eqn. D5-2, Asf = 2*t*(e+dh/2), cons. to assume dh/2=0)

Gross Section Yielding of Lifting Lug (AISC Eqn D2-1):

P5 = 52.20 kips P5 = (Fy*t*b) / F.S.2

Tensile Strength of Lifting Lug (ASME Eqn. 3-45):

Cr = 0.818 Cr = 1 - 0.275*sqrt{1 - (dpin^2 / dh^2)}

a,eff = 1.53 in. a, eff = min(a, 4*t, 0.6*a*(Fu/Fy)*sqrt(dh / a)

P6 = 30.22 kips P6 = (Cr*Fu*2*t*a,eff) / (1.2*F.S.3)

Single Plane Fracture Strength of Lifting Lug (ASME Eqn. 3-49):

R= 1.500 in. R = e+(dh/2)

P7 = 16.67 kips P7 = [(Cr*Fu)/(1.2*F.S.3)] *

[1.13*(R-.5*dh)+(0.92*a,eff)/(1+a,eff/dh)] * t

Double Plane Fracture Strength of Lifting Lug (ASME Eqn. 3-50):

f= 41.25 deg. f = 55*(dpin / dh)

Z' = 0.000 in. Z' = R - sqrt{R^2 - [(dpin/2)*sin(f)]^2}, only applicable for rounded edges

Av = 1.640 in.^2 Av = 2*{e+0.8*dpin*[1-cos(f)]-Z'}*t

P8 = 18.49 kips P8 = (0.7*Fu*Av) / (1.2*F.S.3)

Bearing Capacity of Lifting Lug (ASME Eqn. 3-53):

P9 = 8.44 kips P9 = (1.25*Fy*dpin*t) / F.S.3 <============= Controls

Summary:

Pallow = 8.44 kips Pallow = min(P1, P2, P3, P4, P5, P6, P7, P8, P9)

Required Weld Strength for Vertical Load:

Pdesign = 12.66 kips Assuming fillet weld and F.S. = 5.0 against Fexx. Use Pdesign

to design welds using 0.3*Fexx*0.707*weld size. Could also use

Pallow, but need to use 0.2*Fexx*0.707*weld size for F.S. = 5.0.

Comments:

02/25/2019 file:///conversion/tmp/scratch/410284276.xls Page 3

14:23:20 410284276.xls of 3

Você também pode gostar

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocumento3 páginas"Lifting - Lug" - Lifting Lug Analysis: Program Descriptionnamasral100% (3)

- M8 McKissick SheavesDocumento18 páginasM8 McKissick Sheavesmahmoud heikal100% (1)

- Pveng: Pressure Vessel Engineering LTDDocumento5 páginasPveng: Pressure Vessel Engineering LTDBruno TrujilloAinda não há avaliações

- Sheave Design 10tDocumento1 páginaSheave Design 10tSubratAinda não há avaliações

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQDocumento3 páginas8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshAinda não há avaliações

- Pad Eye New ReleaseDocumento10 páginasPad Eye New ReleaseEnrique BarajasAinda não há avaliações

- Calculation Sheet: Design of PadeyeDocumento7 páginasCalculation Sheet: Design of PadeyeIkade SuartanaAinda não há avaliações

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocumento4 páginasBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiAinda não há avaliações

- Design and Verification of Lifting LugsDocumento3 páginasDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- TrunnionDocumento7 páginasTrunnionRUDHRA DHANASEKAR100% (1)

- Lifting Lug DesignDocumento7 páginasLifting Lug DesignadammzjinAinda não há avaliações

- Calculation of Lifting Eye: 1. Tear-Out StressDocumento2 páginasCalculation of Lifting Eye: 1. Tear-Out StressMirza CaticAinda não há avaliações

- Skid BeamDocumento2 páginasSkid BeamYuni Ari WibowoAinda não há avaliações

- Lifting Lug Design-MrDocumento5 páginasLifting Lug Design-MrMiguelRagasAinda não há avaliações

- Estimate weight and compressive force calculationsDocumento2 páginasEstimate weight and compressive force calculationsAmi PutraAinda não há avaliações

- Tailing LugDocumento3 páginasTailing LugSajad AbdulAinda não há avaliações

- SS316 Steel Assembly Shear and Tensile Load CalculationDocumento4 páginasSS316 Steel Assembly Shear and Tensile Load Calculationmimi_chan_17Ainda não há avaliações

- Lifting Lug DesignDocumento18 páginasLifting Lug DesignRui Salvador0% (1)

- Vessel lifting lug design data and stress analysisDocumento3 páginasVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEDocumento4 páginasLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VAinda não há avaliações

- Most Applications, F.S. 5.0) : Calculation ReferenceDocumento5 páginasMost Applications, F.S. 5.0) : Calculation ReferenceParthibanAinda não há avaliações

- Calculo Plug Hex HeadDocumento18 páginasCalculo Plug Hex HeadDalberto RamirezAinda não há avaliações

- Lifting TrunionDocumento1 páginaLifting TrunionRUDHRA DHANASEKAR0% (1)

- Ccsviiid1 2260Documento2 páginasCcsviiid1 2260DieguitoOmarMoralesAinda não há avaliações

- Appendix B Design Example Lifting LugDocumento6 páginasAppendix B Design Example Lifting LugfernandoAinda não há avaliações

- 25 Lifting Lug Design Per ASME BTH-1-2005Documento6 páginas25 Lifting Lug Design Per ASME BTH-1-2005luis nunezAinda não há avaliações

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocumento1 página2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanAinda não há avaliações

- ASME BTH-1 Lifting Lug DesignDocumento4 páginasASME BTH-1 Lifting Lug DesignTim McCorkle50% (2)

- Spreader Bar For LiftingDocumento1 páginaSpreader Bar For LiftingTran ThoAinda não há avaliações

- Lifting Eye Bolts (Rotating) : Technical InformationsDocumento3 páginasLifting Eye Bolts (Rotating) : Technical InformationsBruno Thiago DamascenoAinda não há avaliações

- Secondary Condensate B API650 Sloshing Impact RoofDocumento22 páginasSecondary Condensate B API650 Sloshing Impact RoofFrancisco OrtuzarAinda não há avaliações

- Spur Gear DesignDocumento3 páginasSpur Gear DesignThirumalaimuthukumaranMohan100% (1)

- Platform Cleat CalculationDocumento1 páginaPlatform Cleat Calculationmiteshpatel191Ainda não há avaliações

- AWWA D100 Tension TableDocumento1 páginaAWWA D100 Tension Tablejojo_323Ainda não há avaliações

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Documento7 páginasLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonAinda não há avaliações

- Below-the-Hook Lifting Equipment MaintenanceDocumento8 páginasBelow-the-Hook Lifting Equipment Maintenancerpatel12Ainda não há avaliações

- Weld Consumable CalculatorDocumento7 páginasWeld Consumable CalculatoretienetergolinoAinda não há avaliações

- Input Rev. NO: L + (c1 + c2) TWDocumento6 páginasInput Rev. NO: L + (c1 + c2) TWMudasir MughalAinda não há avaliações

- Design of JointsDocumento41 páginasDesign of JointsVivek LevinAinda não há avaliações

- Lifting Lugs Design Per ASME BTH-1-2005 PDFDocumento2 páginasLifting Lugs Design Per ASME BTH-1-2005 PDFHernâniCruz100% (1)

- Anvil Fig137 U-Bolt PDFDocumento1 páginaAnvil Fig137 U-Bolt PDFAin AzmiAinda não há avaliações

- WPS ExampleDocumento2 páginasWPS ExampleMarcio Jr.Ainda não há avaliações

- Design and Analysis of Storage Tank - ANSYS AnalysisDocumento8 páginasDesign and Analysis of Storage Tank - ANSYS AnalysisrosemaryAinda não há avaliações

- 17 TonsDocumento8 páginas17 Tonsabuzahrau100% (3)

- Q235 Steel, Q235A Q235B Q235C Q235D Specification, Chemical Composition, Properties & EquivalentDocumento4 páginasQ235 Steel, Q235A Q235B Q235C Q235D Specification, Chemical Composition, Properties & EquivalentWaqas WaqasAinda não há avaliações

- Design of fillet weld as per BS EN 1993 1 8 CL 4.5.3Documento2 páginasDesign of fillet weld as per BS EN 1993 1 8 CL 4.5.3Giri DharanAinda não há avaliações

- Lifting LugDocumento39 páginasLifting LugSasikumar JothiAinda não há avaliações

- Lifting Lug CalculationsDocumento1 páginaLifting Lug CalculationsshazanAinda não há avaliações

- Design of base plate for columnDocumento6 páginasDesign of base plate for columnsoumyaAinda não há avaliações

- Is-5372-Taper Washer For ChannelDocumento2 páginasIs-5372-Taper Washer For ChannelSurendra Kumar ChordiaAinda não há avaliações

- Mcnichols Master Catalog PDFDocumento60 páginasMcnichols Master Catalog PDFing_julio_siviraAinda não há avaliações

- Tail Lifting Lug Calculation MS WordDocumento11 páginasTail Lifting Lug Calculation MS WordWijayanto BekasiAinda não há avaliações

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocumento3 páginas"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionfuffinoAinda não há avaliações

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocumento3 páginas"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonAinda não há avaliações

- Lifting LugDocumento4 páginasLifting LugUmmer BavaAinda não há avaliações

- Lifting LugDocumento4 páginasLifting Lugsjkang0226100% (4)

- Stiffner13-Steel Beam Web Stiffeener AnalysisDocumento12 páginasStiffner13-Steel Beam Web Stiffeener AnalysisRafael ReyesAinda não há avaliações

- Lifting Lug Analysis DesignDocumento5 páginasLifting Lug Analysis DesignAlessio BarboneAinda não há avaliações

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionAinda não há avaliações

- 10.0m LIGHTING POLES - Concrete Design BS8110Documento7 páginas10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianAinda não há avaliações

- Anchor Bolt CalcDocumento22 páginasAnchor Bolt CalcNicoleta cristianAinda não há avaliações

- Two-Tier Pipe Rack Connection DesignDocumento4 páginasTwo-Tier Pipe Rack Connection DesignNicoleta cristianAinda não há avaliações

- C1 - Design Criteria For Civil and Structural WorkDocumento33 páginasC1 - Design Criteria For Civil and Structural WorkNicoleta cristianAinda não há avaliações

- European Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Documento16 páginasEuropean Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Nicoleta cristianAinda não há avaliações

- Anchor Bolt CalcDocumento22 páginasAnchor Bolt CalcNicoleta cristianAinda não há avaliações

- Cantilever Retaining WallDocumento5 páginasCantilever Retaining WallRalph Kenneth BrillanteAinda não há avaliações

- General: Rev. 8 - 20130422 PDFDocumento20 páginasGeneral: Rev. 8 - 20130422 PDFNicoleta cristianAinda não há avaliações

- 10.0m LIGHTING POLES - Concrete Design BS8110Documento7 páginas10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianAinda não há avaliações

- "Footings" - Rectangular Spread Footing Analysis: Program DescriptionDocumento17 páginas"Footings" - Rectangular Spread Footing Analysis: Program DescriptionNicoleta cristianAinda não há avaliações

- Anchor Bolt CalcDocumento22 páginasAnchor Bolt CalcNicoleta cristianAinda não há avaliações

- European Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Documento16 páginasEuropean Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Nicoleta cristianAinda não há avaliações

- 12ft F&G DETECTOR POLES REV-A Concrete Design BS8110Documento7 páginas12ft F&G DETECTOR POLES REV-A Concrete Design BS8110Nicoleta cristianAinda não há avaliações

- 10.0m LIGHTING POLES - Concrete Design BS8110Documento7 páginas10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianAinda não há avaliações

- 10.0m LIGHTING POLES - Concrete Design BS8110Documento7 páginas10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianAinda não há avaliações

- C1 - Design Criteria For Civil and Structural WorkDocumento33 páginasC1 - Design Criteria For Civil and Structural WorkNicoleta cristianAinda não há avaliações

- 06 Eurocodes Steel Workshop WALDDocumento136 páginas06 Eurocodes Steel Workshop WALDIonut SavaAinda não há avaliações

- Heat Exchanger Foundation Design GuideDocumento53 páginasHeat Exchanger Foundation Design GuideandyhrAinda não há avaliações

- Calcolo Bulloni Di Ancoraggio Ec2-Ec3 - IngDocumento5 páginasCalcolo Bulloni Di Ancoraggio Ec2-Ec3 - IngNicoleta cristianAinda não há avaliações

- SPPU TBSC CS Syllabus 2021 22 PDFDocumento60 páginasSPPU TBSC CS Syllabus 2021 22 PDFSHWETA GANGURDEAinda não há avaliações

- Employee Onboarding Process at OlaDocumento9 páginasEmployee Onboarding Process at OlaAyush JainAinda não há avaliações

- Automatic Forest Fire Detection Machine Learning PipelineDocumento12 páginasAutomatic Forest Fire Detection Machine Learning PipelineJAinda não há avaliações

- Food PowerP2Documento9 páginasFood PowerP2Winda FeAinda não há avaliações

- English 7 ModuleDocumento21 páginasEnglish 7 ModuleJaycelyn BaduaAinda não há avaliações

- HiTutor Emergency Contact GuideDocumento3 páginasHiTutor Emergency Contact GuideEdén Verde Educación Con SaludAinda não há avaliações

- "Online Examination For Hawassa University Informatics Department" Project School of InformaticsDocumento13 páginas"Online Examination For Hawassa University Informatics Department" Project School of InformaticsAnonymous 5Hk0VoIFh100% (1)

- Create Excel Files CDocumento29 páginasCreate Excel Files CSaka Kely100% (1)

- This Document Provide Details of Pick N Place ProcessDocumento21 páginasThis Document Provide Details of Pick N Place Processrahul19bteel013Ainda não há avaliações

- FORE0714ra Davao071114Documento17 páginasFORE0714ra Davao071114angelomercedeblogAinda não há avaliações

- Fault Code 111Documento2 páginasFault Code 111Enrrique LaraAinda não há avaliações

- Living in The IT Era ReviewerDocumento3 páginasLiving in The IT Era ReviewerJennelyn Bajado100% (2)

- Common GST Login Problems and SolutionsDocumento3 páginasCommon GST Login Problems and Solutionscalcchamp calculatorAinda não há avaliações

- Onshape College 7-1 Lesson PlanDocumento43 páginasOnshape College 7-1 Lesson Planhezron100% (1)

- Cisco Intelligent WANDocumento878 páginasCisco Intelligent WANHernán Conrado Krause LeytonAinda não há avaliações

- project 1Documento11 páginasproject 1teferi GetachewAinda não há avaliações

- Oracle OTL Frequently Asked QuestionsDocumento4 páginasOracle OTL Frequently Asked QuestionsKotakonda MuraliAinda não há avaliações

- EPSOLAR APP Install & Use GuideDocumento8 páginasEPSOLAR APP Install & Use GuideYohanner FisterraAinda não há avaliações

- Callsign Mobile App Test PlanDocumento7 páginasCallsign Mobile App Test PlanIosef Kebesh KohenAinda não há avaliações

- CompArch CH 1 1Documento23 páginasCompArch CH 1 1Esuyawkal AdugnaAinda não há avaliações

- Stable BaselinesDocumento239 páginasStable BaselinesdridiAinda não há avaliações

- Sans 876Documento1 páginaSans 876Sandro MeloAinda não há avaliações

- 194986-Millennium Wiring Manual July 2006Documento20 páginas194986-Millennium Wiring Manual July 2006ramjoceAinda não há avaliações

- Fi 6110 DatasheetDocumento2 páginasFi 6110 DatasheetJesus RoldanAinda não há avaliações

- Sp. Reserve MagazineDocumento21 páginasSp. Reserve MagazineViraf DasturAinda não há avaliações

- Bio-Medical Engineer C.VDocumento4 páginasBio-Medical Engineer C.Veng_aymanhamdan80% (5)

- Grade 6 ICT Term 3 Assessment SpreadsheetDocumento6 páginasGrade 6 ICT Term 3 Assessment SpreadsheetIbrahim AdnanAinda não há avaliações

- FANUC's Standard SCA Sealing Programming (Version4.0)Documento20 páginasFANUC's Standard SCA Sealing Programming (Version4.0)Leinad OicaloAinda não há avaliações

- SQL ExamplesDocumento12 páginasSQL Examplessaleem_zeejaAinda não há avaliações

- Fire Alarm: HarringtonDocumento4 páginasFire Alarm: HarringtonNacho Vega SanchezAinda não há avaliações