Escolar Documentos

Profissional Documentos

Cultura Documentos

DIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance Conditions

Enviado por

Noe MarinDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

DIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance Conditions

Enviado por

Noe MarinDireitos autorais:

Formatos disponíveis

1

TOLERANCES

Production-related dimensional variations

Technical Information

Rev. Index 03

GENERAL INFORMATION

The deviations from the nominal dimensions and the subsequent processing of our parts are generally

dependent on the manufacturing or production processes used.

DIN ISO 16742 applies for injection moulding, and the tolerance group TG 6 applies for our thermoplastics.

DIN 12020-2 applies for the production of aluminium profiles.

If the parts are mechanically processed, DIN ISO 2768m always applies.

INJECTION-MOULDED PLASTIC PARTS

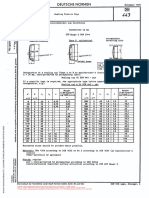

Deviations from nominal dimension according to DIN 16742 TG 6

Tolerance- Nominal dimensional range

group over 1 3 6 10 18 30 50 80 120 180 250 315 400 500 630 800

up to 3 6 10 18 30 50 80 120 180 250 315 400 500 630 800 1000

General tolerances

TG6 W ±0,07 ±0,12 ±0,18 ±0,22 ±0,26 ±0,31 ±0,37 ±0,57 ±0,80 ±0,93 ±1,05 ±1,15 ±1,60 ±2,20 ±2,50 ±2,80

NW ±0,12 ±0,18 ±0,22 ±0,26 ±0,31 ±0,37 ±0,57 ±0,80 ±0,93 ±1,05 ±1,15 ±1,60 ±2,20 ±2,50 ±2,80 ±3,10

W for dimensions that are tool-specific

NW for dimensions that are not tool-specific

MACHINING, SILK-SCREEN / TAMPO PRINTING, SAWING, EMBOSSING, CUTTING,

DIGITAL PRINTING

All dimensions < 30 mm to the reference edge of the case with a tolerance of ± 0.3 mm.

All other dimensions: unless otherwise specified against DIN ISO 2768m T1.

At the same time, the tolerances of the basic parts must be taken into account.

Linear measure

Nominal dim. 0.5 – 6 mm 6 – 30 mm 30 – 120 mm 120 – 400 mm 400 – 1000 mm

Tolerance ± 0.1 mm ± 0.2 mm ± 0.3 mm ± 0.5 mm ± 0.8 mm

Angular measure

Nominal dim. up to 10 mm 10 – 50 mm 50 – 120 mm 120 – 400 mm > 400 mm

Tolerance ± 1° ± 0.5° ± 0.33° ± 0.16° ±0.08°

Radii

Nominal dim. 0.5 – 3 mm 3 – 6 mm 6 – 30 mm 30 – 120 mm 120 – 400 mm

Tolerance ± 0.2 mm ± 0.5 mm ± 1 mm ± 2 mm ± 4 mm

www.okw.com Subject to change without notice

Você também pode gostar

- General Tolerances DIN ISO 2768Documento4 páginasGeneral Tolerances DIN ISO 2768NaveenRajAinda não há avaliações

- Iso 1502 1996Documento12 páginasIso 1502 1996Emaculata Monalisa0% (1)

- Din 16742Documento1 páginaDin 16742Rafael CastroAinda não há avaliações

- DIN en ISO 1101 Berichtigung 1 (2011-10) Geometrical Product Specifications (GPS) - Geometrical TolerancingDocumento2 páginasDIN en ISO 1101 Berichtigung 1 (2011-10) Geometrical Product Specifications (GPS) - Geometrical Tolerancingloud_storm0% (1)

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocumento7 páginasFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganAinda não há avaliações

- Mechanical Properties - Bolt, Nut, FastenersDocumento4 páginasMechanical Properties - Bolt, Nut, FastenersmegatornadoAinda não há avaliações

- Din 443 PDFDocumento1 páginaDin 443 PDFLuciano Fontes100% (1)

- SAE J1926, MS 16142 - CuttersDocumento11 páginasSAE J1926, MS 16142 - CutterspbsurfAinda não há avaliações

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocumento17 páginasFord Worldwide Fastener Standard: Printed Copies Are UncontrolledRico MalibiranAinda não há avaliações

- Ford 970Documento4 páginasFord 970amanAinda não há avaliações

- Zinc Flake Technology-Technical PDFDocumento1 páginaZinc Flake Technology-Technical PDFKalyan DhakaneAinda não há avaliações

- Iso 25178 600 2019 en PDFDocumento11 páginasIso 25178 600 2019 en PDFFouad BenlakbirAinda não há avaliações

- Iso 4162 1990Documento9 páginasIso 4162 1990lokesh prakashAinda não há avaliações

- International Standard: Plastics Moulded Parts - Tolerances and Acceptance ConditionsDocumento11 páginasInternational Standard: Plastics Moulded Parts - Tolerances and Acceptance ConditionsAhmad Eltaweel0% (1)

- Powder Metallurgy Material MPIF StandardDocumento2 páginasPowder Metallurgy Material MPIF Standardidanfri100% (1)

- Din 7168Documento1 páginaDin 7168Anderson SantosAinda não há avaliações

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocumento4 páginasForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinAinda não há avaliações

- Surface RoughnessDocumento35 páginasSurface Roughnessds_srinivasAinda não há avaliações

- Fasteners (Bolts and Nuts)Documento17 páginasFasteners (Bolts and Nuts)Manojkumar Thilagam100% (1)

- General Tolerances - DIN - IsO - 2768Documento1 páginaGeneral Tolerances - DIN - IsO - 2768Luis Eduardo García MaltosAinda não há avaliações

- GMW14400 May2007 PDFDocumento9 páginasGMW14400 May2007 PDFAkmal NizametdinovAinda não há avaliações

- JIS B0419-1991 (Dung Sai Kich Thuoc)Documento1 páginaJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáAinda não há avaliações

- Din 8062-3 2009 PDFDocumento10 páginasDin 8062-3 2009 PDFkoalaboi33% (3)

- Iso 15330 en PDFDocumento6 páginasIso 15330 en PDFScube engineersAinda não há avaliações

- WX100 World Wide Fastener Standard PDFDocumento16 páginasWX100 World Wide Fastener Standard PDFRico Malibiran100% (1)

- Hand Out To Borbet GMBH: Coating Adhesion TestDocumento8 páginasHand Out To Borbet GMBH: Coating Adhesion Testferhat aydoganAinda não há avaliações

- DIN ISO 8296 en - 2008-03Documento8 páginasDIN ISO 8296 en - 2008-03tanyaAinda não há avaliações

- Part Identification of Thermoplastics For RecyclingDocumento4 páginasPart Identification of Thermoplastics For RecyclingAw Keng Shing100% (1)

- ASCOMETAL Steel Grades ENDocumento8 páginasASCOMETAL Steel Grades ENasad144Ainda não há avaliações

- Iso 2702 2011Documento16 páginasIso 2702 2011Gerald CelisAinda não há avaliações

- JIS Fasteners Lib PDFDocumento312 páginasJIS Fasteners Lib PDFNguyễnTúSơnAinda não há avaliações

- BS en 12329 PDFDocumento21 páginasBS en 12329 PDFSenthil Kumar GanesanAinda não há avaliações

- MIL STD 120 Gage InspectionDocumento216 páginasMIL STD 120 Gage Inspectionokamo100% (4)

- Mil DTL 23053 5CDocumento7 páginasMil DTL 23053 5Cdenys.castanedatAinda não há avaliações

- Jis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresDocumento11 páginasJis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresAnonymous gQyrTUHX38Ainda não há avaliações

- Jis 1196Documento19 páginasJis 1196VISHAL kUMARAinda não há avaliações

- Vda 260Documento9 páginasVda 260Marisol Sanchez HernandezAinda não há avaliações

- Iso 3302 1 2014Documento9 páginasIso 3302 1 2014Sandhya SinghAinda não há avaliações

- DIN ISO Equivalent FastenersDocumento12 páginasDIN ISO Equivalent FastenersGunnie PandherAinda não há avaliações

- Iso 8015 - 1985-12-15Documento7 páginasIso 8015 - 1985-12-15Ionut FarcasAinda não há avaliações

- DIN 3016 P-Clip Form DDocumento2 páginasDIN 3016 P-Clip Form Dsrushti100% (1)

- D271389 F' PDFDocumento13 páginasD271389 F' PDFReza AbdolahiAinda não há avaliações

- Alloy Steels - Grades - Compositions - PropertiesDocumento7 páginasAlloy Steels - Grades - Compositions - PropertiesAnirudhreddy SafalAinda não há avaliações

- Wilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Documento3 páginasWilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Ray Mark De TorresAinda não há avaliações

- (JISF) : Japanes E IndustrialDocumento19 páginas(JISF) : Japanes E IndustrialTrịnh Thanh TùngAinda não há avaliações

- Aisi 1018Documento1 páginaAisi 10188085roAinda não há avaliações

- Saej 356 V 002Documento7 páginasSaej 356 V 002Evandro Luis GomesAinda não há avaliações

- BS en Iso 10644-2009 PDFDocumento14 páginasBS en Iso 10644-2009 PDFMadheswaran Dharmapuri100% (1)

- Worldwide Fastener Standard: Printed Copies Are UncontrolledDocumento2 páginasWorldwide Fastener Standard: Printed Copies Are UncontrolledRasatja Yongskulrote100% (1)

- Astm B571Documento4 páginasAstm B571Tushar Ranpise100% (2)

- Din 13-1Documento4 páginasDin 13-1Sankha Dasgupta100% (3)

- 9.57405-Eng - Plating Std.Documento20 páginas9.57405-Eng - Plating Std.Baravkar Auto Parts100% (1)

- General Tolerances - DIN - IsO - 2768Documento2 páginasGeneral Tolerances - DIN - IsO - 2768Pasca GheorgheAinda não há avaliações

- Din 2393-1Documento6 páginasDin 2393-1alextentwentyAinda não há avaliações

- En 10263-2 2001Documento7 páginasEn 10263-2 2001Luca TurraAinda não há avaliações

- TSB1503G 9 P 1Documento18 páginasTSB1503G 9 P 1kk_pammu_915176926Ainda não há avaliações

- Din 7168Documento2 páginasDin 7168Miroslav MyšičkaAinda não há avaliações

- Din 7168Documento2 páginasDin 7168Amândio Santos75% (4)

- According To DIN ISO 2768-1: Branco Engineering BureauDocumento1 páginaAccording To DIN ISO 2768-1: Branco Engineering BureauPHUONGAinda não há avaliações

- Iso 2768-1Documento2 páginasIso 2768-1Jennifer Cossette Manicom100% (2)

- Braking SystemDocumento3 páginasBraking SystemmegaspiceAinda não há avaliações

- Aun Infusomat Space - Service Manual PDFDocumento130 páginasAun Infusomat Space - Service Manual PDFsusiloAinda não há avaliações

- Range of Flocculants and Caogulants For Water and Wastewater TreatmentDocumento6 páginasRange of Flocculants and Caogulants For Water and Wastewater Treatmentginga716Ainda não há avaliações

- MulcoaDocumento2 páginasMulcoaRolando Cordova100% (1)

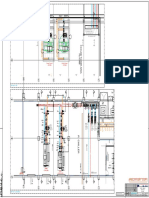

- A-16-1-0028-K-050b - Chiller-House - Plan View - 20170303Documento1 páginaA-16-1-0028-K-050b - Chiller-House - Plan View - 20170303Danur RiswantoAinda não há avaliações

- Scrap MGT - Optimization SolutionsDocumento25 páginasScrap MGT - Optimization SolutionsRodolfoMarínAinda não há avaliações

- Hop Catalog V 3.0Documento16 páginasHop Catalog V 3.0শরীফ সিকদারAinda não há avaliações

- Manufacturing ProcessesDocumento17 páginasManufacturing ProcessesTh GmAinda não há avaliações

- ACI 506.1 (1998) Committee Report On Fiber Reinforced ShotcreteDocumento11 páginasACI 506.1 (1998) Committee Report On Fiber Reinforced ShotcretephilipyapAinda não há avaliações

- Flushing ProcedureDocumento1 páginaFlushing Proceduremahi1437Ainda não há avaliações

- Dispersing Agents PDFDocumento14 páginasDispersing Agents PDFalmasAinda não há avaliações

- CVD-5B Metal Hardening BulletinDocumento2 páginasCVD-5B Metal Hardening BulletinSergio Gana GonzalezAinda não há avaliações

- iKOTE CM 30R (TDS) 02-APRIL-2024Documento2 páginasiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhAinda não há avaliações

- Man Made FibreDocumento23 páginasMan Made FibreKhushboo ThakurAinda não há avaliações

- Geomet 500bDocumento1 páginaGeomet 500bellisforheroesAinda não há avaliações

- McQuay AWS User Manual EngDocumento37 páginasMcQuay AWS User Manual EngHermelindo Samuel Rabanales Cifuentes50% (2)

- (Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Documento168 páginas(Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Rachael Hoo100% (7)

- Aliplast Katalog enDocumento140 páginasAliplast Katalog enJelena GraovčevićAinda não há avaliações

- PFR PDFDocumento3 páginasPFR PDFezraAinda não há avaliações

- History of The Development of Cement and Concrete (Non-HydraulicDocumento2 páginasHistory of The Development of Cement and Concrete (Non-HydraulicourebooksAinda não há avaliações

- DD Folio p01170 CC TuxpanDocumento102 páginasDD Folio p01170 CC TuxpanErnesto VazquezAinda não há avaliações

- Materiales de Construcción CanaletasDocumento40 páginasMateriales de Construcción CanaletasErick Joel OcampoAinda não há avaliações

- Creamery Juice HACCP PlanDocumento27 páginasCreamery Juice HACCP PlanDavid ChanAinda não há avaliações

- SKF Lubricating Oil SystemDocumento104 páginasSKF Lubricating Oil Systemthreek0123Ainda não há avaliações

- Biopolymers of Microbial Origins PDFDocumento4 páginasBiopolymers of Microbial Origins PDFManish SoniAinda não há avaliações

- 3D Printed Desktop CNC Mill: Technology Workshop Living Food Play OutsideDocumento13 páginas3D Printed Desktop CNC Mill: Technology Workshop Living Food Play OutsideMladen PorubovicAinda não há avaliações

- Mastercast 764: Description PackagingDocumento2 páginasMastercast 764: Description PackagingGaneshAinda não há avaliações

- Bearing Design CalculationsDocumento42 páginasBearing Design Calculationsarunurs1100% (1)

- Manufacture of Alum PDFDocumento450 páginasManufacture of Alum PDFKimberly ConleyAinda não há avaliações

- Cador 300 - Manual de OperacionDocumento99 páginasCador 300 - Manual de OperacionAndreyna BreaAinda não há avaliações